Week 16: Applications and Implications¶

What will it do? Who’s done what beforehand?¶

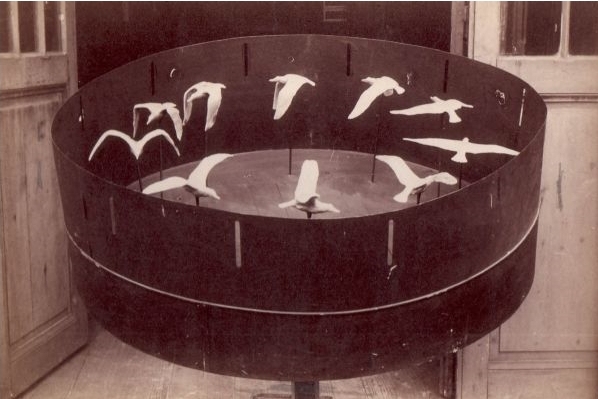

My final project will be a zoetrope. This kind of devices uses the persistence of vision and the phi phenomenon to animate still images placed on a rotating disc. These images can be seen, for example, through narrow slits:

My goal is to make some simple animation of 3D printed solids using the stroboscopic effect created by flashing LEDs.

During my research, I found few former Fabacademy students who made zoetropes: Juliana Henno and Alex Garcia made a 3D zoetrope that animates a deforming cube. Faisal Al Kilani animated a 3D sculpture based on a Fibonacci sequence and adjusted the rotation speed using Hall effect sensors and PID controlling. In 2022, the Waag Fablab made a zoetrope during the machine week.

Mat Collishaw made some large 3D printed animated sculptures that look really beautiful.

Akinoro Goto made an incredible animation of a ballet dancer. This one since to use a slightly different technique that doesn’t use a stroboscopic effect, but continuously animates a 2D shape inside a 3D print using a narrow beam of light.

What will you design? What parts and systems will be made? What processes will be used?¶

For this project, I will have to design:

| Part | Processes |

|---|---|

| Zoetrope itself | Design with Blender; 3D printed objects; maybe some parts could be CNC milled; if some 2D animation is added, laser cutter for cardboard/paper |

| Support for the zoetrope | Design with FreeCAD; Plywood cut with the CNC |

| PCB board capable of controlling LEDs and a DC motor, as well as reading a sensor (probably a Hall effect sensor) | PCB milling, soldering |

What materials and components will be used? Where will they come from? How much will they cost?¶

| Material/Component | Origin | Approximate Price [$] |

|---|---|---|

| ELECTRONICS | 37 | |

| SAMD11C | our lab | 2 |

| 5V power supply | our lab | 8 |

| LEDs | our lab | 15 |

| DC motor | our lab | 10 |

| motor driver | our lab | 2 |

| ZOETROPE | 24 | |

| 3D printed objects | our lab | 3 |

| paint | our lab | 3 |

| Plywood | our lab | 12 |

| Cardboard and paper | local shop | 3 |

| 20 x magnets | our lab | 3 |

| Support | 12 | |

| Plywood (same as for zeotrope) | - | |

| 2 x bearings | recycled from old printer | 2 |

| metal axis | recycled from old printer | 10 |

| TOTAL | 73 |

What questions need to be answered?¶

-

How to accurately measure time with the microcontroller?

-

What microcontroller to use?

-

How much power will the whole system need?

-

What sensor should I use?

How will it be evaluated?¶

-

The first achievement will be to make all the different parts of the system work: DC motor turning the zeotrope, sensor giving data to the MCU and LEDs flashing.

-

The next one will be to be able to see a smooth motion with the eyes, and then the camera.

-

The last one will be the esthetics of the zeotrope.

Make a schedule¶

| Task | Time allocation |

|---|---|

| 3D modeling for 3D prints | until 25.05 full time, and then until 05.06 |

| 3D printing | 26.05 - 05.06 |

| board design | 26.05 - 28.05 |

| board production | 29.05 - 01.06 |

| CAD design | 28.05 - 01.06 |

| CNC cutting | 29.05 - 05.06 |

| painting | 28.05 - 06.06 |

| assembling and programming | 01.06 - 09.06 |

| video and slide | 09.06 - 10.06 |