Input Devices

Group Assignment

1) Study of Different materials for molding and casting

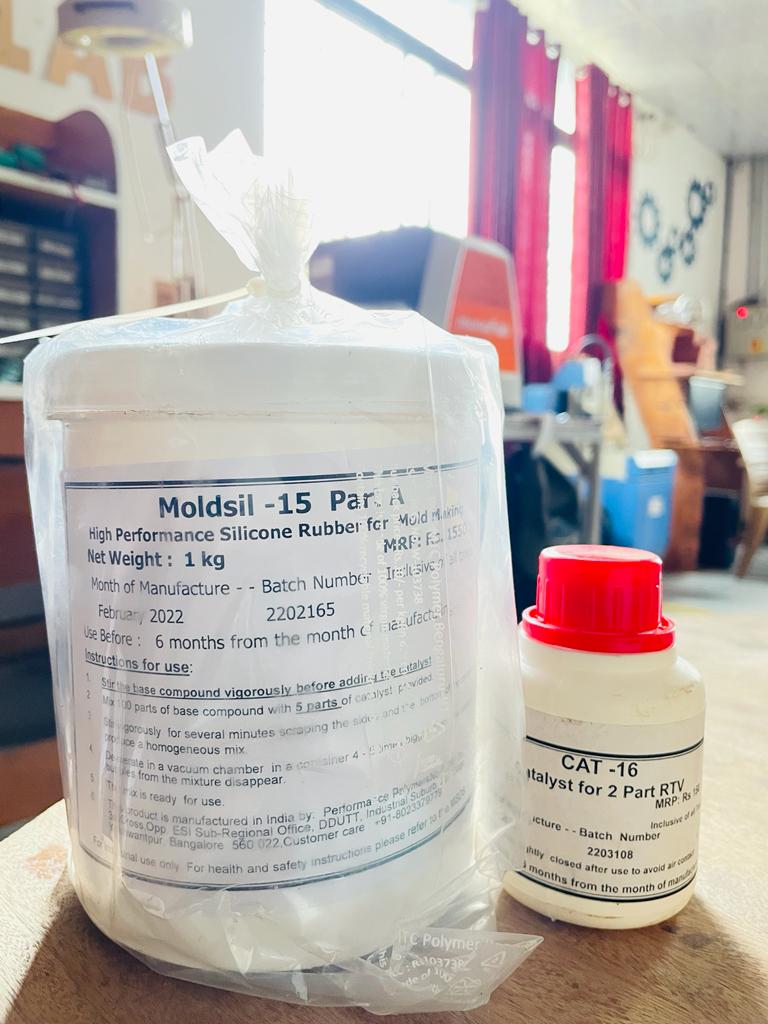

We have a variety of materials at our Fab lab Vigyan ashram, we have gone through almost all the materials available and studied their datasheet to understand their mixing concentration, curing time etc.

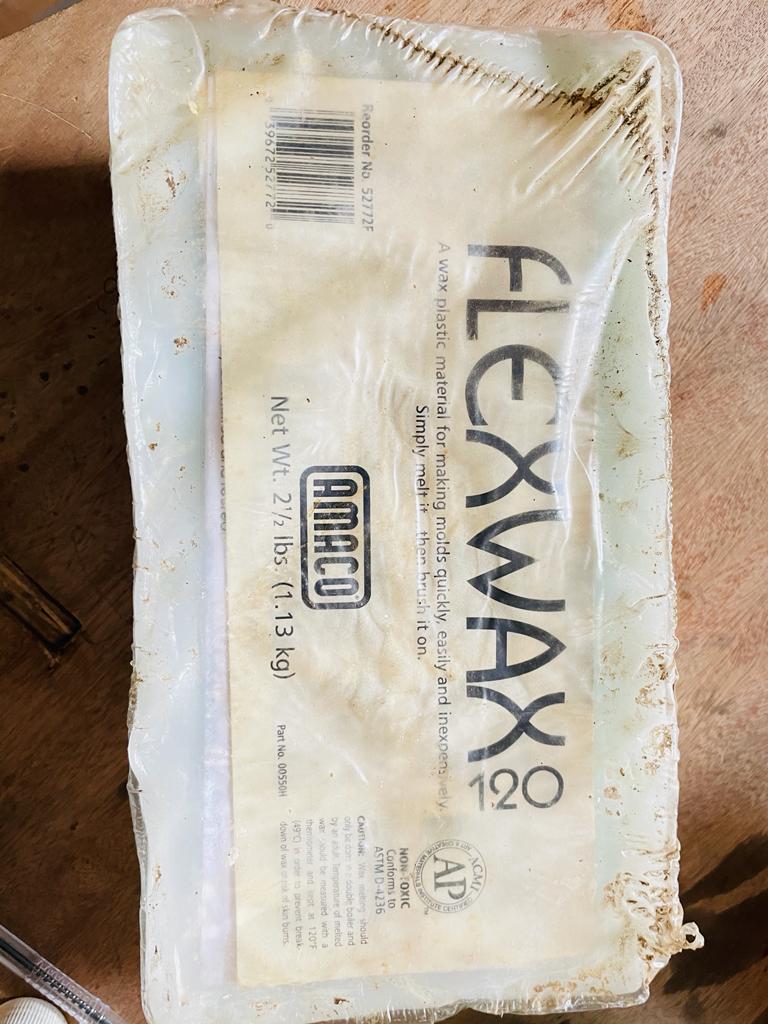

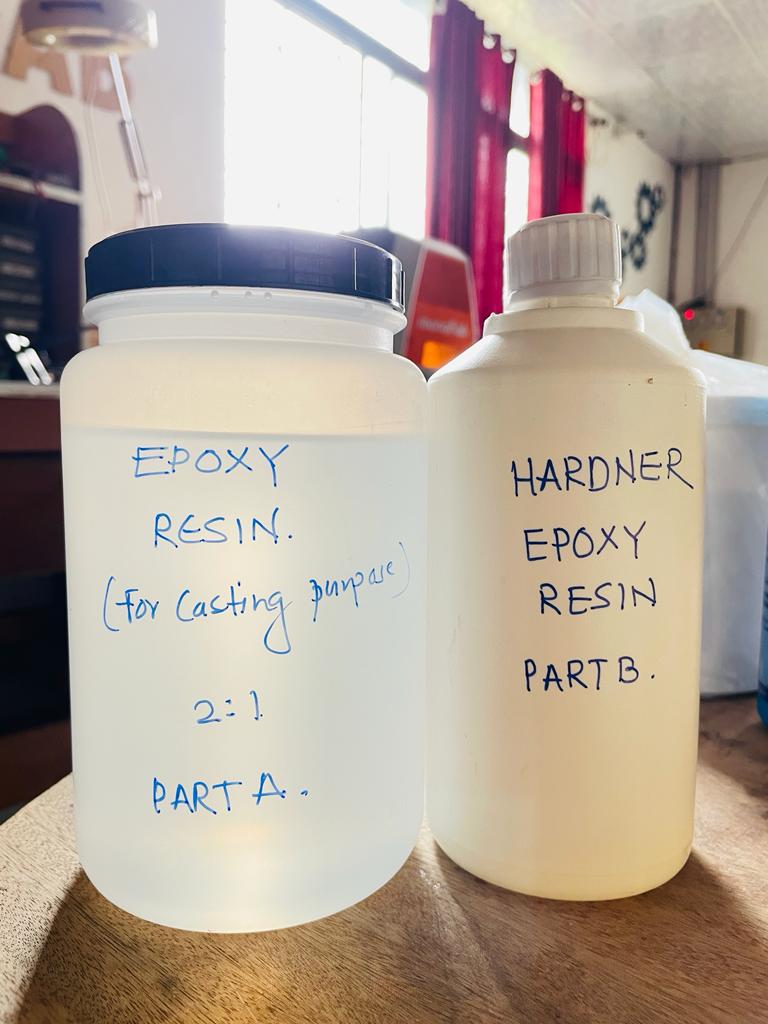

Studied data sheet and safety information for Low temp vax, Epoxy resin, silicon rubber, and any other materials.

Datasheet of low tempreture wax material.

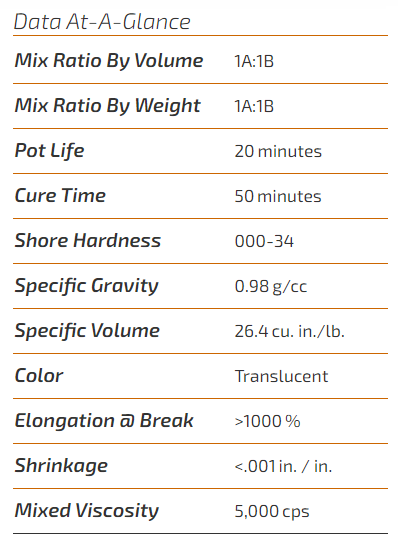

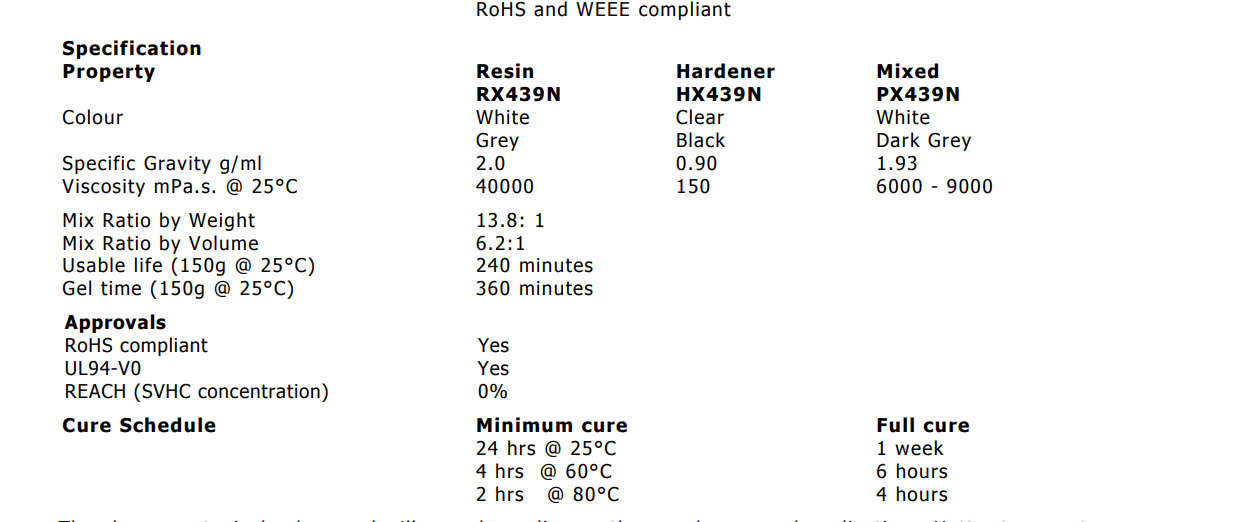

Data sheet of Smoothon epoxy resin material with mixing ration of 1:1

Data sheet of epoxy resin with mixing ratio of 2:1

2) Tested Curing time of Materials.

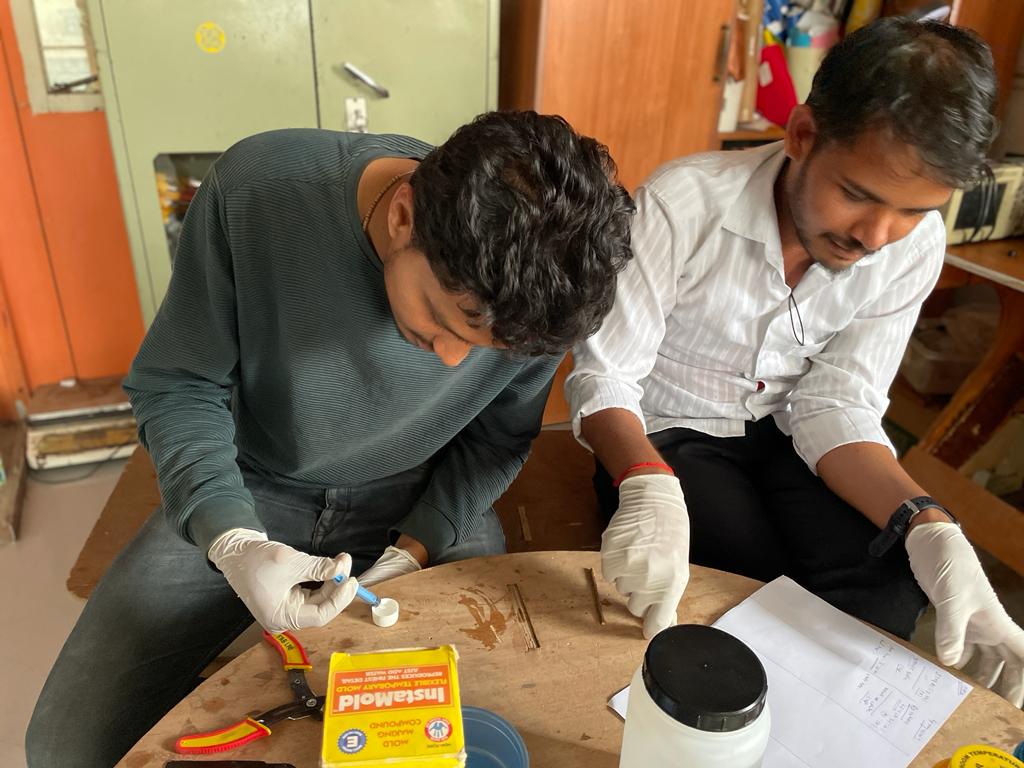

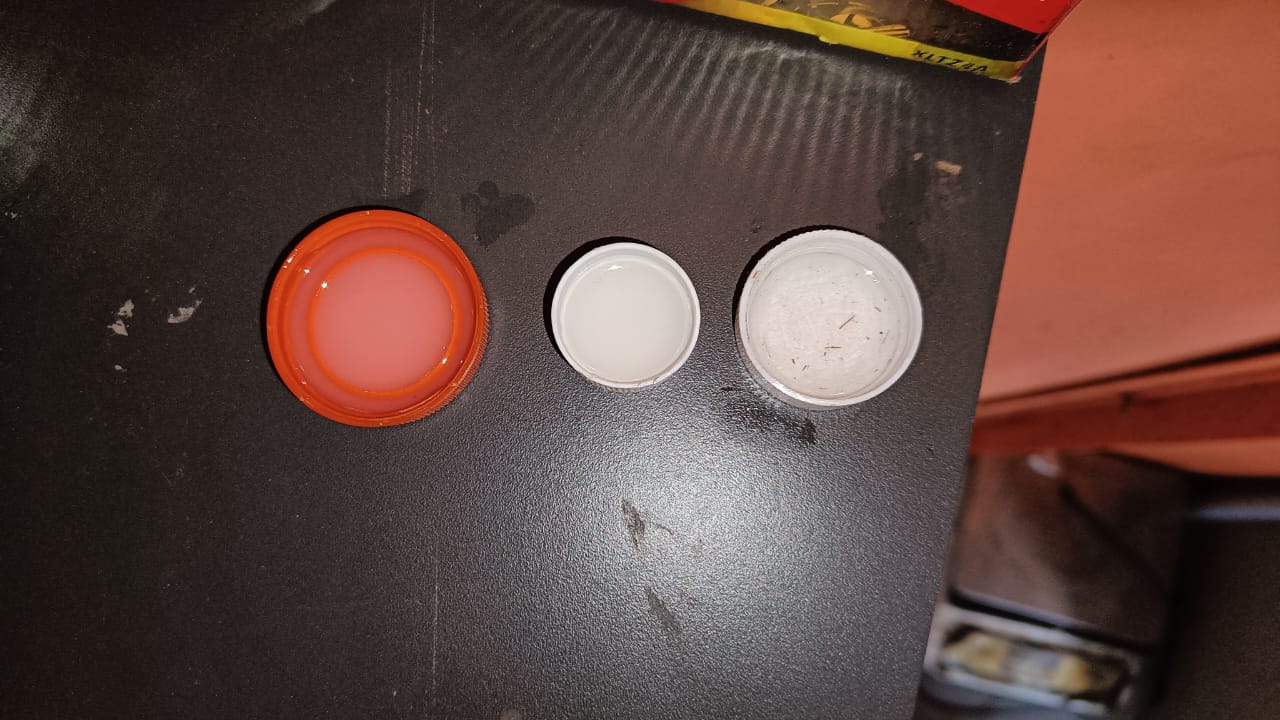

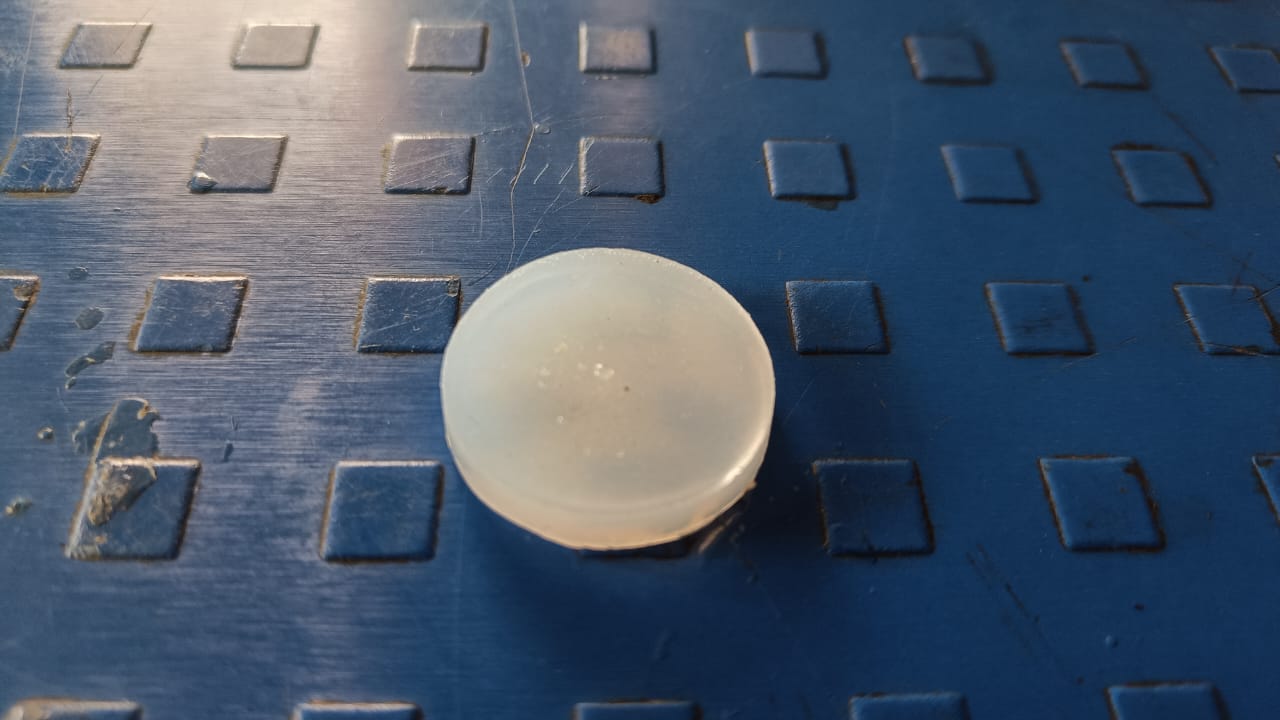

By maintaining all the safety instructions and by understanding the mixing concentration of each material we pour it to the bottle caps of different shapes and calculated the curing time of each material.

We got final ouput of testing mold without any bubble formation issues and noted down curing time of material at different temperatures.

After mixing we did inserted it into caps of unused bottle with different sizes.

Results after Curing.

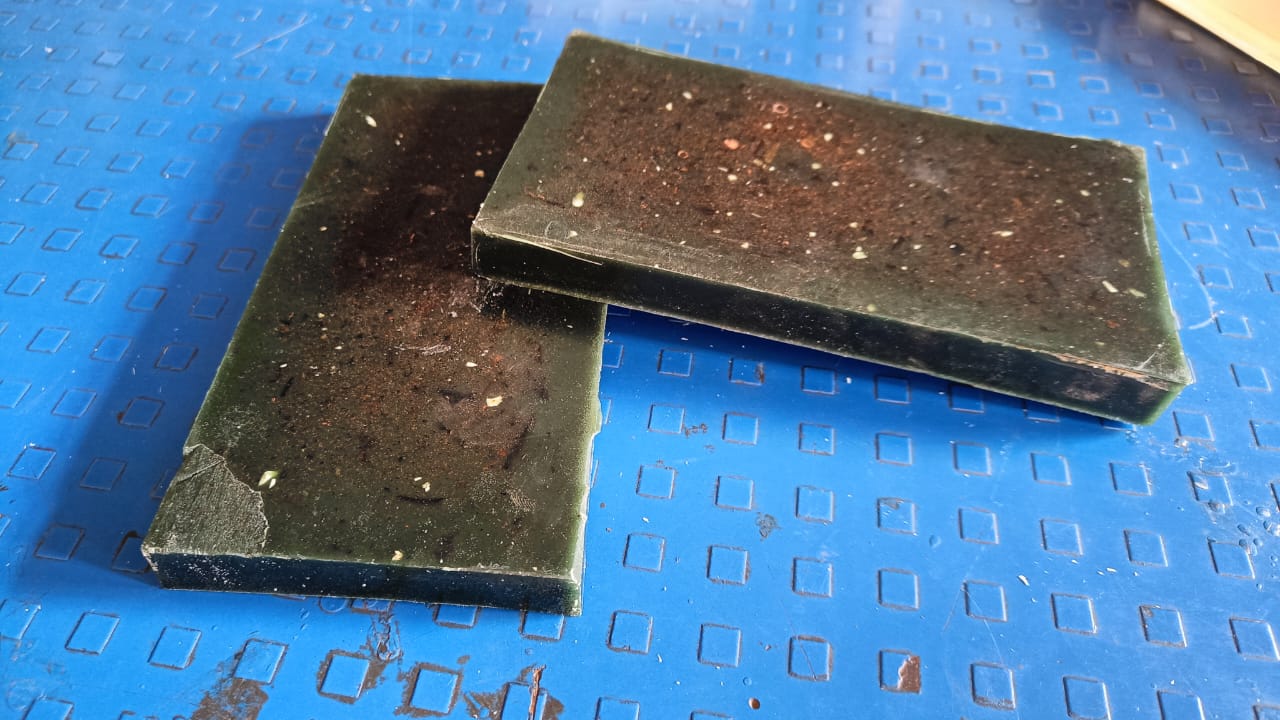

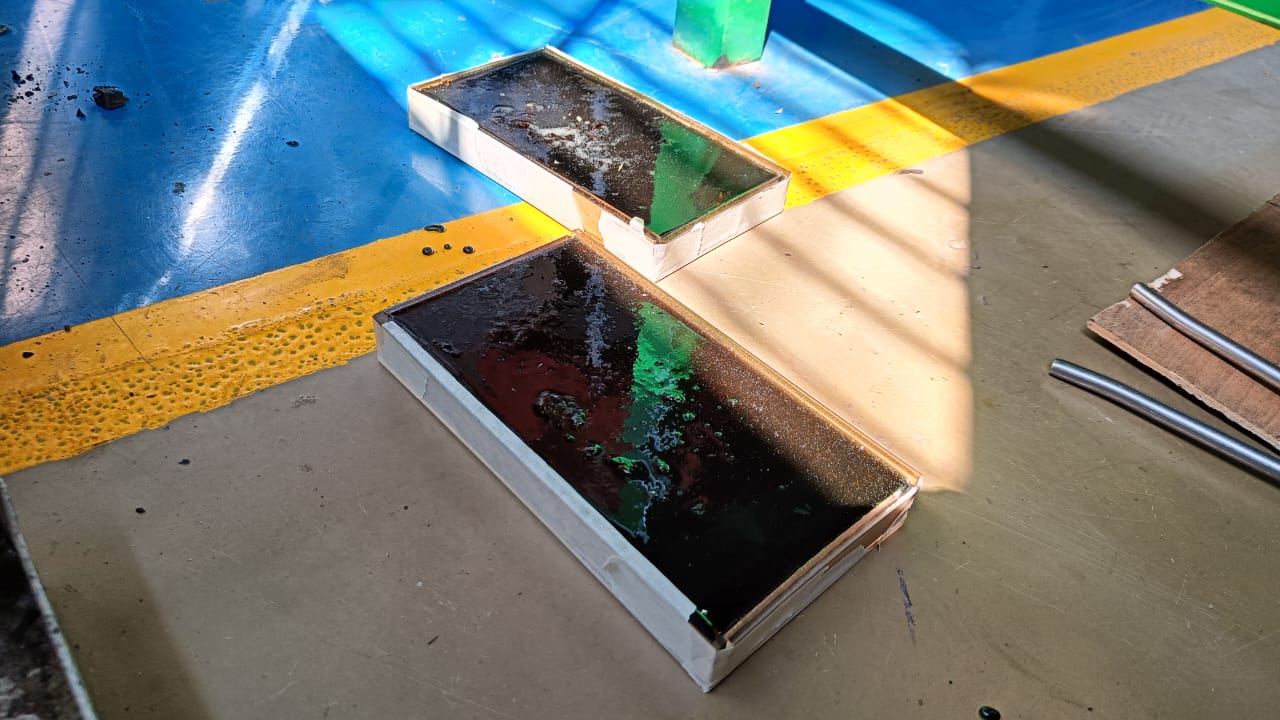

3) Recycle and reuse Machinable Epoxy resin.

We had lots of blocks of used machinable epoxy resin at our lab, so decided to reuse those.

Initially we broken those used block into small parts.

Meanwhile fabricated molds of rectangular shape using laser cutting as per our requirement.

Melted those small parts of epoxy at 250 degree and poured it into the molds.

After colling it removed those blocks from the mold.

And these are the final results. We used these block for making positive mold in our SRM 20 milling machine.