Final Project: Neostruder

Problem

Integrating an extruder with an industrial robotic arm is often more complicated than it should be. Different robotic arms use various flanges, voltages, programming logic, etc., requiring custom solutions for each robot. This complexity necessitates building almost everything from scratch when integrating with a new robot.

Introduction

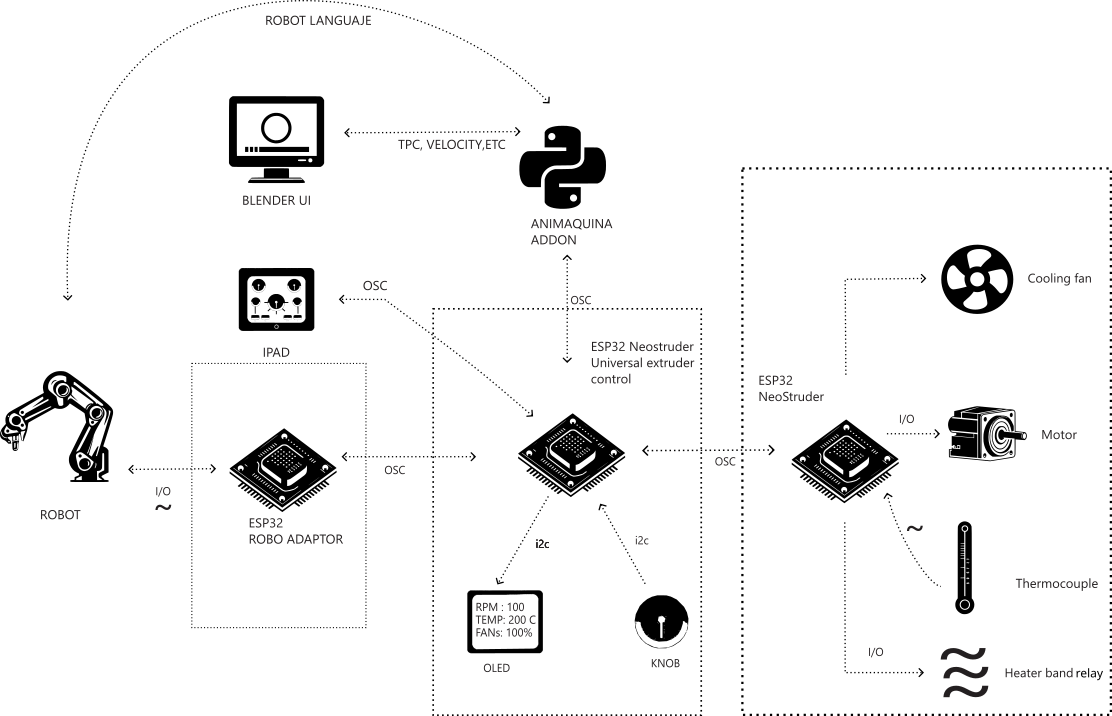

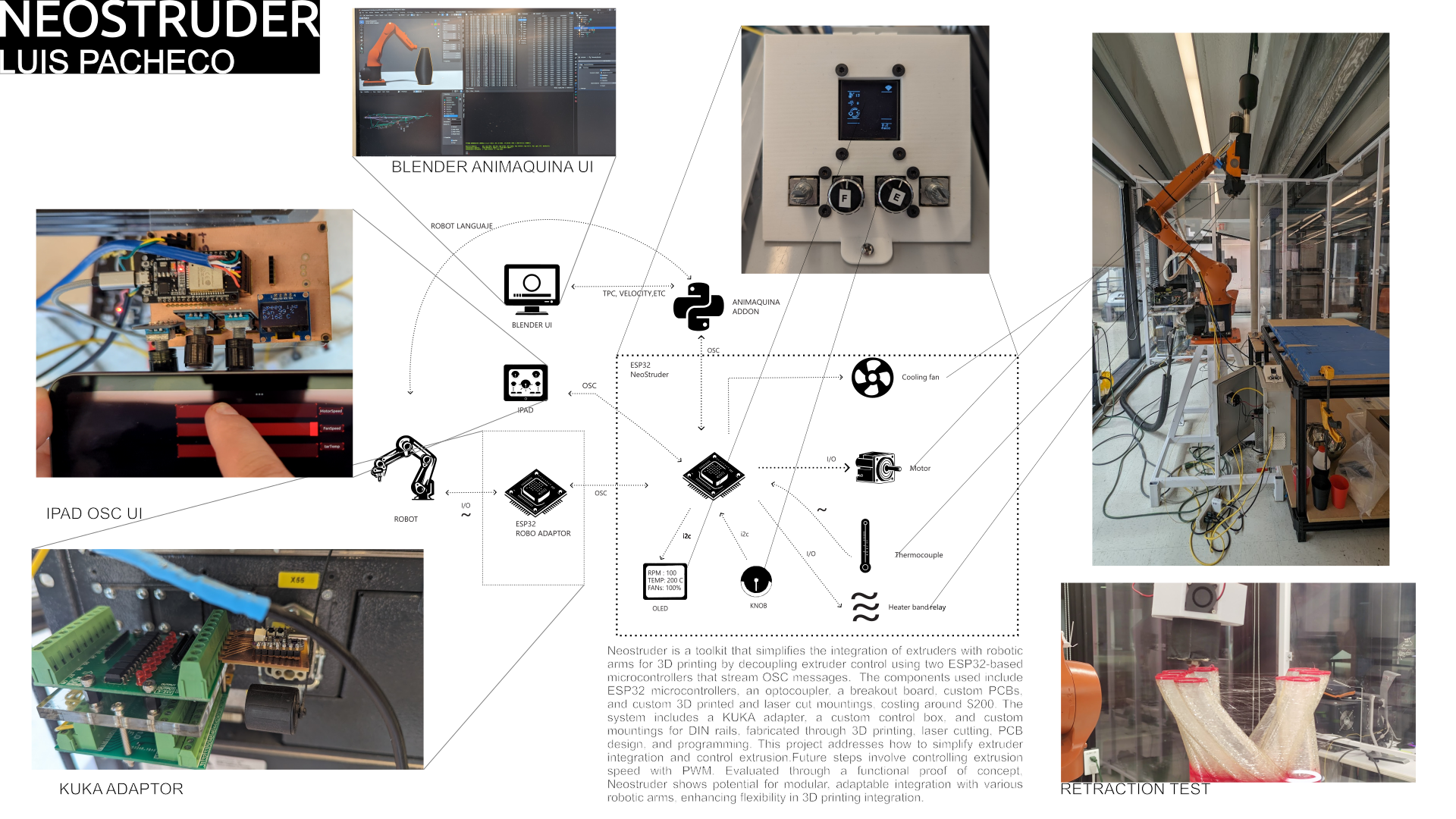

The Neostruder control box aims to simplify the integration of extruders on robotic arms for 3D printing. By decoupling the extruder from the robot using an IoT interface, Neostruder allows for wireless data streaming to control the extruder efficiently.

Objectives

- Provide a one-stop solution for controlling a 3D printing extruder (typically a stepper motor).

- Accept “simple” signals from a UDP server (OSC with ESP32).

- Enable remote “adjustment” through IoT.

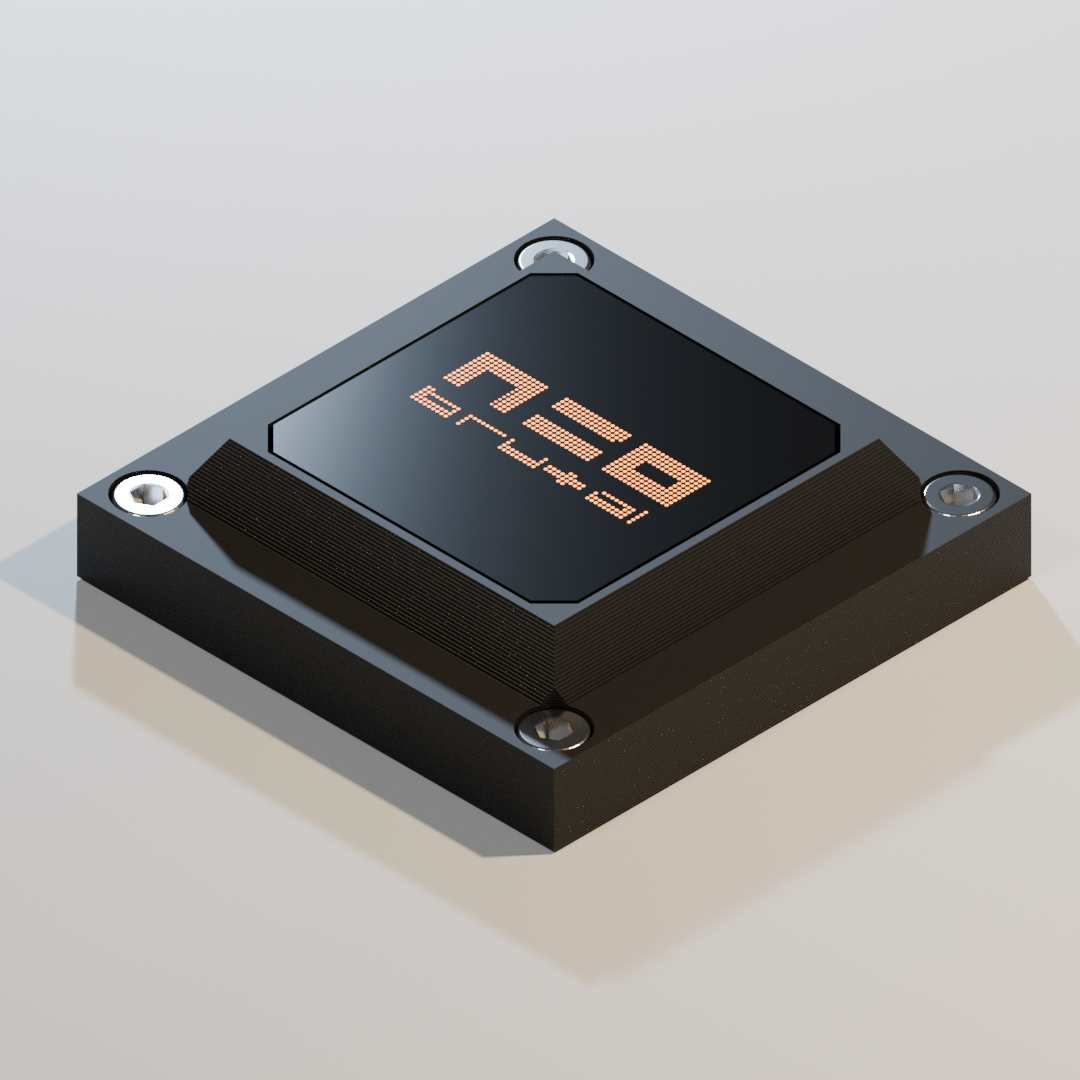

- Allow display and manual adjustment of values (OLED + knob):

- RPM (Flow)

- Fan Speed

- Temperature

- Implement an IoT adapter that streams values from the robot control box to adjust these values through the robot program.

What does it do?

Neostruder simplifies the integration of extruders with robotic arms for 3D printing by decoupling the extruder control using two ESP32-based microcontrollers that stream OSC messages. It offers an easier interface to work with stepper motor extruders.

Who’s done what beforehand?

Currently some comercial FDM printers are separating the extruder control from the motion control. This projects aims to bring this idea to robotic arms.

What did you design?

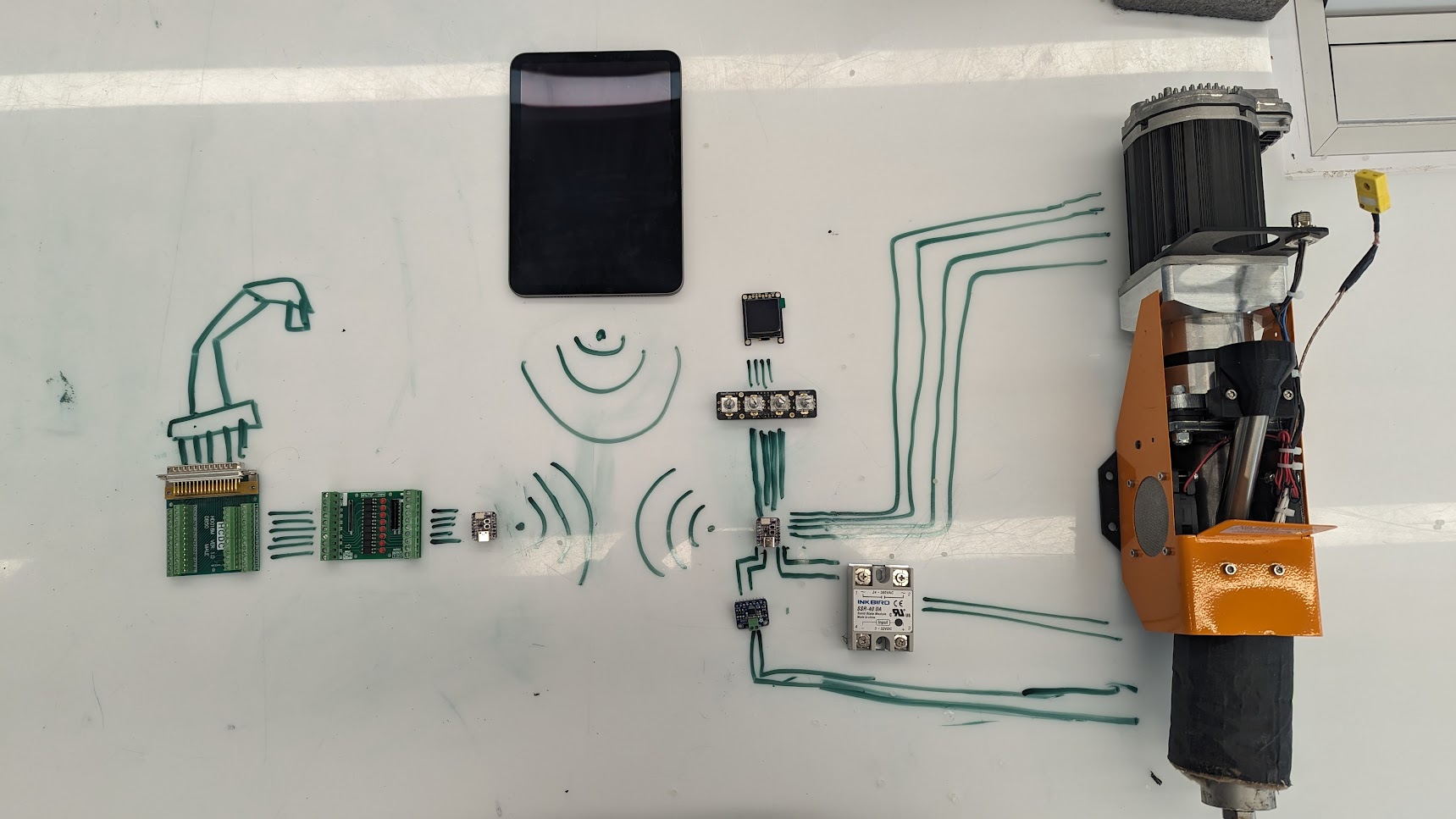

- KUKA adapter that connects a 24V IO to a breakout board and an optocoupler, reducing the voltage to 5V and streaming the IO values

- A control Box based on a custom ESP32 PCB that monitors and controls the extruder’s functions with an oled display and knobs.

- Custom 3D printed and laser cut mountings, electronic enclosures, and standoffs were developed for electronics, fans, din rails, etc.

What materials and components were used?

- ESP32 microcontrollers

- Optocoupler board

- Breakout board

- Custom PCBs

- Custom 3D printed and laser cut mountings, electronic enclosures, and standoffs

- Electrical box

- i2c knobs, OLED, thermocuple amplifier.

Where did they come from?

These components were sourced from various electronics suppliers like adafruit, sparkfun, amazon and mouser.

How much did they cost?

The total cost of the components was approximately $200.

What parts and systems were made?

- KUKA adapter for 24V IO to OSC data stream

- Custom control box that controls motor RPM, Fan Speed, monitors temperature.

- Custom ESP32 PCBs for the adapter and control box

- Custom 3DP parts for mounting fans and enclosing electronics.

What processes were used?

- 3D printing

- Laser cutting

- PCB design and fabrication

- Programming ESP32 microcontrollers

- CNC for cutomizing the electrical box

What questions were answered?

The project addressed how to simplify extruder integration with robotic arms and how to control extrusion.

What worked? What didn’t?

Worked:

- Display values for RPM, Fan Speed and temperature

- Use a Knob to change RPM, Fan speed

- Receive OSC messages to update this values

- TouchOSC Ipad interface

- Stream IO state from the robot controller to the extruder controller to stop and start the extruder

Pending

- Stream PWM values to set a specific PWM , Fan Speed or temperature from the robot controller

- Issues with the thermocouple amplifier, most likely due to noise

- power the adapter from the robot control box (24 - 5v)

How was it evaluated?

The system was evaluated through a functional proof of concept that demonstrated the ability to start and stop the extruder to prevent oozing on a 3D print.

What are the implications?

Neostruder shows potential for a modular, adaptable system for integrating extruders with various robotic arms, enhancing flexibility and efficiency in 3D printing applications.

Project Summary

Mockup Diagram

AI Sketches

3D Concept Render

Electronics

Gallery

Summary Slide and Video

Summary Slide

Incorporation of Skills

- 2D and 3D Design: Custom 3D printed and laser cut mountings and enclosures.

- Additive and Subtractive Fabrication Processes: 3D printing, laser cutting.

- Electronics Design and Production: Custom ESP32 PCBs, wiring.

- Embedded Microcontroller Design, Interfacing, and Programming: ESP32 programming and interfacing.

- System Integration and Packaging: Integration of all components into a functional system.

Individual Mastery

While this project was completed independently, it demonstrates individual mastery of the skills required, ensuring that the final product is operable and showcases comprehensive integration of the covered units.

Files:

electronics

fan mount

mdpe adaptor

laser cut bracket