3D Scanning and Printing¶

We’ve printed several design rules to test our 3D printers.

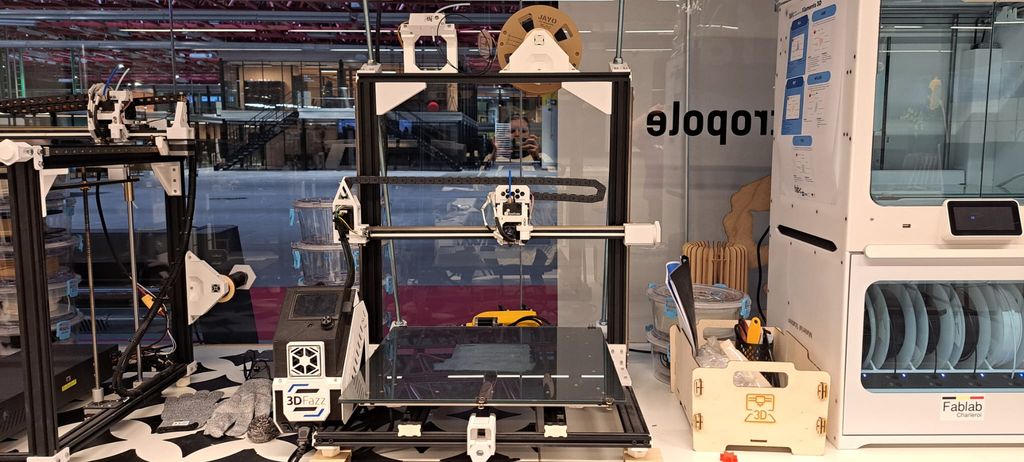

Our Fab Lab’s 3D printers¶

Ultimaker S5¶

- 330 x 240 x 300 mm build volume

- Composite-ready dual extrusion

- Award-winning touchscreen UI

- Click and print with 280+ materials

Creality CR-10S5¶

- FDM fused deposition molding

- print volume of 480 x 480 x 490mm

- Maximum hot end temperature less or equal to 260°C

- Heated print platform max temperature less or equal to 60°C

- Bed leveling: CR Touch Leveling

- Filament diameter: 1.75 mm

- Industrial-grade Circuit Board

Creality Ender-5 Plus¶

- FDM fused deposition molding

- print volume of 350 x 350 x 400mm

- Maximum hot end temperature less or equal to 260°C

- Print platform max temperature less or equal to 110°C

- Printing material : PLA, ABS, Soft glue, Wooden, Copper containing, Gradient, etc.

- Filament diameter: 1.75 mm

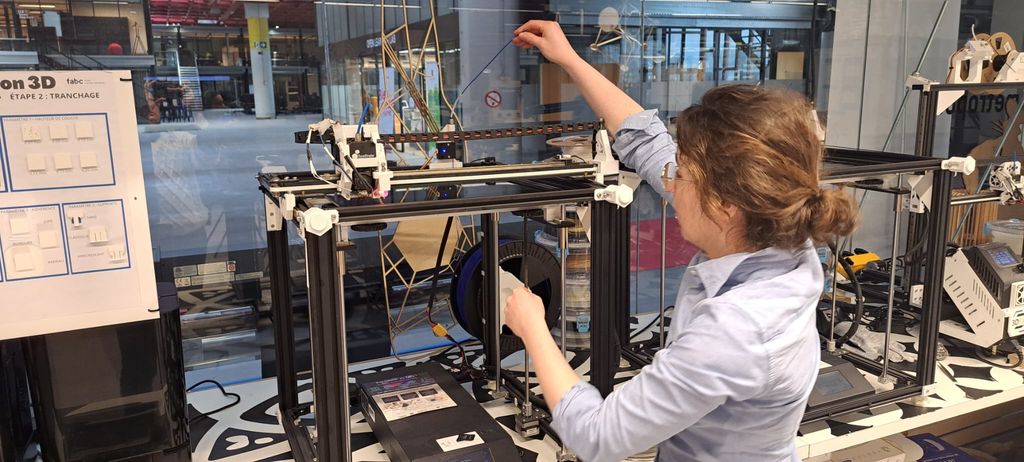

How to prepare the 3D printer¶

We’ve learned to turn on the machine, to place the filament and to add the file with SD card (for the Creality printers) or directly with wifi (for the Ultimaker).

Software¶

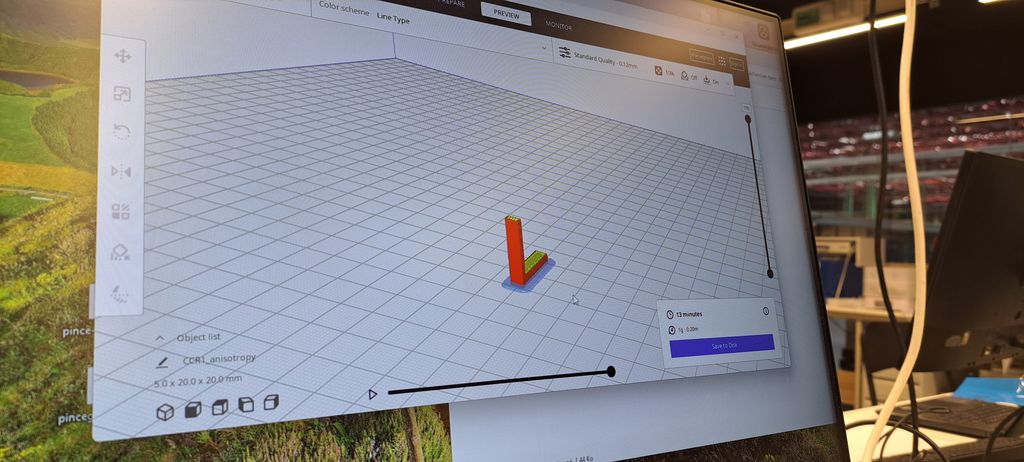

As 3D print software we use Cura.

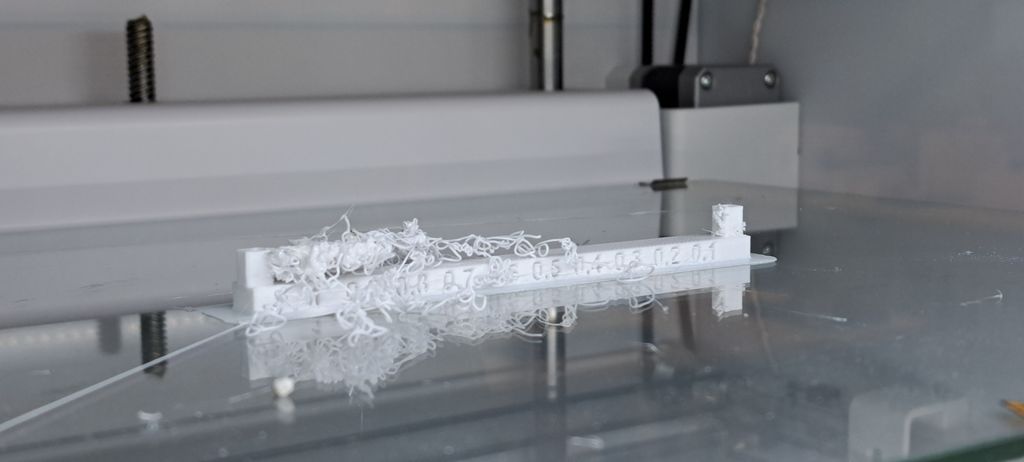

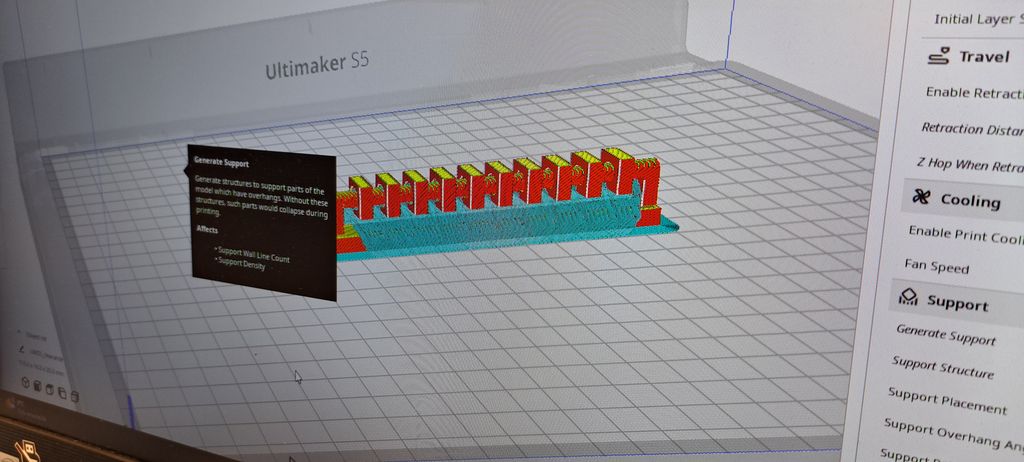

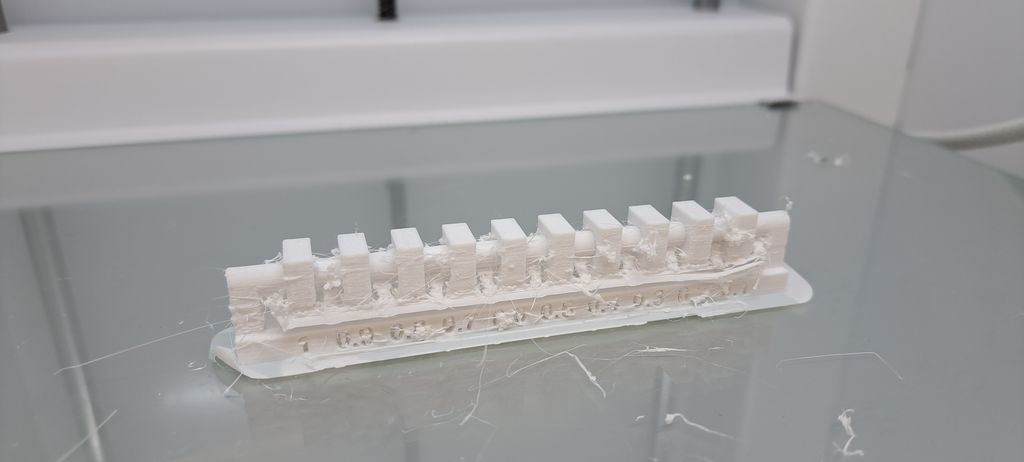

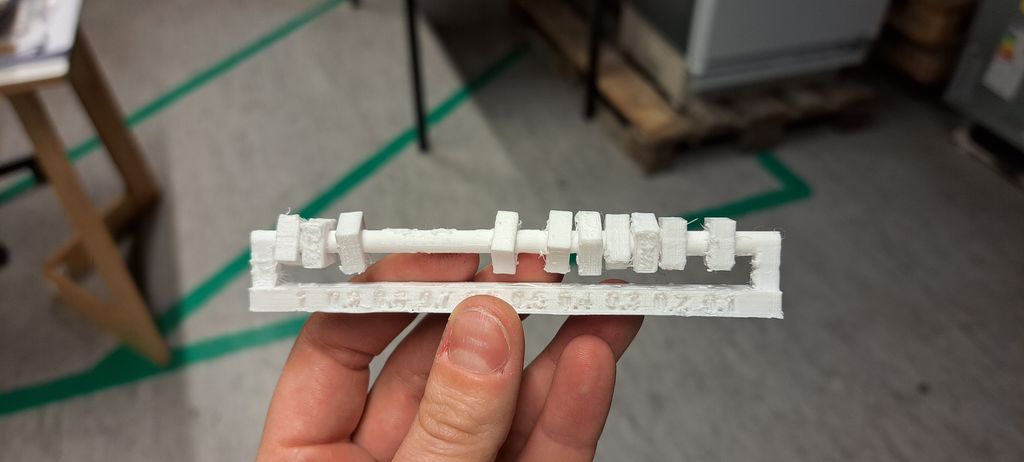

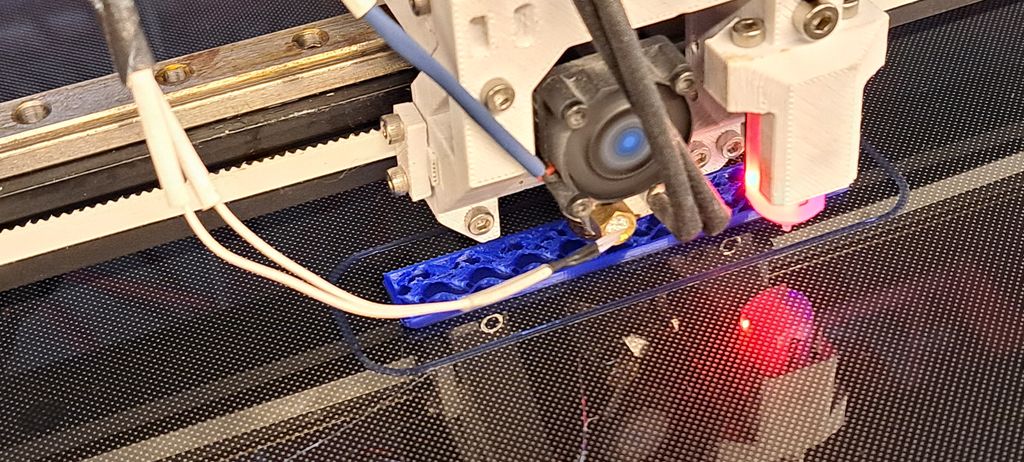

Clearance test on the Ultimaker S5¶

The first attempt without supports failed.

- Printing material : PETG

- Filament temperature : 205°C

- Plate temperature : 60°C

- Print speed : 80mm/sec

- Infill : 10%

- Layer height : 0.4mm

- Plate adhesion : skirt

We added the supports.

The second attempt was a success but printing in PETG made the cleaning hard and the final result is kind of messy.

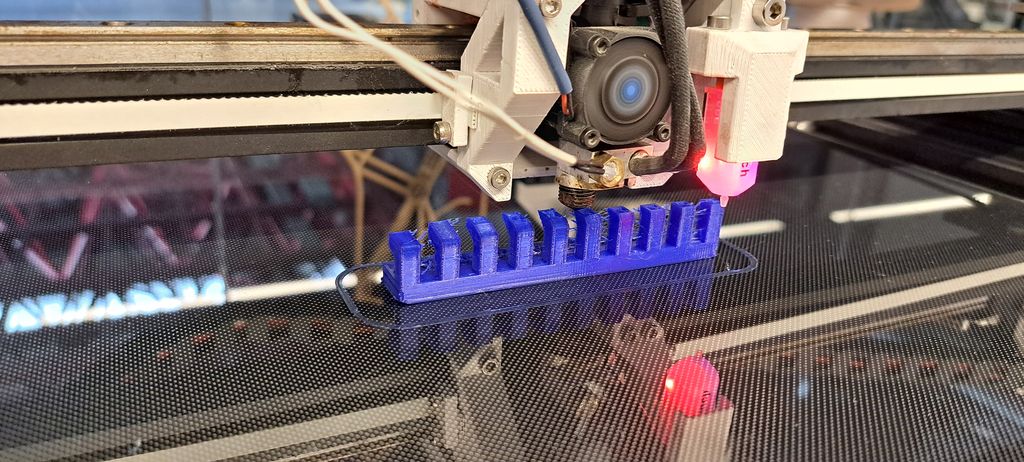

Angle test on Ender-5 Plus¶

We’ve pritned the angle test on one of our Ender-5 Plus and everything went well.

- Printing material : PLA

- Filament temperature : 205°C

- Plate temperature : 60°C

- Print speed : 80mm/sec

- Infill : 10%

- Layer height : 0.4mm

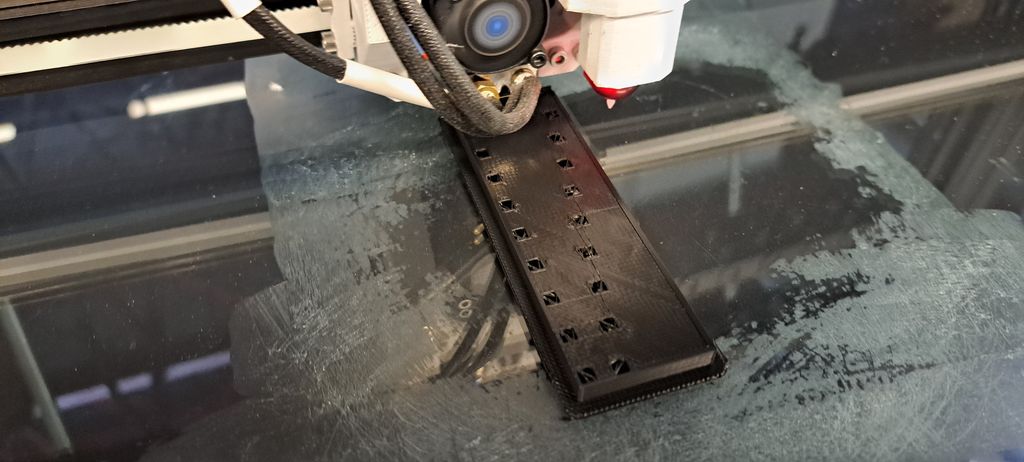

Bridging on Ender-5 Plus¶

The bridging test printing went also well.

- Filament temperature : 205°C

- Plate temperature : 60°C

- Print speed : 80mm/sec

- Infill : 10%

- Layer height : 0.4mm

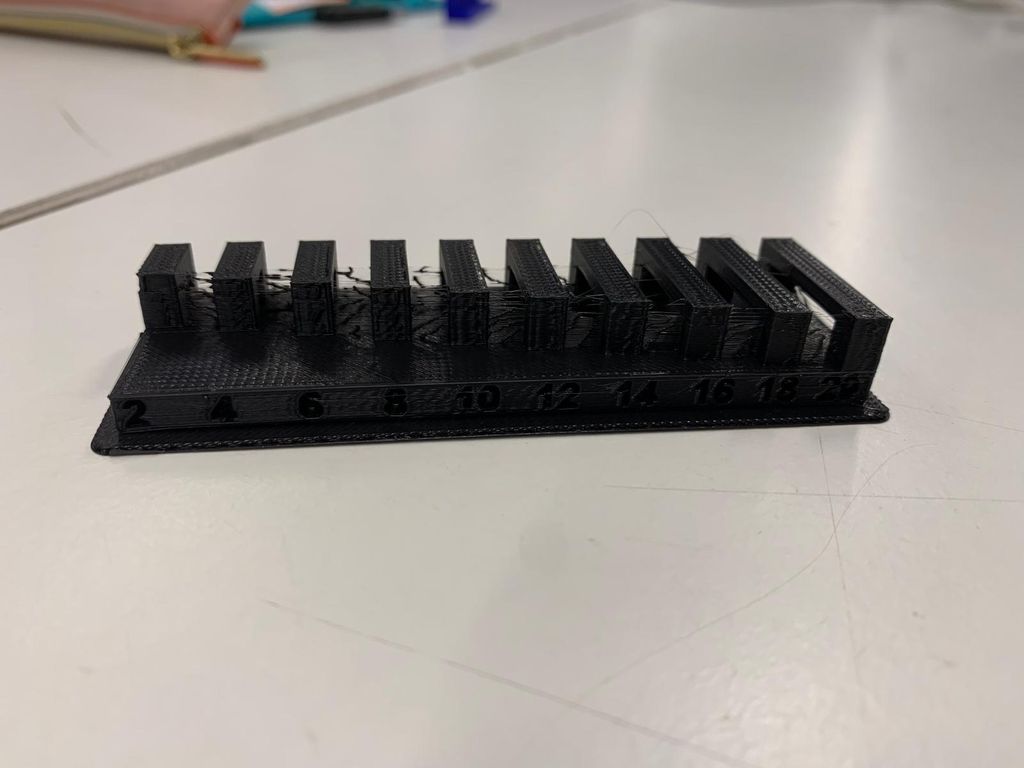

Dimensions on Ender CR-10¶

The dimensions test went well too.

- Filament temperature : 205°C

- Plate temperature : 60°C

- Print speed : 80mm/sec

- Infill : 10%

- Layer height : 0.4mm

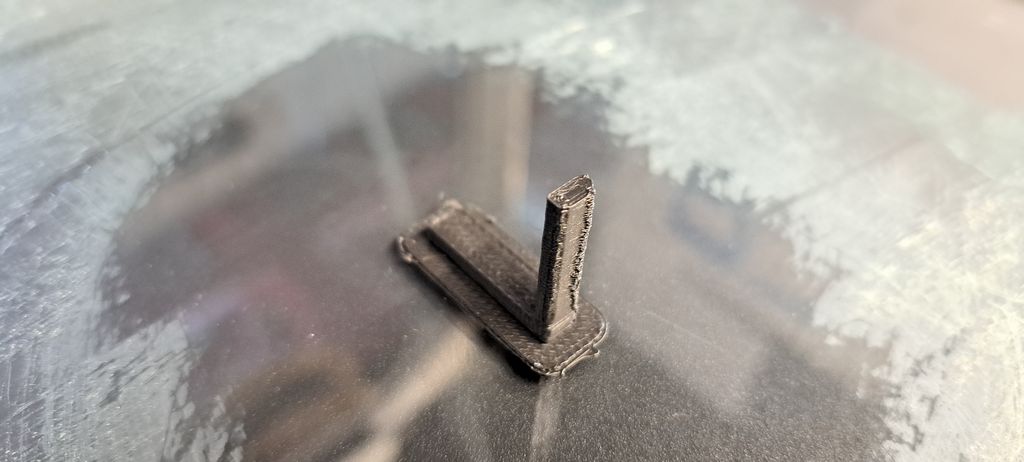

Anisotropy¶

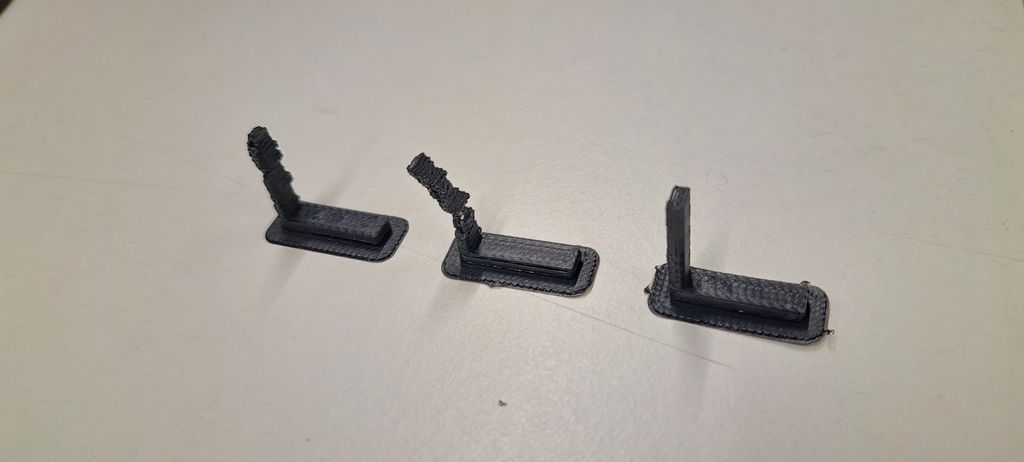

This piece was the smallest but the trickiest…

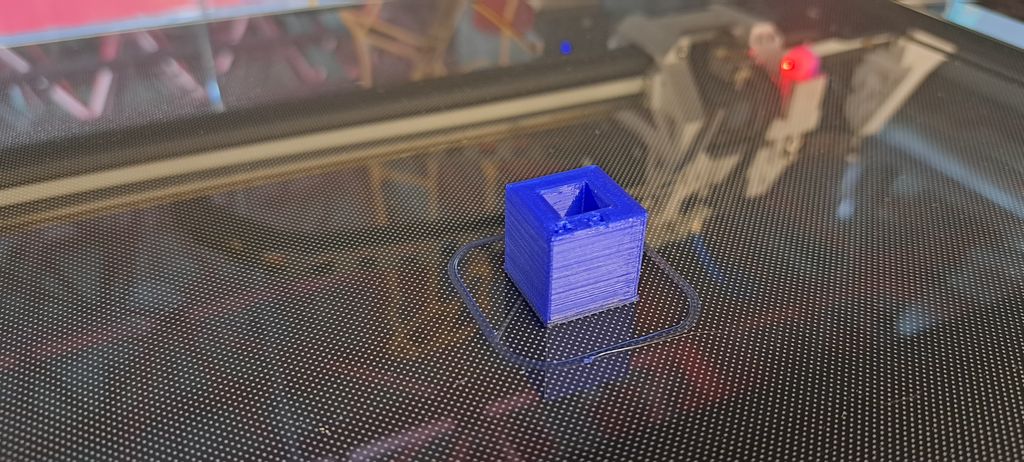

First, we didn’t get the base layer to stick on the heated board with a 50°C plate temperature so we pushed it to 60°C and added a raft.

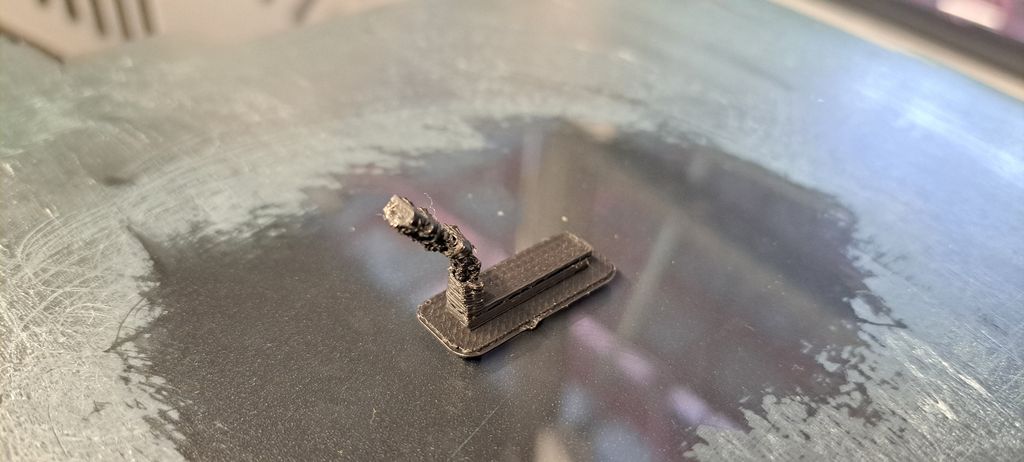

It sticked to the plate but was horrible…

As the print still wasn’t right we lowed the speed from 70mm/sec to 50mm/sec.

As the print was worse and even broke, we checked again the parameters and discovered that the problem came from the travel as the retraction was on, which shouldn’t in this case.

And so we finally got our piece correctly ! Yay !