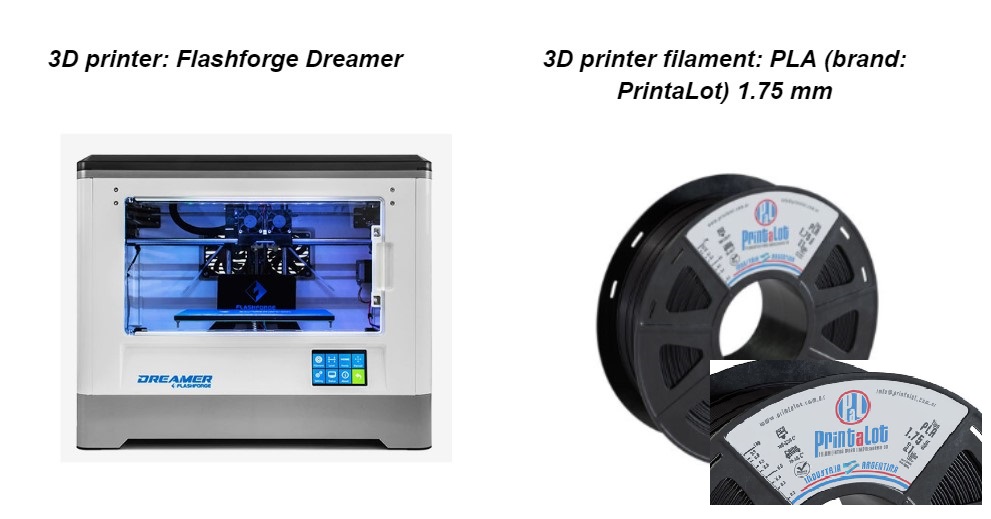

Equipment used

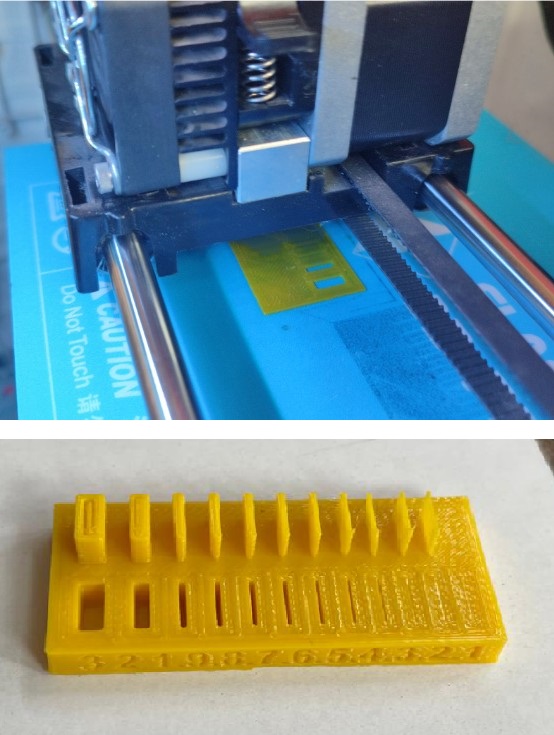

For our group task we print two tests that we have selected, for all of us it was our first interaction with 3D printers. we hope that these tests will show us certain capabilities of our machine, the tests used were:

- clearance.stl

- thickness.stl

On this tests, we used PLA, 200°c extruder and 40° bed temperature with 15% infill. Here in the lab we have the 3 FlashForge dreamer. This machine has an enclosed case, this improves printing because the outside conditions don't affect the environment inside the machine. We can print with different plastics filaments that came in spools and have 1.75 mm in diameter.

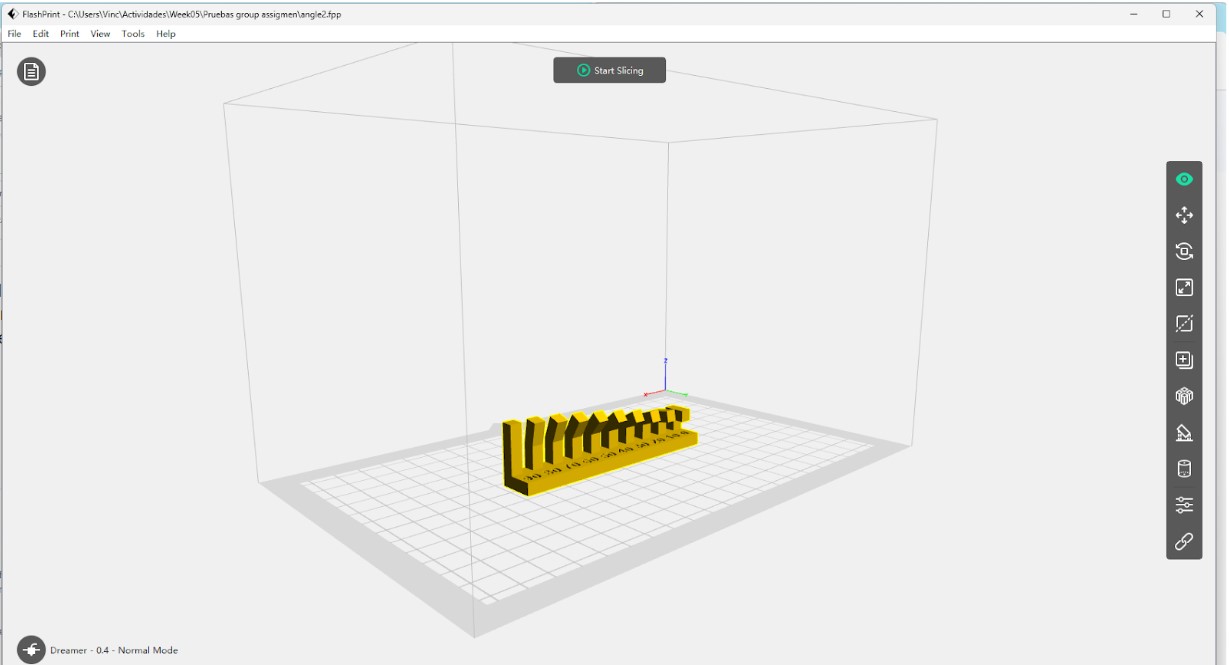

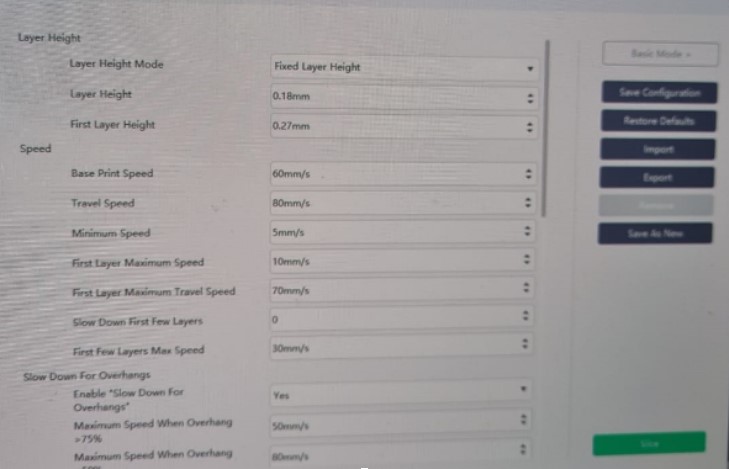

The software used to configure the printing was FlashPrint 5.8.63

The parameters we used with the best results were:

- Temperature

- Extruder Temperature: 215℃

- Platform Temperature: 70℃

- Speed:

- Base Print Speed: 80mm/s

- Minimum Speed: 120mm/s

- Fill Density: 20%

- Fill Pattern: Hexagon

- Overlap Perimeter: 15%

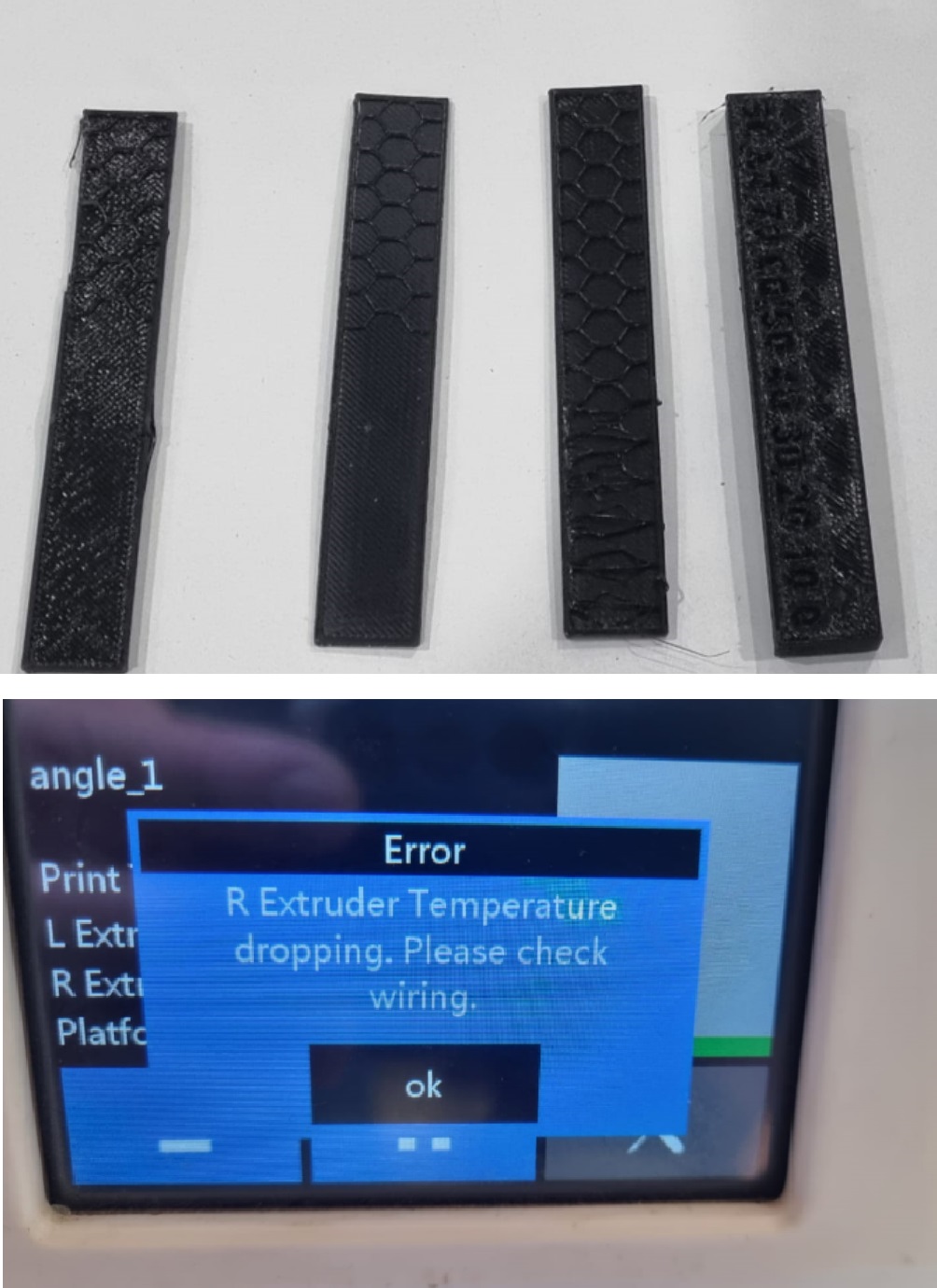

As the image below shows, we had some failures, which we basically improved by varying the temperature of the stud and the platform.

The initial mistake was having set the base temperature too low (we started with 50℃).

With the Extruder temperature we started with a high temperature and gradually lowered it, we obtained the best result with 215℃.

Thanks to the experience acquired with the first test, the second one was much faster with a better result. We changed the color but we used the same parameters because it had the same indications as the previous filament.

Results

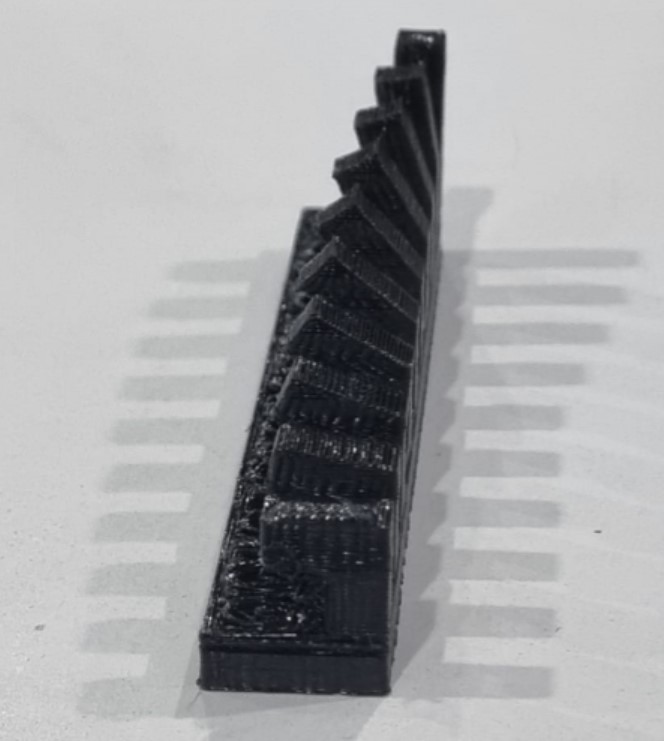

After the test we concluded that for PLA we have to use a range between 200-215 ºC for the extruder, 50 ºC for the bed, 50 to 60mm/s speed of printing.

We also tried to 3d print over fabric. For this printings we used TPU 95, with the settings 220 ºC for the extruder, 70 ºC for the bed and a printing speed of 20 mm/s. For this kind of 3d print, you have to 3d print a couple of layers and then add the fabric, tighten it, and keed printing the rest of the layers over the fabric surface. The heat of the filament fuses the materials and generate a strong bond between them.