3D Scanning and Printing

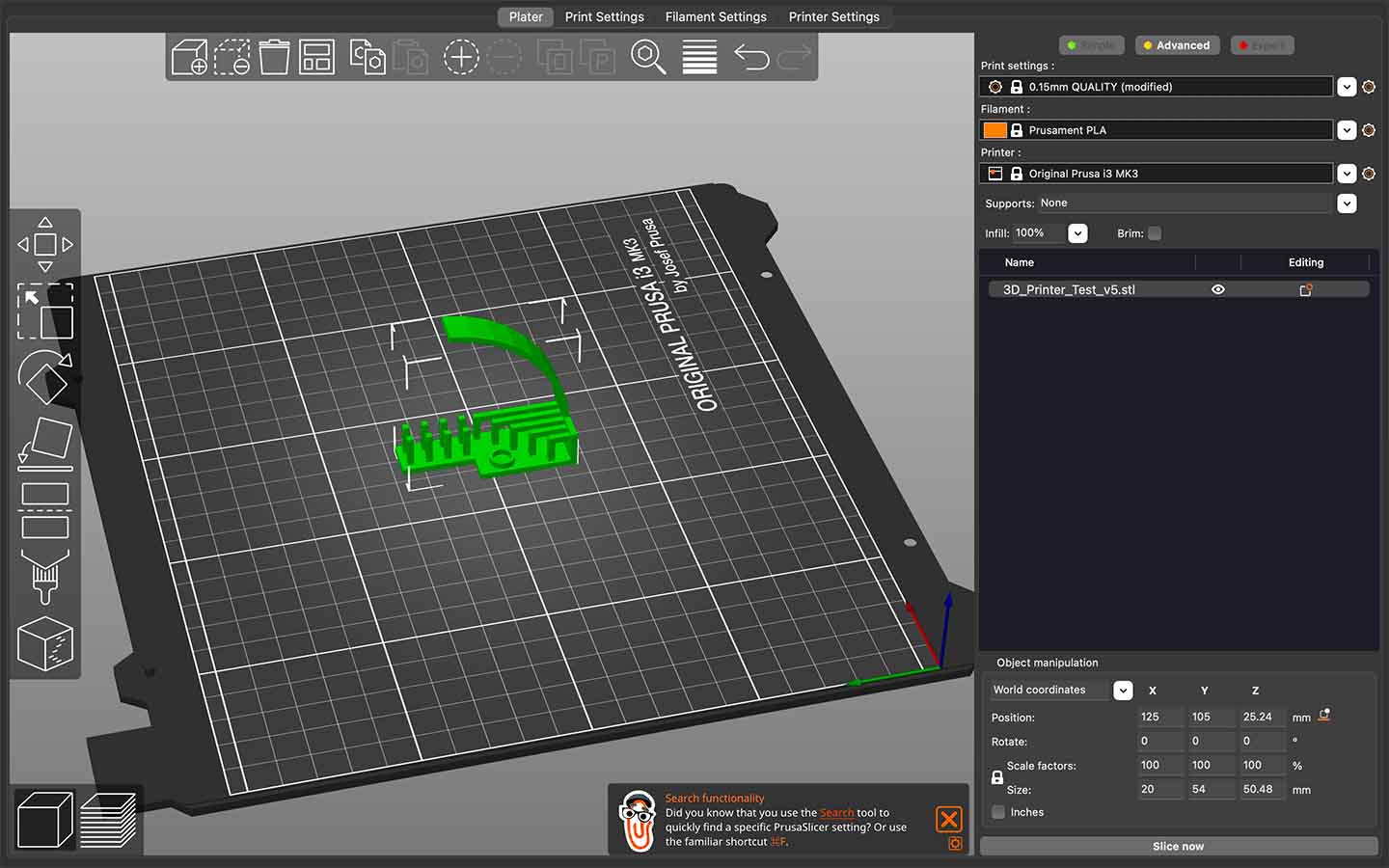

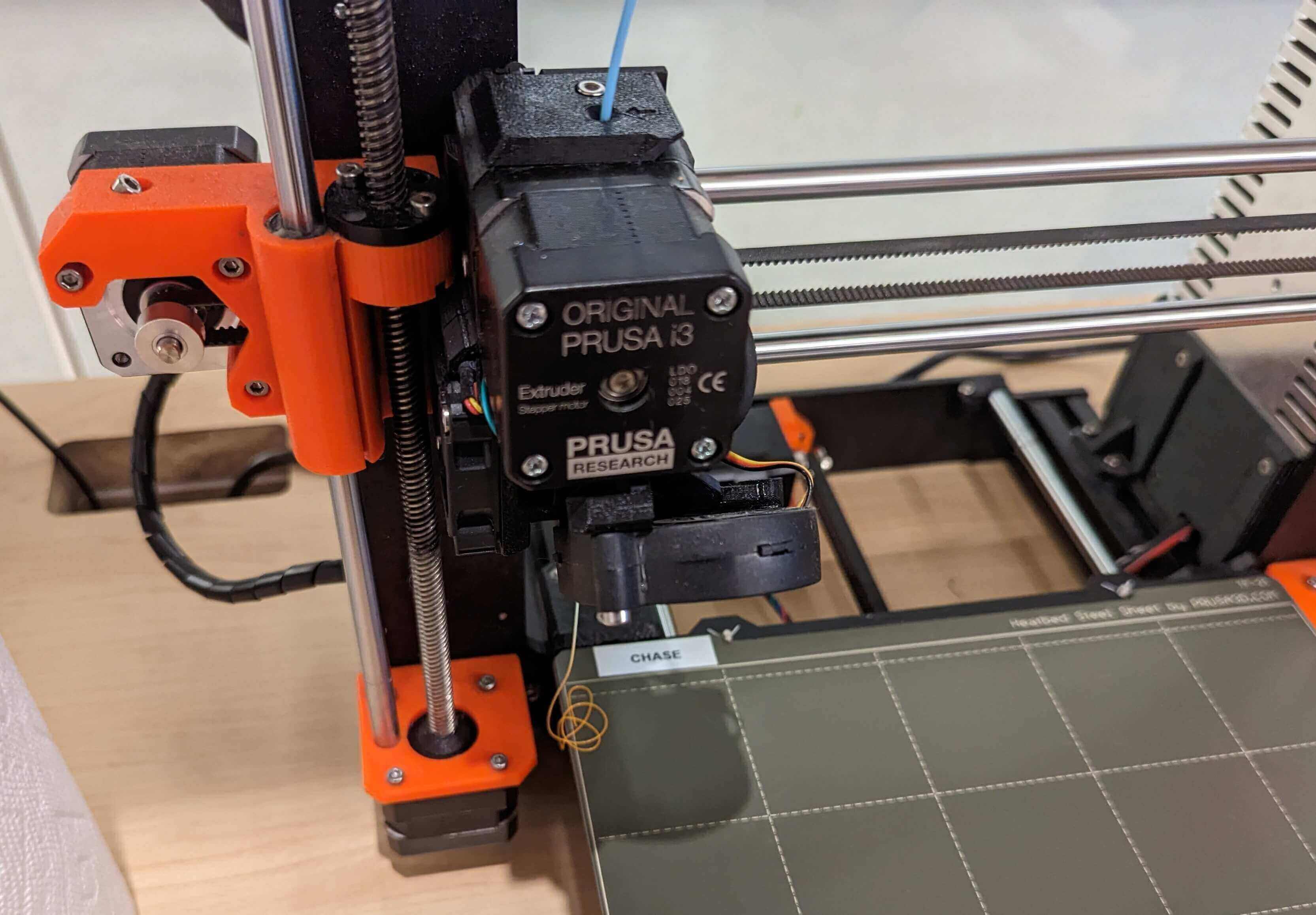

This week our group tested our Fablab's Prusa MK3+ printer's capabilities. Using a predesigned file provided by our instructor, we were able to determine the our printer's physical limitations, such as bridging, angles, and holes.

Process

To import the file, we went through the the following steps:

1. We downloaded the STL file provided from our instructor and designed by Thingiverse We opened it in PrusaSlicer, the main software that changes the settings of the print and sends it to Prusa 3D printers.

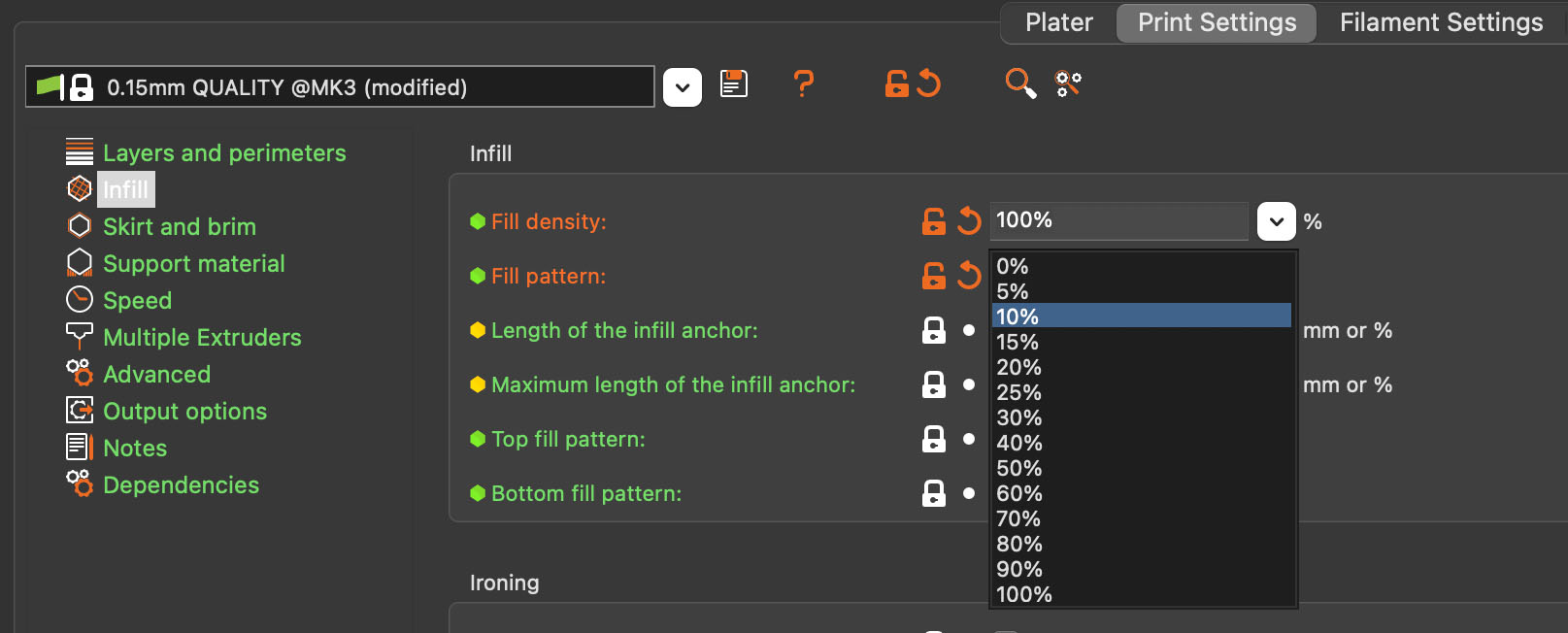

2.We changed the infill to 100% because that is the recommended infill based on the website where we exported the design from. We also changed the pattern to rectangular because the default Gyroid pattern does not work with 100% infill.

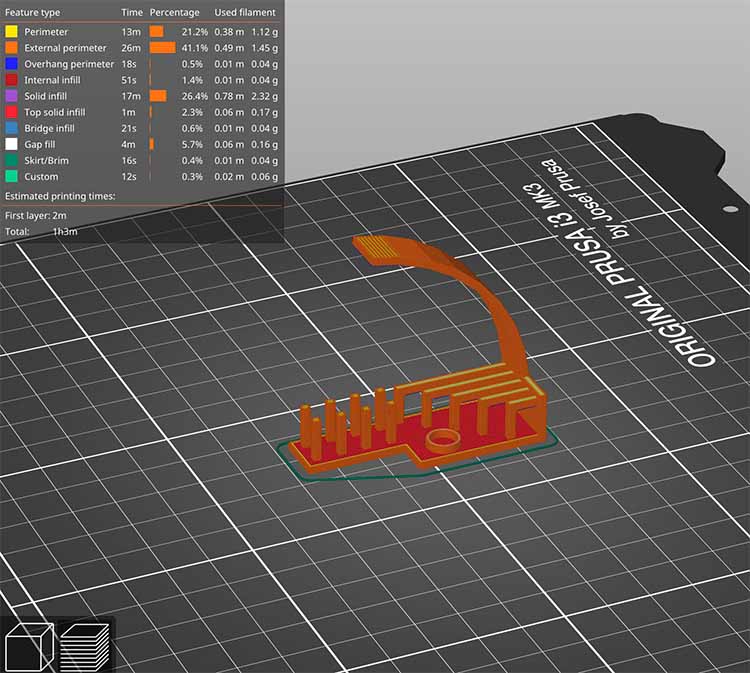

3.We turned off all supports because we wanted to test where overhangs occur in the design to be aware of Prus printer’s limitations.

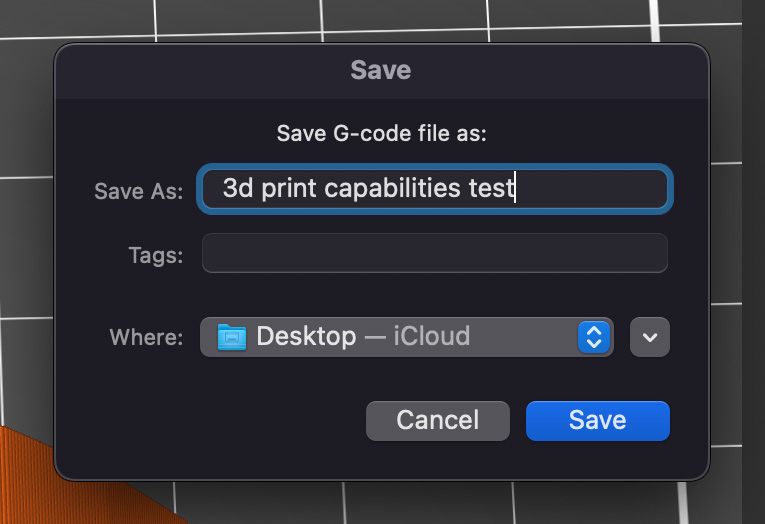

4.Then, we clicked on slice to export it as a G-code(.gcode) file, the language the Prusa printer understands. We moved the file to our SD card, inserted it in the Prusa printer.

5.We used light blue PLA filament for this print. To load the filament, we heated up the nozzle(reaching 215 Celsius) and fed the filament into the top of the nozzle, pushing it till it came out of the nozzle melted.

6.Then, we went through the SD card menu and selected our file to print.

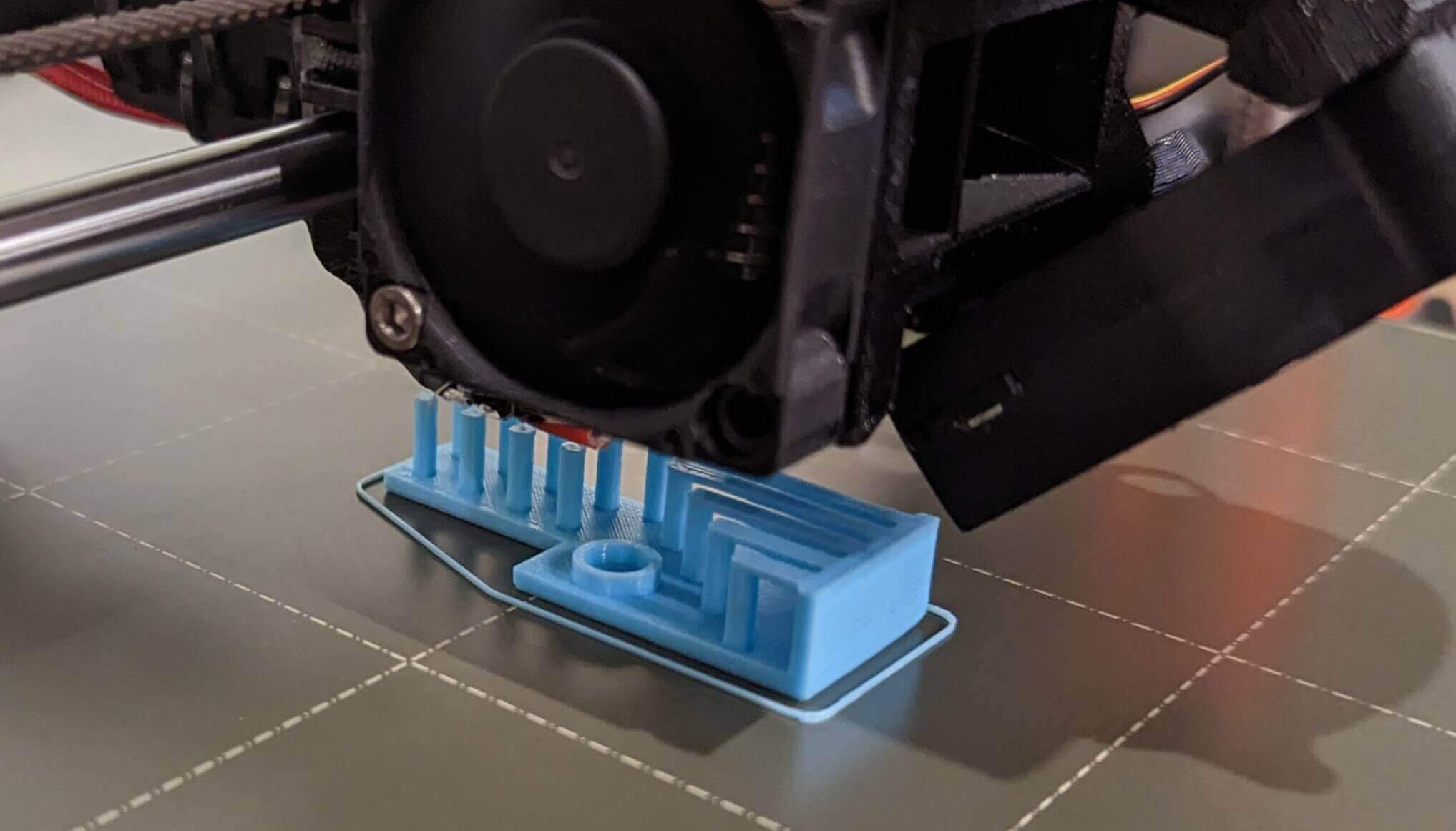

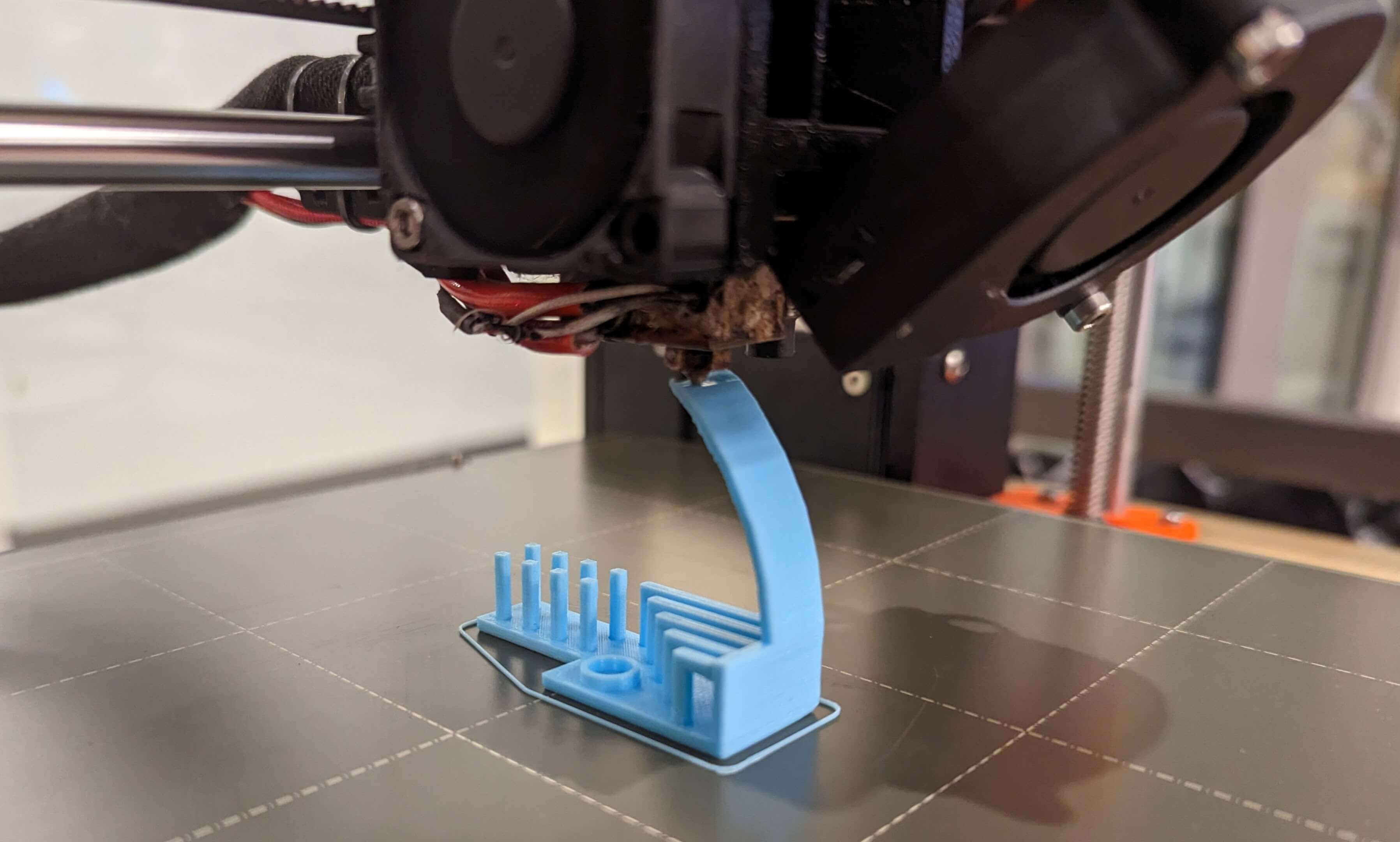

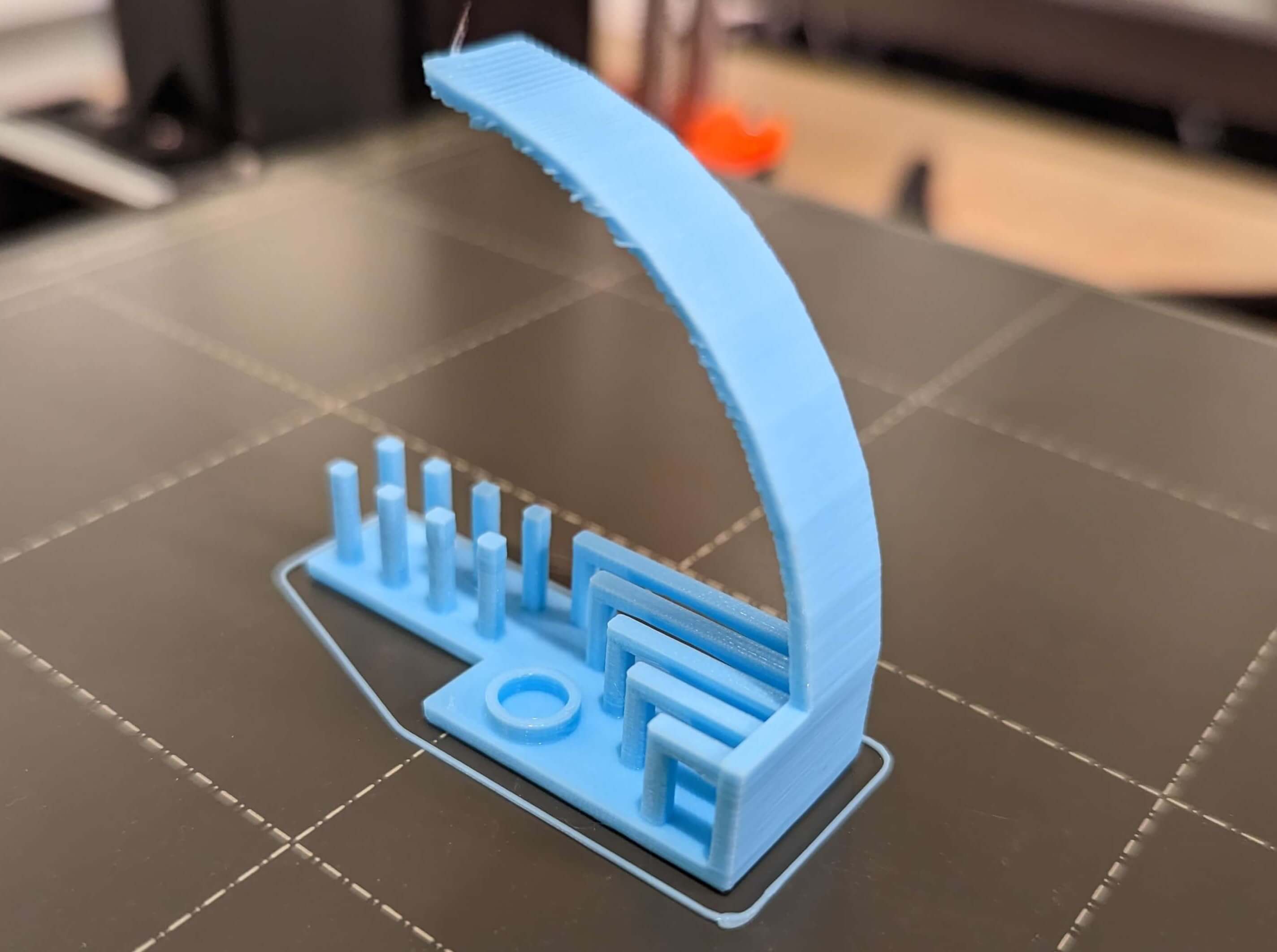

Process pictures of the print!

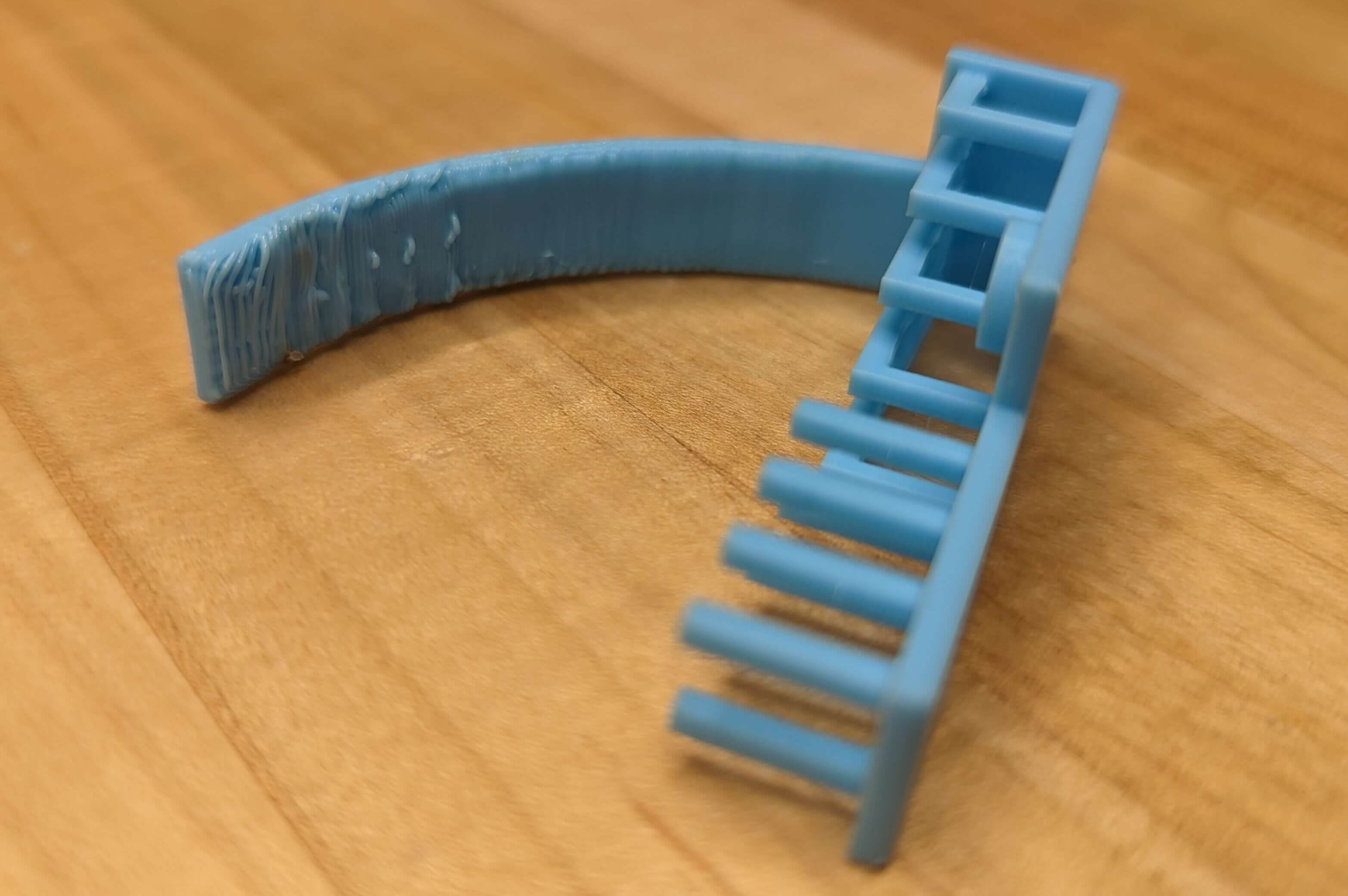

As we compared our final physical print to what was on the original STL file, we concluded the following:

1. Our printer can do overhang up to 80 degrees with some shifted layers at the end.

2.Our printer can handle bridges up to at least a 25mm length.

3.We also made a hole with 6 mm diameter and 1 mm wall accurately.

4. The printer is also capable of printing 2mm by 2 mm columns with a height of 10 mm with little to no error.