Project Development

Week 18 Assignment summary

My Final Project entails the creation of a technologically advanced backpack with a smart suspension system. Initially, during my final year of graduation, it was solely intended to be a suspension load backpack. However, due to the pandemic, I needed to adapt the project. This led me to explore digital fabrication through the Fab Academy course, and I realized it was the opportune moment to incorporate these new skills into my project.

The problem that my project aims to address is the negative impact of carrying heavy loads in backpacks. Such loads generate significant dynamic forces that can have severe repercussions on one's health. The strain caused by the dynamic load while walking or running can lead to various issues, such as shoulder, knee, neck, and other bodily ailments.

During my research, I came across several case studies highlighting the medical problems experienced by Army soldiers, professional trekkers, and hikers who frequently carry heavy loads. This motivated me to focus my efforts on tackling this issue.

Additionally, as part of my Fab Academy training, I gained knowledge in the field of electronics. This inspired me to enhance the functionality of the backpack by incorporating electronic components and making it smarter.

Currently, I am in the process of developing the initial prototype of my design. My target audience for this backpack is primarily trekkers and hikers, as I am tailoring its features to cater to their specific needs.

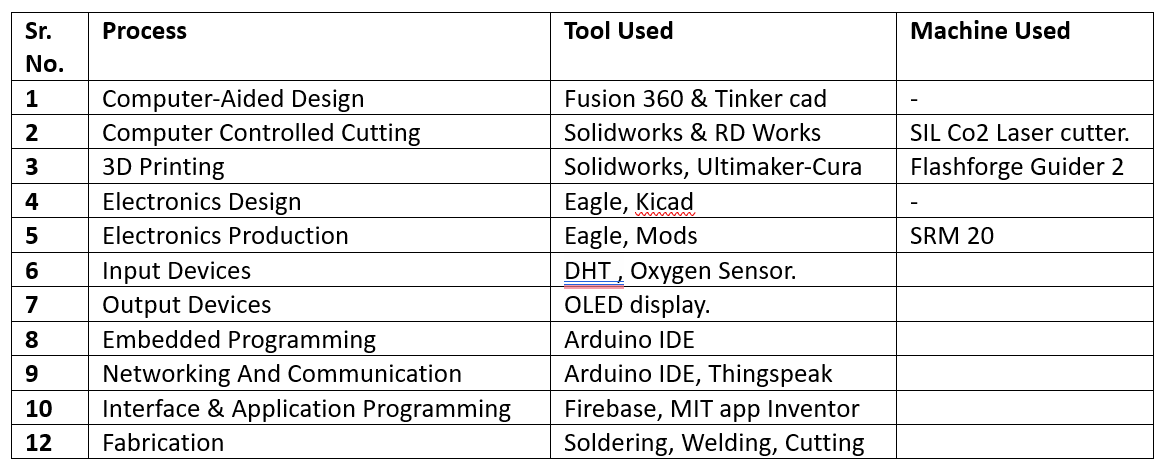

What Fabrication Process do you used.

For the completion of my final project i need lots of different Digital Manufcaturing process along with several traditional manufcaturing process.

What tasks have been completed, and what tasks remain?

Completed Task

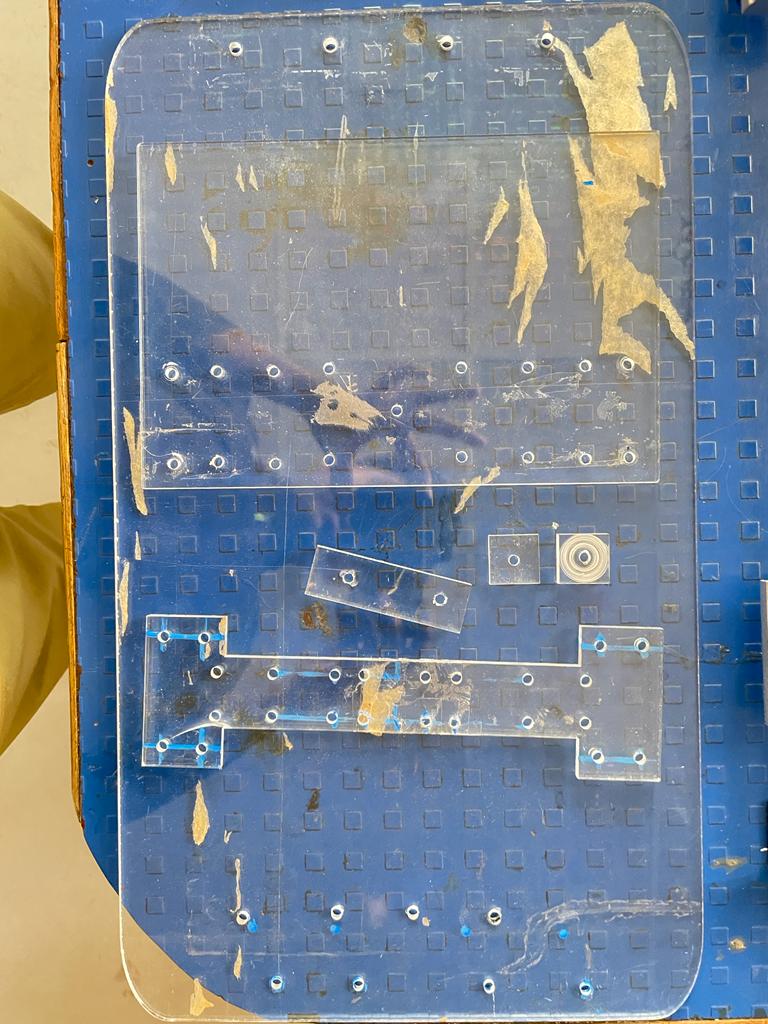

Developed a basic framework for the entire mechanism- A foundational framework was created to serve as the backbone of the entire mechanism. This framework formed the structural and functional basis for further development.

Laser Cutting of Vital Components: Multiple crucial components were subjected to laser cutting techniques. This process involved using laser technology to precisely shape and cut these components, ensuring their accuracy and reliability.

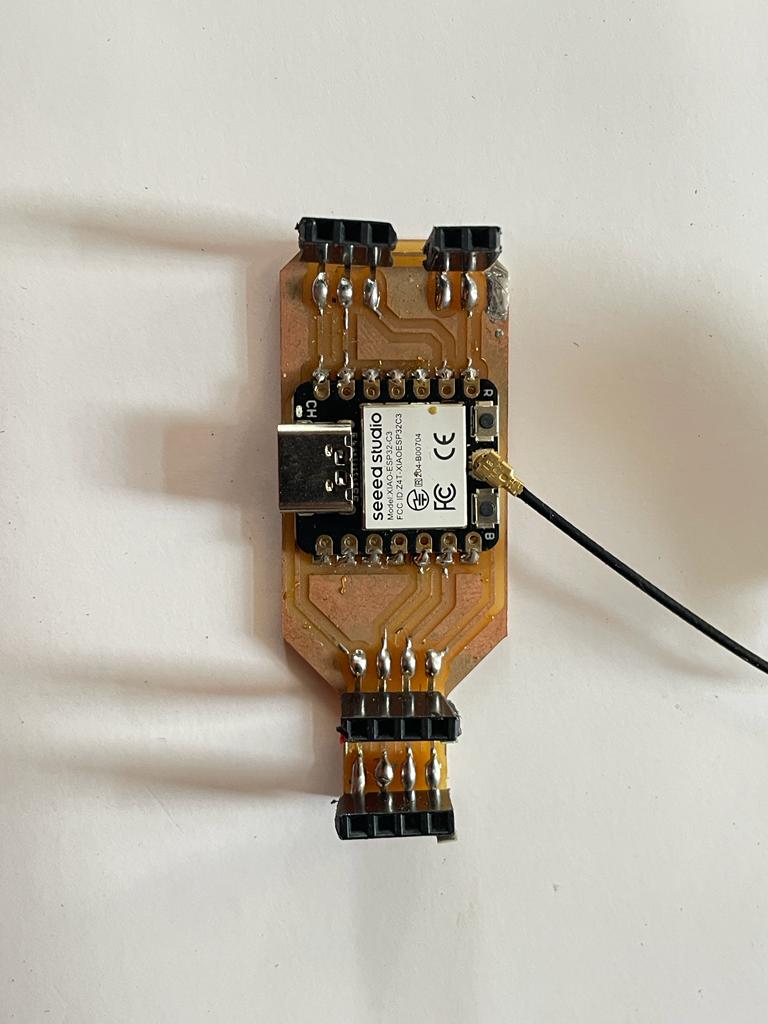

Design and Soldering of PCB: The printed circuit board (PCB) underwent a successful design phase, where the layout and connections of electrical components were meticulously planned. Following the design, the soldering process was carried out to securely connect the electronic elements onto the PCB.

Comprehensive Testing of Input and Output Devices: A thorough testing phase was conducted to evaluate the performance and functionality of all input and output devices. This involved assessing the proper functioning of sensors, actuators, and other components to ensure their seamless integration within the mechanism.

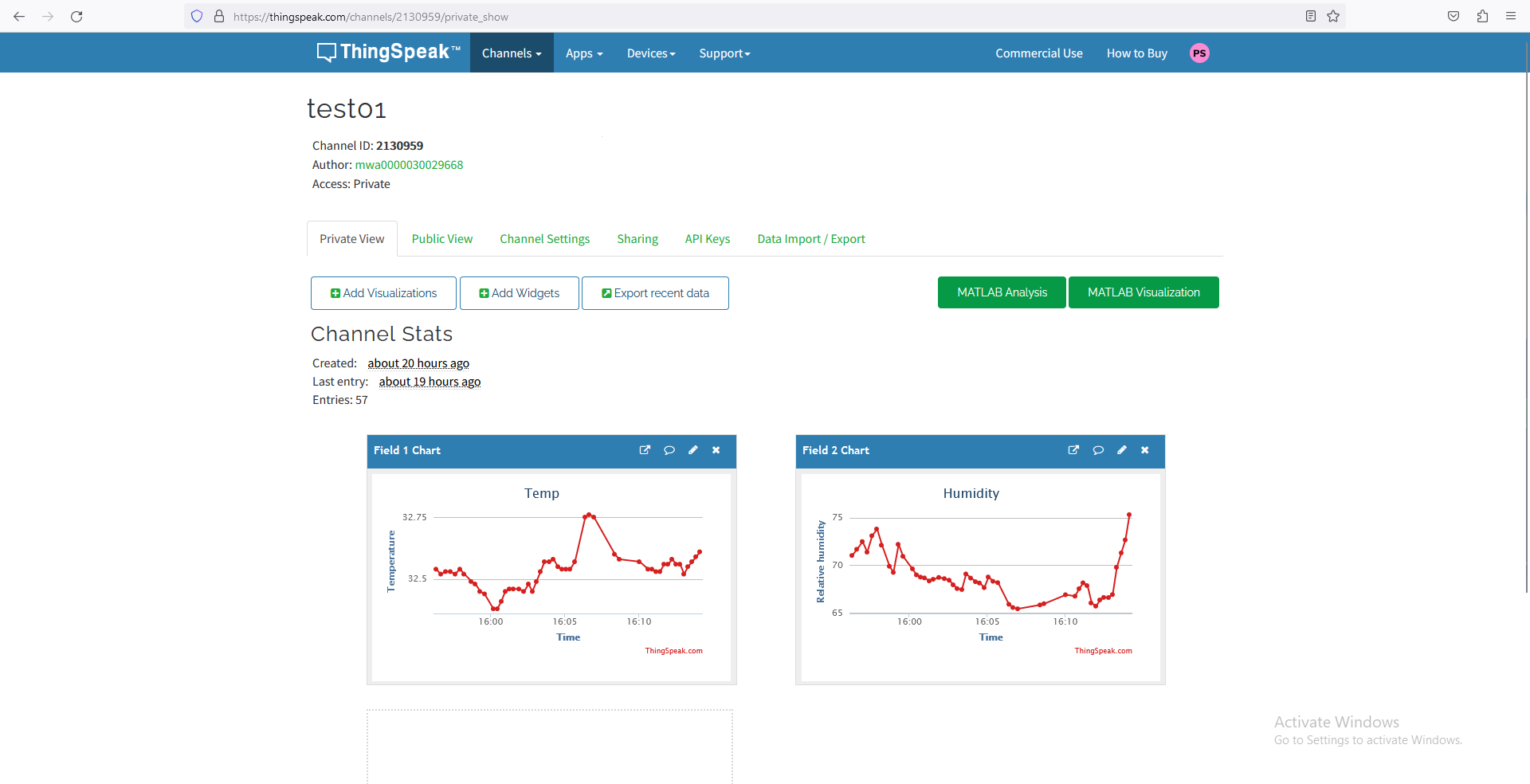

Establishment of Thinkspeak IoT Channel: An IoT (Internet of Things) channel on Thinkspeak was established, providing a platform to monitor and control the mechanism remotely. This integration allowed for data collection, analysis, and real-time interaction with the device, enhancing its connectivity and functionality.

Remaining Tasks

Android App Integration: The integration of the Android app has not been finished yet. This means that the app has not been fully incorporated into the project, and its functionalities are not yet operational. Further work is required to successfully integrate the Android app.

3D Modeling Task: The task of creating a 3D model is still pending. This indicates that the process of developing a three-dimensional representation of an object or a concept has not been finalized. The team needs to complete this task to have a complete and accurate 3D model.

Assembly Process and Final Testing: The assembly process and the final testing are yet to be carried out. This means that the various components or parts of the project have not been put together or assembled, and the project has not undergone the final testing phase. These steps are crucial to ensure that all the elements function correctly and meet the required standards.

D) What has worked? what hasn't?

What has worked-

The microcontroller board, which is an essential component of the project, is operating flawlessly. It is performing all the necessary functions and meeting the requirements set for it.

In addition to the successful testing of the sensors, the programming aspect of the project has also been accomplished without any issues.

What hasn’t worked well-

The BME sensor, which was originally installed, had to be replaced with a DHT sensor due to its malfunction. The malfunctioning of the BME sensor necessitated the replacement in order to maintain accurate data collection.

The assembly process of the building is taking longer than originally estimated or anticipated. The actual time required for the construction is surpassing the expected timeframe, leading to delays in completing the assembly.

The integration of the Android app is facing connectivity issues. The process of combining or merging the Android application with other systems or components is encountering problems related to establishing and maintaining a stable connection. These connectivity issues are impeding the smooth integration of the app.

E) What questions need to be resolved?

• The placement of the electronic components requires adjustment.

• A reconfiguration of the Android application is necessary in order to mitigate any problems arising from app integration.

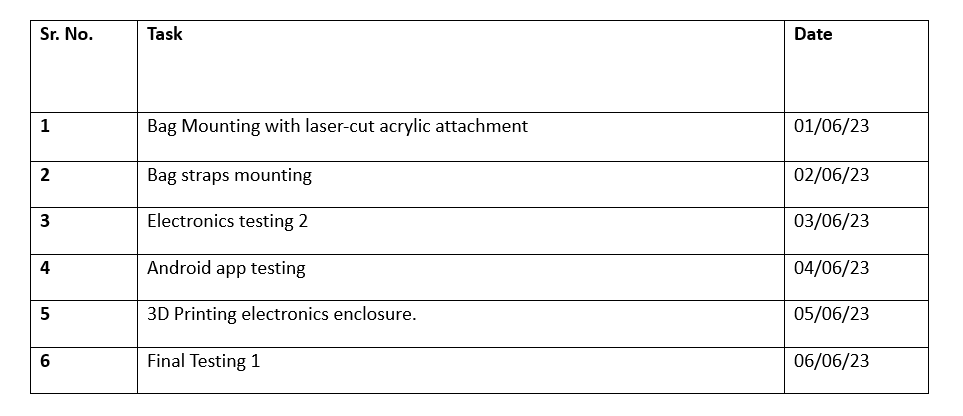

F) What will happen when?

What you have Learned?

1) I designed and developed my own website and gained proficiency in the proper documentation process.

2) I acquired knowledge of various electronic terms, such as board design, board milling, programming, etc.

3) I successfully worked with a variety of controllers including Arduino, ESP32, XIAO ESP32 C3, Xiao Rp2040, ATTiny 1614, and more.

4) I utilized Kicad and Eagle software for the design of microcontroller boards.

5) I explored and comprehended different programming languages and their corresponding integrated development environments (IDEs).

6) I gained valuable hands-on experience by operating laser cutters and vinyl cutters for the first time.

7) During the wildcard week, I acquired the skills to operate a plasma cutter and an embroidery machine.

8) I designed and constructed a CNC jalebi maker machine during the machine design week.

9) I learned and applied the process of molding and casting, in addition to operating a wood router machine.

10) A major aspect of my learning experience was developing effective teamwork skills and time management techniques.