IDIT | Universidad Iberoamericana Puebla, México

FAB Academy 2023

Mechanical design, machine design

Abstract

A CNC (Computer Numerical Control) machine is an automated manufacturing tool that uses a set of software-controlled cutting tools to perform cutting, engraving, milling, drilling and other processes.

The machine is controlled by a computer that uses software to translate designs and specifications into instructions that the machine can follow. Usually the precision of a CNC machine is very high, allowing the production of complex and accurate parts, these also gives repeatability to the processes. CNC machines are widely used in industrial manufacturing and are also popular among fabrication hobbyists and makers who use these tools for prototyping and custom part creation.

Some of the most common challenges encountered during de creation of a CNC are:

Mechanical design: The mechanical design of a CNC machine is crucial to its success, and any errors in the design can cause problems in the operation of the machine. It is important to ensure that the machine structure is solid and strong, and that the components fit together correctly.

Component selection: It is important to select the right components for the machine, and make sure that they are compatible with each other. Poor quality components can cause problems in the operation of the machine and reduce its service life.

Programming: Programming a CNC machine can be a complicated process that requires knowledge in programming. Creating G-codes and using control software can be difficult, and errors in programming can cause problems in machine operation.

Calibration: Calibration of a CNC machine is important to ensure that the machine operates effectively. Incorrect calibration can affect the accuracy of the machine and reduce the quality of the parts produced.

Maintenance: The CNC machine requires regular maintenance to ensure proper operation. Proper maintenance can help prevent problems and extend the life of the machine.

These are just a few of the difficulties that can arise when setting up a CNC machine. It is important to have experience and expertise in mechanical engineering, electronics and programming to ensure that the machine is built safely and operates effectively.

Our Project

To create our CNC machine we followed the next steps:

- Ideation: came up with a innovative idea to create a CNC machine for your Lab.

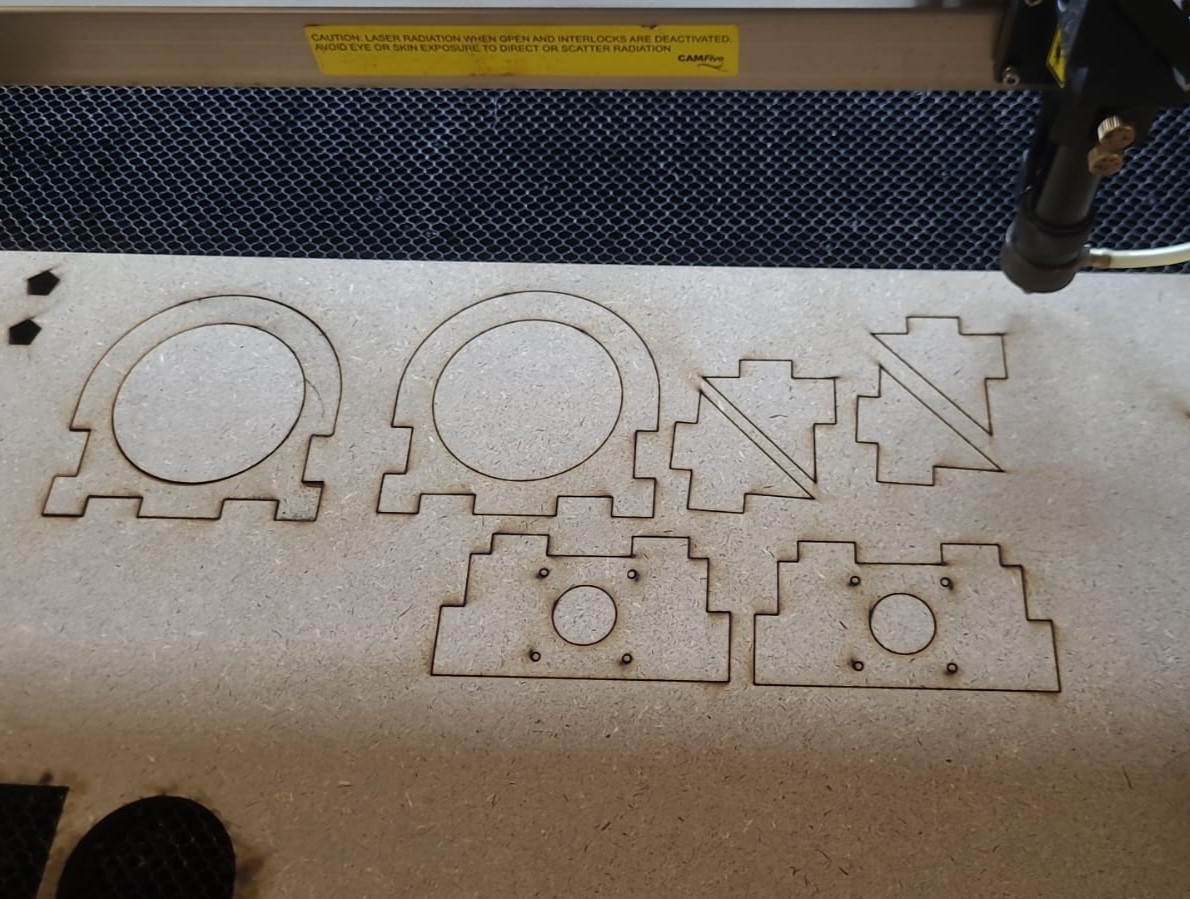

- Design the model: The first step is to design the model of the CNC machine in CAD (computer-aided design) software. This design should include all the details of the structure, motors, controllers, sensors and cutting tools.

- Select the materials: after designing the model, the materials needed for the construction must be selected. These materials must be strong, durable and able to withstand the forces and stresses of machine operation.

- Purchase the components: the electronic components, motors, controllers, sensors and cutting tools needed to build the CNC machine must be purchased.

- Build the structure: the structure of the CNC machine must be built following the previously prepared design.

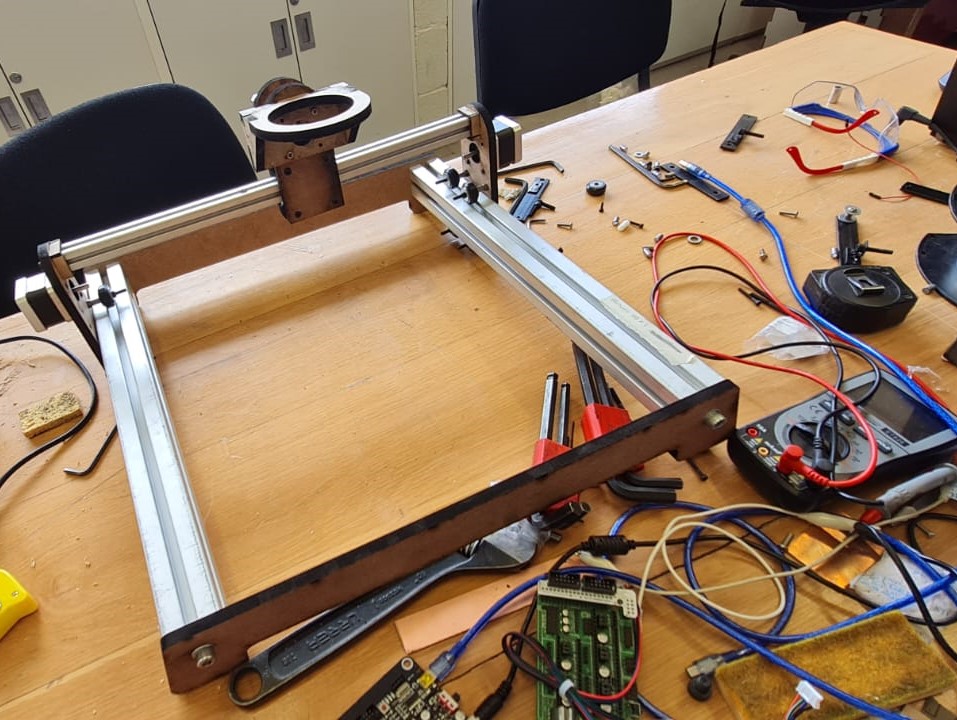

- Assemble the components: once the structure is built, the electronic components, motors, controllers, sensors and cutting tools must be installed according to the previously prepared design.

- Test and adjust: Finally, the CNC machine must be tested and adjusted to ensure that it operates correctly and produces accurate, high quality parts.

Ideation

Our inspiration for these CNC machine came from the Huamantla carpets. Huamantla is a town in Tlaxcala, Mexico where every year an amazing tradition happens in honor of the Virgin of Charity. The festivity is on the night of 14th of August; “the night when no one sleeps” because everybody participates in the making of amazing carpets out of colored sawdusts and sand. As a result the Huamantla streets become beautiful pieces of art functioning as decoration for the celebration.

Similar traditions are found in other latitudes and cultures. Such is the case of the Tibetan sand mandala carpets. The main idea involving it is the creation and destruction of life symbolized by mandalas mane out of colored sand.

Design

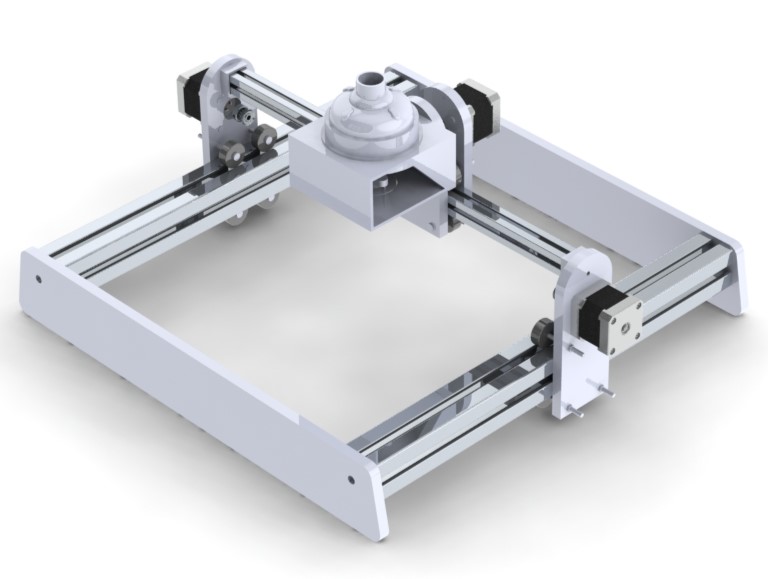

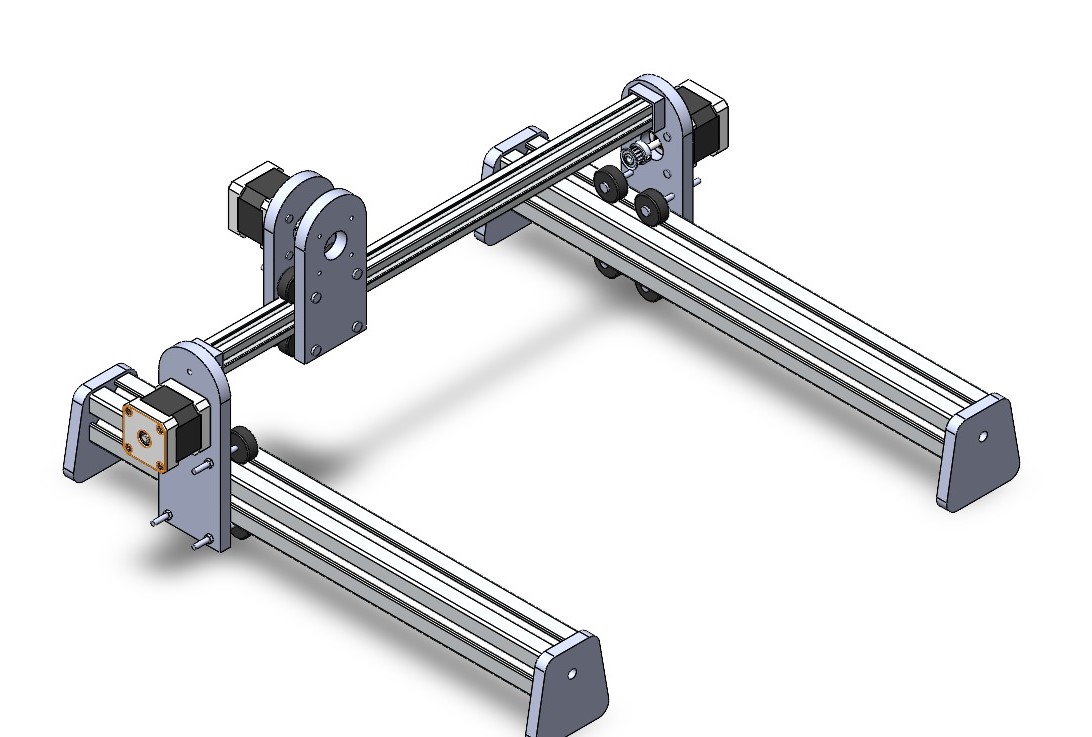

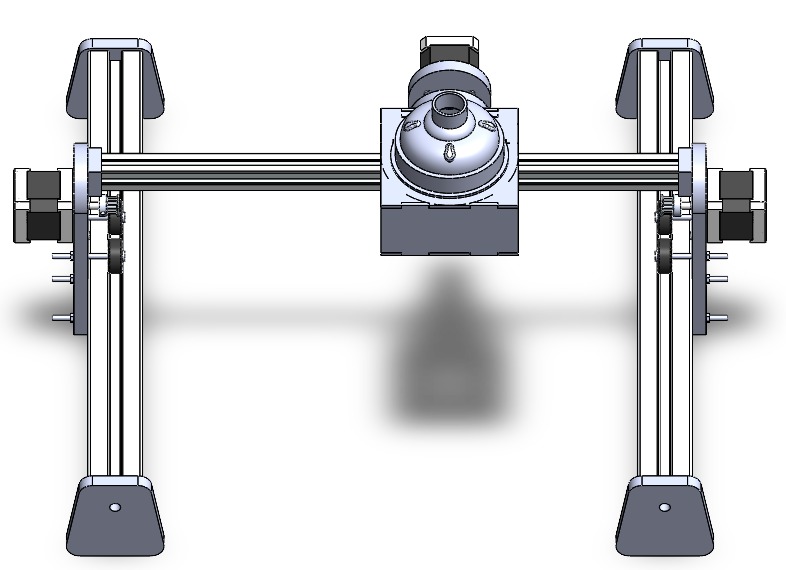

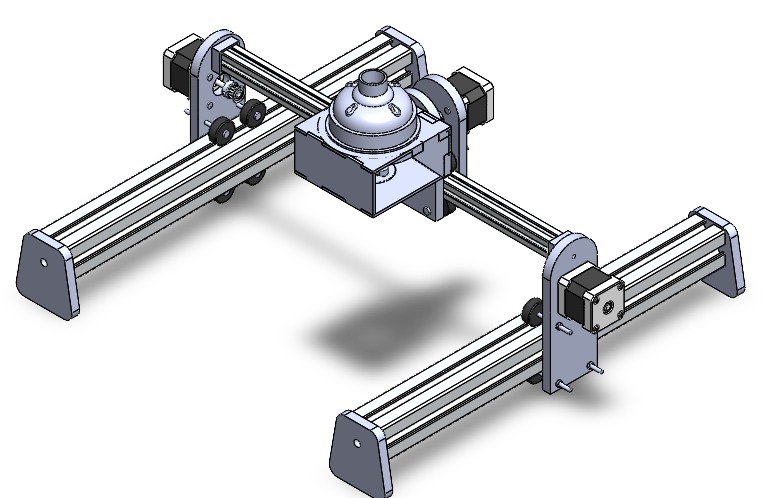

We based our design on a sand machine that works similar to what we wanted to do. This machine has two Y axis motors and one X axis motor. Our plan is to control everything using a generic GRBL compatible control board and the main challenge is to create a way to dispense the MDF sawdust.

Here is the reference project we took as baseline for our CNC

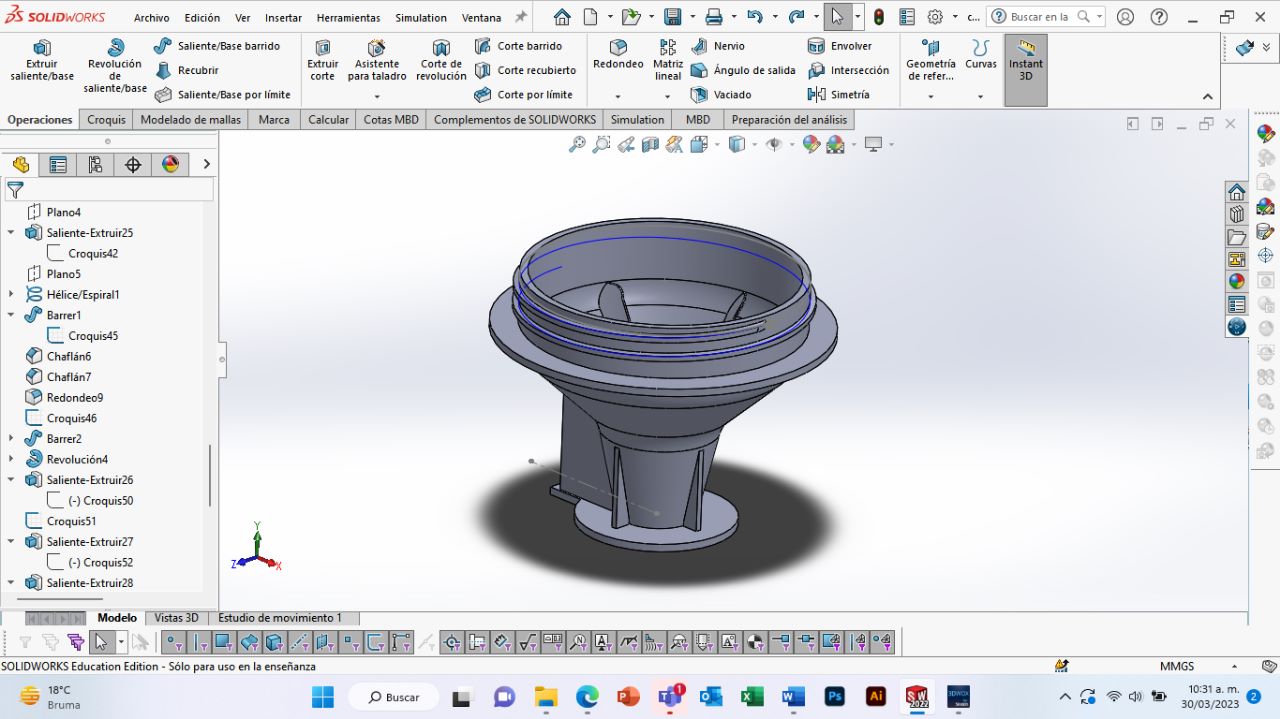

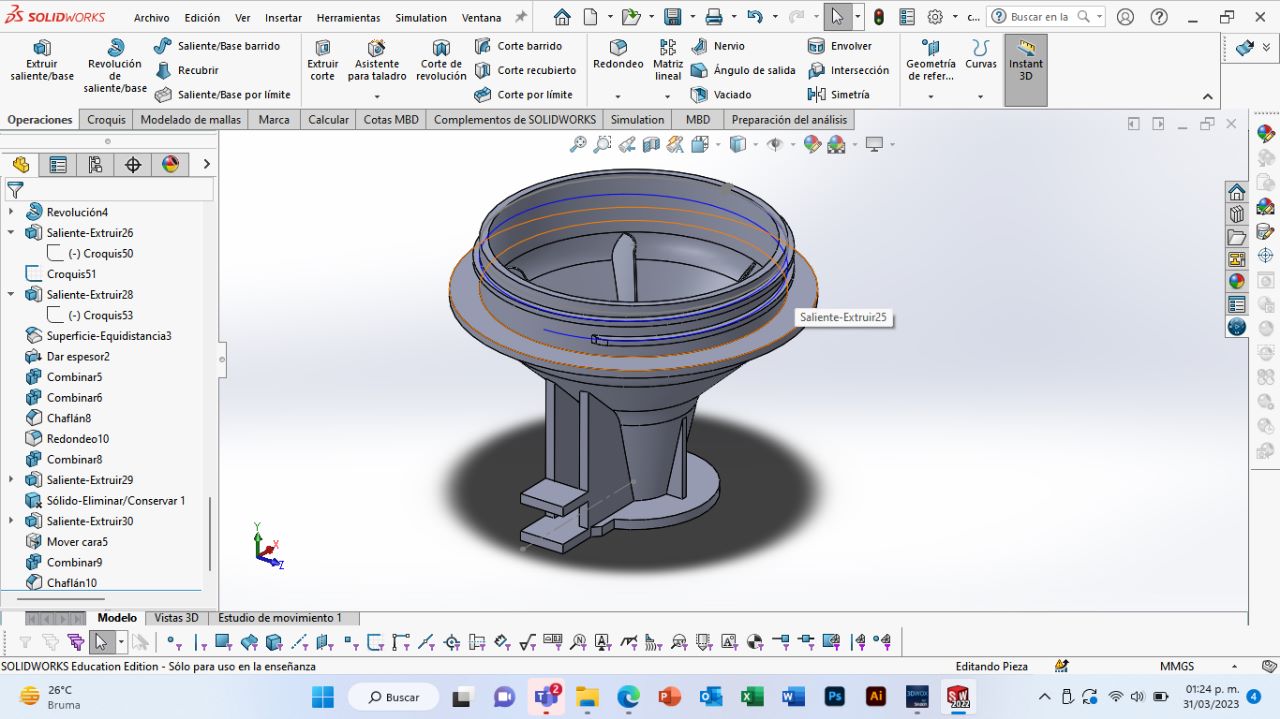

For the CAD design we focused on the cone that delivered the sawdust. This are the first iterations:

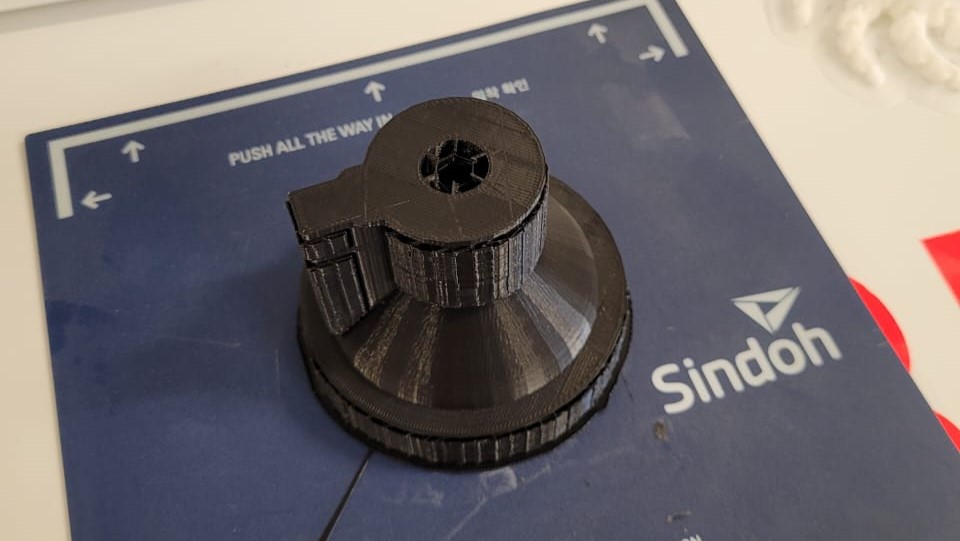

When we tested the cone we saw that it could work by tapping or vibrating to liberate the sawdust.

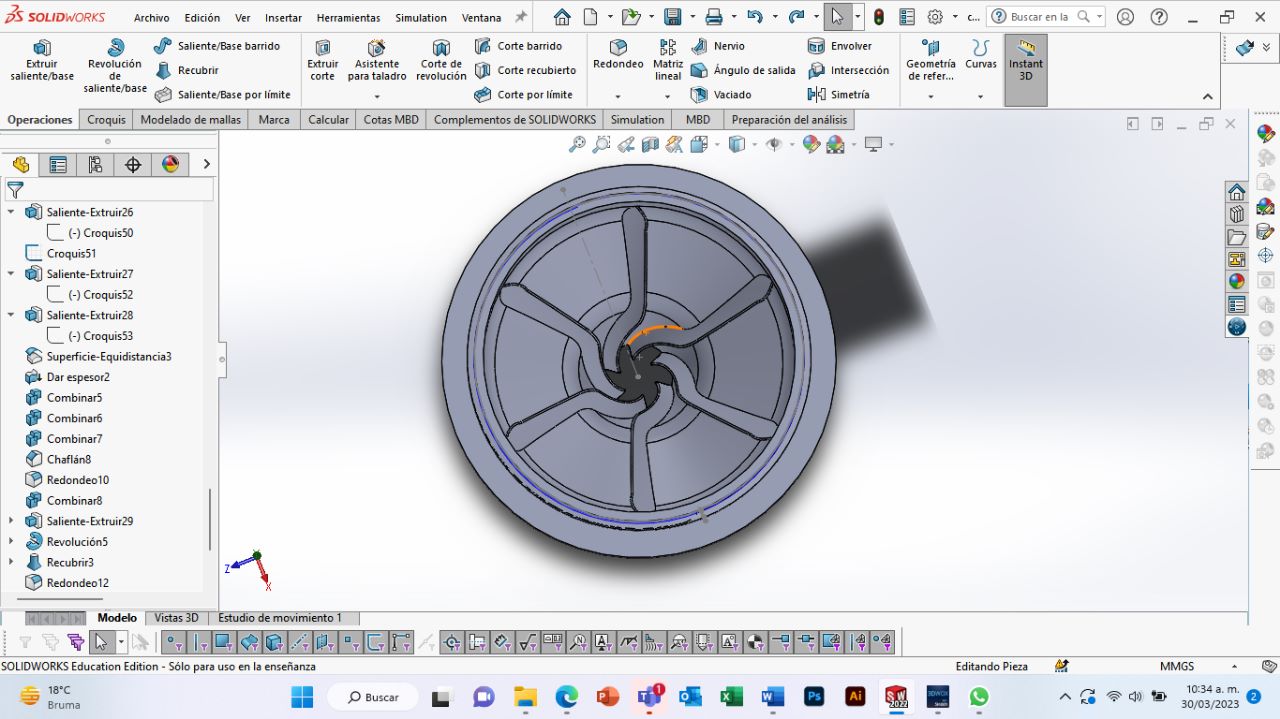

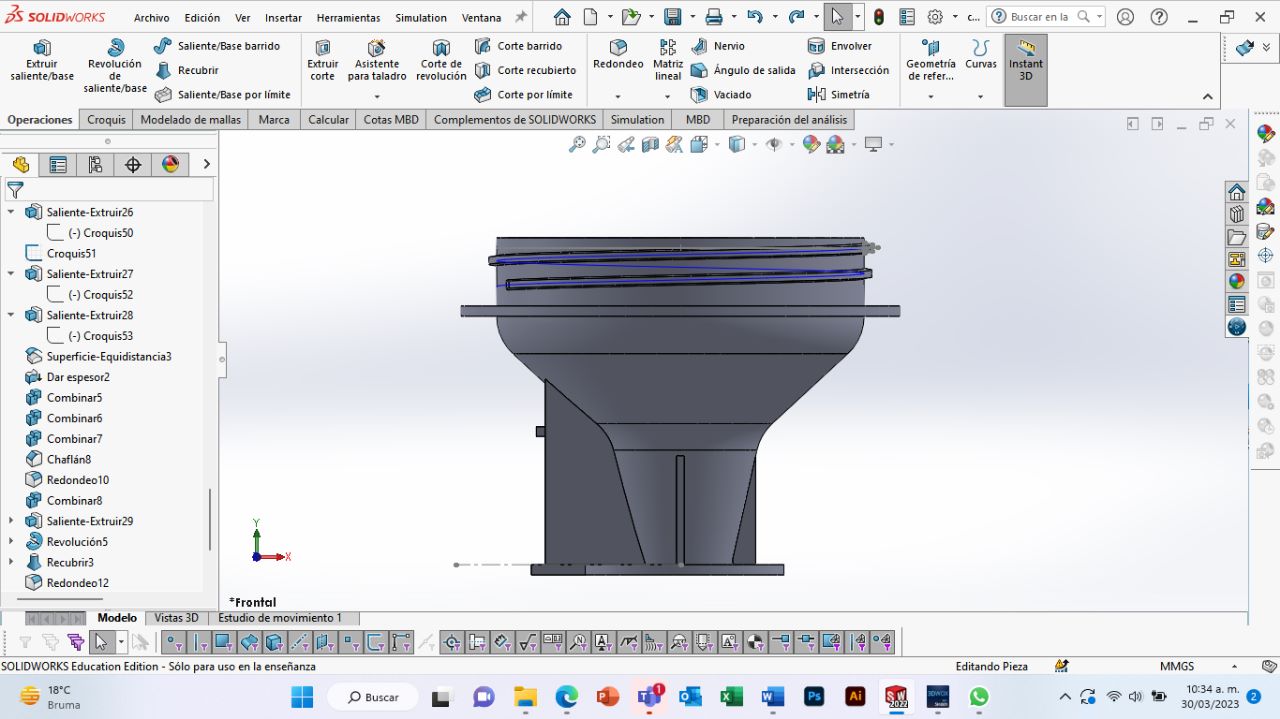

After testing many times and different methods we found that the cone needed modifications so it was back to the design board. And after some tries we finally dialed it in.

The moment to test how the sawdust will be delivered came and we tried to use a servomotor to tap on the cone to let go little amounts on each tap.

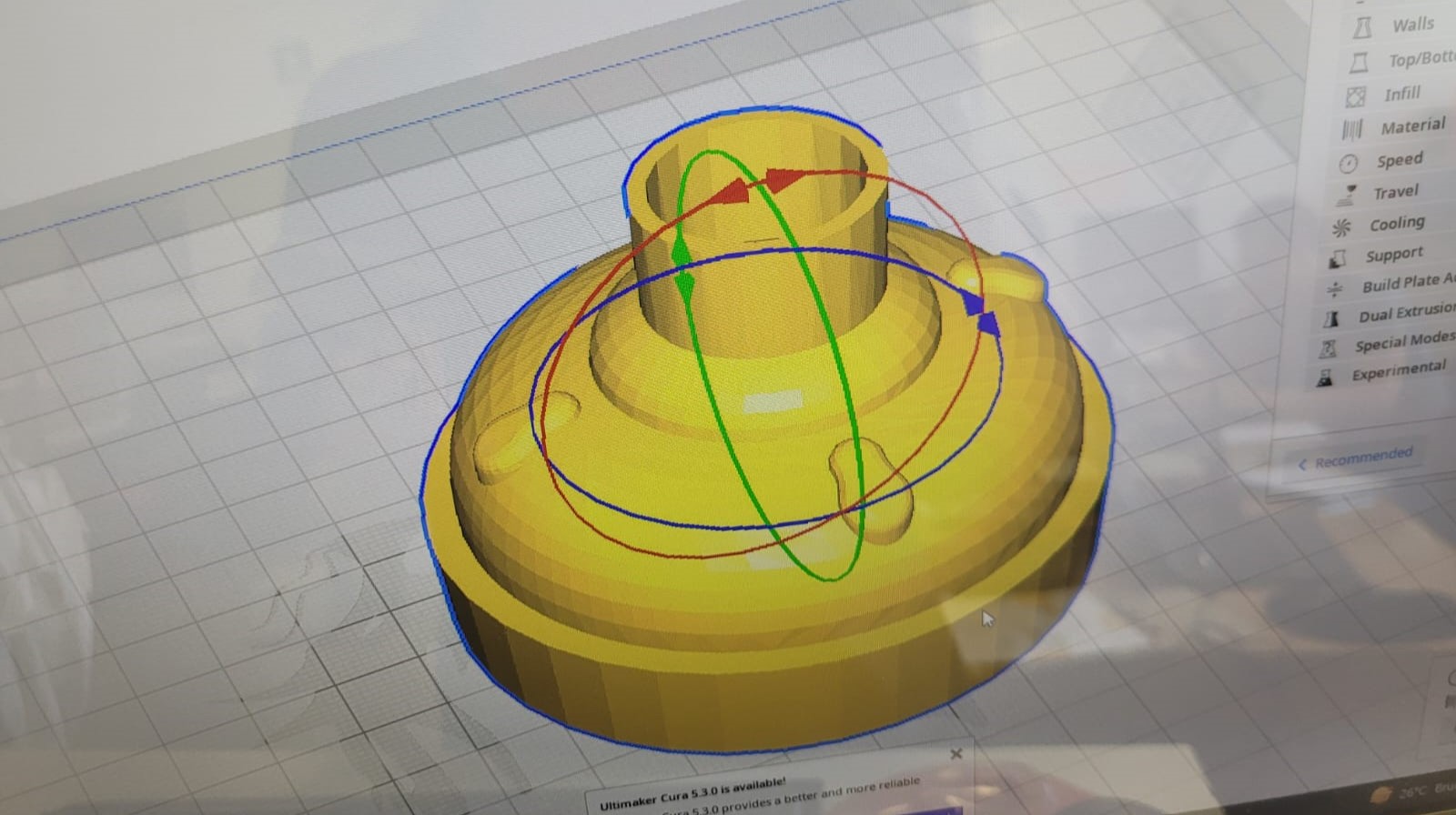

As you can see in the next video (Video on the left), it didn't work, so we had to change the idea, and using a shape like the one of a drill bit was the solution to our problem. So we printed it out and tested the results.(Video on the right)

Once our main challenge was solved we continued with the design, creation and assembly of all the mechanical pieces the CNC needed.

Electronics

For the electronics as mentioned before we used a GRBL compatible board. Here is the PoC for it as well as one with all the components assembled:

Test

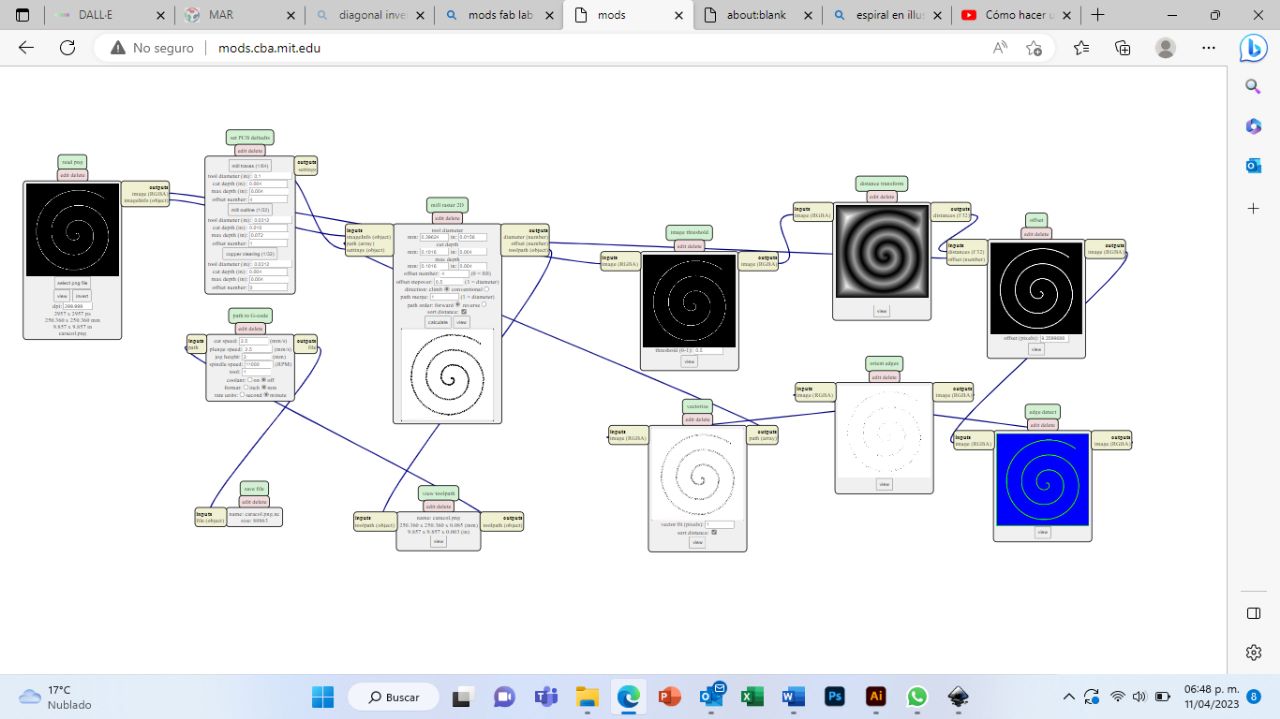

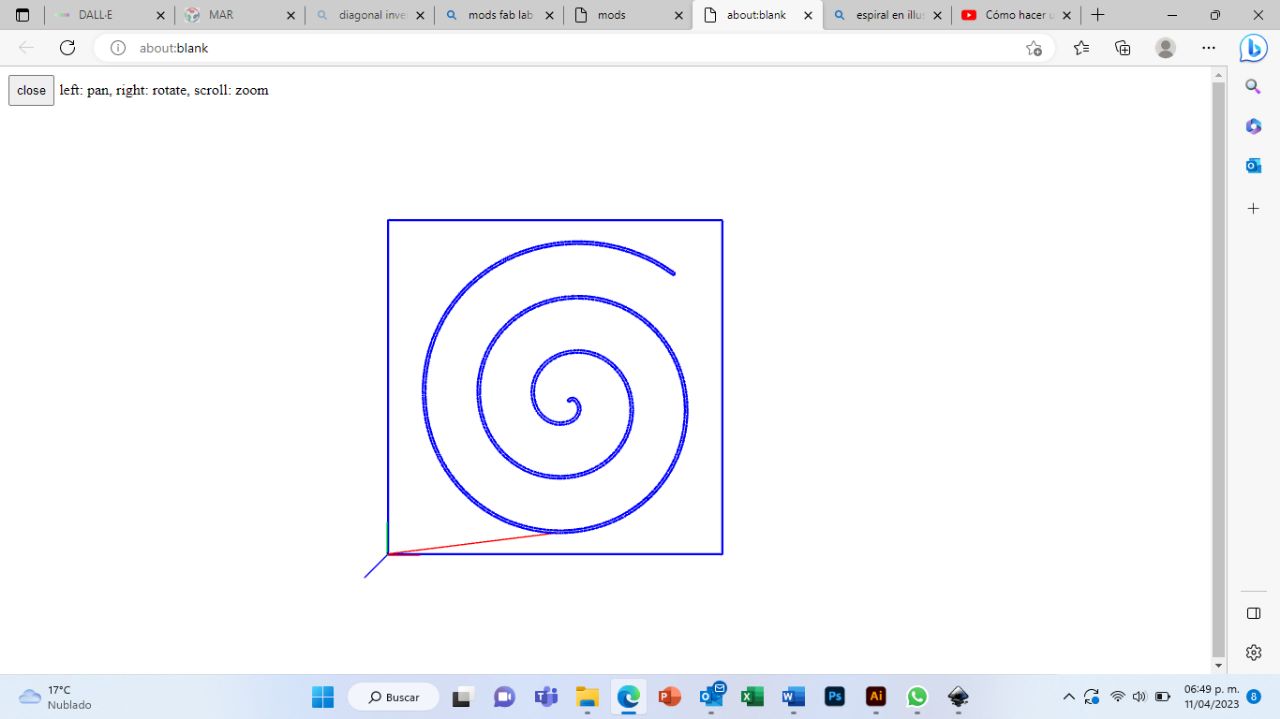

For testing we use moods to generate the G-Code. I important to mention that we use UGS to send the code to the GRBL compatible board. A complete guide on how to install and configure UGS and all of its dependencies can be downloaded here.

Here are some videos of the CNC working: