moulding and casting

Assignment

Group-Assigniment

- Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

here there is more description on work on this group web page:Group work description is on here

Individual assignment

- Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

Individual assignment

Design a mold around the stock and tooling that you’ll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts.

Table of Content

- designed of mold in soldworks

- Mill 3d design on cnc machine

- cast a part with manufacture mould

DESIGN PROCEDURE OF MY DESIGN of my molding

design considelation of of mold

Molding: Molding is the process of manufacturing by shaping pliable raw material using a rigid frame or model called a pattern. A mold is a hollowed-out block that is filled with a liquid like plastic, glass, metal, or ceramic raw materials. The liquid hardens or sets inside the mold, adopting its shape. A mold is the counterpart to a cast. The manufacturer who makes the molds is called the mold maker. A release agent is typically used to make removal of the hardened/set substance from the mold easier. Typical uses for molded plastics include molded furniture, molded household goods, molded cases, and structural materials.

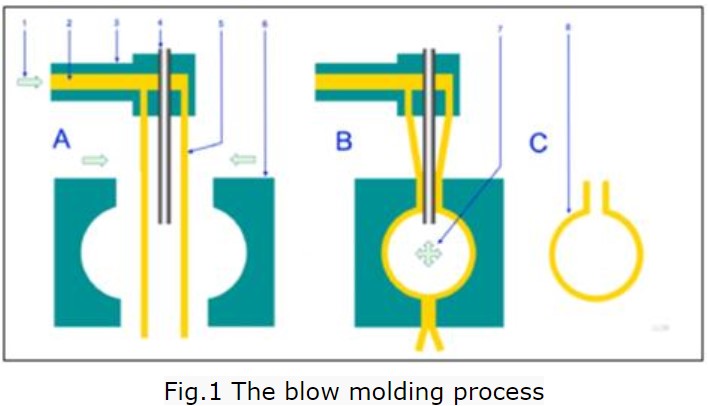

Type of moulding

- Blow molding

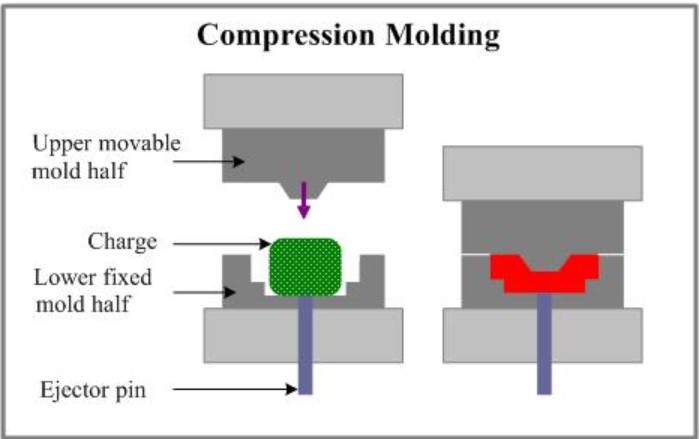

- Compression molding

- Extrusion molding

- Injection molding

- Reaction injection molding

- Transfer molding

- Thermo forming

- Vacuum forming

Reffernce used can is this link :more description on molding and casting

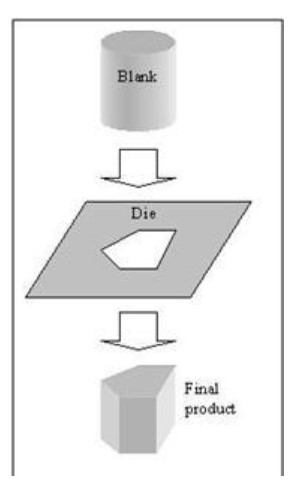

casting process (DEFINITION)

Casting: Casting is a manufacturing process by which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various cold setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods.

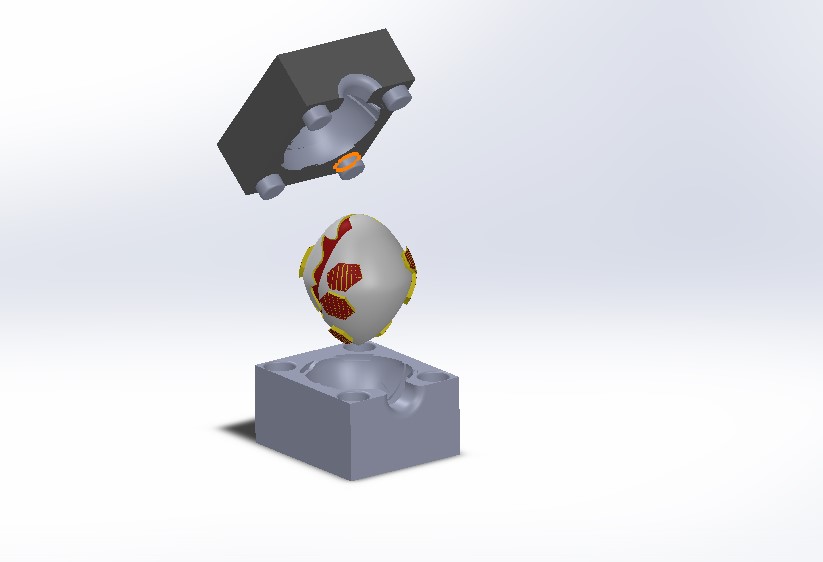

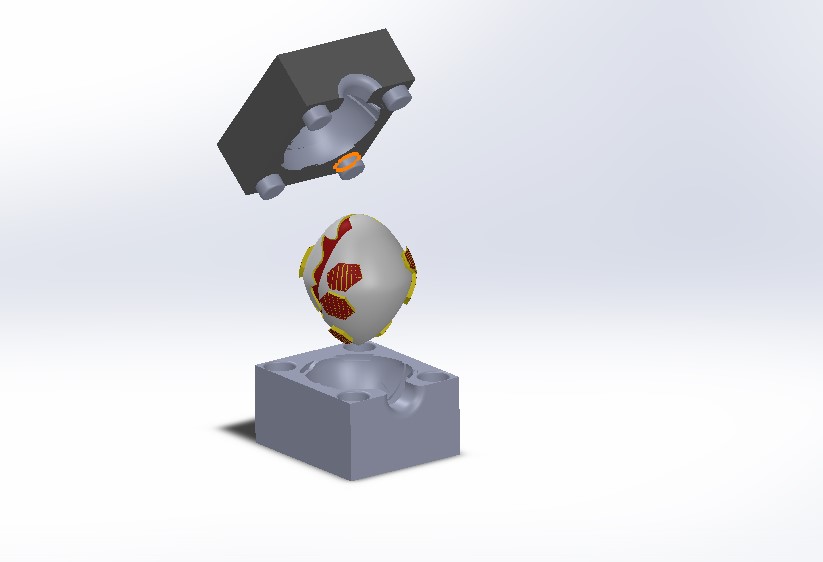

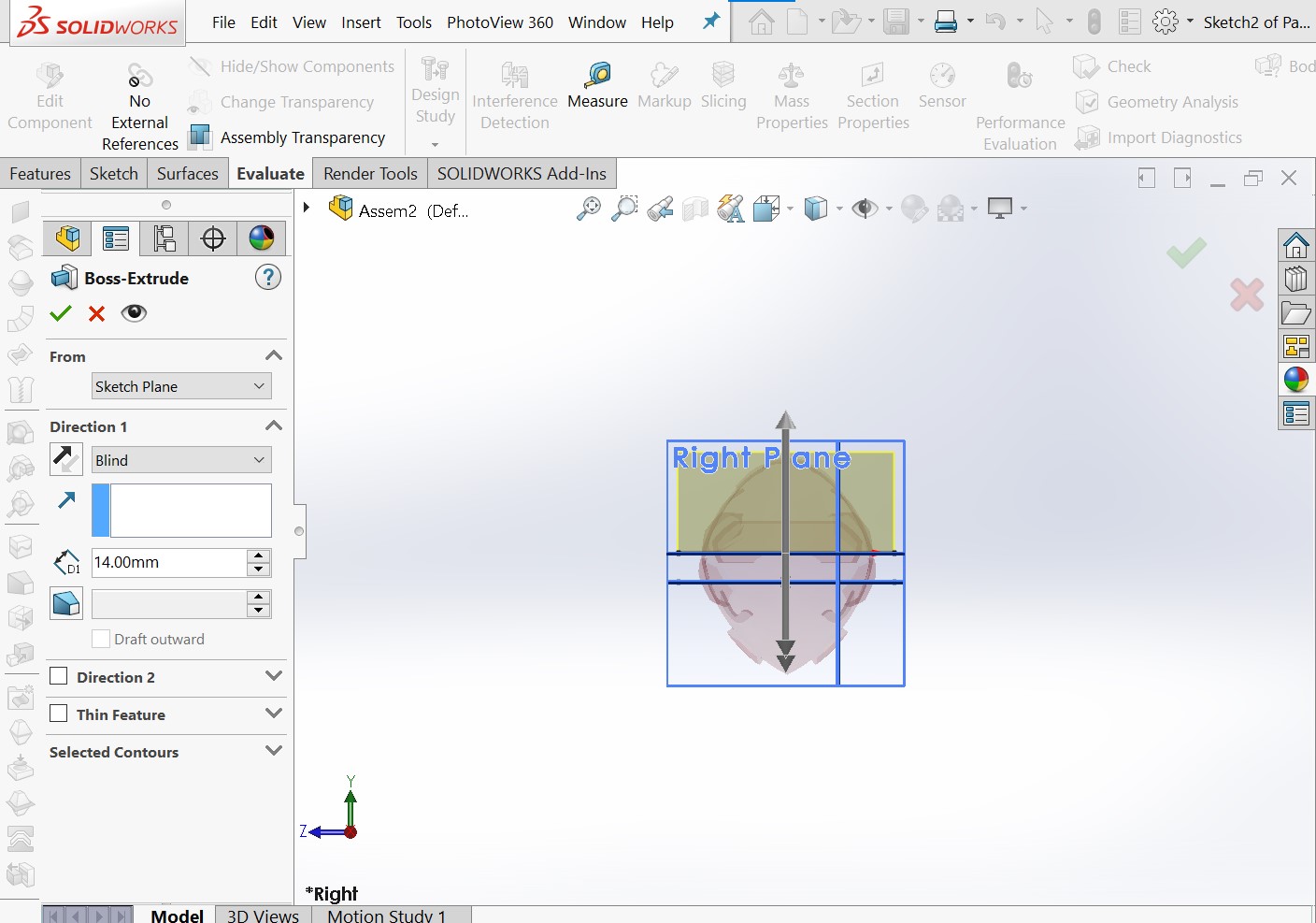

SOLIDWORKS DESIGN OF MY mold

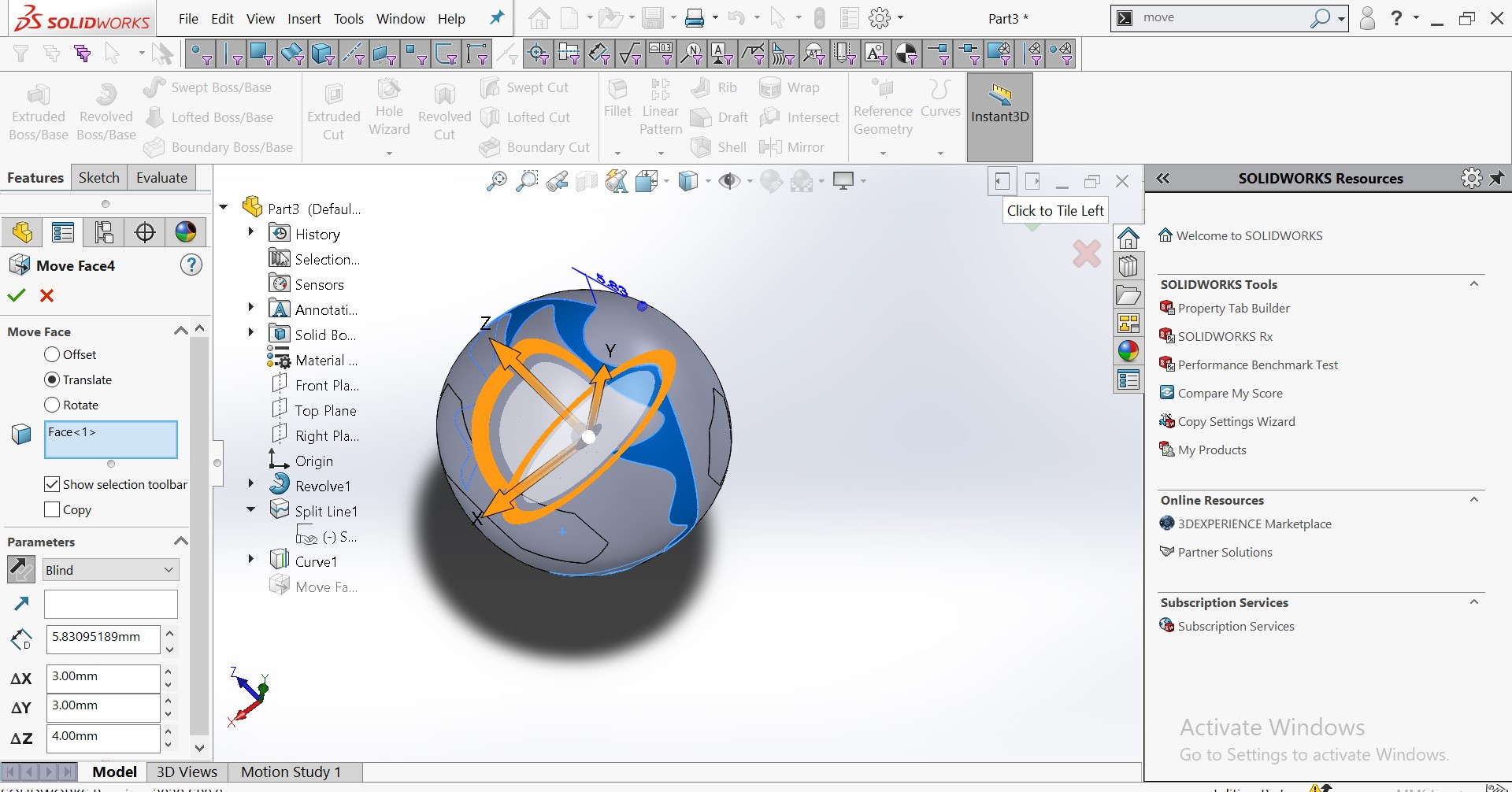

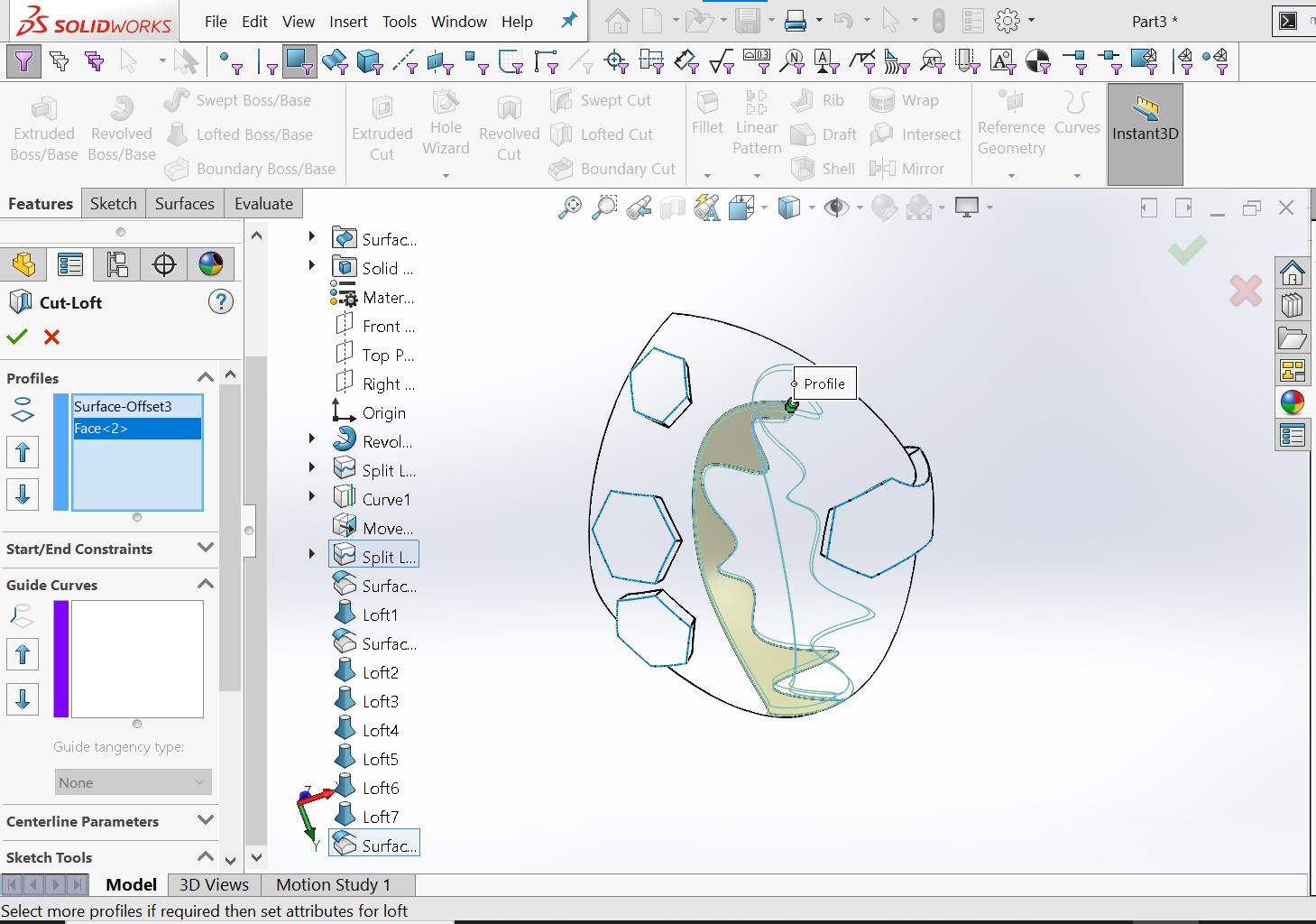

mold design soldworks design

soldworks design

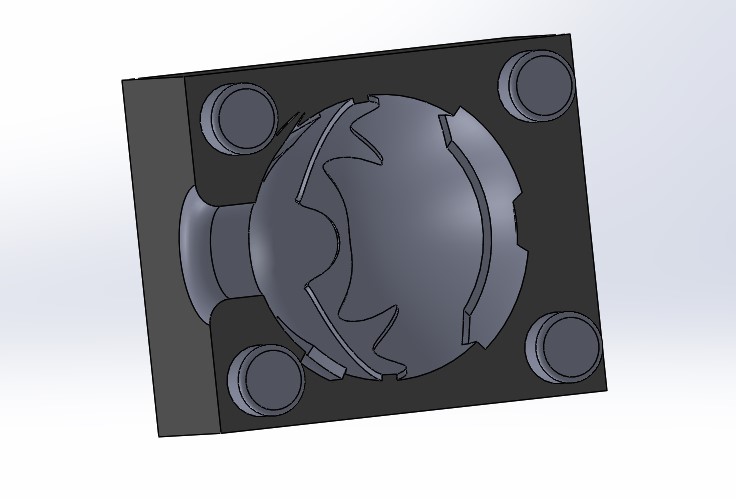

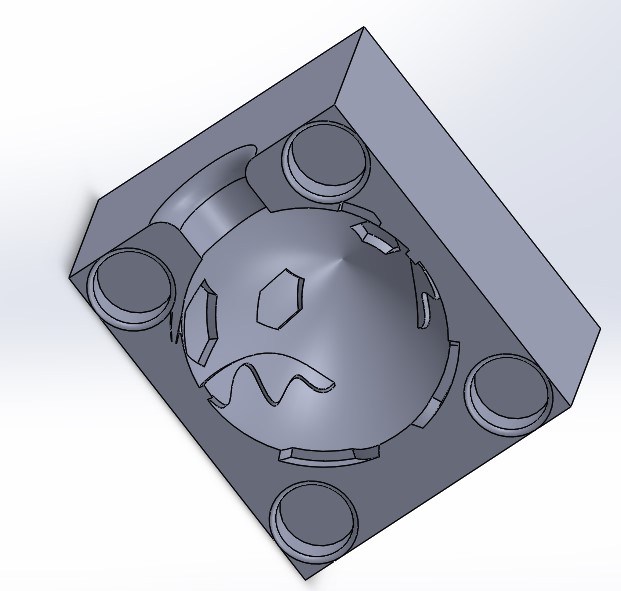

mold design based on designed key

mold design based on designed key

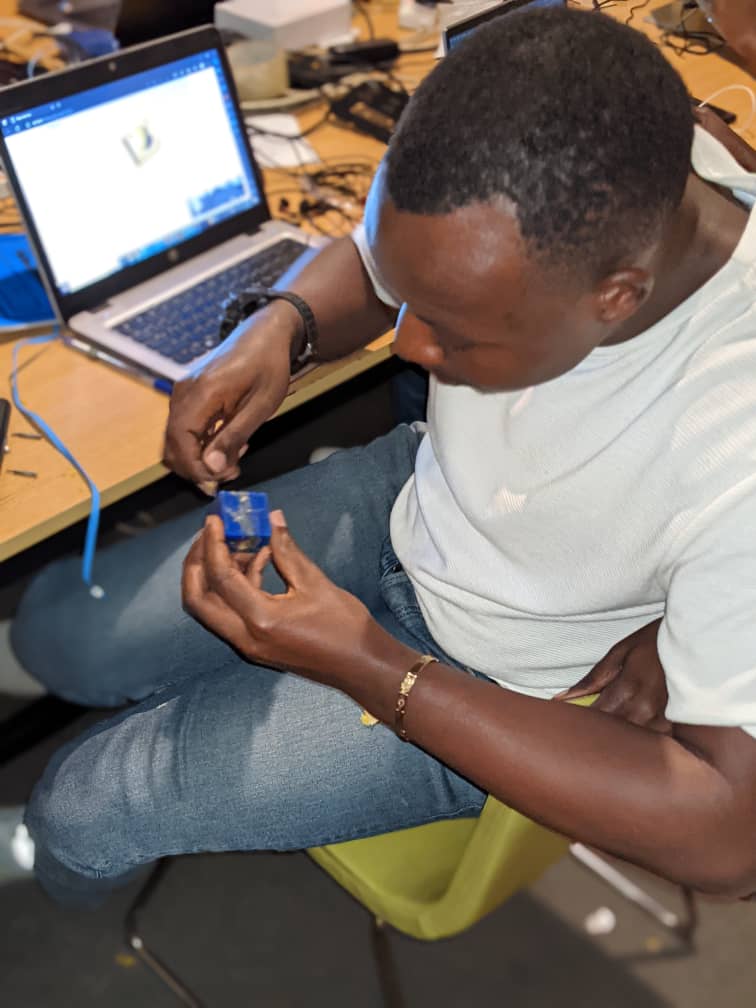

us showned above the process of creating the mold by using solidworks in assembly the component is to use tool colled mold and sellecting cavity to create hollow shape inside the body.

final mold of my key going through , obove process.mold manufacturing proccedure

after designing my mold we gona use v-curve software and gerate g-code and its tool paths

final mold of my lyguby balon is going through , obove process.After milling my mould on cnc

- Compression molding