Group Assignment 1

This week’s assignment is to characterize our lasercutter.

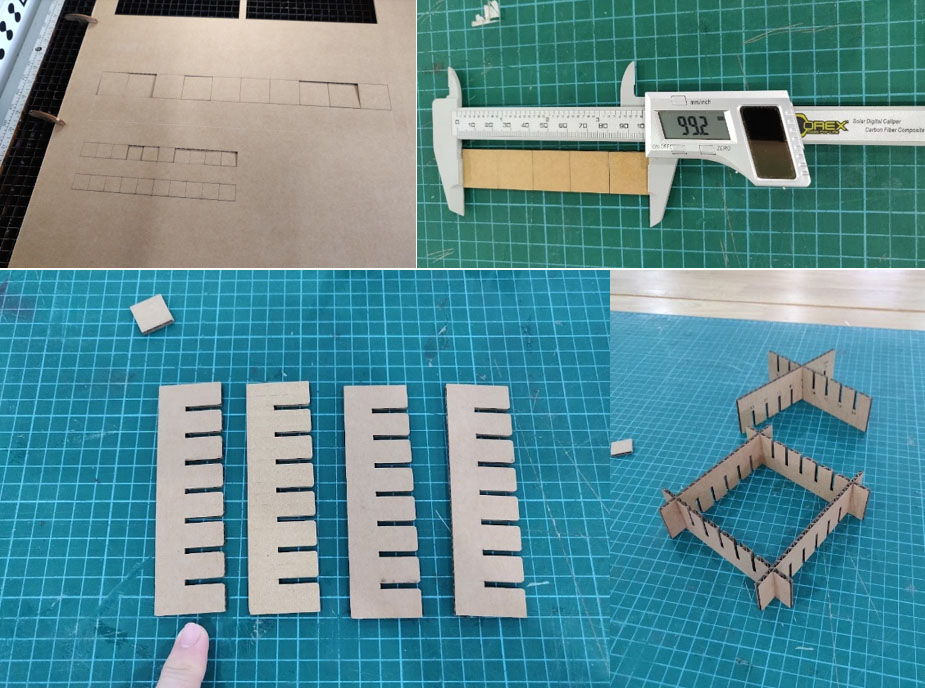

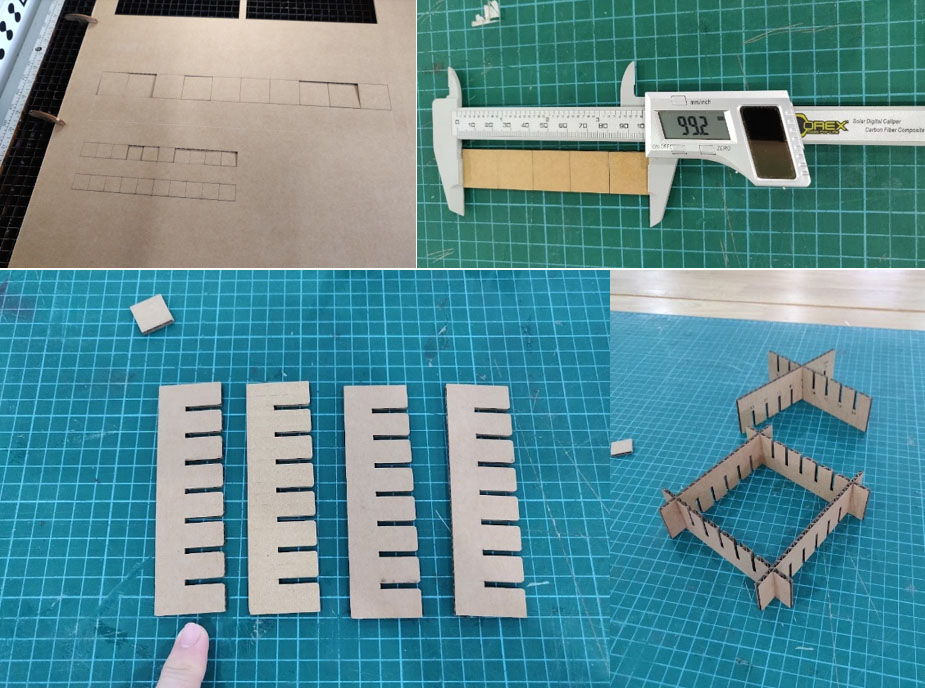

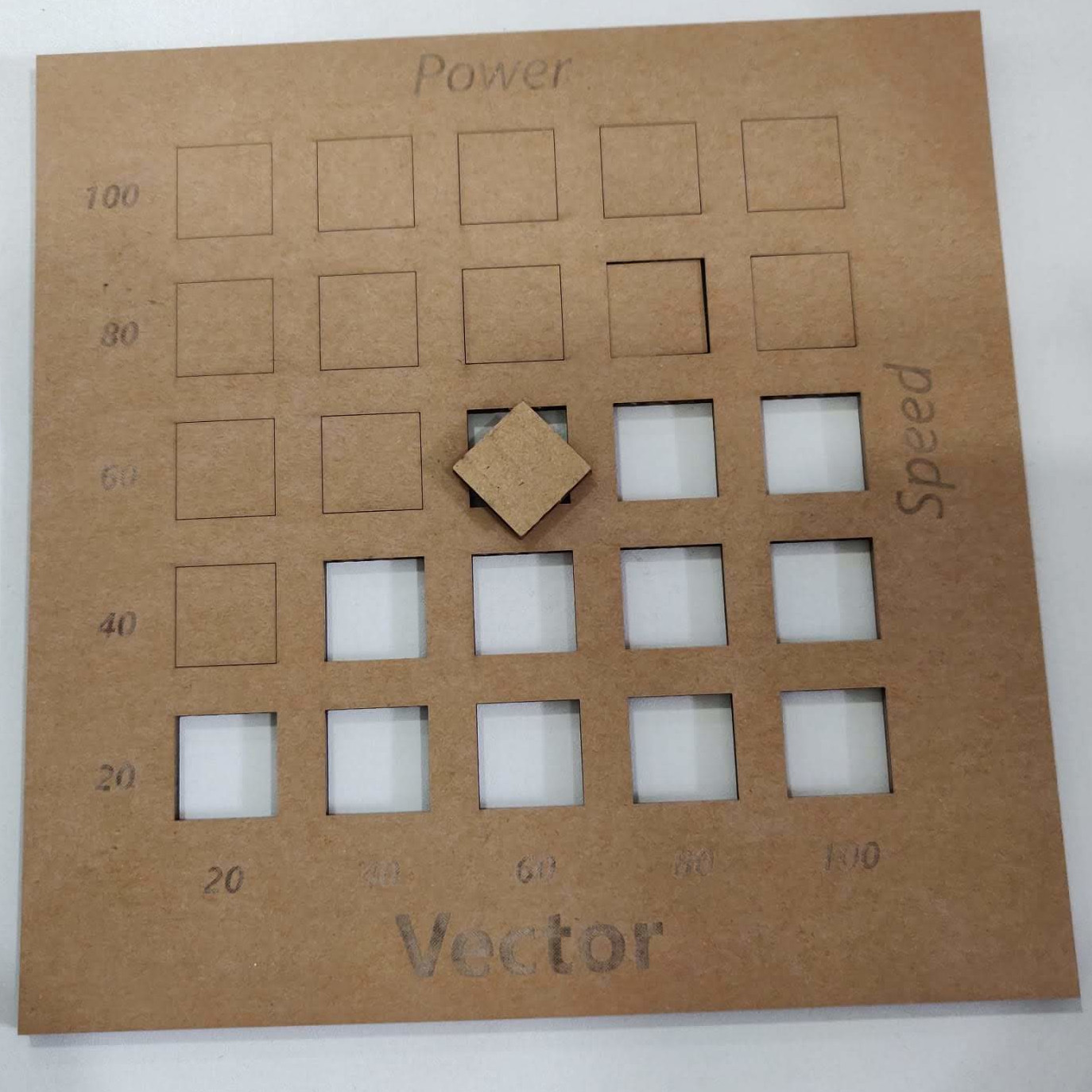

The model of our laser cutter is the Epilog Fusion Pro, with a maximum cutting size of 1219mm x 914mm (48" x 36"). For Epilog pro, it comes with an in-build camera for alignment of material so we don't have to manually gauge the material boundaries before cutting. So we then characterize the speed/power setting for vectoring and rastering.

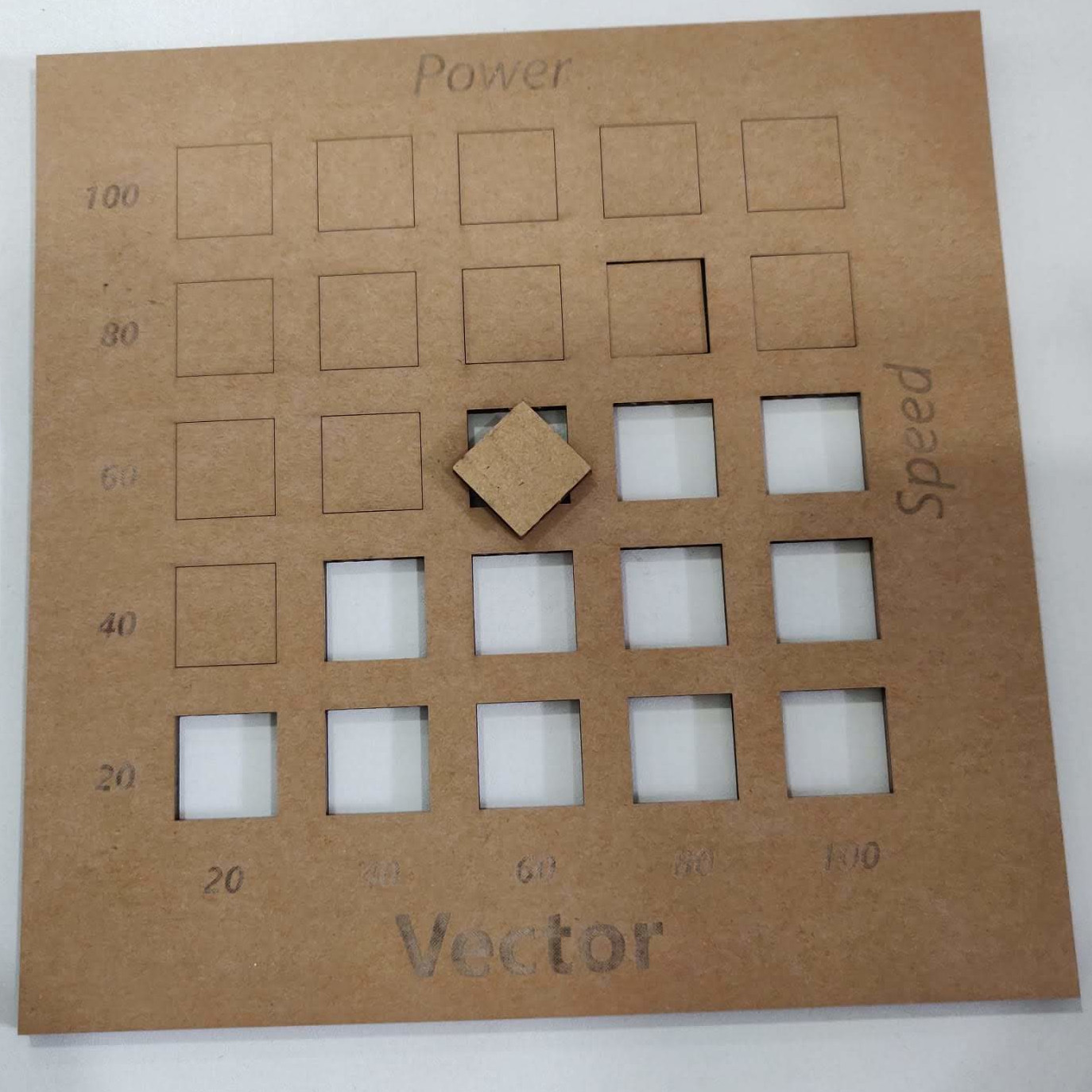

Using the templates that we created, we determined the optimal settings for vectoring for cardboard is 40% speed, 40% power and 15% frequency.

The model of our laser cutter is the Epilog Fusion Pro, with a maximum cutting size of 1219mm x 914mm (48" x 36"). For Epilog pro, it comes with an in-build camera for alignment of material so we don't have to manually gauge the material boundaries before cutting. So we then characterize the speed/power setting for vectoring and rastering.

Using the templates that we created, we determined the optimal settings for vectoring for cardboard is 40% speed, 40% power and 15% frequency.

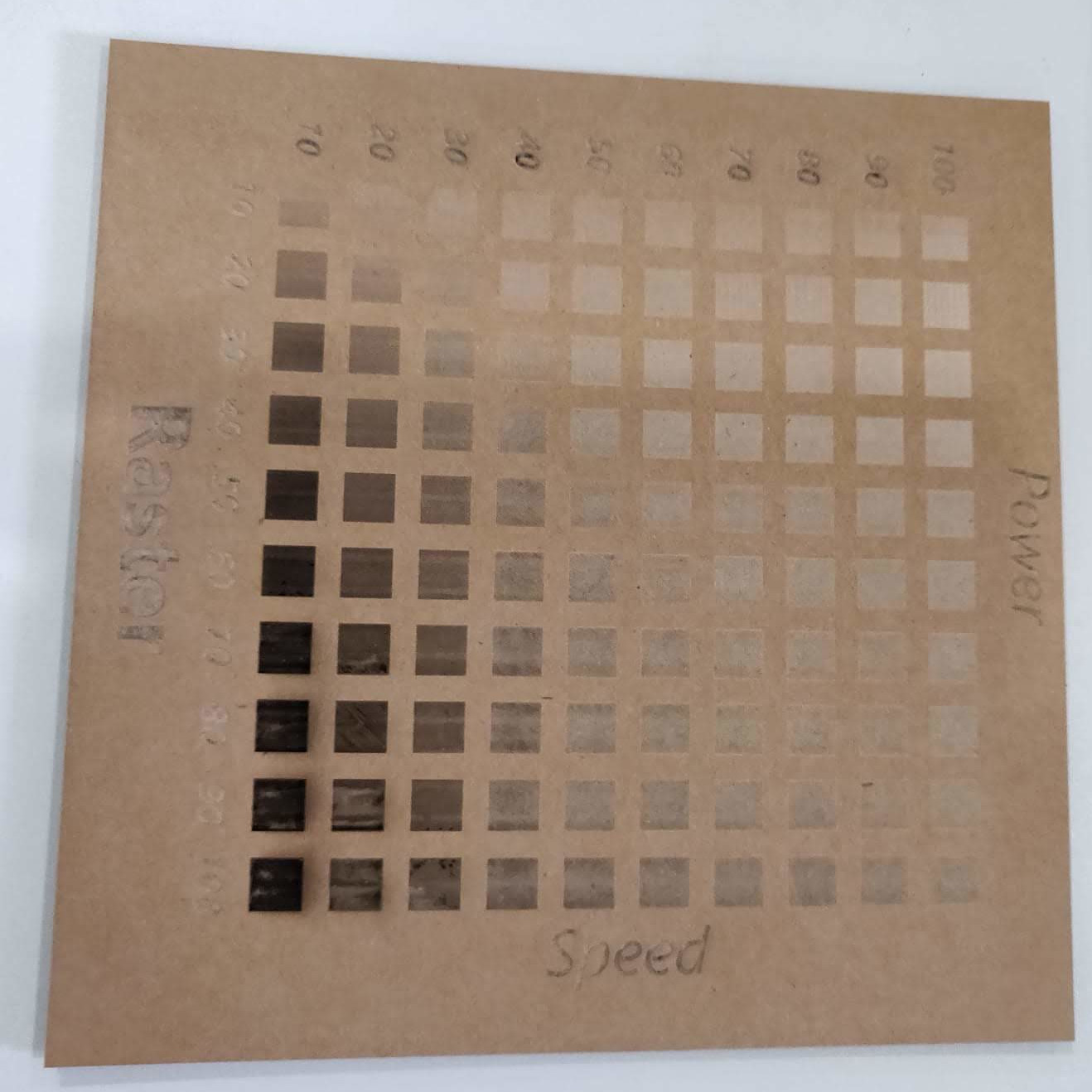

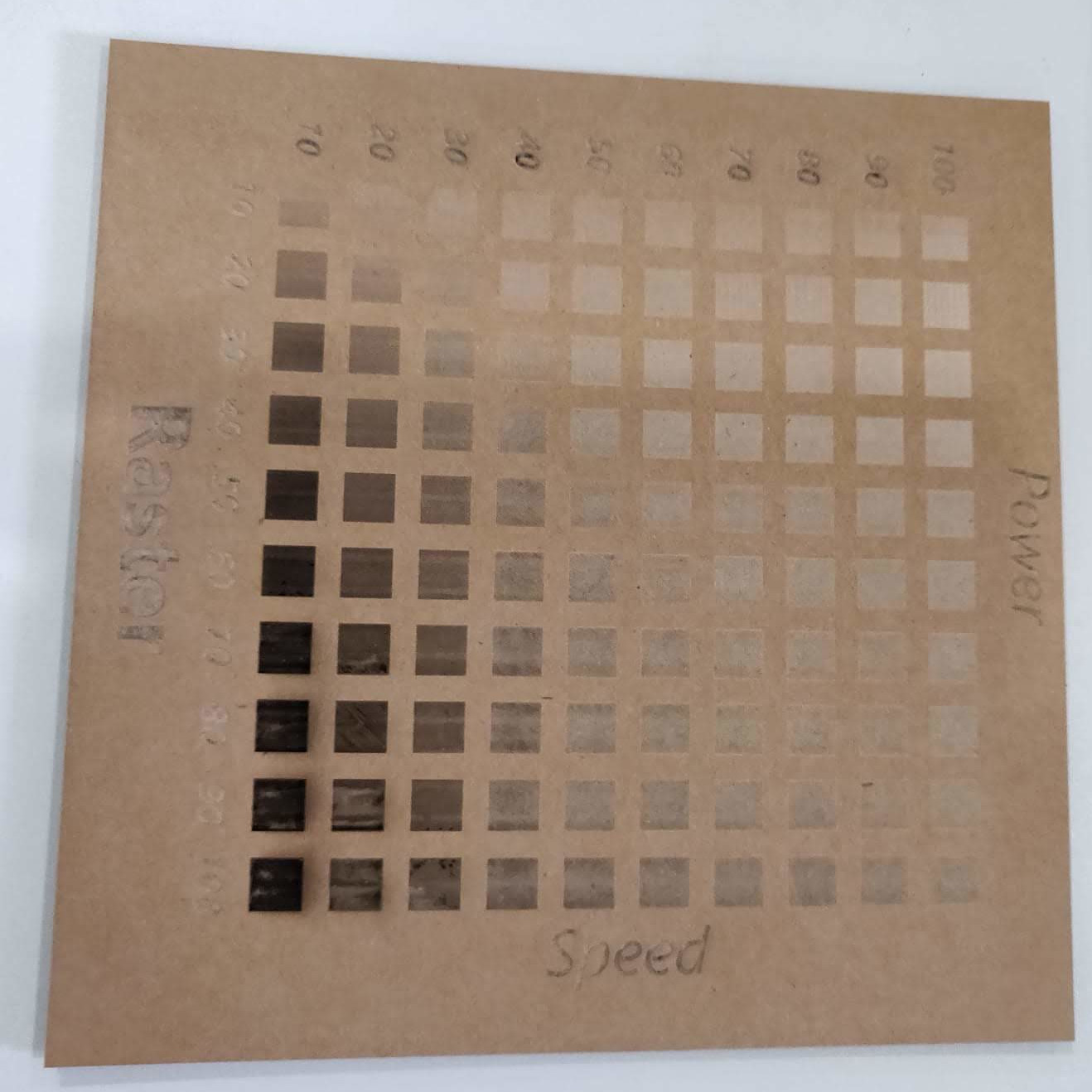

For the rastering, we used a 10 x 10 template to map out the rastering effect on cardboard of the laser cutter. We can see from the template that having high speed and low power gives light rastering, while low speed and high power gives deeper rastering. Interestingly, it is also observed from the template that the rastering effect is diagonally similar (e.g. rastering at 10% speed & 10% power is similar to rastering at 20% speed & 20% power.)

For the rastering, we used a 10 x 10 template to map out the rastering effect on cardboard of the laser cutter. We can see from the template that having high speed and low power gives light rastering, while low speed and high power gives deeper rastering. Interestingly, it is also observed from the template that the rastering effect is diagonally similar (e.g. rastering at 10% speed & 10% power is similar to rastering at 20% speed & 20% power.)

We also determined the kerf and found it to be ~0.1mm.

We also determined the kerf and found it to be ~0.1mm.

The model of our laser cutter is the Epilog Fusion Pro, with a maximum cutting size of 1219mm x 914mm (48" x 36"). For Epilog pro, it comes with an in-build camera for alignment of material so we don't have to manually gauge the material boundaries before cutting. So we then characterize the speed/power setting for vectoring and rastering.

Using the templates that we created, we determined the optimal settings for vectoring for cardboard is 40% speed, 40% power and 15% frequency.

The model of our laser cutter is the Epilog Fusion Pro, with a maximum cutting size of 1219mm x 914mm (48" x 36"). For Epilog pro, it comes with an in-build camera for alignment of material so we don't have to manually gauge the material boundaries before cutting. So we then characterize the speed/power setting for vectoring and rastering.

Using the templates that we created, we determined the optimal settings for vectoring for cardboard is 40% speed, 40% power and 15% frequency. For the rastering, we used a 10 x 10 template to map out the rastering effect on cardboard of the laser cutter. We can see from the template that having high speed and low power gives light rastering, while low speed and high power gives deeper rastering. Interestingly, it is also observed from the template that the rastering effect is diagonally similar (e.g. rastering at 10% speed & 10% power is similar to rastering at 20% speed & 20% power.)

For the rastering, we used a 10 x 10 template to map out the rastering effect on cardboard of the laser cutter. We can see from the template that having high speed and low power gives light rastering, while low speed and high power gives deeper rastering. Interestingly, it is also observed from the template that the rastering effect is diagonally similar (e.g. rastering at 10% speed & 10% power is similar to rastering at 20% speed & 20% power.) We also determined the kerf and found it to be ~0.1mm.

We also determined the kerf and found it to be ~0.1mm.