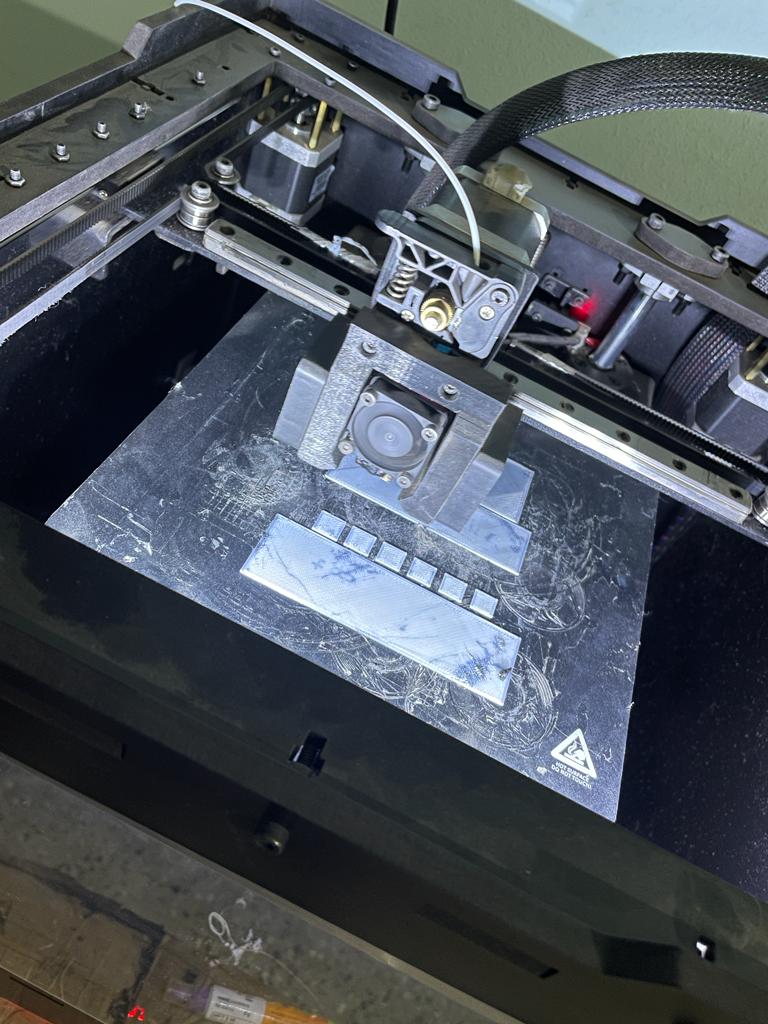

3D Scanning & Printing

Group Assignment

Design Considerations for 3D Printing: -

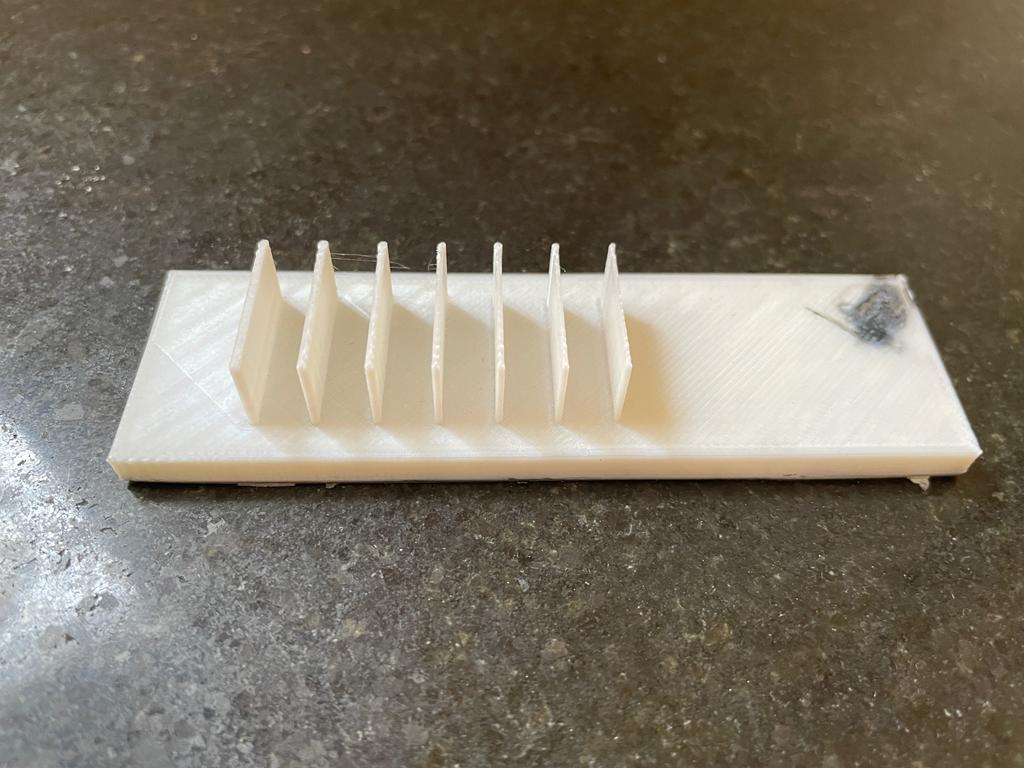

Overhang: -

Objects having overhangs needs to be supported. Without support, the structure might fail. The efficiency to print overhangs depends on the printer and its specification.

The 3D Printer in our lab can print objects with a 60-degree overhang angle. Angle more than this needs to be supported.

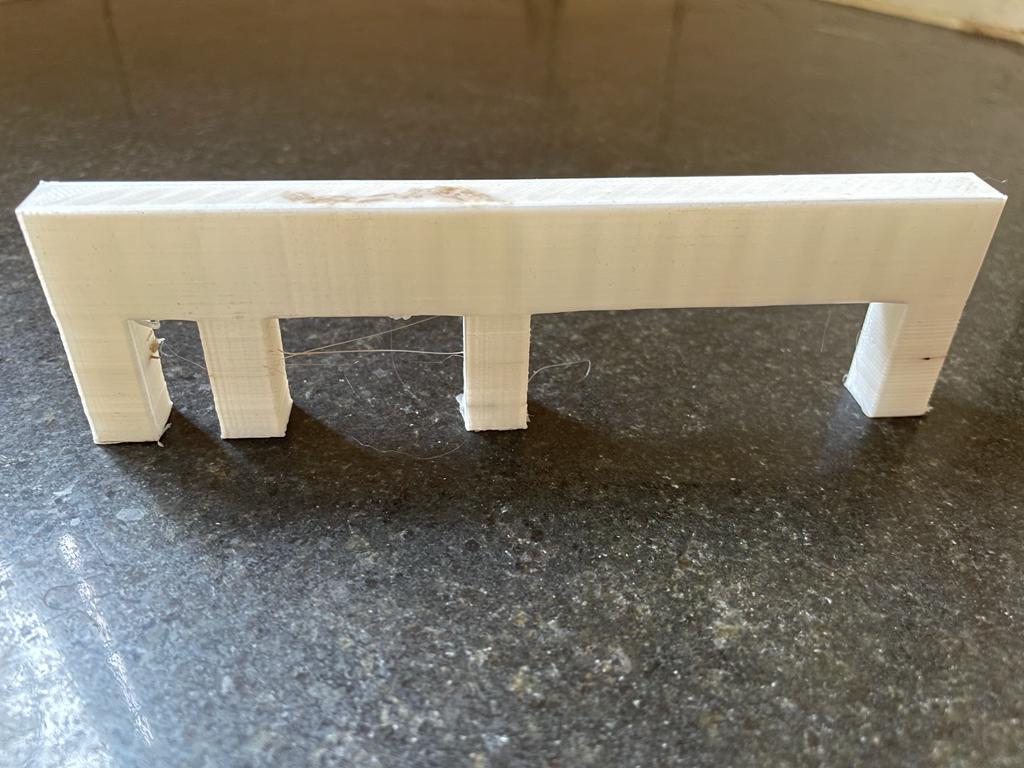

Bridging: -

Some objects have horizontal overhang across two points, if the distance between two points is less than we need not use a support structure; again, efficiency depends on a 3D printer.

The 3D Printer in our lab successfully prints overhangs with less than 30 mm bringing distance, for more distance we might have to use a support structure.

Tolerance: -

FDM prints have a rough surface finish so while creating interlock parts tolerance must be considered.

Different parameters of a 3D Printer can vary the tolerance value of a 3D printer. Objects with a tolerance value of 0.3mm give us a tight tolerance value.

Orientation: -

Support structures are very difficult to remove but by changing the orientation of objects we can minimize support structures.

Wall thickness: -

Generally, this value depends on the size of the nozzle and the value of wall thickness. We used a 0.4 mm nozzle hence wall thickness with a value less than 0.4 mm is not printed.

Surface steps: -

This value depends on the value of resolution or layer height and accuracy of the 3D Printer, for this we have used 0.2mm layer height.