Applications and Implications

Assignment (MY PROJECT PROPOSAL)

- Here we have to propose final project which includs the following knowledge

- 2D and 3D design

- Additive and subtractive fabrication processes

- Electronics design and production

- Embedded microcontroller interfacing and programming

- System integration and packaging

Table of Content

- what does it do?

- Who has done what beforehand?

- What will you design?

- What materials and components will be used?

- Where will they come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

what does it do

The remote-controlled cold room I'm working on will provide a controlled environment for keeping perishable food items, like fruits and vegetables, at a temperature between 25 and 5 degrees Celsius. At temperatures ranging from 5 to –20 degrees Celsius, it also offers storage for meats and vaccines. By allowing for exact temperature control, this system creates the ideal environment for maintaining the quality and security of the stored goods.

Who has done what beforehand

many researchers and manufacteres have done the same concept of using the peltier to provide the coldness in specif room regarding to the degree of coldness required. through that allow me to presante this coleague called "Silvio Pietro Monticelli"who done "Gene Freezz which is the prototype of a portable cooler, with an embedded freezer, to support DANA barcoding activities in the field." here you can find more detail on the project even if he did'nt controlled the cold room remotely.click here:References

-

What will you design

the design of my project will concerns with mechanical structure design and eletronic circuit design and cooling system design

The materials and components used are listed below including loacation & price and

MATERIALS USED No ITEM NAMES SPECIFICATIONS QUANTITY UNIT PRICE(Rwf) TOTAL PRICE(Rwf) location source of material 1. Microcontroller ESP-wrom-32 1 15000 15000 2. DHT11 SENSOR 15.5mm x 12mm x 5.5mm. 1 8000 8000 3. FOUR CHANEL RELAY DC 5V 4 4500 18000 4. OLED 96' 1 3500 3500 5. FANS 12V 8 5000 40000 6. POWER Supply 12V ,30A 1 25000 25000 7. Voltage Regulator 5V AMS1117 1 500 500 8. HEAT SINK 20×4 8 5000 40000 9. Copper PCB single side 7x10cm 1 2000 2000 10. Jumper Wires and others Male,Female 1 6000 6000 11. Acrylic 40x40x3 1 80000 80000 12. PELTIA COOLER 12V 5A 4 5000 20000 13. Thermal conductor oil Super conductor greese 1 cap 4000 4000 14. Capacitors Small 3 1000 3000 15. LED Small 3 1000 3000 16. Button_Switch Small 3 1000 3000 17. Buzzer 5V 1 500 500 18. Voltage Regulator IC 3V 1 500 500 19. polystelen insullator 30mm of thicknes 1 sheet 30000 30000 20. Aluminium sheet 0.25 of thicknes 1 sheet 6000 6000 TOTAL N/A 29 154,800 162,800 What parts and systems will be made and processes which will be used.

my system is contains two parts

MECHANICAL PART

,ELETRONIC PART

-

The process used for mechanical part

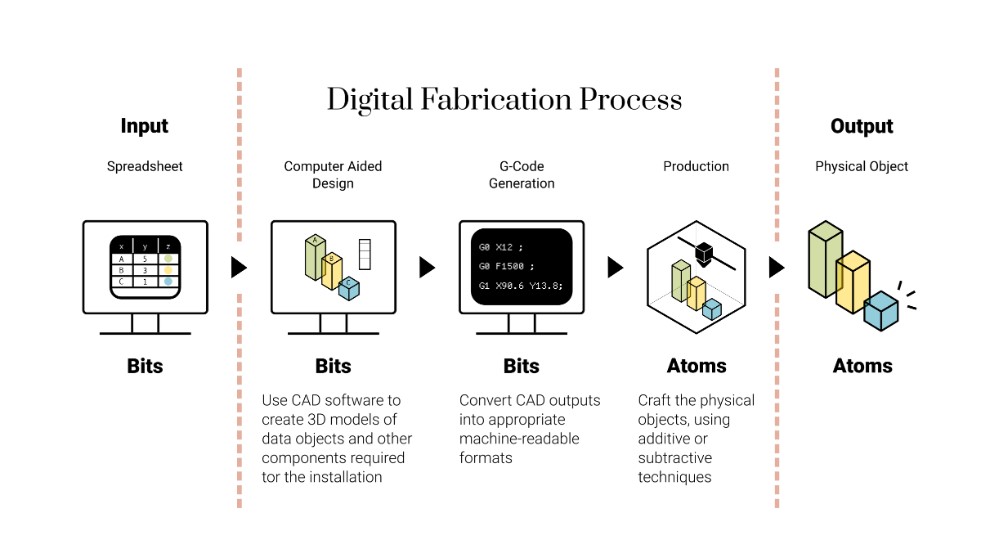

AS we are doing digital fabrication and how to make any thing almost , i started with cad which is computer ided design of my structure and then genarate g-code of my design in CAM process which is computer aide manufucturing .

Process used for eletronics

eletronic part of my project also concerns with CAD and CAM the same with mechanical but the soft ware used and machine used for manufacturing are difference.there for pcb design was designed in kicard and printed with roland machine.

-

What questions need to be answered?

the quastion to be answered are how can we controll the cold rooms remotetly to reduce the post haverst loss?

and What role does effective crop preservation play in reducing post-harvest losses and conserving perishable food in remote-controlled cool rooms?both quastion will be answered by this paragraph of

In order to reduce post-harvest losses and preserve perishable food in remotely controlled cool rooms, effective crop preservation is essential. It is simpler to guarantee ideal storage conditions for crops by putting advanced monitoring and control systems in place, like the culminating project in the Fab Academy program here in Rwanda. Real-time temperature and humidity monitoring made possible by this technology enables prompt adjustments to maintain perfect conditions. Perishable food's shelf life can be increased by lowering temperature variations and environmental control, which also lowers spoilage and post-harvest losses and ultimately promotes sustainability and food security. one of global challenge to be answered.

How will it be evaluated: here we there is a scope of my project which will guide in evaluation process.

my project will reflect on fab academy courses such us

- CAD: general and detailed design;

- Computer controlled cutting / machining: cover boxes

- 3D printing: cover locks and hinges

- Electronics production/design: PCBs

- Embedded programming: boards programming

- Input/output devices: temperature sensors, LCDs, Peltier devices, case fans

- Networking and communications: control board ↔ users ↔ cooler board;

- Interfaces and application programming: temperature application interface.

Regarding to the course and to pic covered in fab academy program my project scope are

- Modular design which will provide the storage area

- The system reacts to ambient ambient temperature variations, according to growth cycle (hot, warm, fresh, cold): absolute and differential temperature readings → moves away from locol to grobal whenever the internet is available .

- The system will indicate to ambient moisture (relative humidity) variations:

- The system records the time spent in the same pot. Sends alert after a set period;

- The system can perform ambient check over a period of time

- the system will have the capability of controlling the actuator remotly and monutering remotely.

honestly i will deliver the following thangible and intergible asset created and procured by me for the sucess of the project

- Modular wooden stand with height modules and cables rod

- Electronics

- Multiple set of sensors: moisture and temperature,

- Electronic board for comparing input signals (sensors) and reference data (database) and triggering actions: output signals to funs switches (peltier plate, and fun),

- Communication system

- WiFi and mobile network communication system

- Mobile App (Android);

- humidity control and condensed watter.

out of scope activities

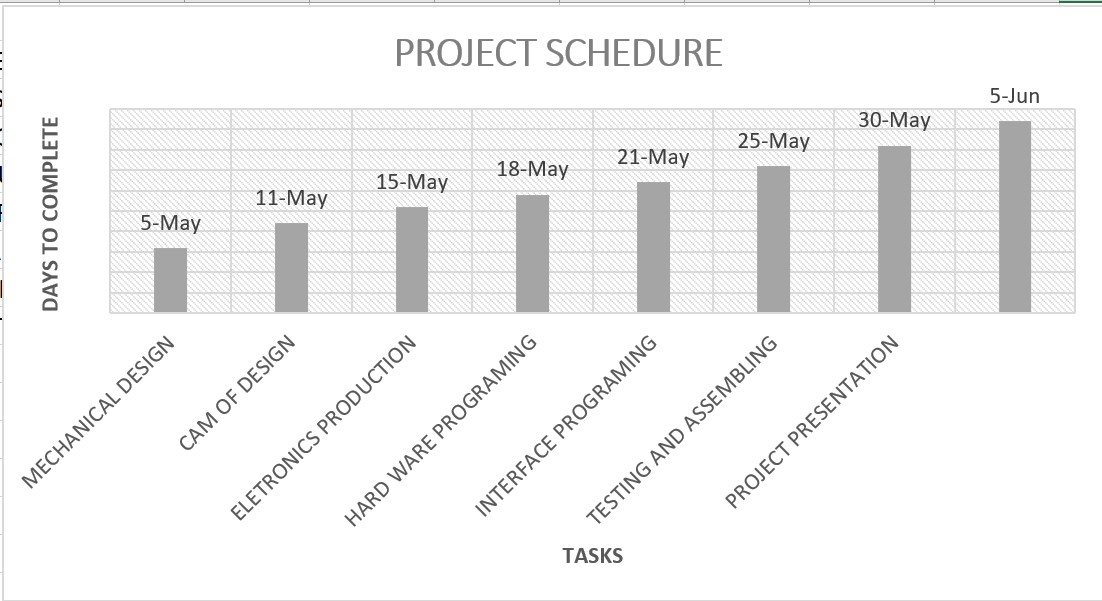

project plan and presantaion day.