Electronics Production

Assignment

- Group Assignment:

- Characterize the design rules for your in-house PCB production process: document feeds, speeds, plunge rate, depth of cut (traces and outline) and tooling.

- Document your work to the group work page and reflect on your individual page what you learned.

- Individual Assignment:

- Make and test the development board that you designed to interact and communicate with an embedded microcontroller.

Evaluation Standards

- Linked to the group assignment page.

- Documented how you made (mill, stuff, solder) the board.

- Documented that your board is functional.

- Explained any problems and how you fixed them.

- Uploaded your source code.

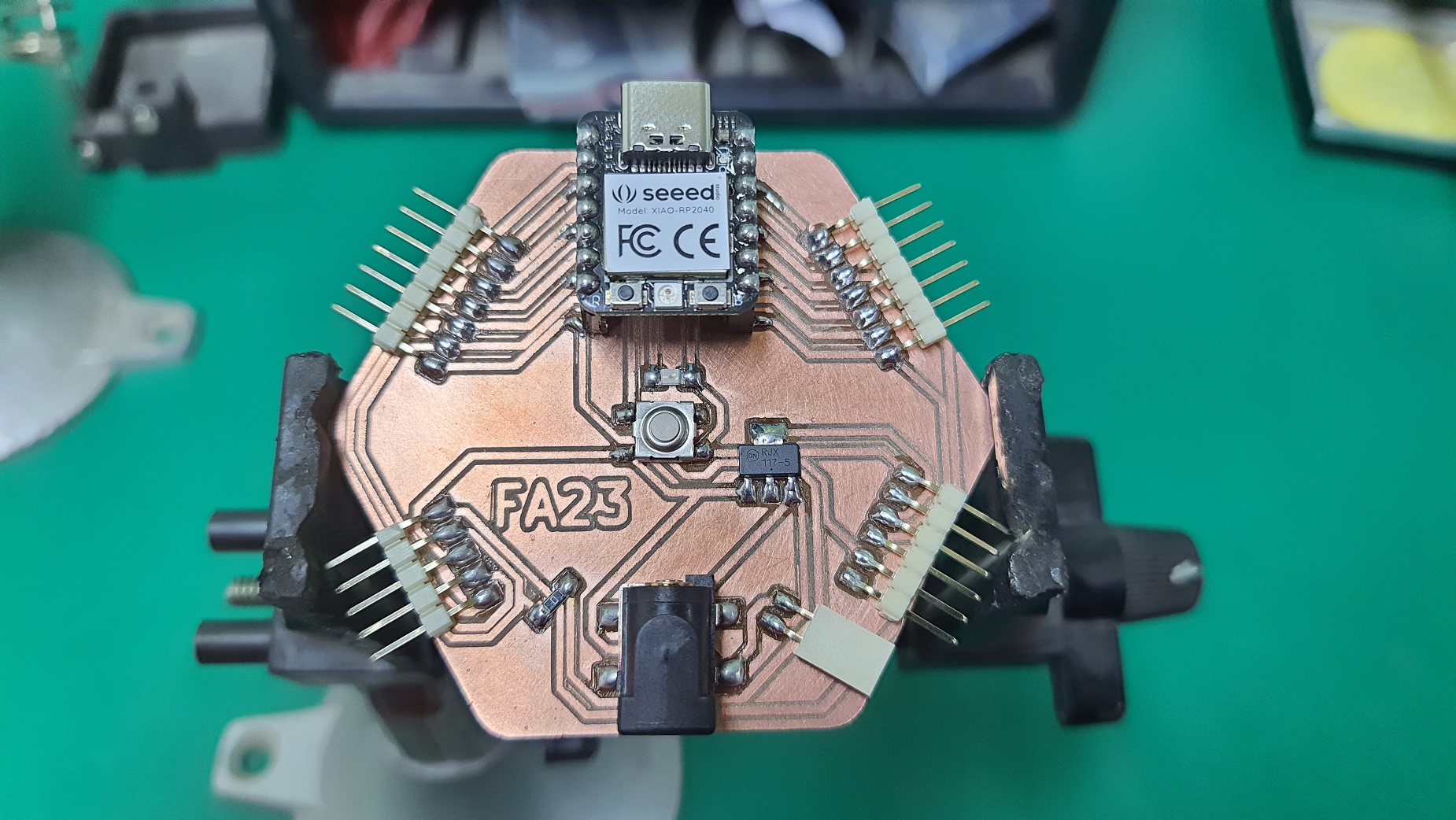

- Included a 'hero shot' of your board.

Output Preview

Group Assignment

Characterization

We start by characterizing the design rules for our Roland

MDX 20.

we used 0.4mm V-bit for the traces and 1.2 Endmill for the outline.

We set the cutting speed for the to be 4mm/s, and we set the cutting speed for the

outline is 2mm/s

Our Lovely Modela with a fresh surfaced bed.

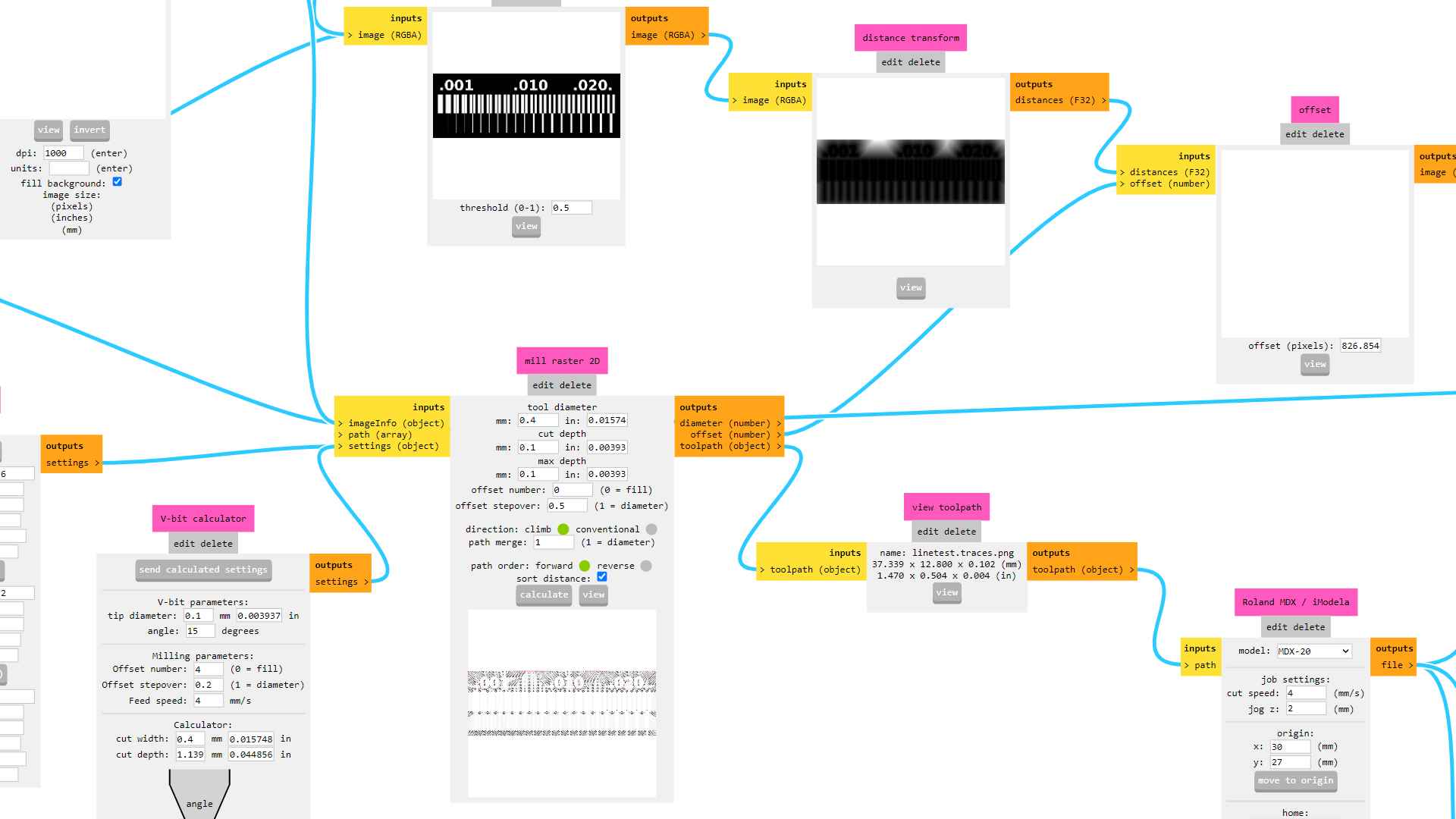

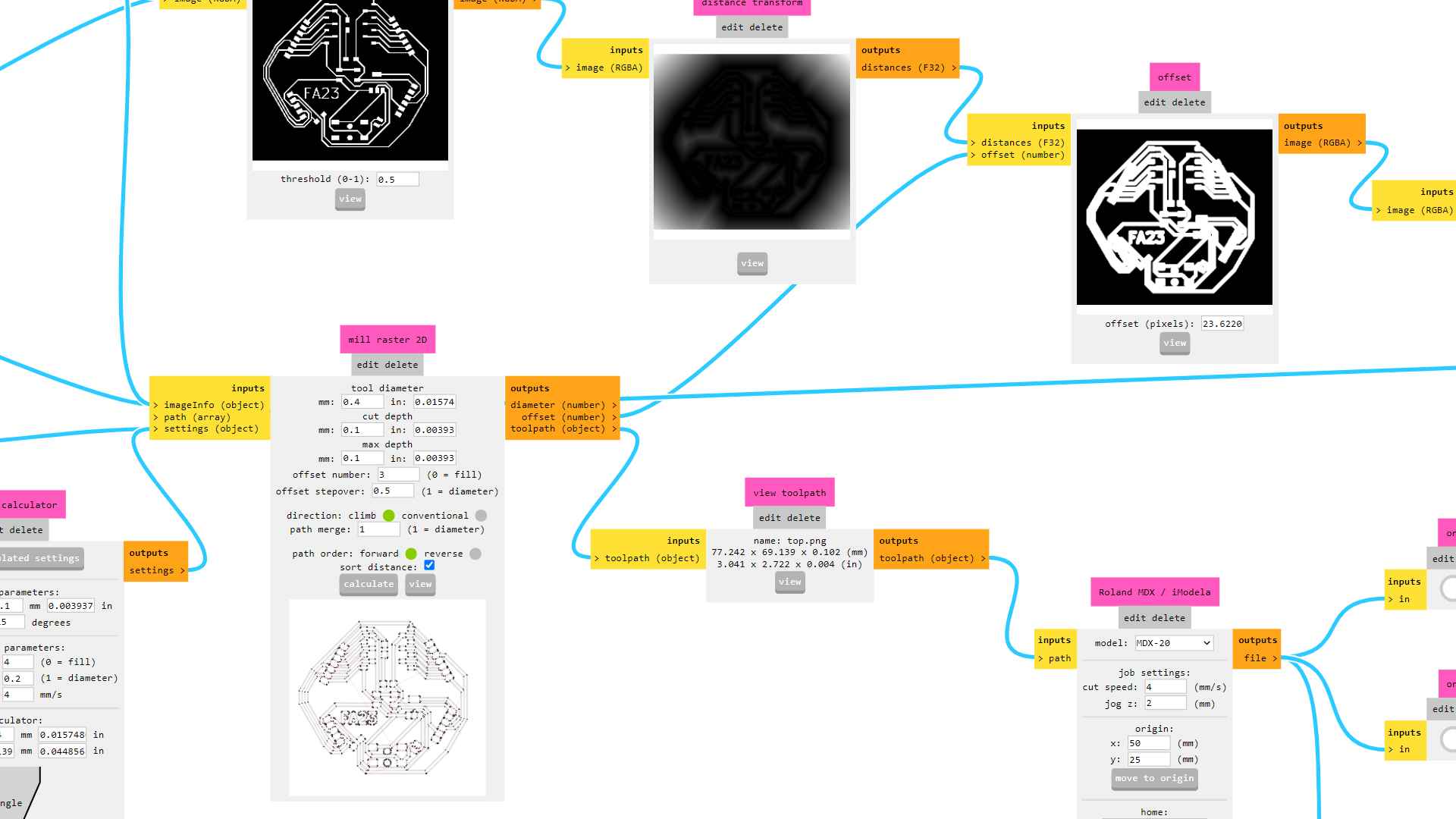

Calculating the toolpath for the design using Mods.

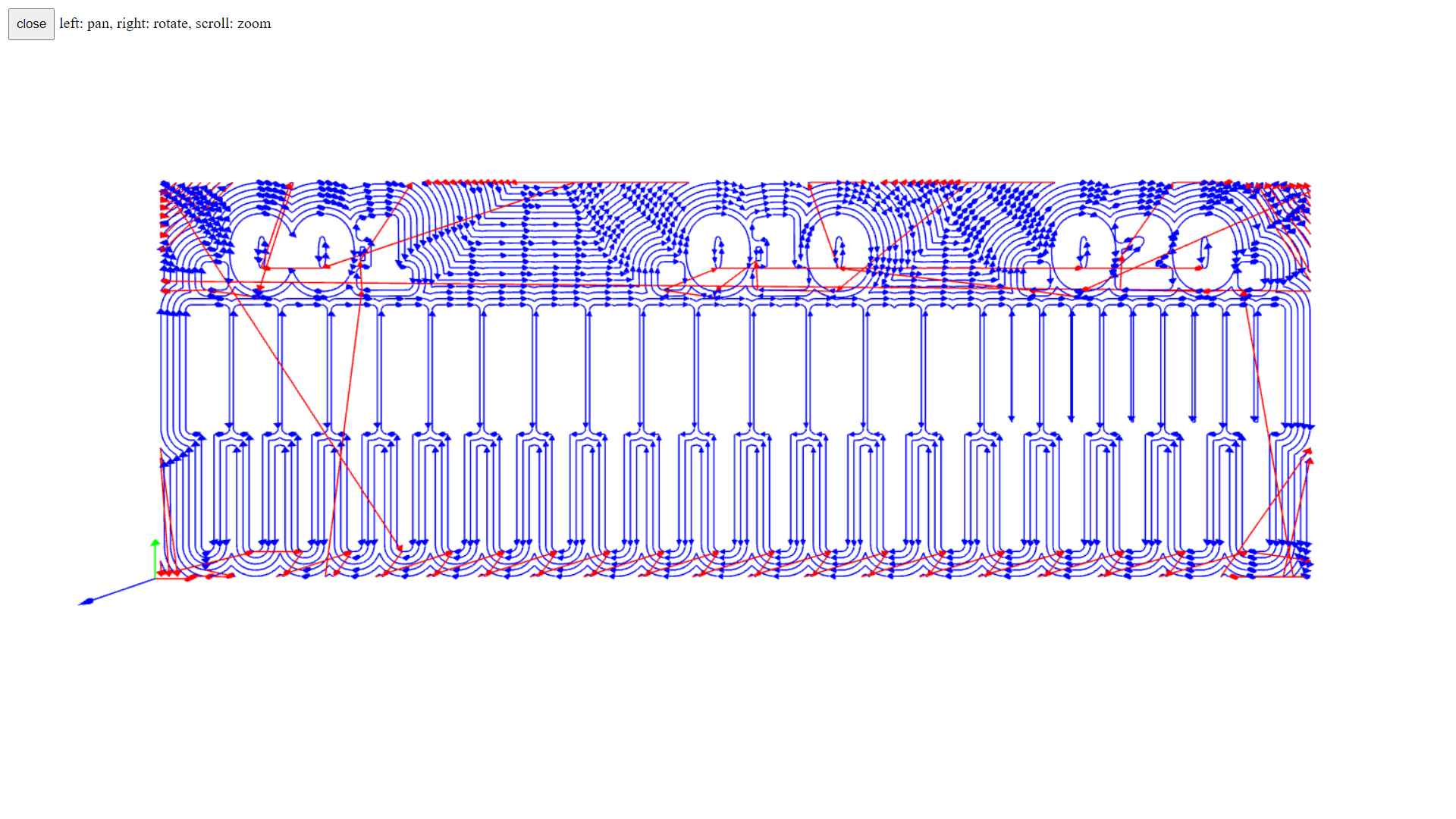

Viewing the toolpath.

Viewing the toolpath.

Using 1.2mm Endmill for outline and 0.4mm V-bit for traces.

Using 1.2mm Endmill for outline and 0.4mm V-bit for traces.

Setting the origin and start the process.

Setting the origin and start the process.

Here is our hero shot!.

Here is our hero shot!.

Check our

Group assignment page to see more of our assignment.

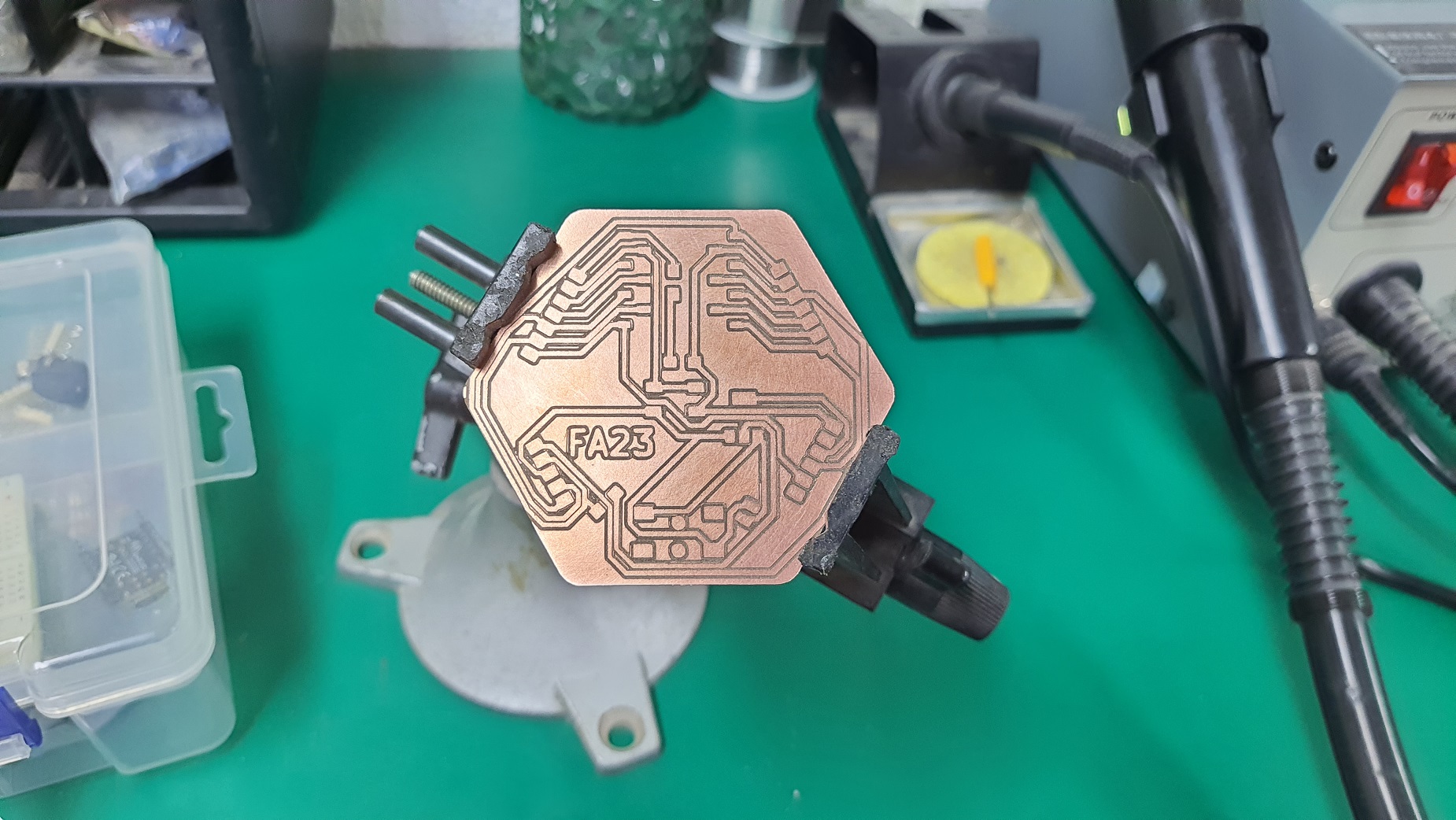

PCB Production

- I fabricated my pcb design using FR1 PCB milled on Roland MDX 20

- I Used duoble face to secure the PCB to the bed of the machine

- Then I imported my PNGs into mods and set the tool diameter that I use (V-Bit 0.4mm).

- Then Then I calculated my toolpath using Mods

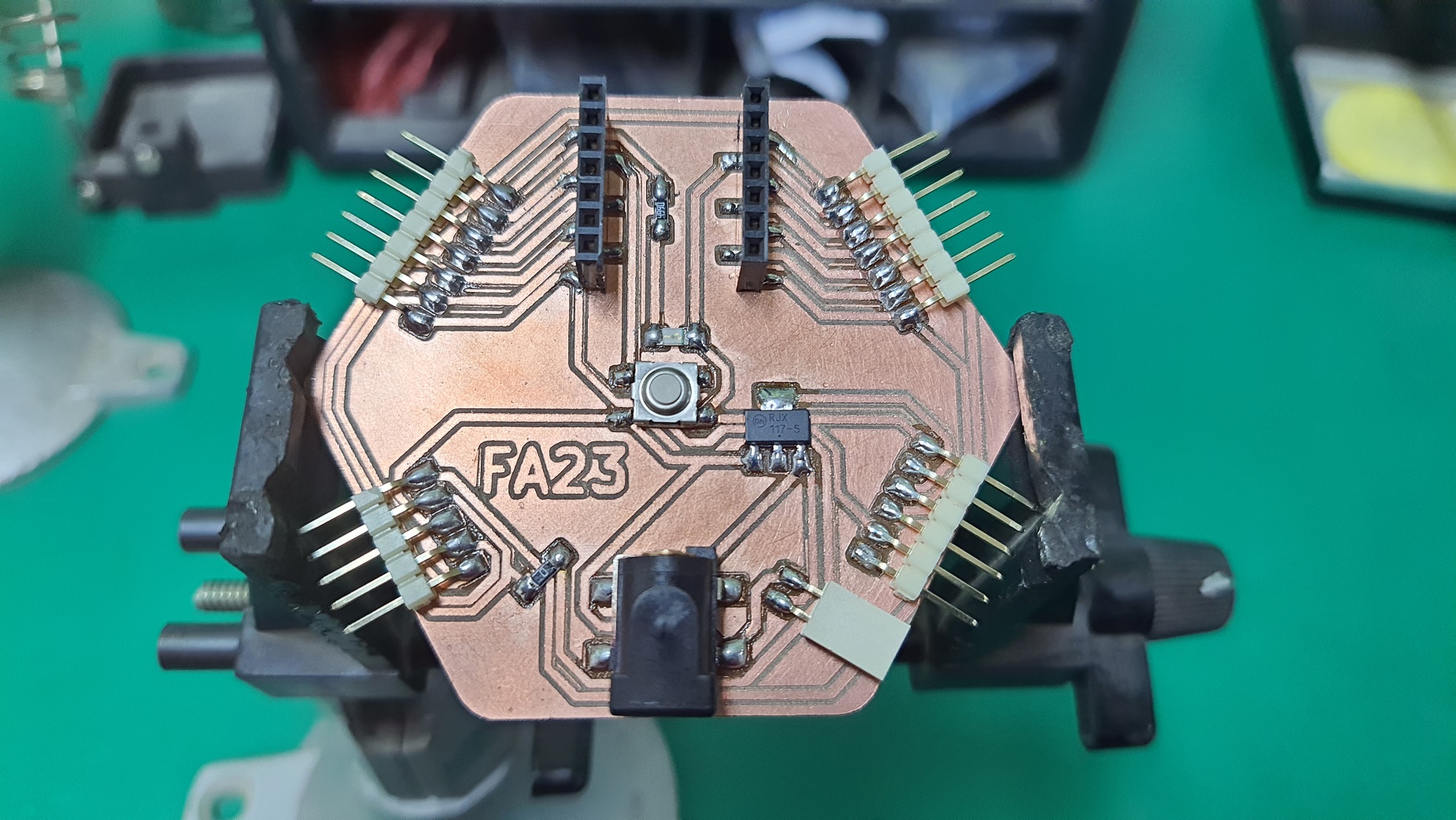

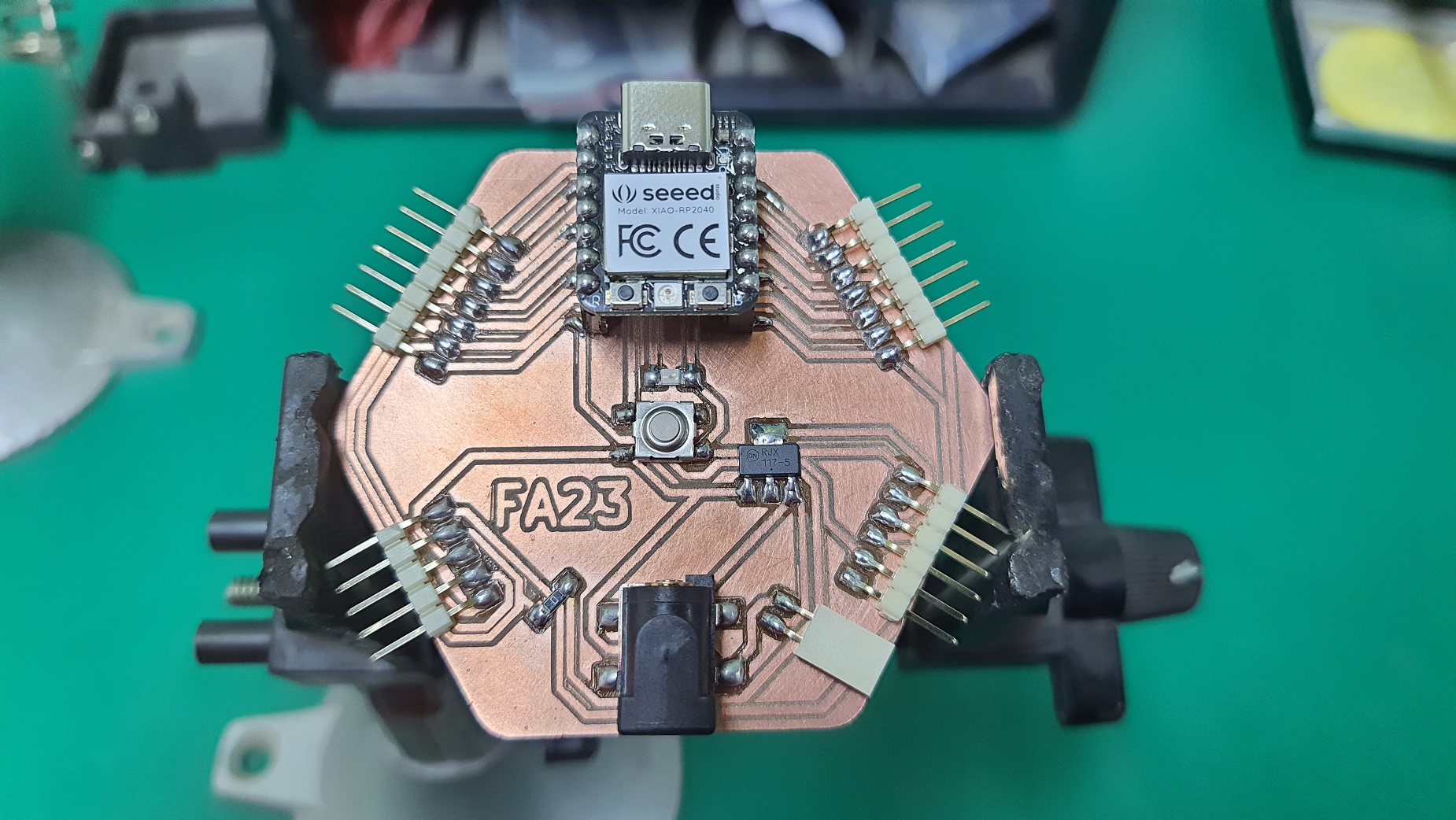

Then I start stuffing the PCB with the components into my PCB.

Then I testing PCB by write a simple code to check if it works.

Arduino C

#define led 26

#define btn 27

void setup() {

pinMode(btn, INPUT_PULLUP);

pinMode(led, OUTPUT);

}

void loop() {

if (digitalRead(btn) == LOW) {

for (int i = 0; i < 3; i++) {

digitalWrite(led, HIGH);

delay(1000);

digitalWrite(led, LOW);

delay(1000);

}

} else {

digitalWrite(led, LOW);

}

}