16.Applications and implications

What will it do?

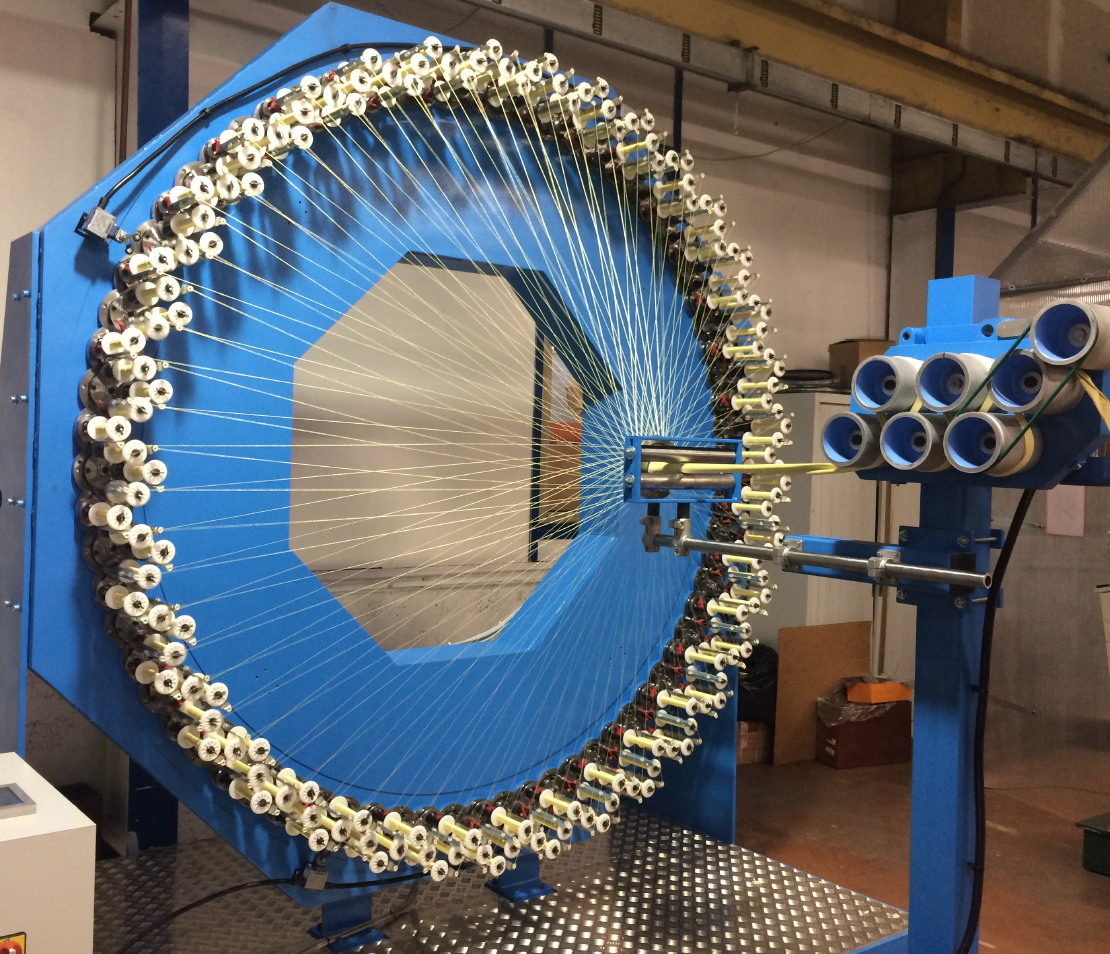

For my final project, I aim to develop a braiding machine that allows me to explore a novel method of CFRP (Carbon Fiber Reinforced Polymer) manufacturing. My objective is to create a machine capable of producing skeletal structures using CFRP manufacturing techniques, where I can precisely define the arrangement of individual fibers within the structure. This is the core idea behind my project, and I am hopeful that it will enable me to push the boundaries of CFRP manufacturing.

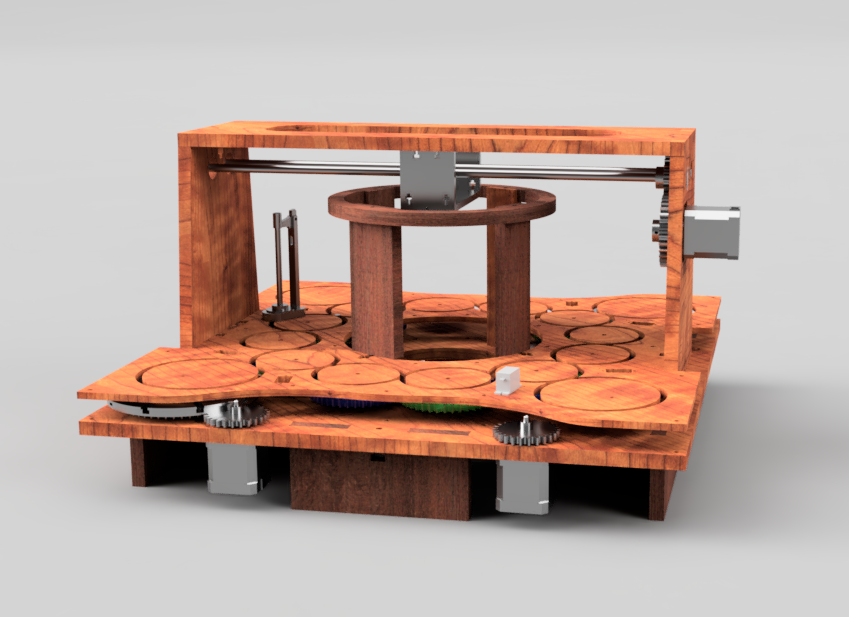

The design of the machine incorporates a standard braiding operation, which serves as the foundation for my experimentation. I have intentionally allowed room for innovative experiments, enabling me to explore different fiber patterns, densities, and orientations within the CFRP structures. By doing so, I hope to uncover new possibilities and insights in the field of CFRP manufacturing.

Overall, my goal for the project is to develop a braiding machine that not only performs the traditional braiding function but also serves as a platform for me to delve into unexplored territories and push the boundaries of CFRP manufacturing techniques. I am excited about the potential discoveries and advancements that this project may bring.

Who's done what beforehand?

The braiding machine has a rich history, spanning a century, as a technology that has made significant contributions to various industries. In my pursuit to create a new version of this time-honored technology, I am driven by the desire to infuse it with my own experimental ideas and push its boundaries. This endeavor involves developing a fresh design, marked as the v.001, to explore uncharted territory and uncover new possibilities. By incorporating my experiments into the braiding machine, I aim to introduce novel features, enhance its performance, and transform it into a more versatile, efficient, and adaptable tool. Building upon the foundation of its history and heritage, I am eager to challenge conventional thinking, embrace innovation, and leave my mark on this enduring technology. Throughout this journey, I am committed to the iterative process, learning from each experiment, and refining the design to pave the way for future advancements of the braiding machine.

What will I design?

I have been completing my designs in accordance with the weekly assignments, and now, for the final project, I need to fully design the electronics and electrical part of the machine myself. I have acquired the means and skills to do so during Fab Academy.

The designs include passive mechanisms created through the meshing of gears and guides, which are cut from acrylic. I have designed them in a way that ensures proper functionality and allows enough room for other bobbins or necessary elements.

As for the electronics, they consist of 2 servo motors, 3 stepper motors, and 2 limit switches. For the microcontroller, I have decided to use the Sam D11D14 AU microchip. I have previous experience with this microchip, and I am confident in my ability to work with it effectively. The microchip offers an adequate number of pins for my needs and fulfills all the necessary requirements. Since there is no requirement for WiFi connectivity in this project, I have chosen not to use an ESP32 chip.

By taking charge of the electronics and electrical design, I can ensure the seamless integration of these components into the overall functionality of the machine. With careful planning, the utilization of appropriate microcontrollers, and the efficient allocation of resources, I am confident in my ability to achieve the desired outcomes for the project.

What Materials ,Where it come from & How Much?

Mechanical parts

| SL NO | Part name | Quantity | Price | Total | Source |

|---|---|---|---|---|---|

| 1 | Stepper motor | 3 | 450 | 1350 | FAB Inventory |

| 2 | Servo motor | 2 | 90 | 180 | FAB Inventory |

| 3 | 6 mm Acrylic 2feetx2 feet | 1 | 600 | 600 | Fab inventory |

| 4 | 12 mm plywood 4feet x 4 feet | 1 | 300 | 300 | Fab inventory |

| 5 | Bearings | 16 | 20 | 320 | Fab Inventory |

Electronics Components

| Sl No | Part Name | Quantity | price | total | Source |

|---|---|---|---|---|---|

| 1 | SAM D11 | 1 | 100 | 100 | Fab Inventory |

| 2 | DRV8825 Driver Module | 3 | 400 | 1200 | Fab Inventory |

| 3 | SMD 1x6 Female Header Pins | 1 | Fab Inventory | ||

| 4 | 1x6 Male SMD Header pins | 1 | Fab Inventory | ||

| 5 | 1x4 Male SMD header pins | 3 | Fab Inventory | ||

| 6 | 1x5 Female SMD Header pins | 6 | Fab Inventory | ||

| 7 | 1x3 Female SMD Header pins | 6 | Fab Inventory | ||

| 8 | 2x2 SMD male header pins | 3 | Fab Inventory | ||

| 9 | Resistors | As per design | Fab Inventory | ||

| 10 | Capacitors | As per design | Fab Inventory |

What Process will be use?

What questions need to be answered?

By doing this project in the FAB LAB, I have high expectations of creating a prototype that addresses the specific problem I am targeting. I am excited to see how it's going to work. Additionally, I have several questions that need to be answered during and after the prototype making.

- Does this solution effectively solve the problem I am targeting and provide a better solution?

- Will the guides be able to move freely and smoothly through the designated paths?

- Can the stepper motor I am using provide sufficient power for all the mechanisms?

- Can my machine successfully perform the experiment I am running?

How will it be evaluated?

The evaluation of the project can be approached in multiple ways to assess its success. It involves checking whether the mechanisms are functioning properly and the system is effectively carrying out the intended braiding process, as this is the first prototype with expected challenges. Evaluating the project also entails examining if the intended functions are working as expected and addressing any problems that arise. Thorough testing, analysis, and observation of the machine's movements and interactions are essential to determine if it operates as intended. Feedback from experts and incorporating their insights can provide valuable perspectives for improvement. Documenting observations and modifications throughout the iterative development ensures future refinements address identified issues. Through comprehensive evaluation, the project can optimize its prototype, meet objectives, and pave the way for future advancements.