GROUP

ASSIGNMENT ONE

Computer Controlled Cutting

About LASER Cutting

This week have to do leran about controlled cutting machine and for this we have a group assignment to check our laser speed and powercombination for better cuttting result with minimum Kerf.

Before doing something we take a breif introduction of laser machine. what is laser cutting mahine ? Laser cutting machine are used to cut and engrave material.

There are different types of lasers cutting machine and we have CO2 laser cutting machine in our lab.

The co2 laser consist a glass tube and it’s both ends are connected to supply.Its one end is connected to cathode and another is connected to anode.

When we supply the power, atoms get energy and the electron excited and move from ground state to high energy state. After some microsecond they again come back

to their ground state by releasing photon of lights and this is called spontaneous emission.

When this released photon are go in contact with another excited atom and then two photons are released at a time and this is called stimulated emission.

Hence the light amplification means increasing in intensity of light is caused by stimulated emission of radiation.

Additional accessories Of laser

1. Chiller - it is used for the cooling process. Our laser are set work when the chiller temp is between 22 to 27C.

The cooled water circulated in tube. Laser dont run without chiller.

2.it is used to reduce smoke, dust and residue on lens. it also help the smoke to exhaust easily.

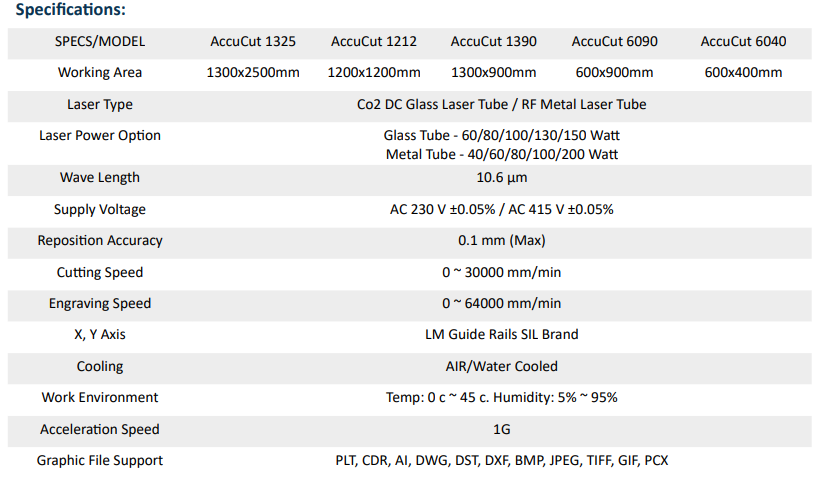

Machine Details

-

We have a Indian Manufactured laser machine. This laser perform cutting and engraving operation. machine have 3 mirror arrangement

by which the laser reflects.All these mirror are set with angle of 45degree because at 45 degree the light reflects at 90 degree by which we turn the the

direction of laser by 90 degree.All these laser are not concentrated so we use focus lens in nozzle to focus the all laser at a point.

Then we have to set our focal length means the distance between nozzle tip and workpiece.

This laser is make perfect focus when the distance between nozzle tip and workpiece is between 6mm to 7.25 mm.

After the setting of Focus lets see some technical details of laser . Starting Step-

Step 1. switch on the laser and chiller and compresor

Step 2.check the temp and water level in chiller

step 3.on the exhaust,laser switch etc

step 4.Download the file in machine

step 5.set focus of laser with material

step 6.shut the door clos of laser

step 6.set origin and check frame

step 7.start cutting

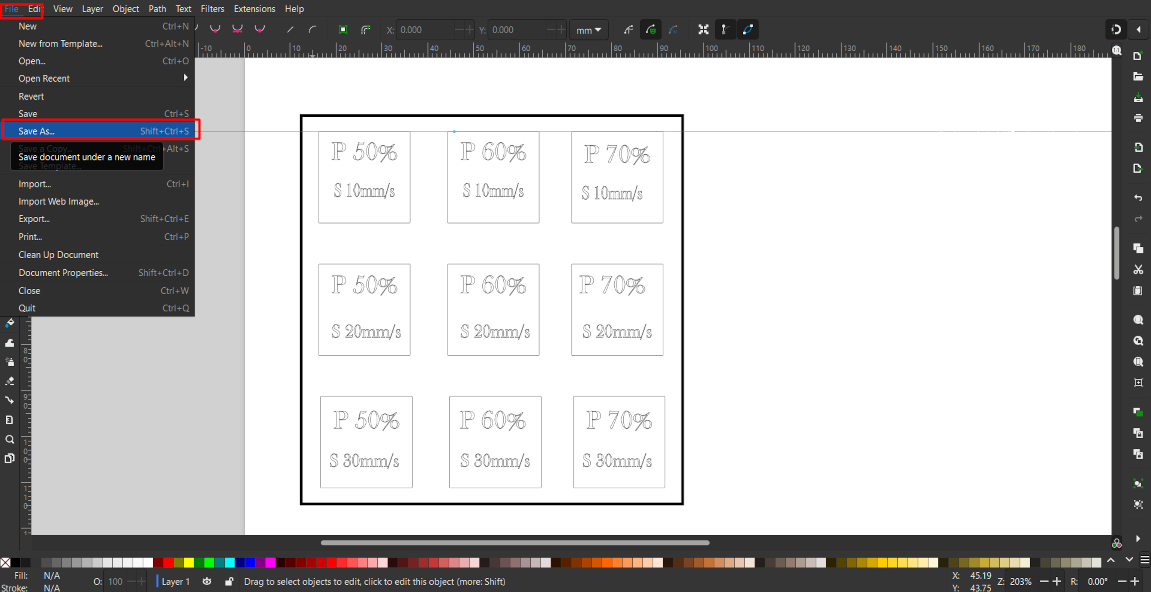

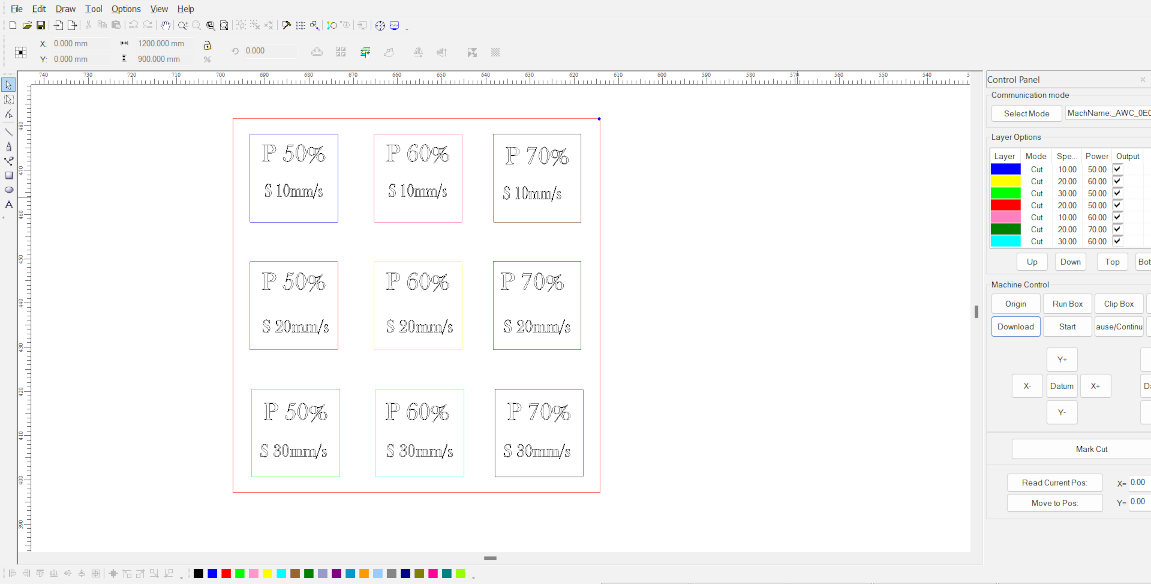

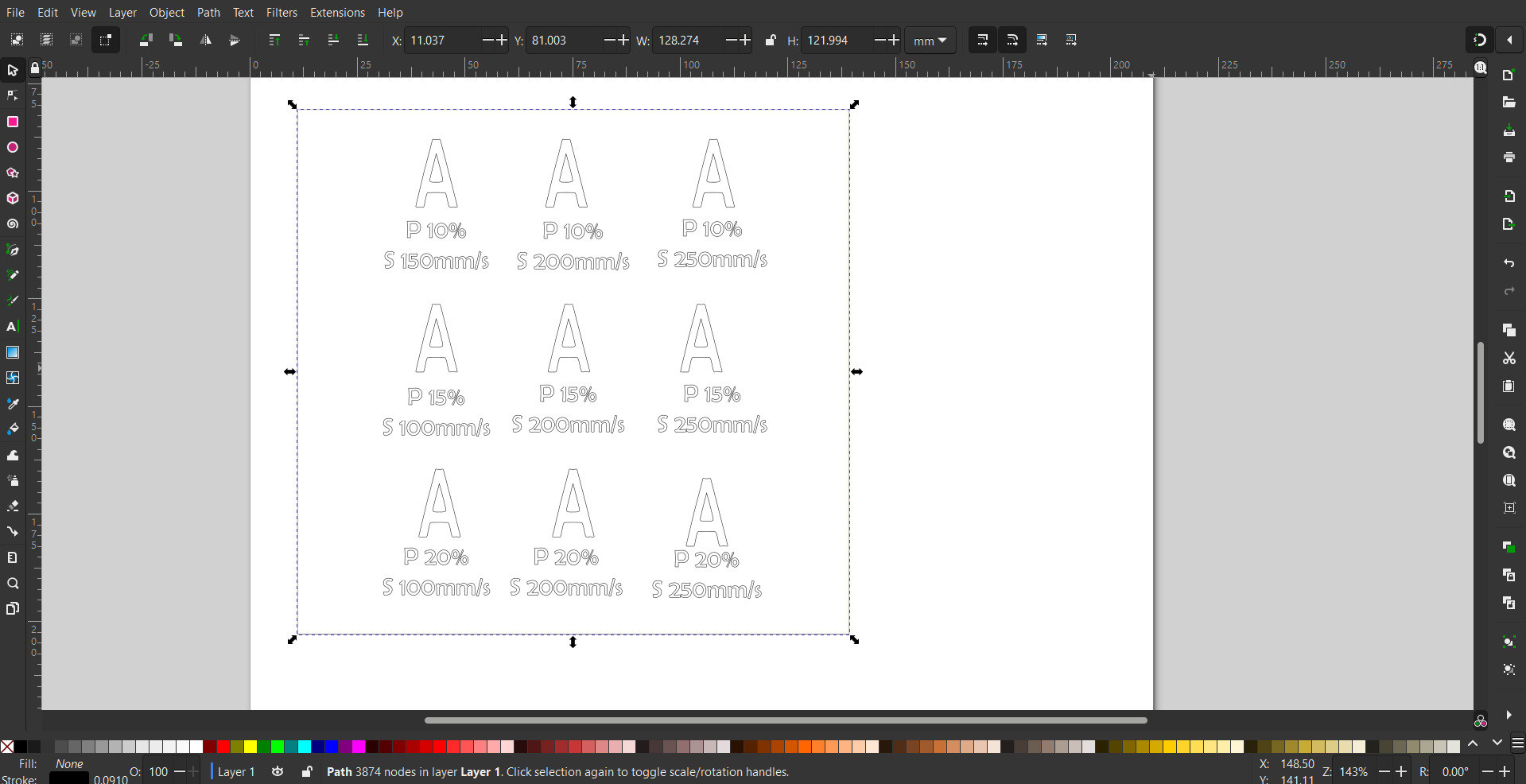

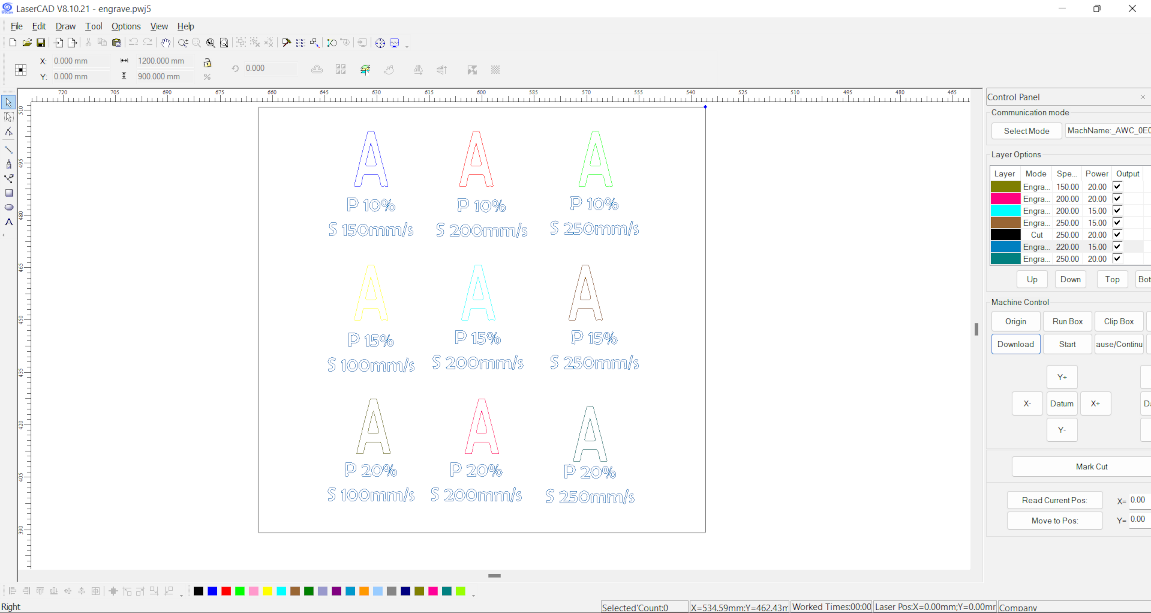

We create a design in Inkscape which cut at different speed and power. Then we save the file in dxf format. We used laser cad software for communication

between computer and machine. after open this software we import our file and choose different color for each box. Then we set different speed and power on different colors.

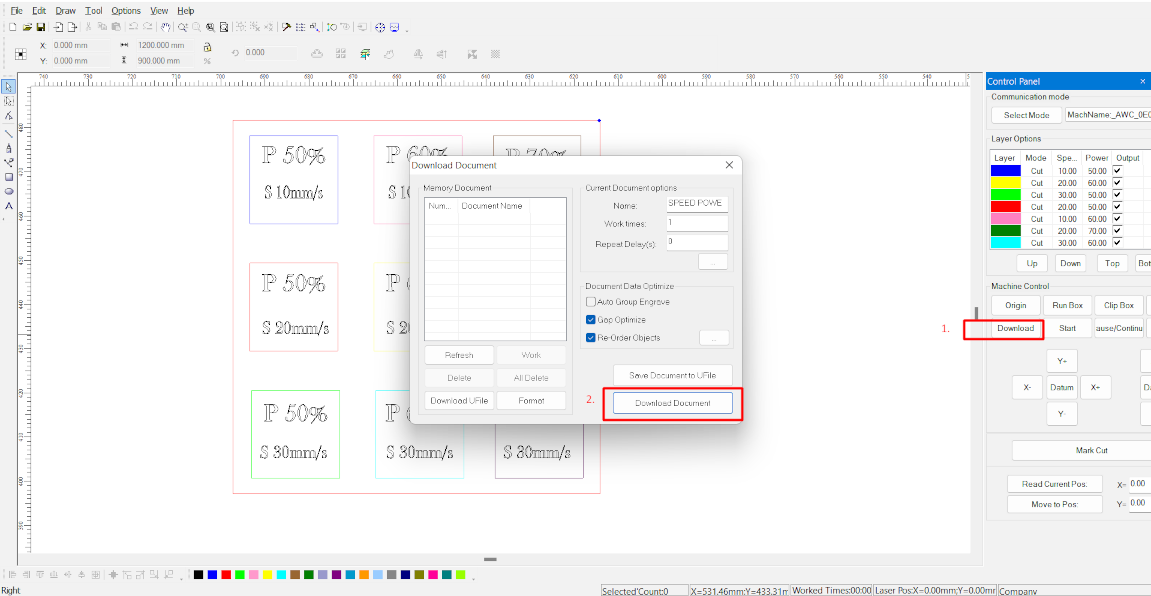

Then we connect USB pin and download the ready file in machine.

Now we cut different material at different speed and power to indetify the best power and speed for that particular material.

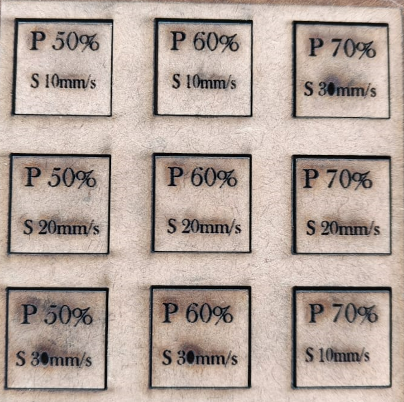

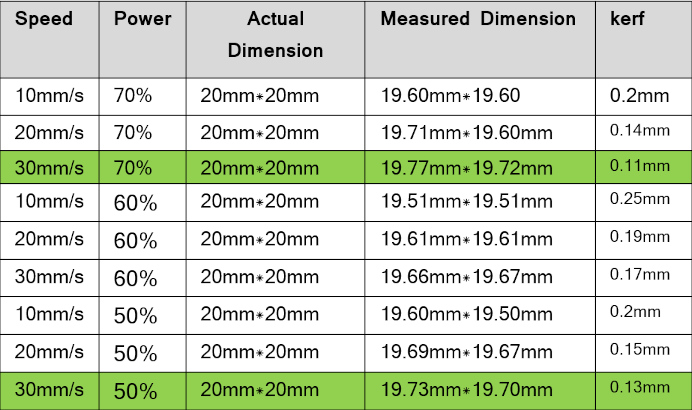

1.MDF 2mm

We used the MDF material of 2mm thickness and perform both operation of cutting and engraving and also calculated kerf for this

Kerf can be calculated by following formula = (actual size-measured size)/2

After find out the kerf we can make same dimension object we want by just including kerf value in it.

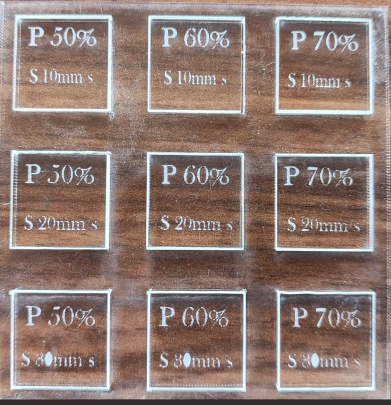

The result of cutting is given below

Result

– this material cuts easily at the power between 50-70% and speed between 20-30mm/s. between this speed and value the kerf value lies between 0.11 to 0.15mm,which is good for this Material.

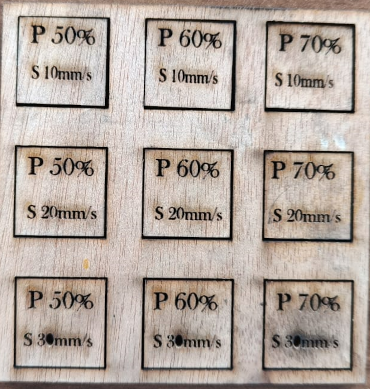

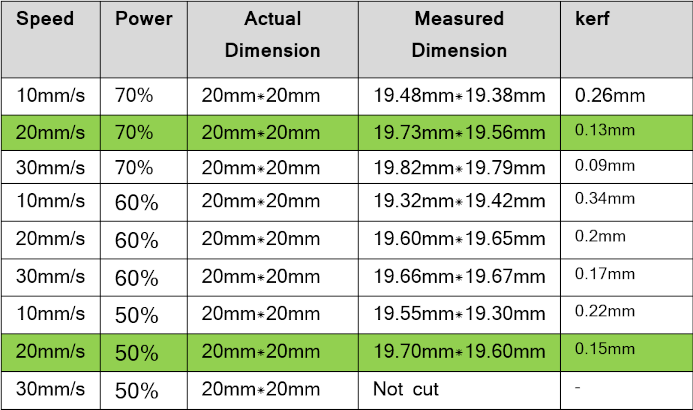

2. Plywood 6mm

After the cutting of mdf we start cutting of 6mm plywood.we use same parameter and design to cut this material.

The results are given below –

Result

- this material cuts easily at the power between 50-70% and speed between 20-30mm/s. between this speed and value the kerf value lies between 0.09 to 0.15mm,which is good for this Material.

3.Acrylic 4mm

After cutting of MDF and plywood we cut the acrylic sheet. For this we also used same design and start cutting.

Result

- this material cuts easily at the power 50 and speed at 20mm/s. at this speed and power the kerf value 0.13. after cutting we check the power and speed for the engravining of the above material

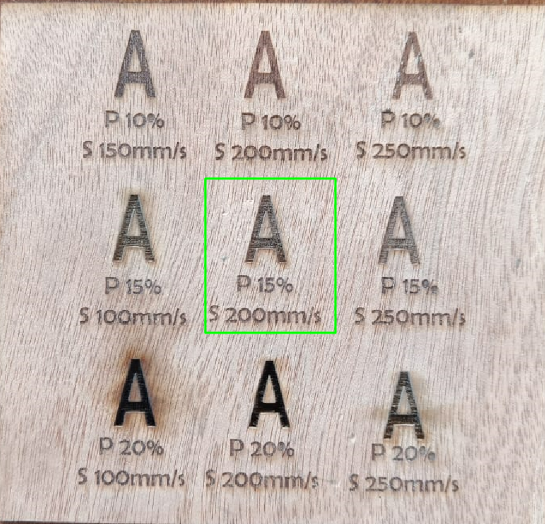

we againn design another file and save that file in dxf format then we import this file in lasercad software and set deiiferent color to different boxes.

particular color have different power and speed

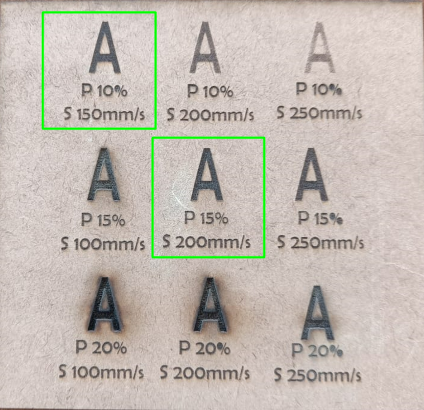

and then we get result for different material for engraving.

1.MDF 2mm

Result

-The best engraving effect are seen at Speed between 150mm/s-200mm/s and power between 10%-15%2.Plywood 6mm

Result

-for engrave the plywood we set the power between 10-15% and speed between 150-200mm/s3.Acrylic 4mm