Wildcard Week

Assignment

Individual assignment

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce

Table of Content

- coffee plastic/rubber

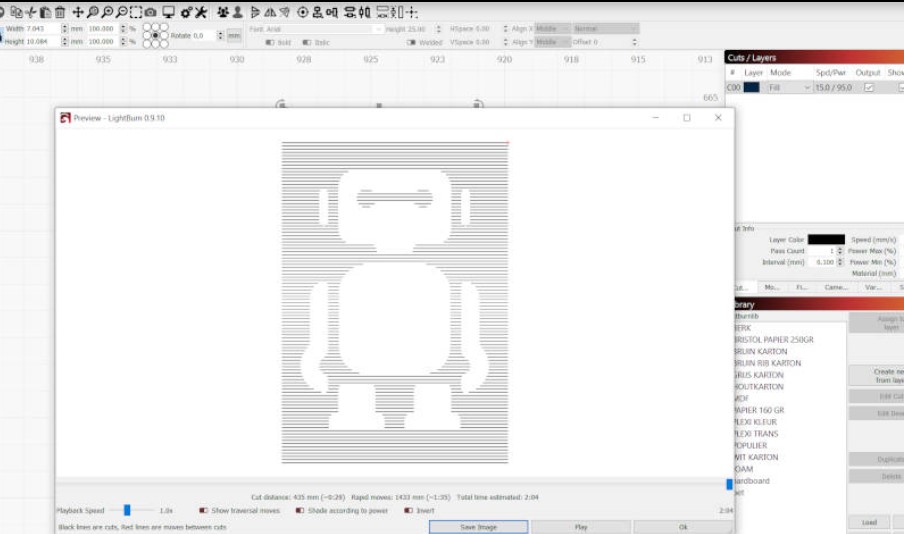

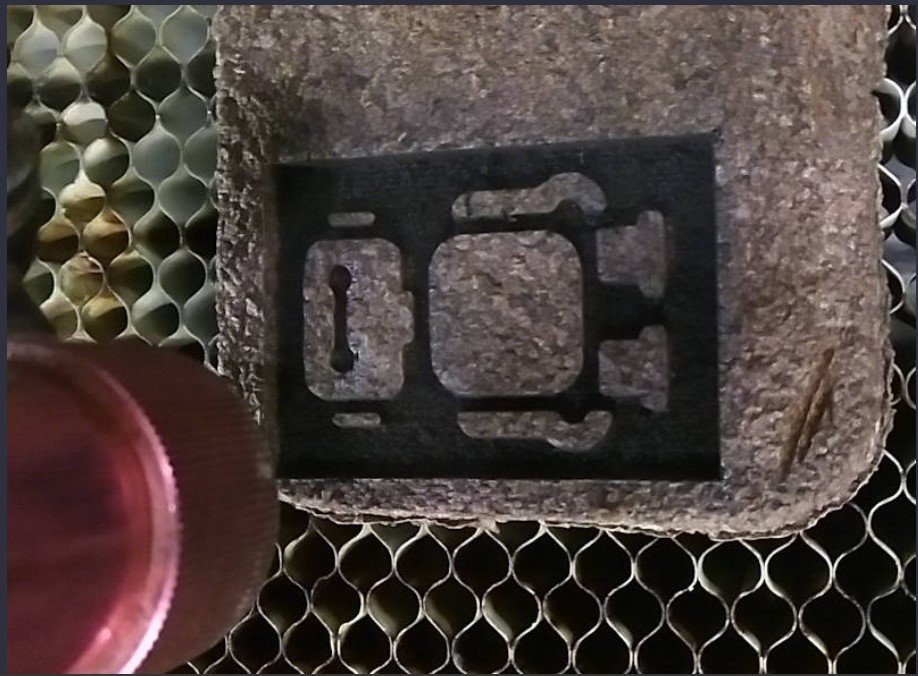

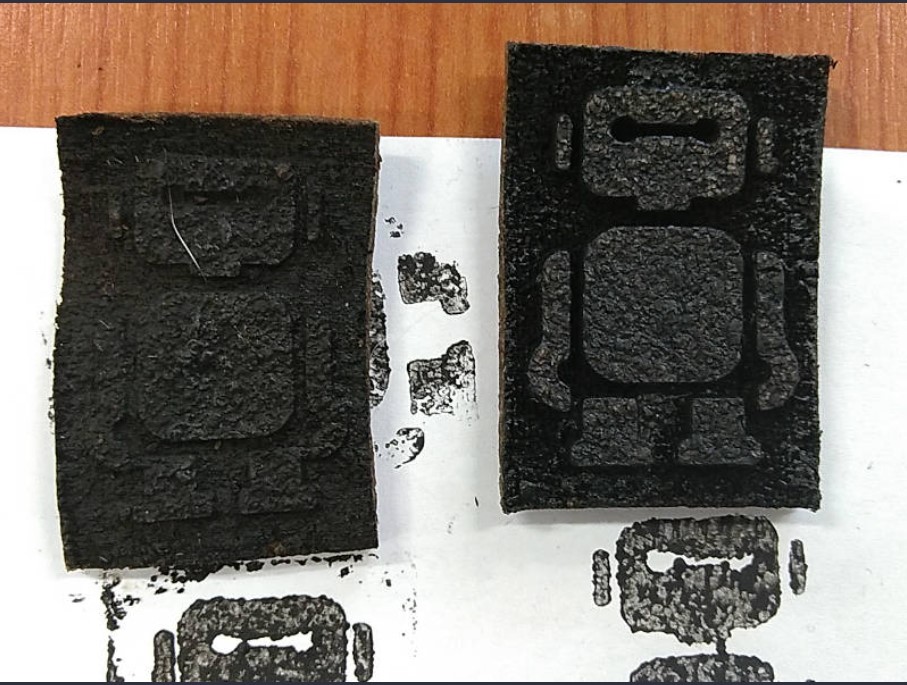

- laser cutting the coffee plastic

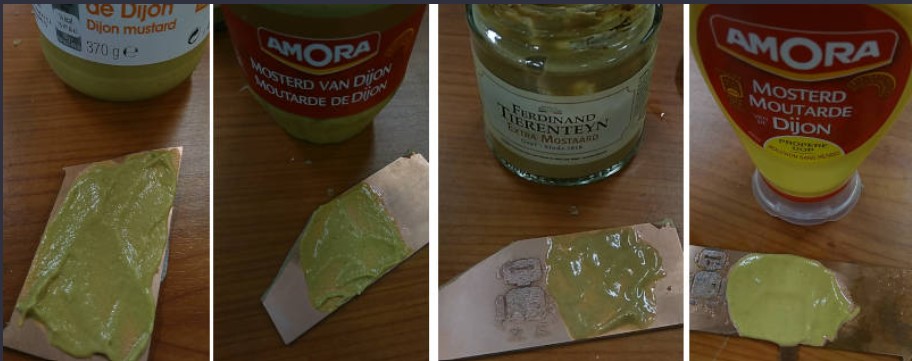

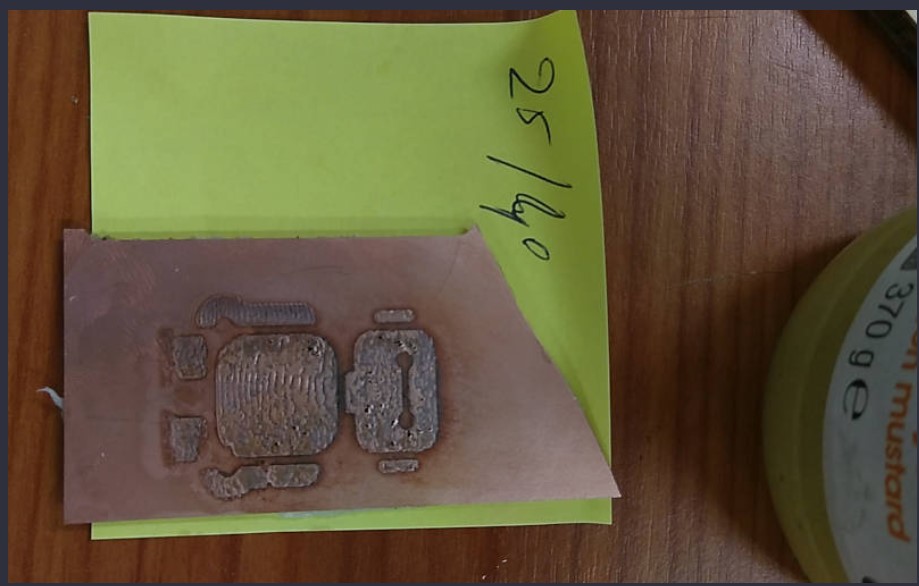

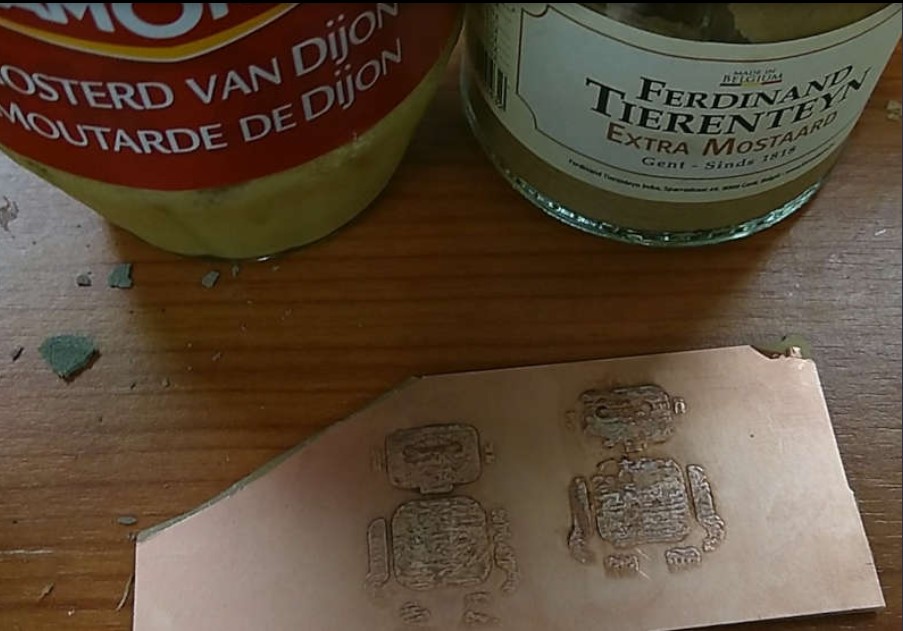

- tests engraving copper with mustard

coffee plastic/rubber

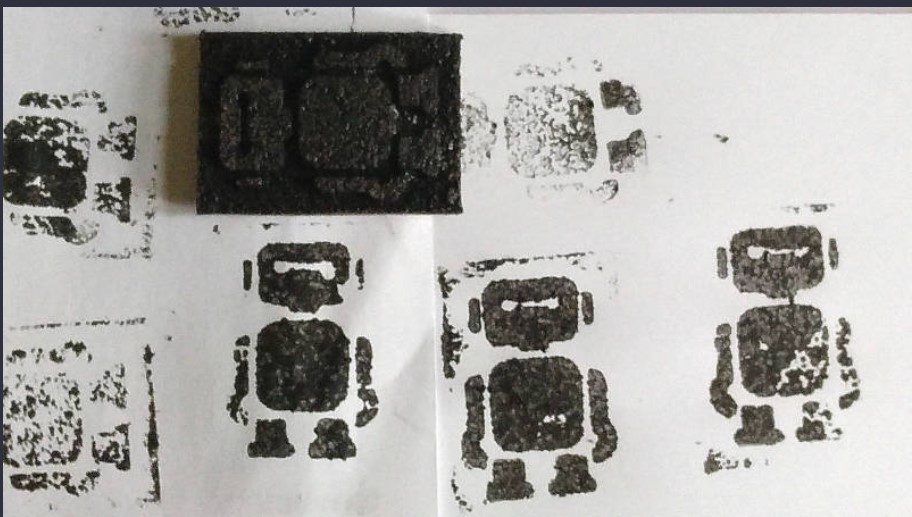

For the final project we also want to use stamps/lino cuts as medium to print. As we want to keep the project as eco friendly and DIY as possible In this week i play around a bit with making bio plastics from food waste. Since we both love coffee. What better to use than left over coffee ground to make plastic. We want a rubbery plastic we can cut graphics in the same as you do in stamps or linoleum. We also would love if we could put it in the laser to engrave it and make stamps that way.

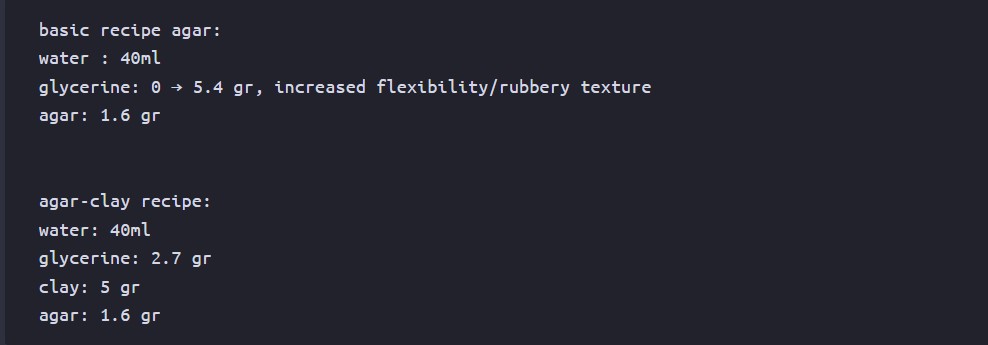

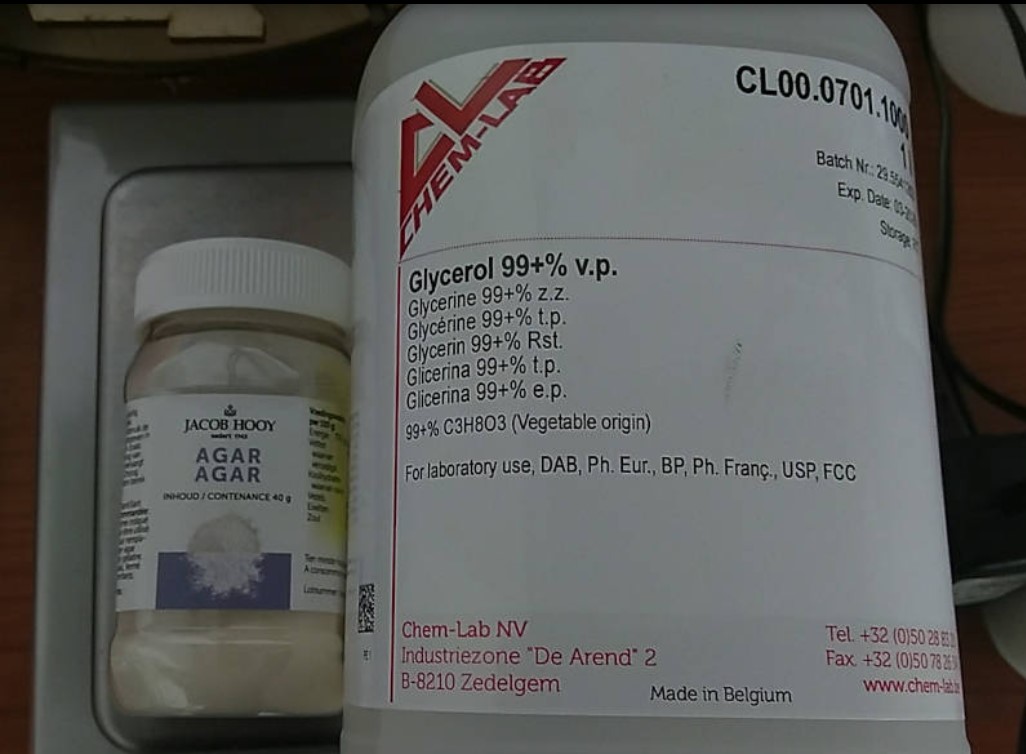

I did some searching the web and collected lots of info on the subjectcoffee plastic/rubber search dataOut of all this we distilled a general agar agar based vegan recipe

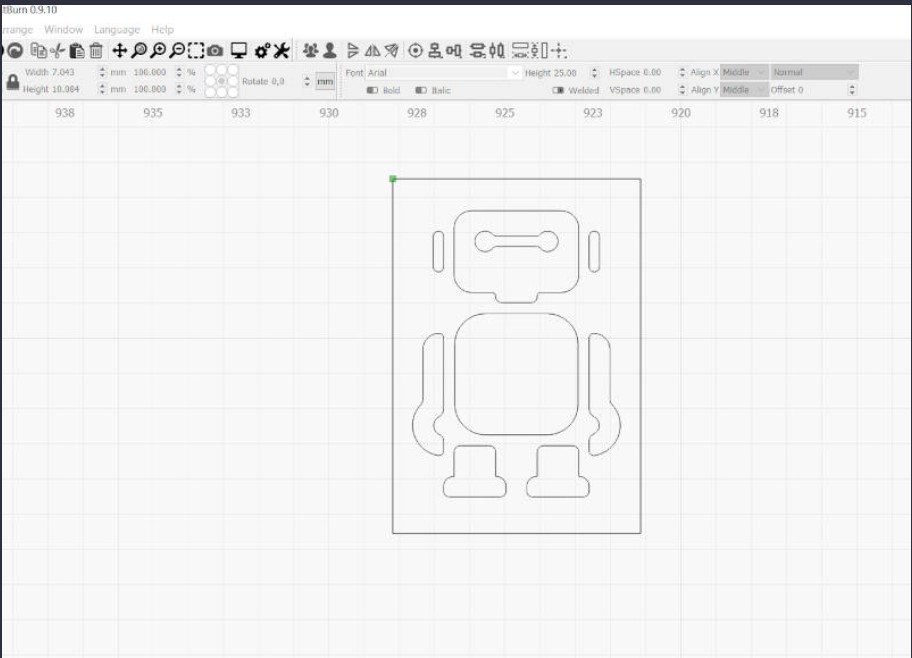

i designed the my log

Time to get alle ingredients and start cooking ,

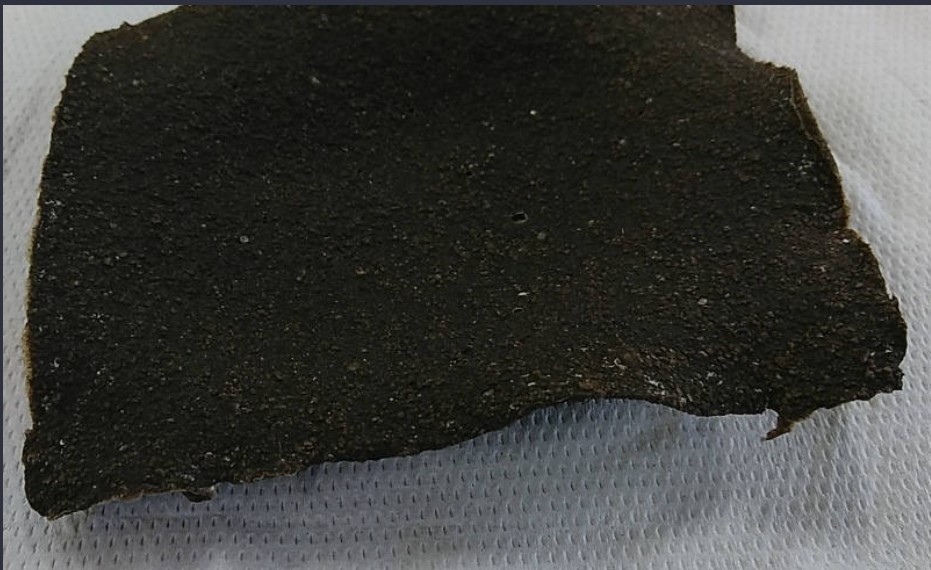

First thing to do is make sure the waste coffee is very well dried before using it. Also the first batch we tried the grounds were to course. We had to grind them much finer to almost dust.

The first test were with agar an glycerine only. Later Isabel tried also a recepi with clay, that looked a bit smoother and less fragile.

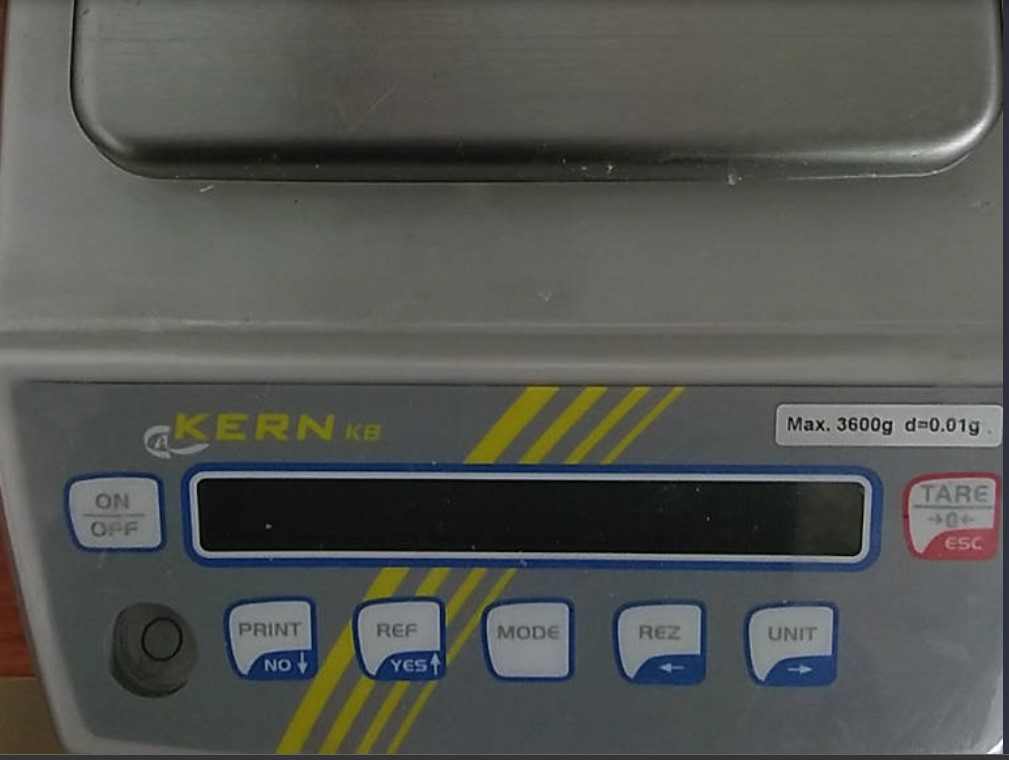

You need a scale to measure the right amount of everything

And a pot to mix and cook everything in. Everything we use is non toxic, but maybe it is best to use a pot you are not using to make food in.

These are the results, at various stages in the drying period. I did leave the first ones in the plastic for to long and got molds in them. The next we put on a grid to dry.

The dried plastic had shrunk a bit and curled so it was difficult to make it flat enough

div class="container">