Computer-Controlled Machining

Assignments:

Group assignment:

⚡Complete your lab's safety training

⚡Test runout, alignment, fixturing, speeds, feeds, materials and toolpaths for your machine

⚡Document your work to the group work page and reflect on your individual page what you learned

Individual assignment:

⚡Make (design+mill+assemble) something big

Shopbot PRSalpha

A Big and (noisier) machine. here you can fabricate BIG things, I mean.. you have a work space of 144 x 60 cm. and this machine have been in touch with us in the FAB LAB CIDI during our CNC practices, the instructor (Silvia) show us how to use it, what do and do not have to do!

Steps to use:

- Air compressed valvule: This vavule is located besides the machine and you have to actioned it to activate the head of the machine

- Red Button and activation key: Those always have to be activated before you begin a job.

Once you do this, you can begin to ubicate your piece following this steps...

Always you have to take a look on this…

When you're going to start using a CNC machine of the Lab with this characteristic you HAVE TO USE

Hearing protection equipment:the exact amount of energy that have to recive to not burn this thing

Visual protective: designed to avoid damage by physical objects such as wood chips from injuring your eyes

Safety Gloves: for protection against grime, abrasion, cuts, and burns, also for transporting materials and stuff

Appropriate clothes: Use tight clothes and closed shoes for protection (weir things can happened haha)

Also you don't have to work with this machine if you are tired.

VCarve is a design and CNC machining software that allows you to create projects with engraving or milling machines, you can import images, draw shapes, edit texts, apply effects and generate tool paths, it is moderately easy to use, has an intuitive interface.

For the individual task I decided to make some geometric benches with pointed legs, the bench would be made by inserts (not joints with screws or nails). For this purpose, there should be fixtures that allow the part to be fixed correctly.

- Thanks to VCarve, which has an option to give small terminations to the subtraction performed (as you can see in the video) it was easy to unembed.

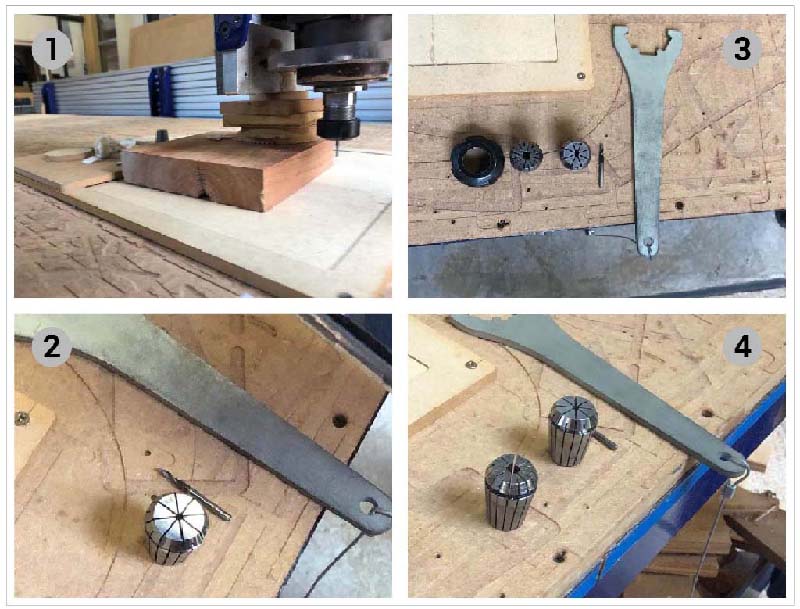

- Another interesting point to highlight is the milling bit choosed (which has to do with the chosen material), it is 6.35

- The material used corresponded to those available in the CIDI workshop, I chose the 18mm Plywood

- Steps: 4 passes with the same mill, 6.35

- For all the work the same cutter was used, both for internal and external cuts.

- In the profile Toolpath were: As Cutting Depth it START at 0 mm and the CUT DEEP 20 mm

- Also cut direction where OUTSIDE/ RIGHT and CONVENTIONAL

- As Kerf I can mencionate the 20.5 tolerance for joints

Problems: For some reason the worksheet generated me with strange distances and when I cut with the Shopbot, the machine went to the bottom and bounced

Solutions: It turns out that from VCarve there was also another option to change the size of the worksheet. The challenging part was to find the pieces of wood of the right thickness, being that in one of the cuts (the one on the seat) it was necessary to indicate that the cut should be made inside and not outside, this caused that the piece is not fully fitted, but it works the same.