Week 15. WildCard Week

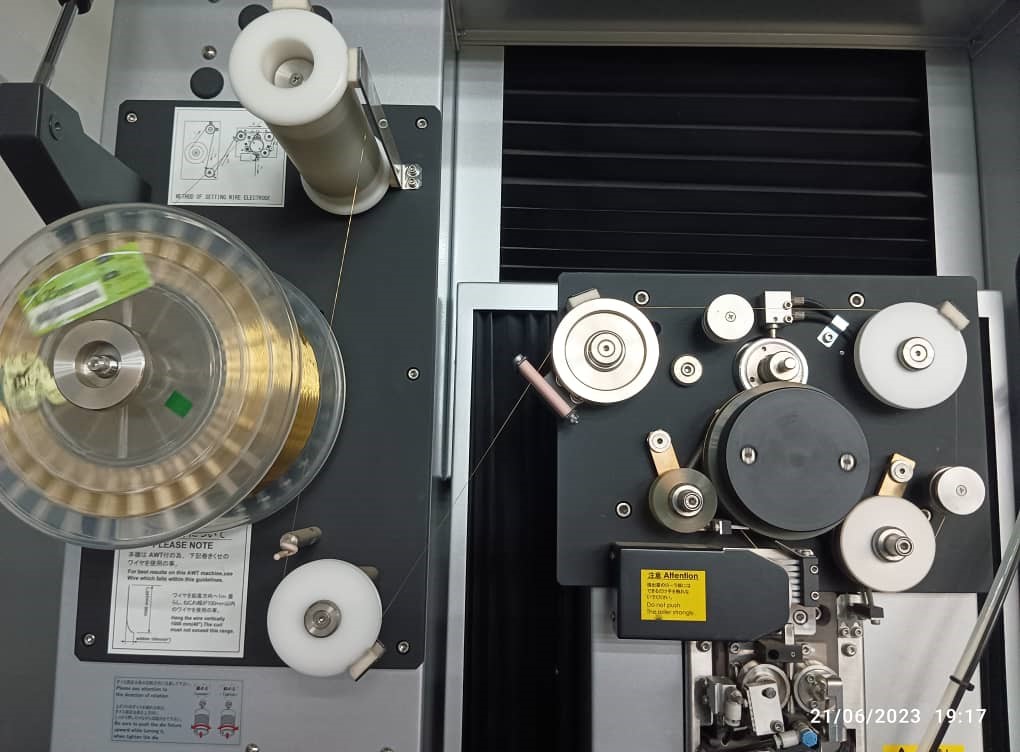

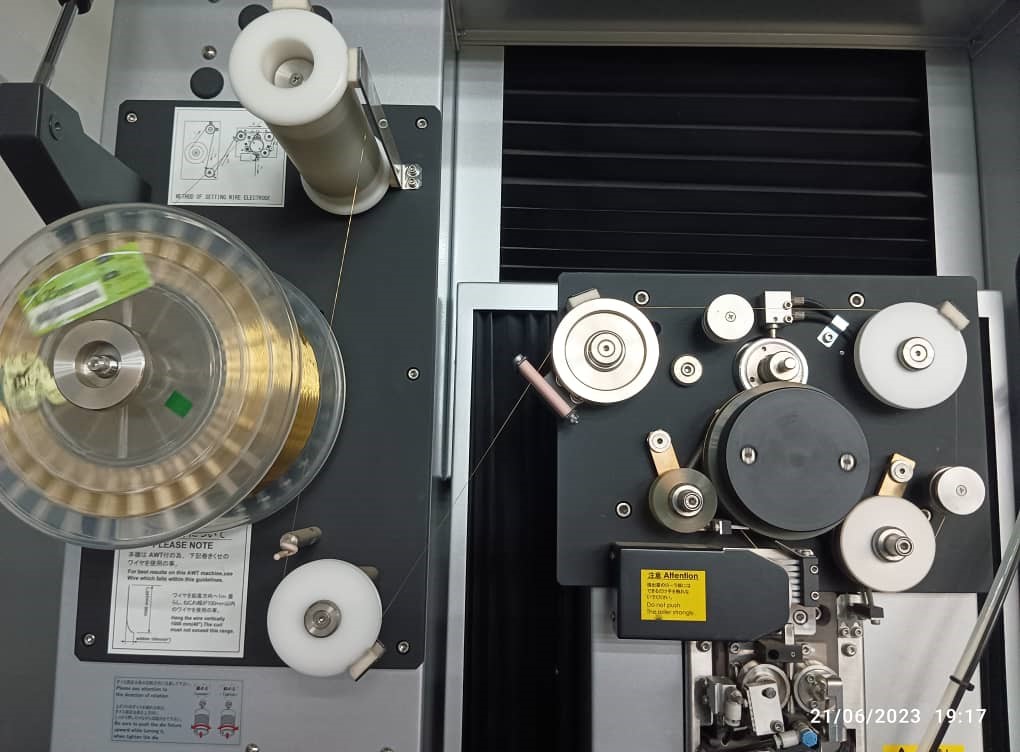

Wire EDM VL400Q

For wildcard week I am going to operation of wire EDM(Electric Discharge Machine) in our lab with the help of Yeshi Wangmo.

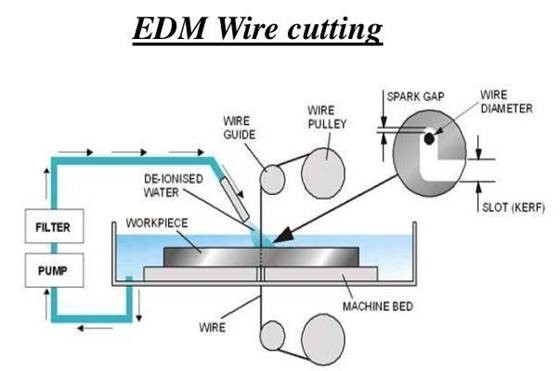

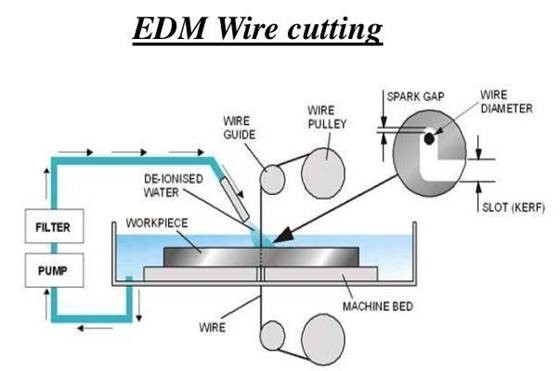

Wire EDM (Electric Discharge Machine)

Wire EDM machining is an electrothermal production process that uses electric discharges to remove material from a workpiece.

Wire electrical discharge machining is a non-contact subtractive manufacturing process that uses an electrically charged thin wire with a dielectric fluid to cut a metal part into different shapes.

Wire EDM Parts

Upper wire guide assembly

Lower wire guide assembly

Auto wire threading

Flushing unit

Control sections

Upper wire guide assembly

Lower wire guide assembly

Auto wire threading

Flushing unit

Control sections

Machine Work Flow

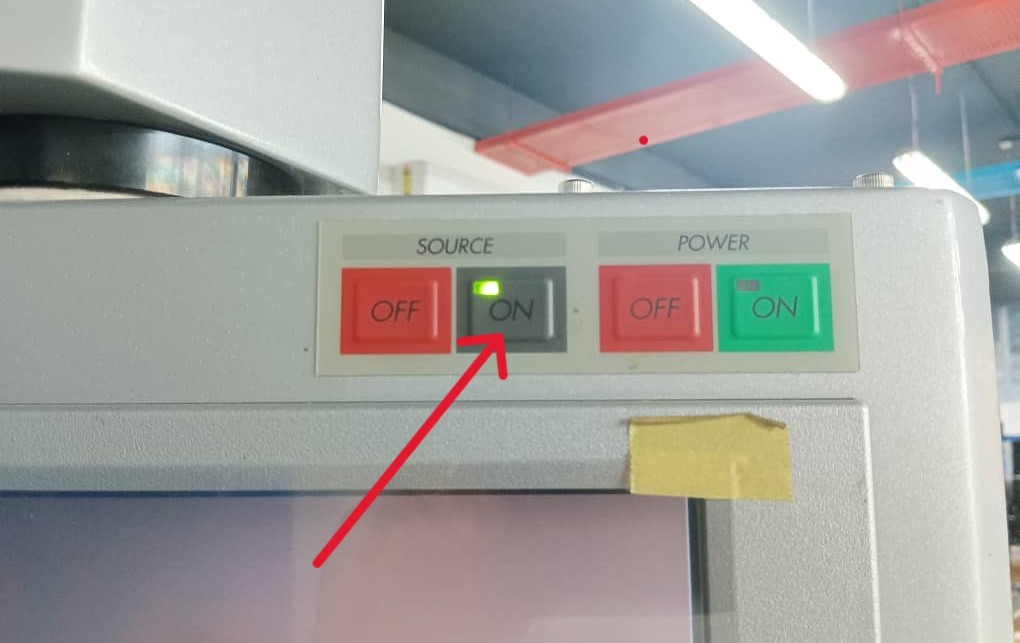

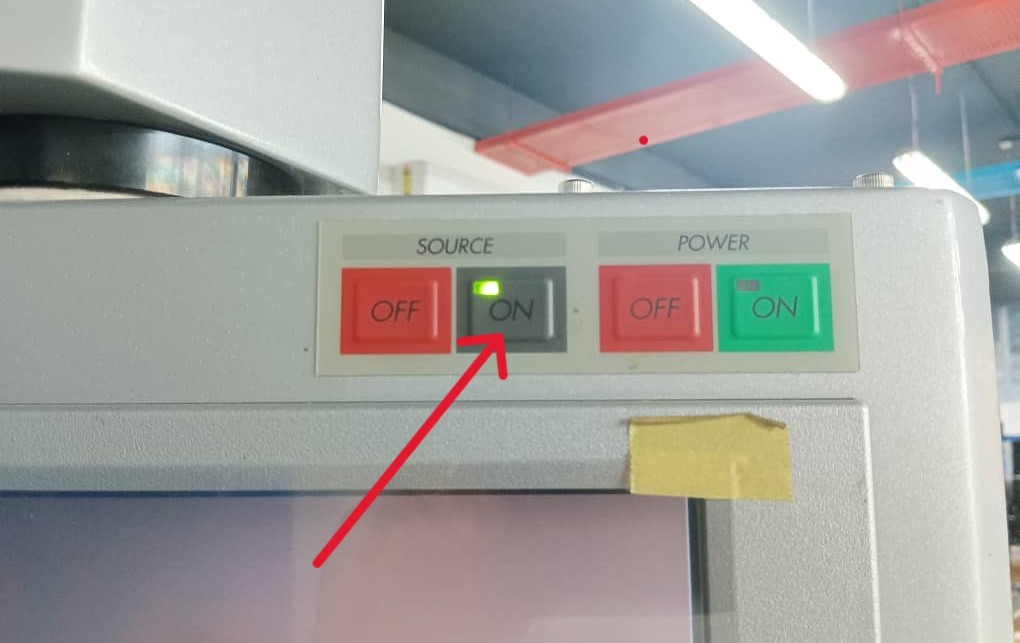

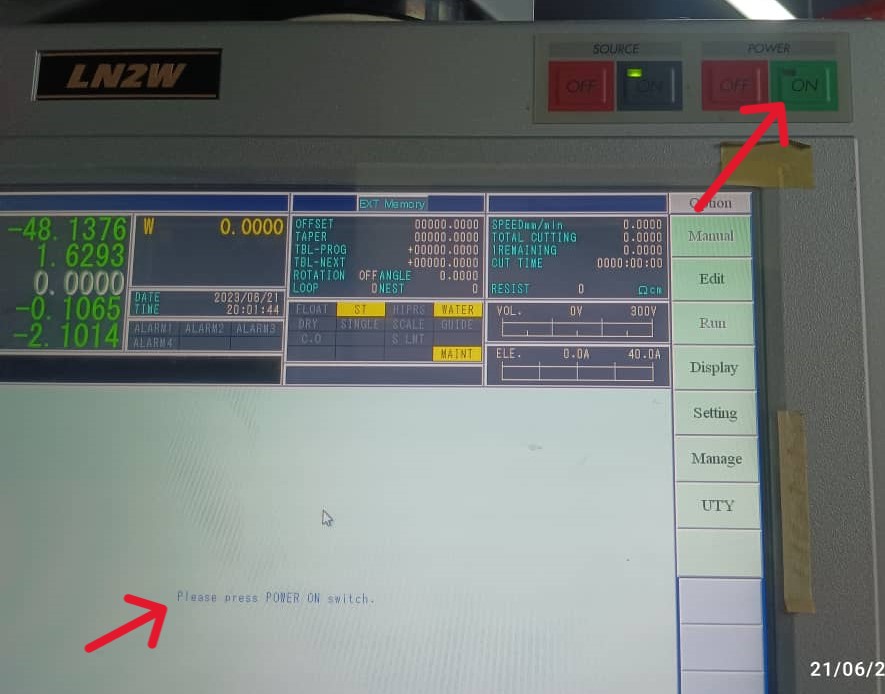

Turn on the MCB from the machine and Turn source ON

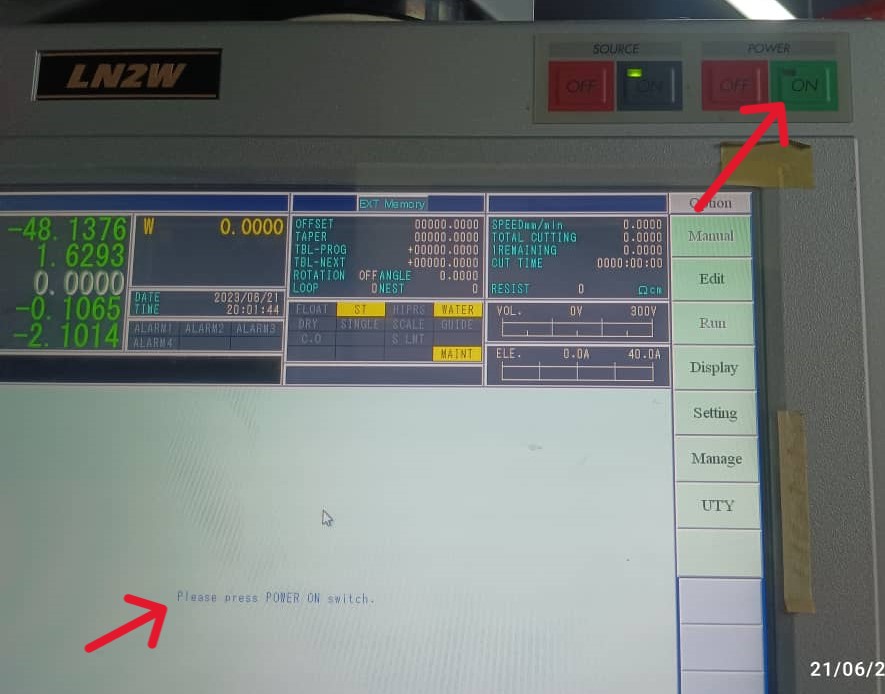

After turning source it will display a message on screen to turn on the power

After turning source it will display a message on screen to turn on the power

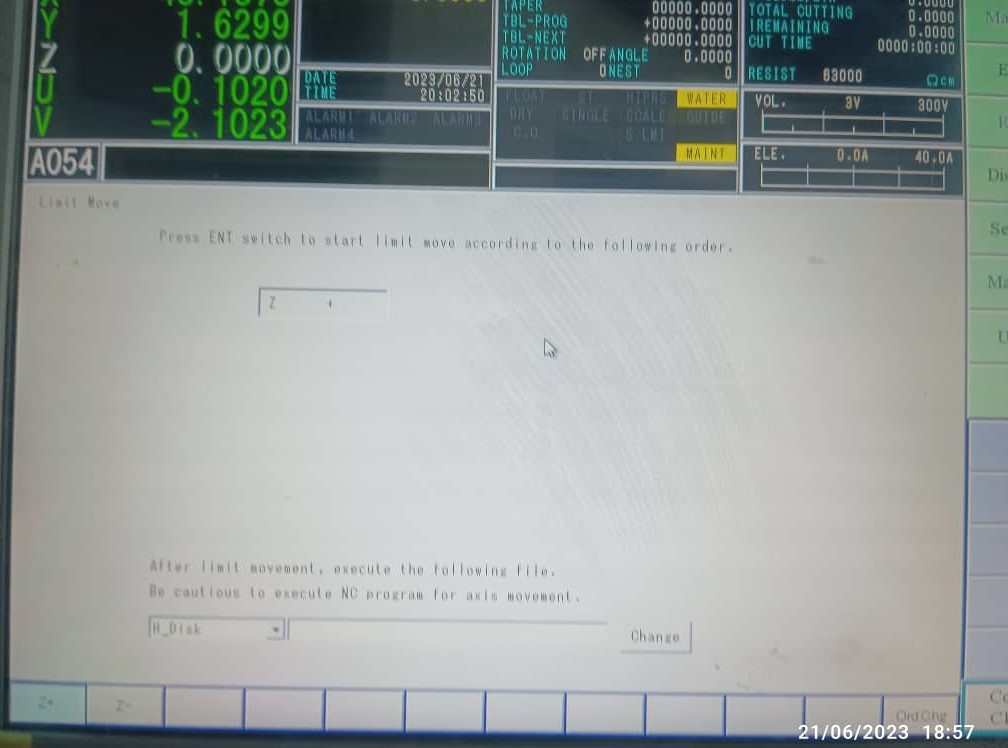

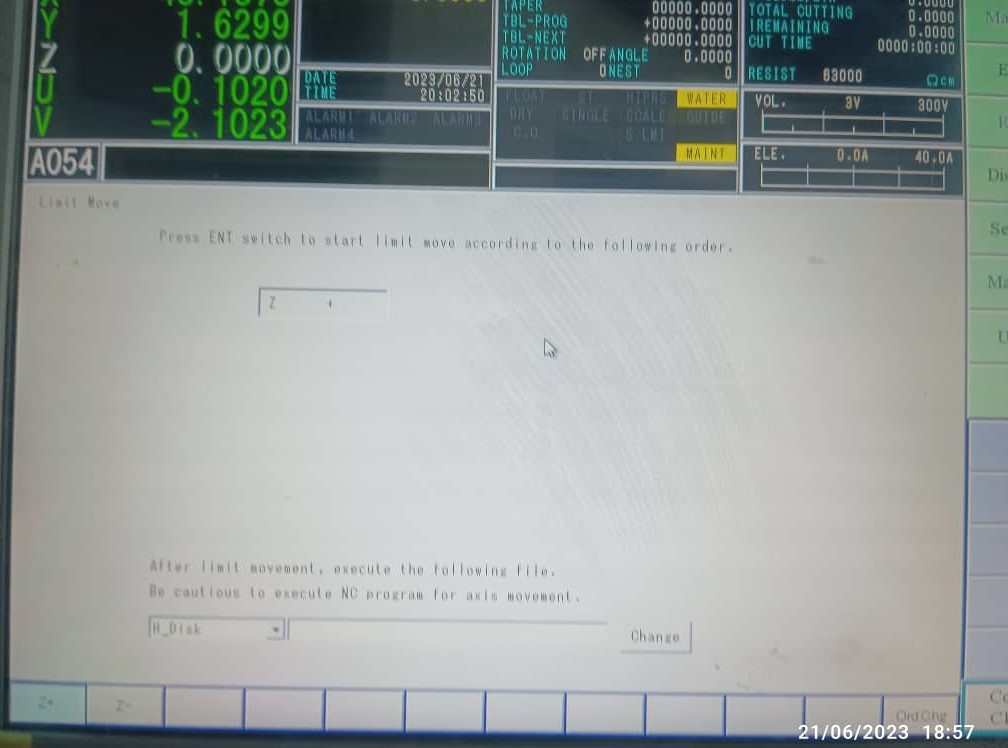

Move your Z axis to its upper limit by pressing Enter.

Move your Z axis to its upper limit by pressing Enter.

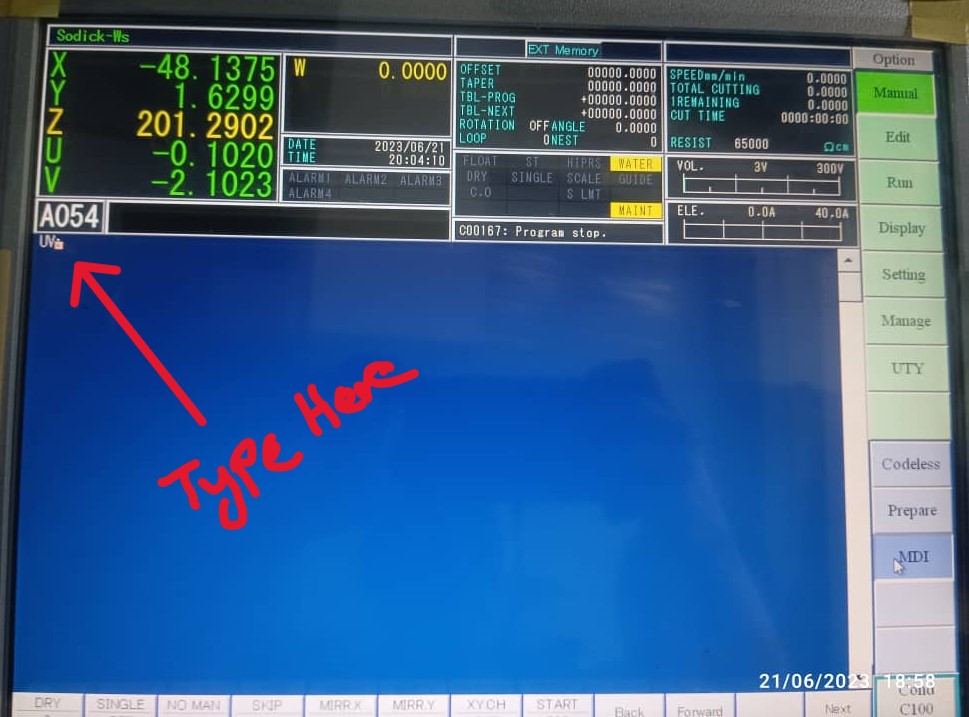

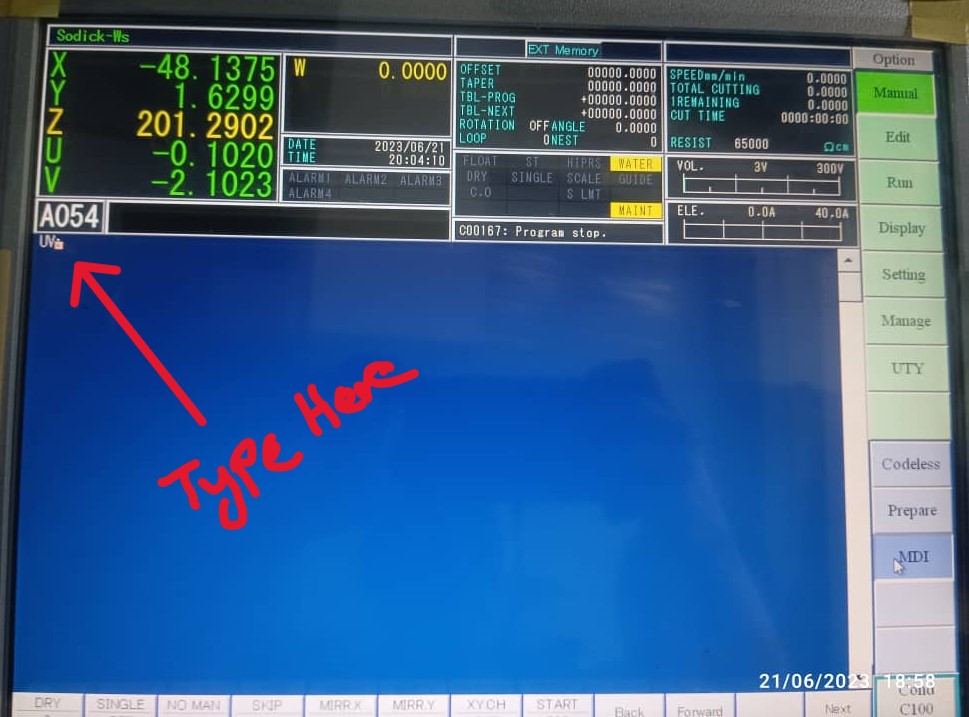

After that, Go to Manual >> MDI >> and Enter (This is to Move UV 00) and to set UV coordinate zero.

After that, Go to Manual >> MDI >> and Enter (This is to Move UV 00) and to set UV coordinate zero.

Type "UV" and Press enter

After this make sure to check the Air pressure (It should be minimum 4-5bar) as given below.

Type "UV" and Press enter

After this make sure to check the Air pressure (It should be minimum 4-5bar) as given below.

Now i started to place my job piece on the work table with the clamped.

Now i started to place my job piece on the work table with the clamped.

Now use the remote to move the machine to XYZ and Lock the UV

Now use the remote to move the machine to XYZ and Lock the UV

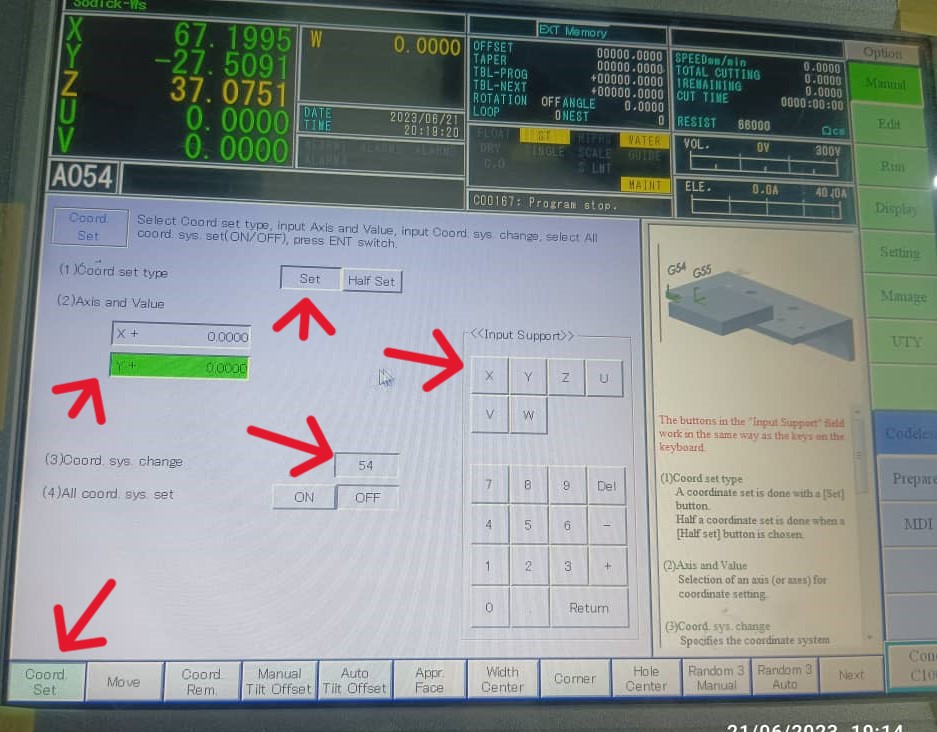

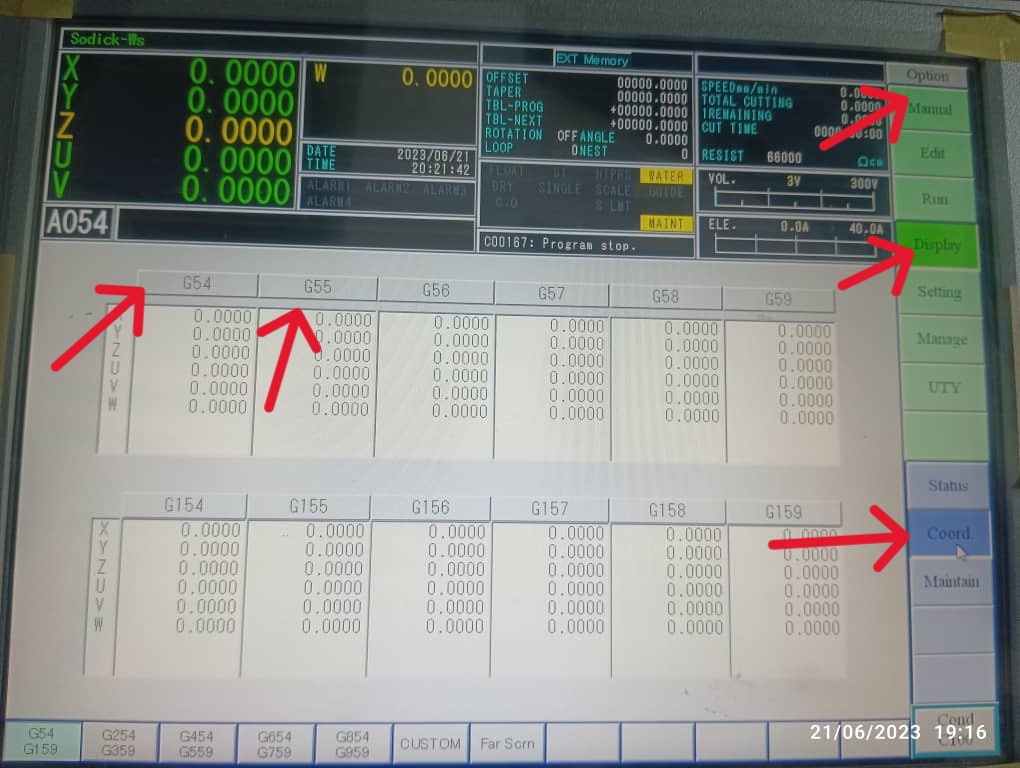

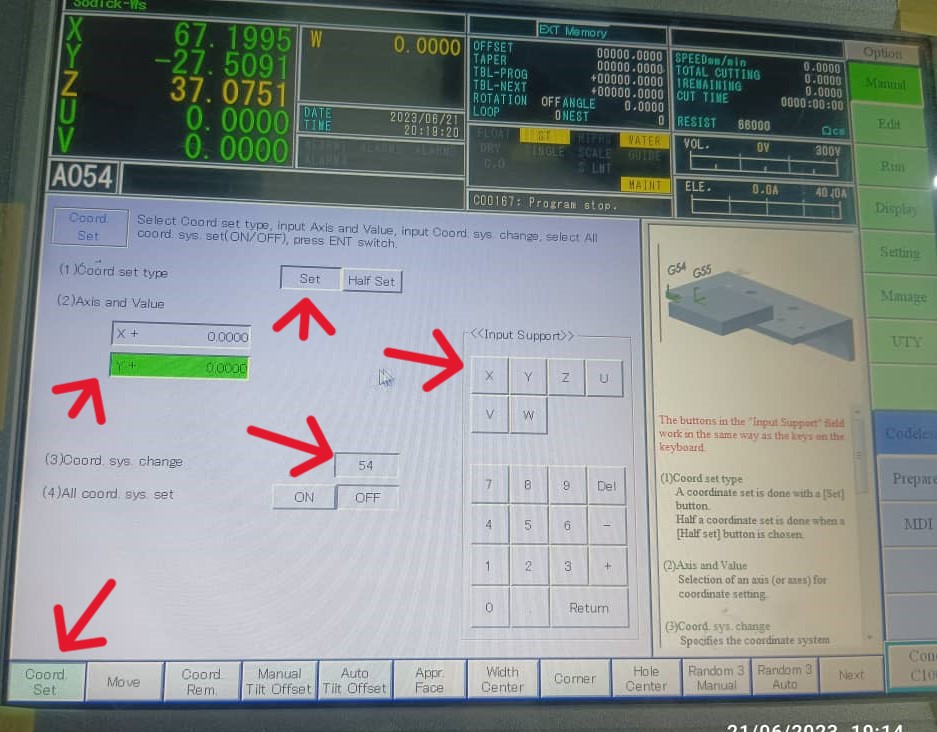

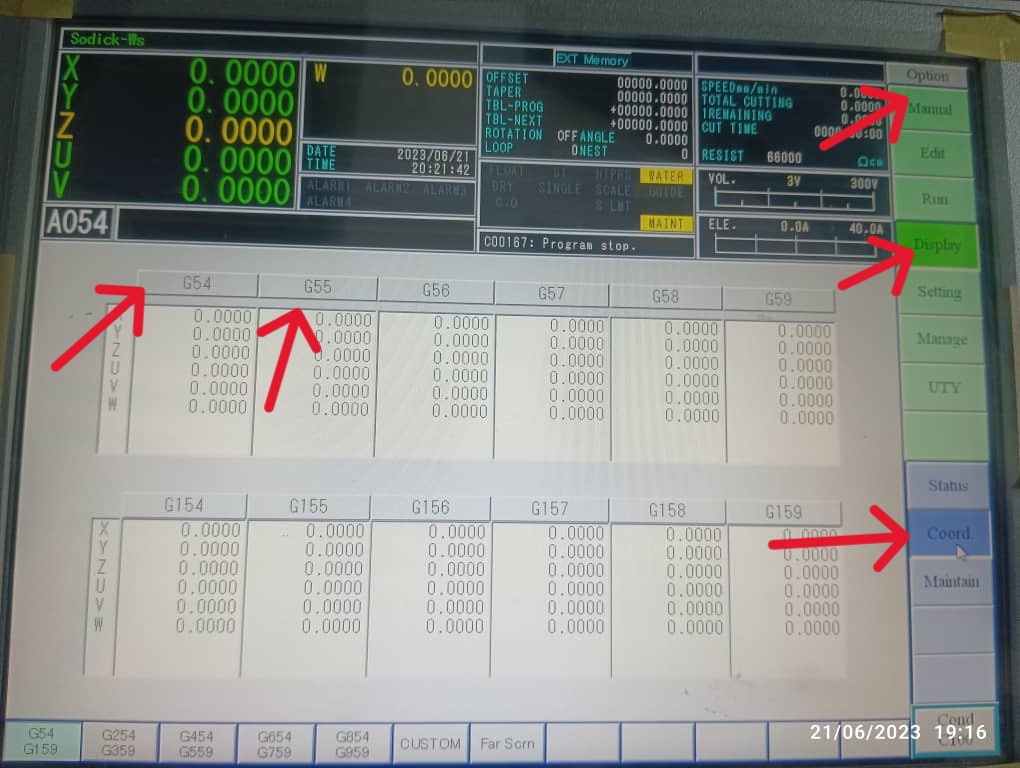

Coordinate setting

To set the machine XY, move the the XY close to the work piece and make sure to keep it 1 0r 2 mm of space and set the XY to Zero.

While setting XY, make sure not to touch the wire to the workpiece.

Go to Manual >> Codeless >> Click Coord set >> select XY.

And enter the coordinate that is going to be used. In my case I have used 54 & 55 and hit Enter from the keyboard.

Go to Manual >> Codeless >> Click Coord set >> select XY.

And enter the coordinate that is going to be used. In my case I have used 54 & 55 and hit Enter from the keyboard.

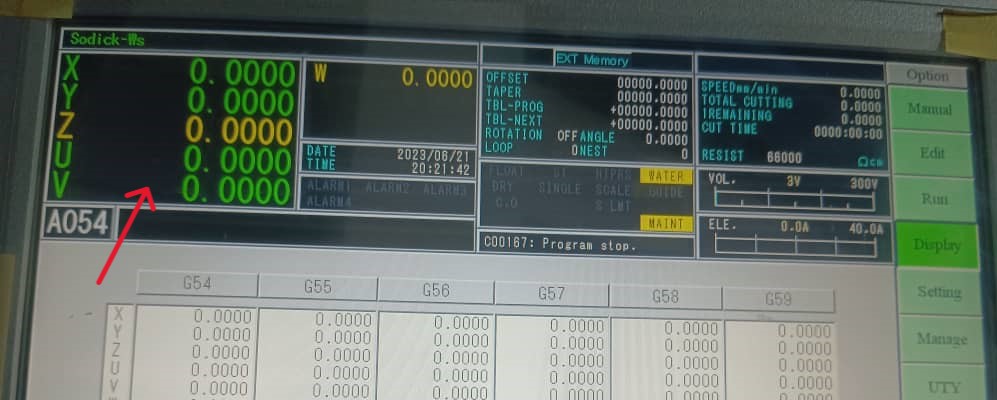

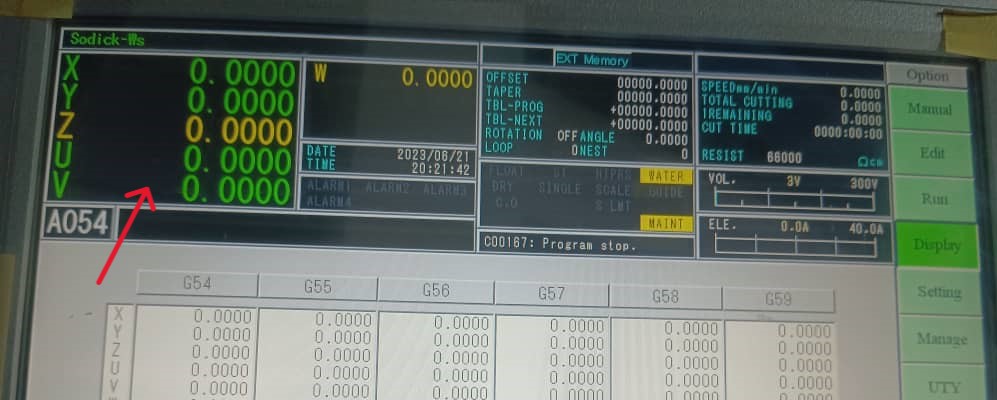

After setting all the XYZ to zero i have check the coordinate by going to Manual >> Coord >> Display.

After your workpiece is set to 0 coordinate,close the front cover.

After your workpiece is set to 0 coordinate,close the front cover.

Import the Design File

File >> Open Uty >> Drage the required file to Heart NC.

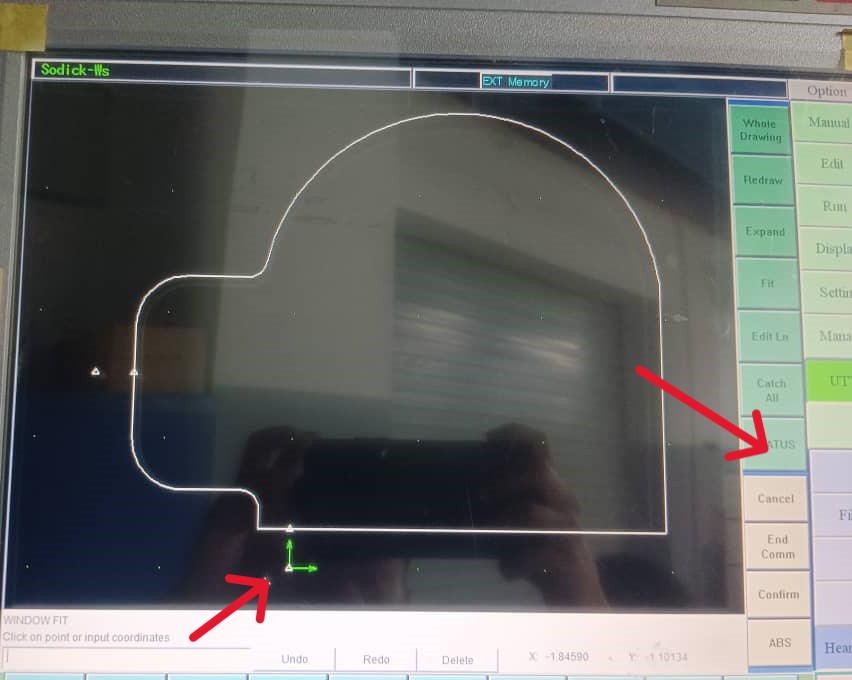

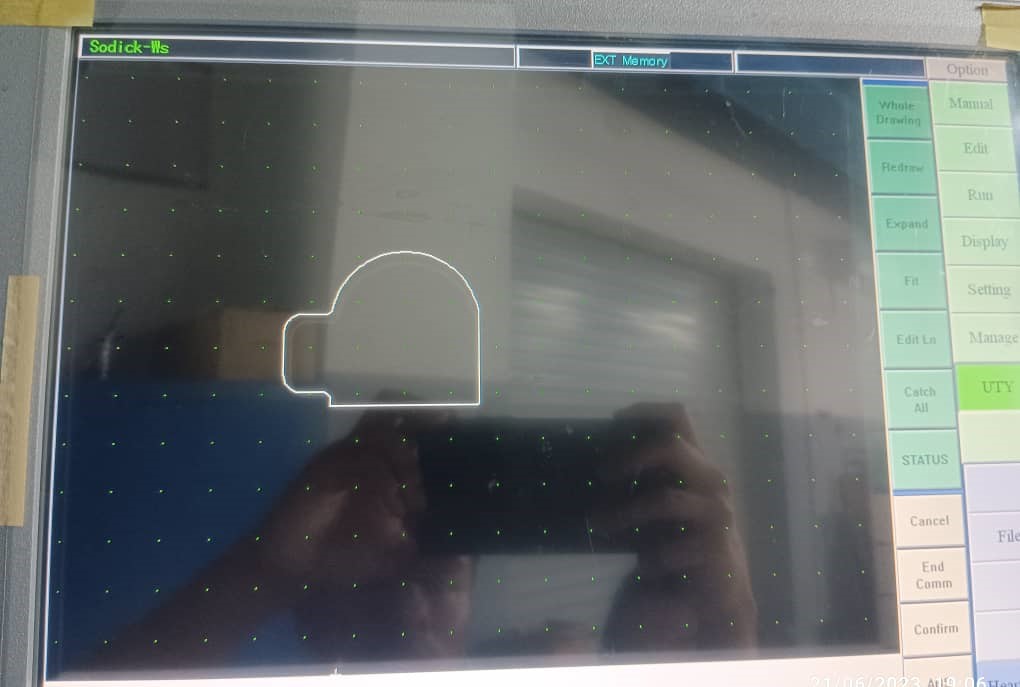

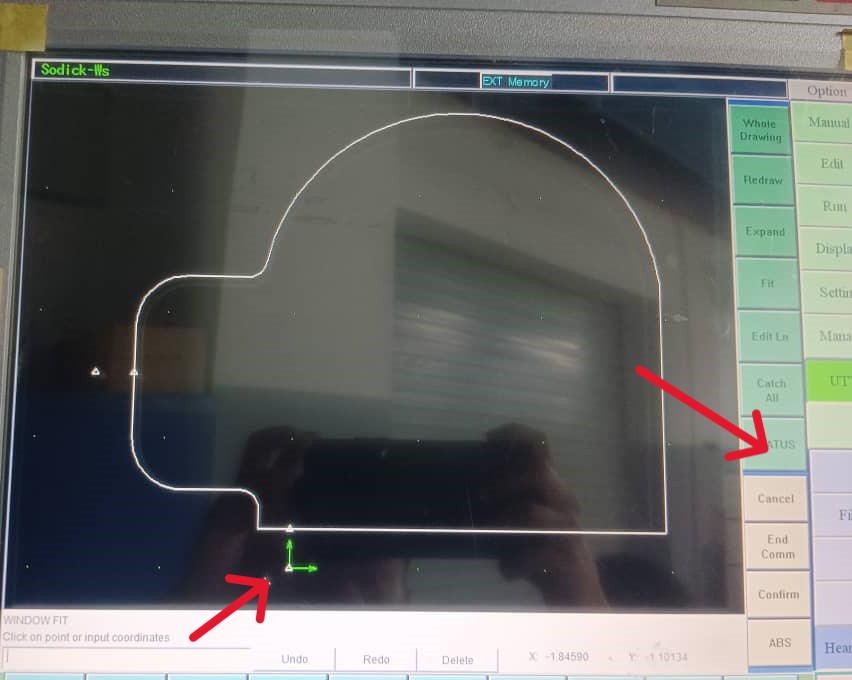

The drawing gets loaded in the screen.

The drawing gets loaded in the screen.

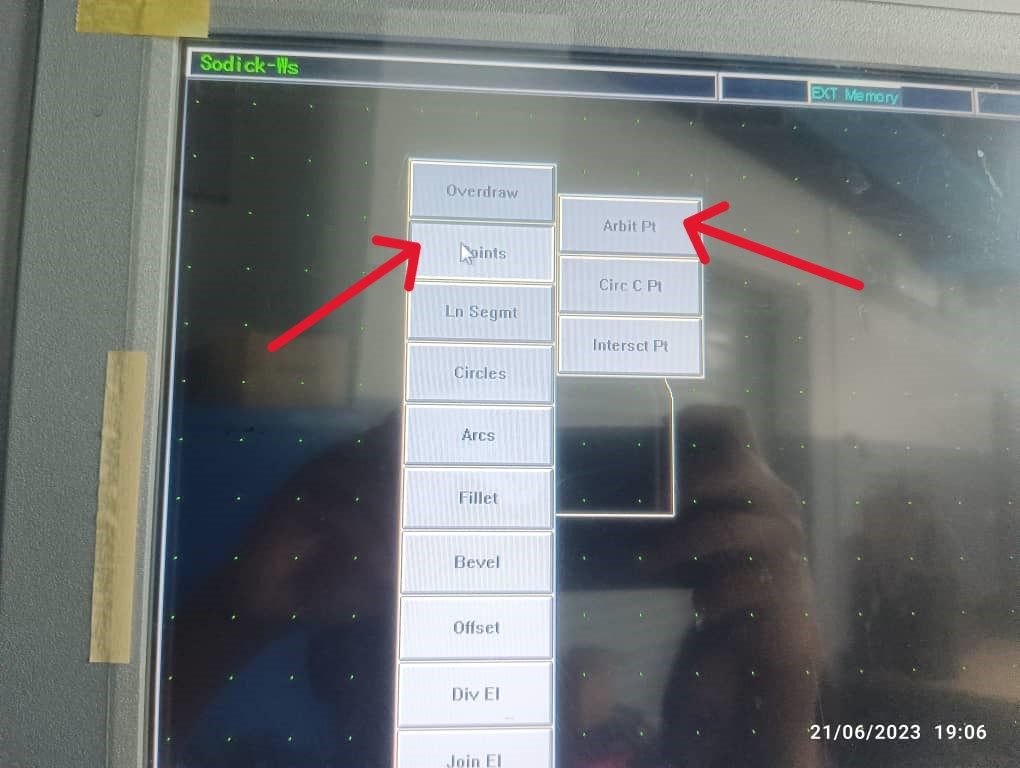

Now I need to set the orgin. To do that Go to Drawing lines >> Points >> Arbit Points.

Now I need to set the orgin. To do that Go to Drawing lines >> Points >> Arbit Points.

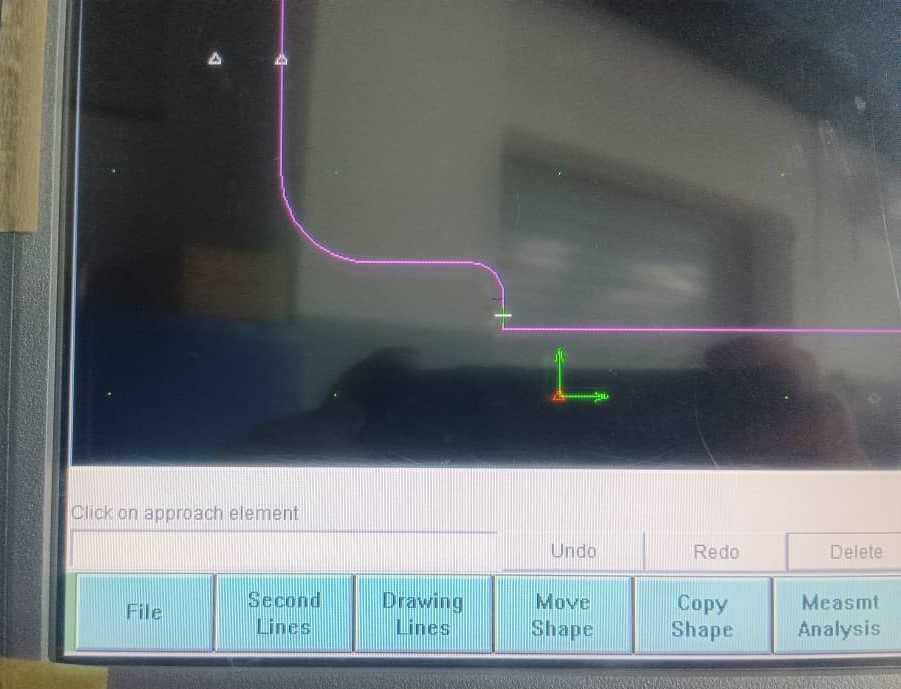

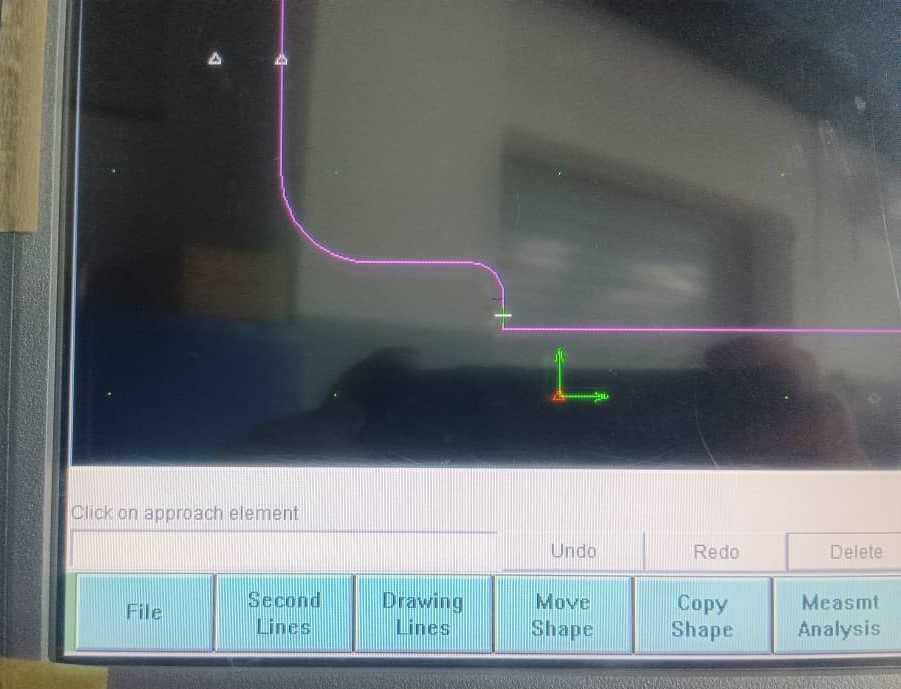

To set origin go to status >> set origin >> click on the point. I placed the points where I want let the wire approach.

To set origin go to status >> set origin >> click on the point. I placed the points where I want let the wire approach.

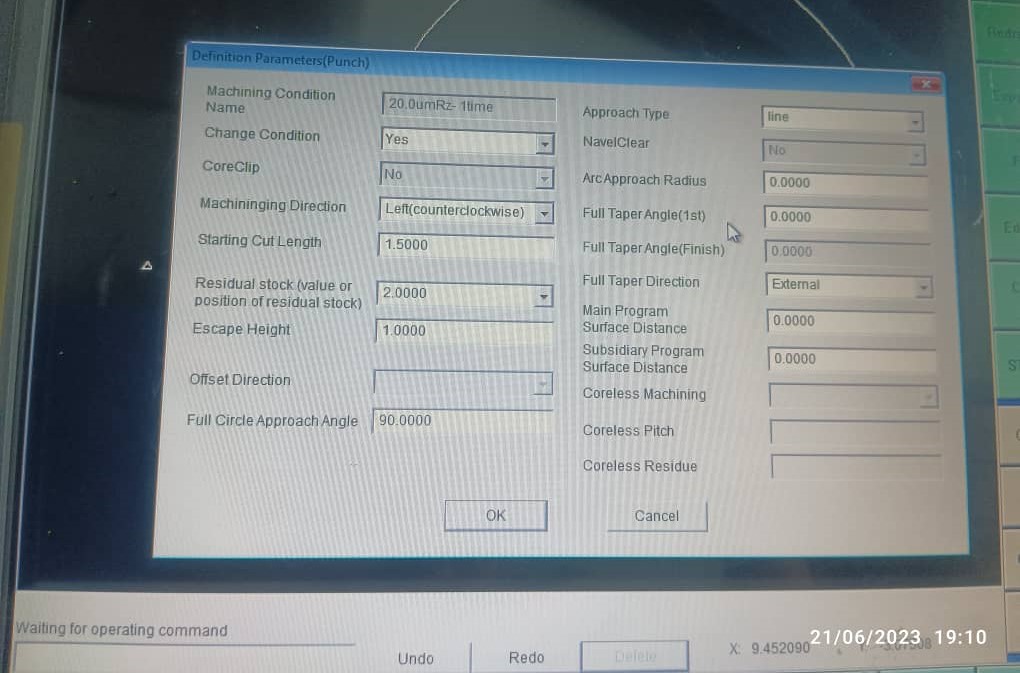

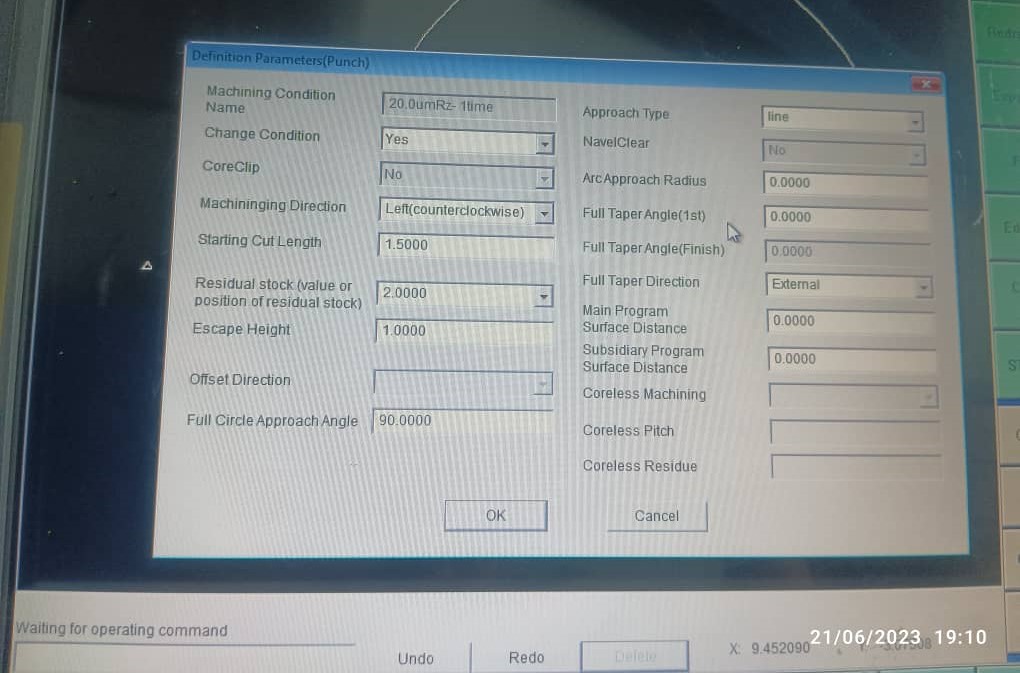

To select the type of cutting got to >> wire cut defs. >> select the punch cut(I will do punch cut).

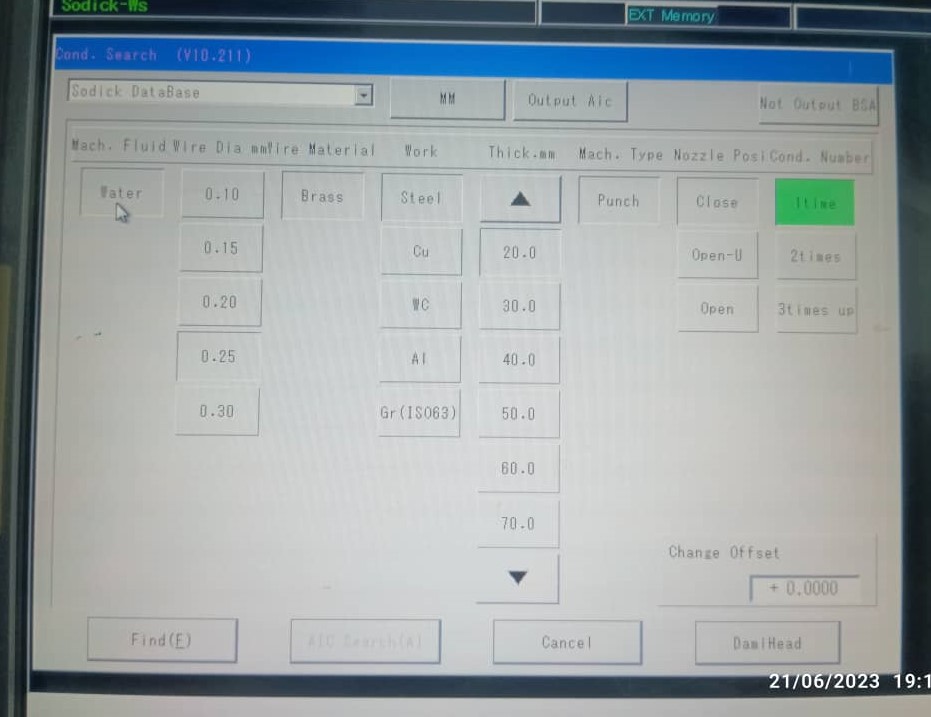

window pop up to set the parameters here

To select the type of cutting got to >> wire cut defs. >> select the punch cut(I will do punch cut).

window pop up to set the parameters here

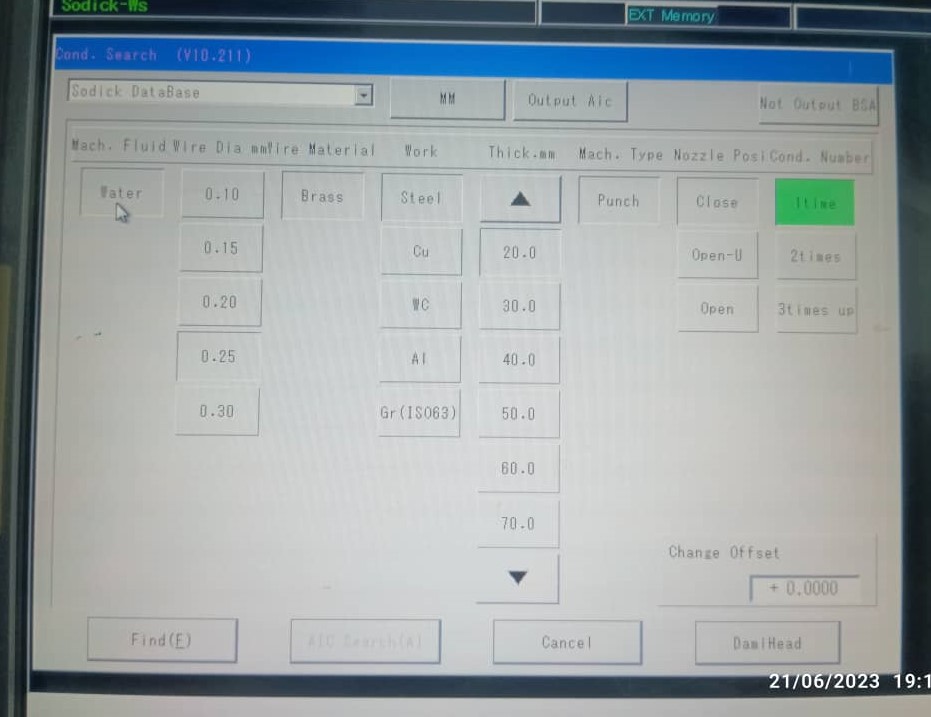

after pressing OK on the window pop up to set parameters as shown below. After setting parameters click on find F.

after pressing OK on the window pop up to set parameters as shown below. After setting parameters click on find F.

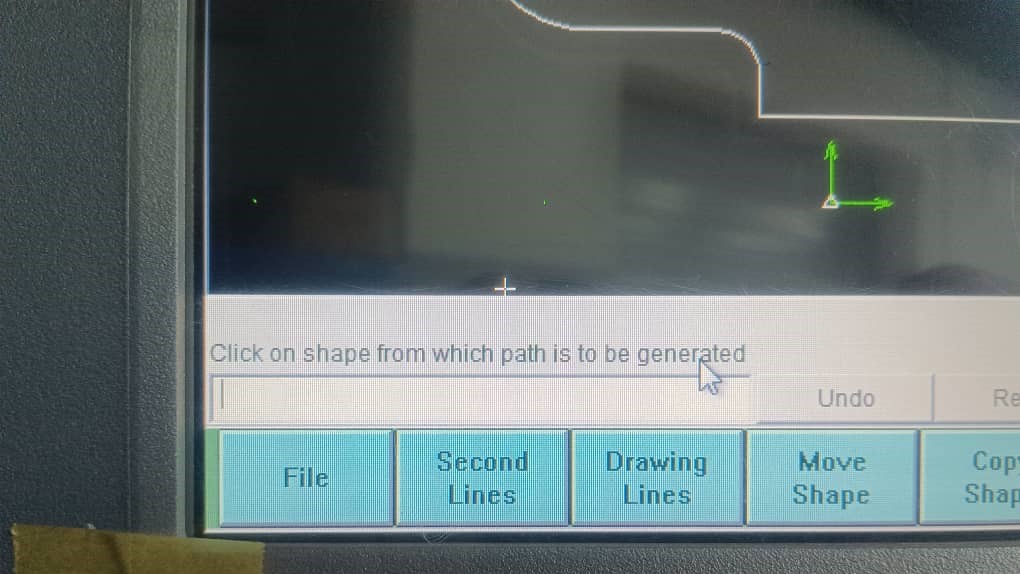

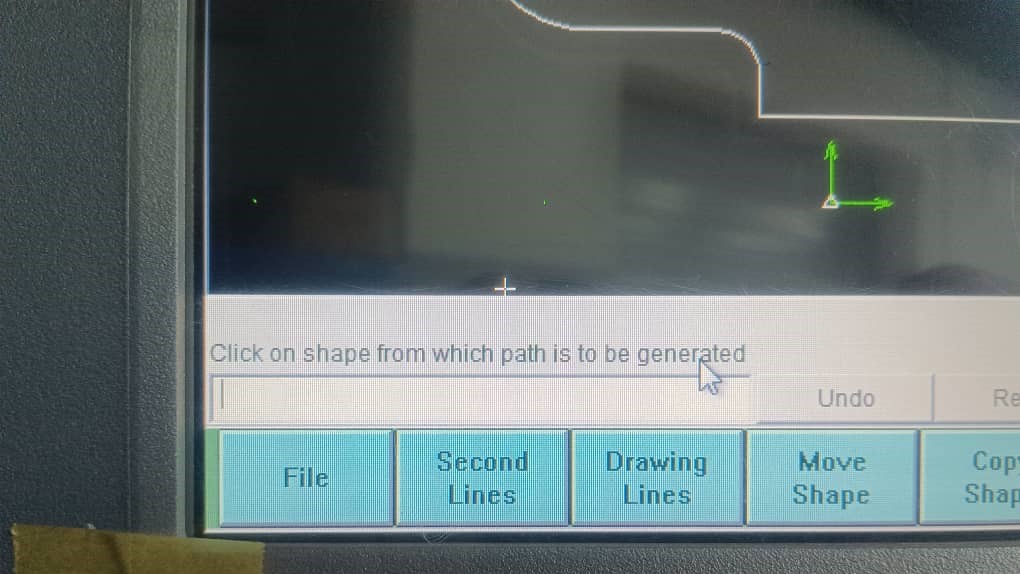

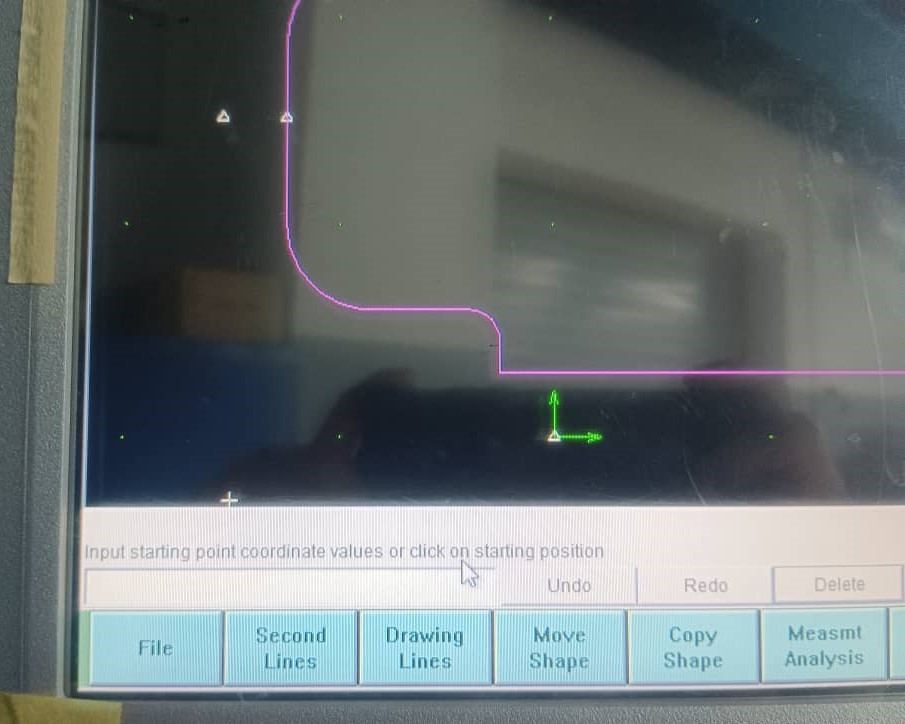

The message will be displayed asking to click on shape.

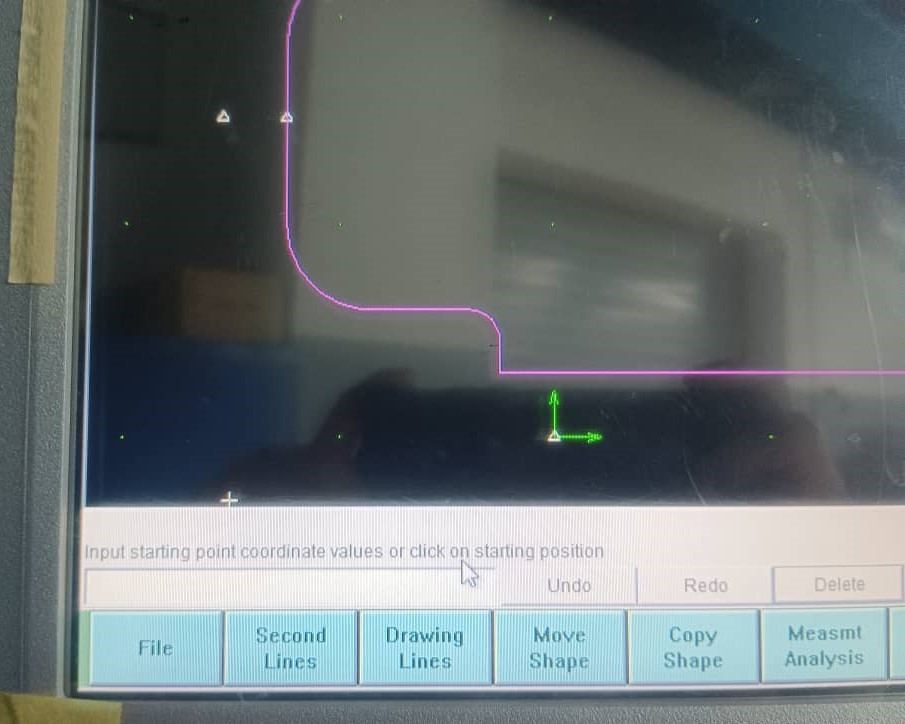

WHen clicking on shape the message displays saying to click on starting position.

The message will be displayed asking to click on shape.

WHen clicking on shape the message displays saying to click on starting position.

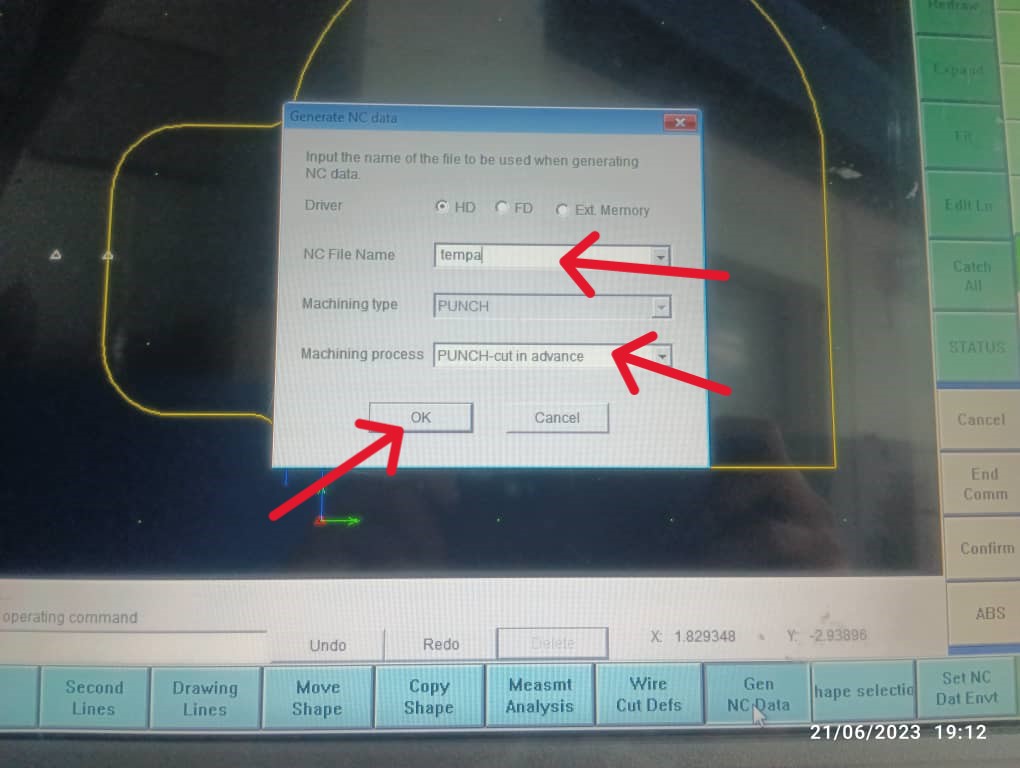

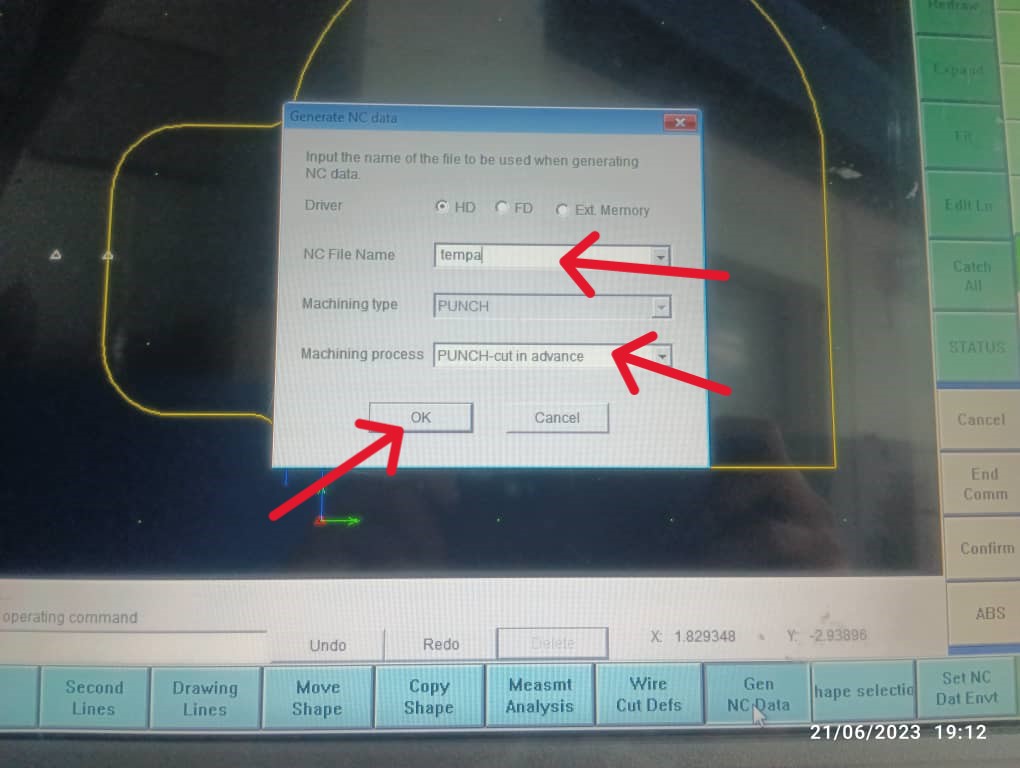

o to GEN NC data option form bottom option and rename the file and select the select Punch cut in advance. Hit OK

o to GEN NC data option form bottom option and rename the file and select the select Punch cut in advance. Hit OK

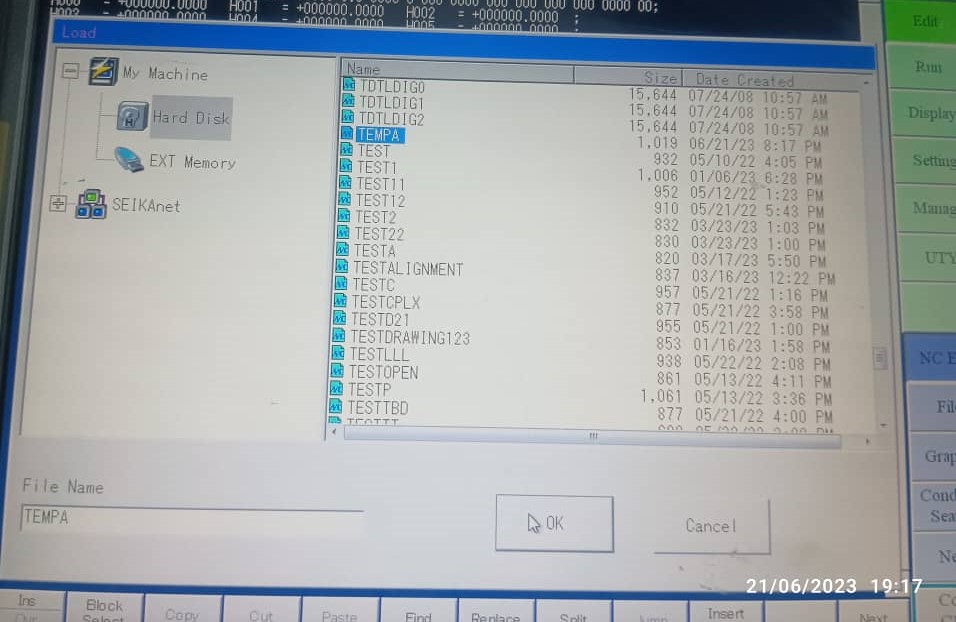

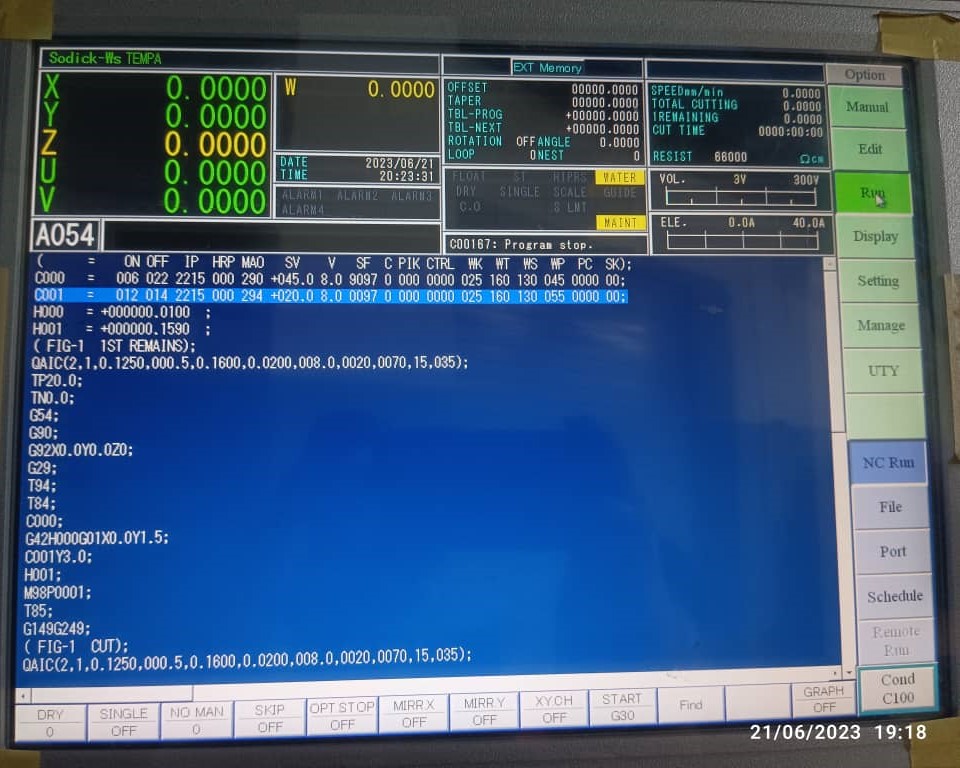

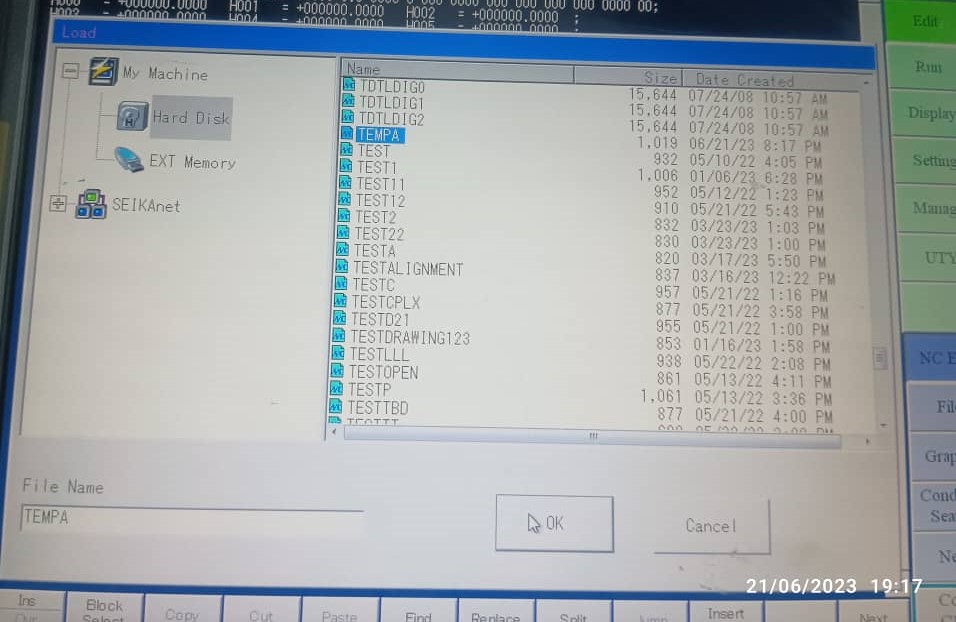

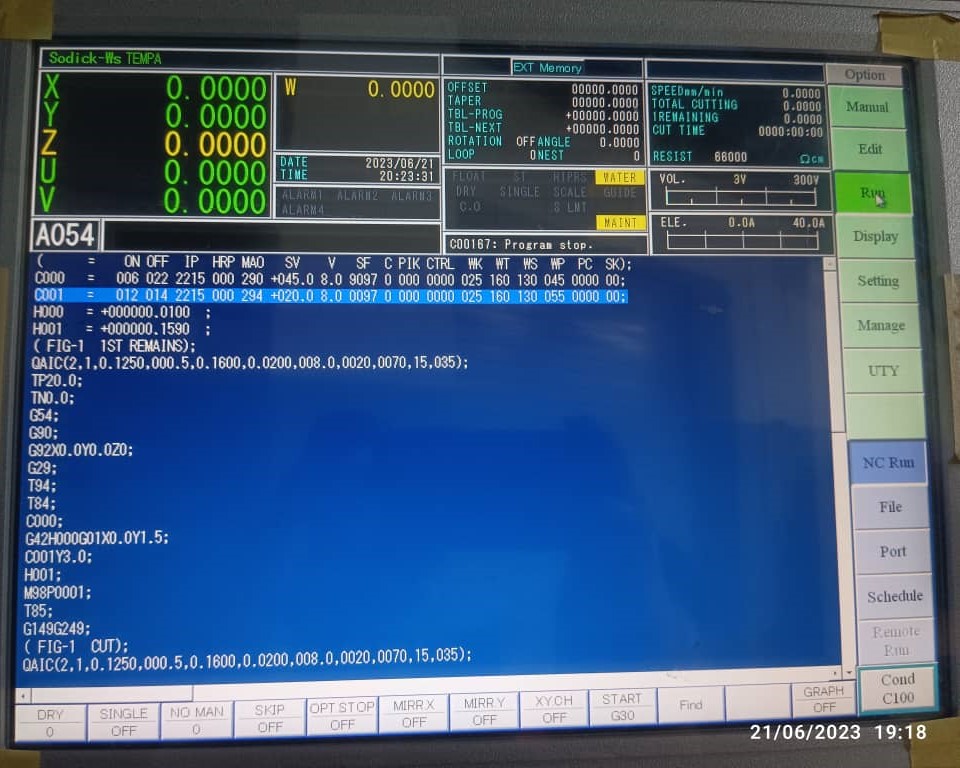

Go to Edit >> load >> select the file. I kept everything as it is.

Go to Edit >> load >> select the file. I kept everything as it is.

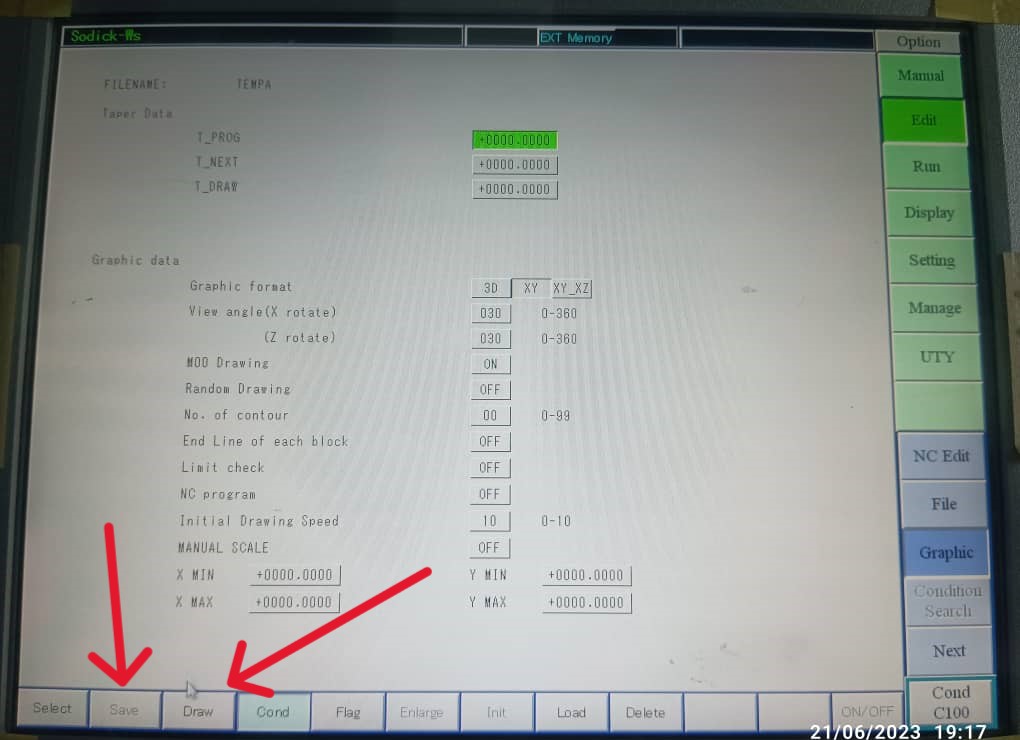

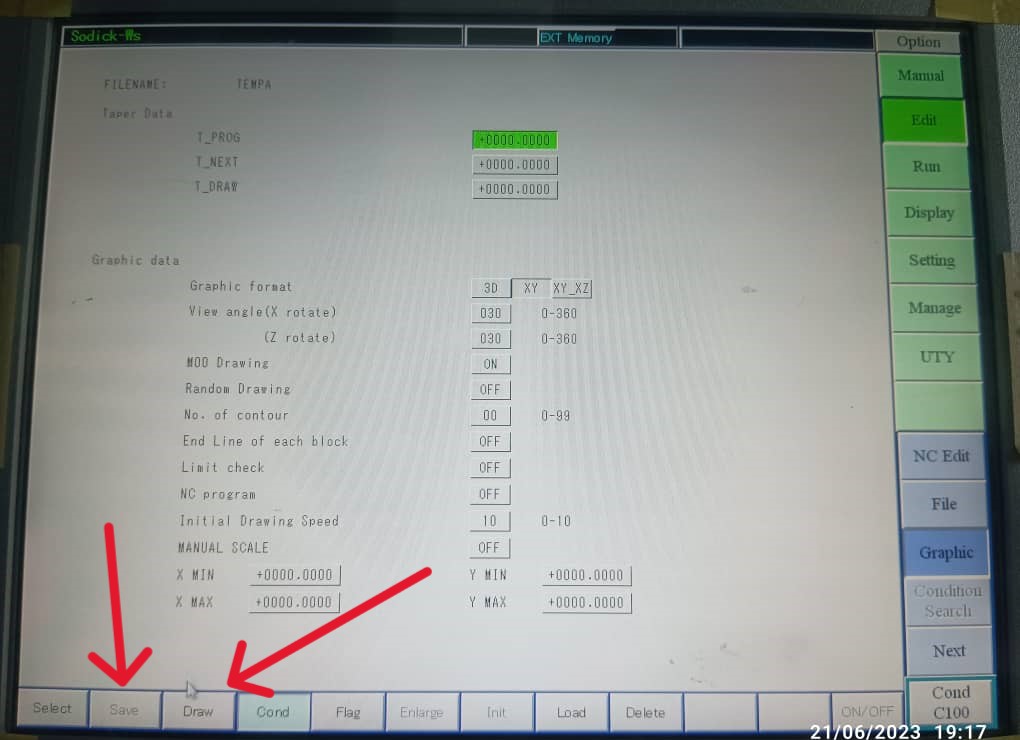

click on Graphics >> from the bottom row options click on >> Draw >> Save.

click on Graphics >> from the bottom row options click on >> Draw >> Save.

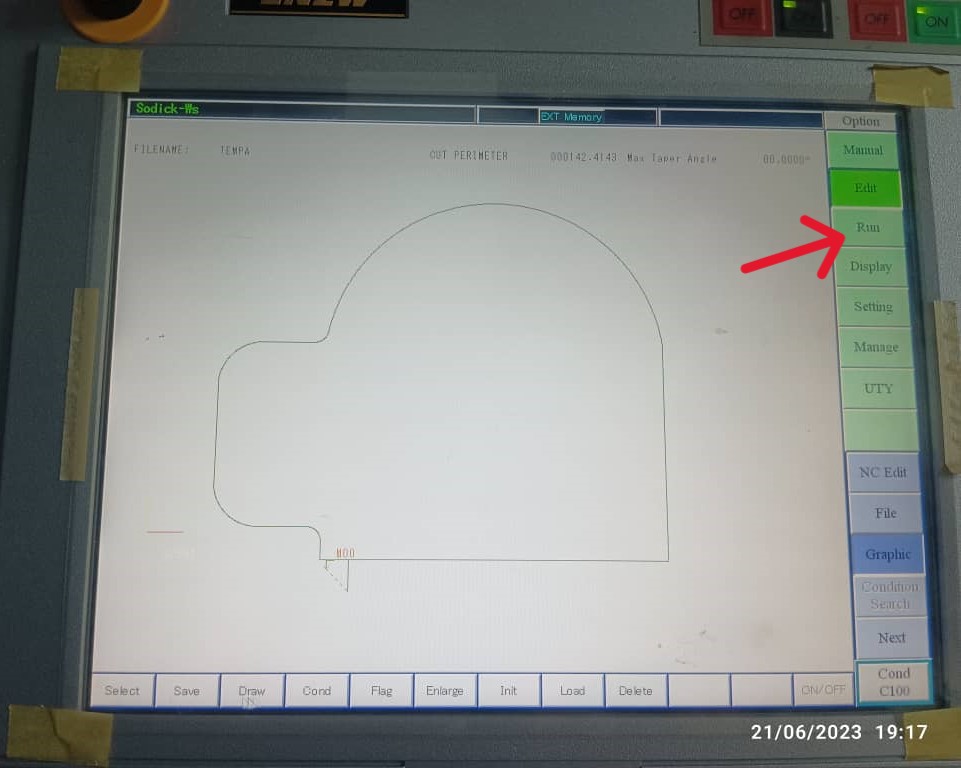

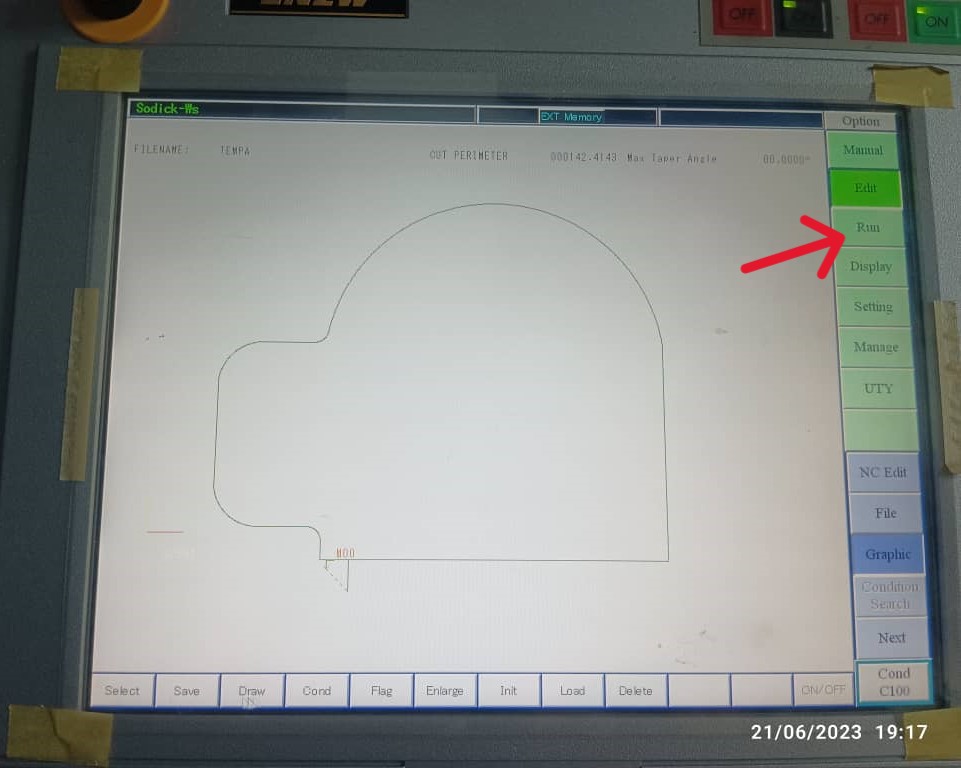

The drawing apears and click on save and Run.

The drawing apears and click on save and Run.

Turn on the graphic if it is off.

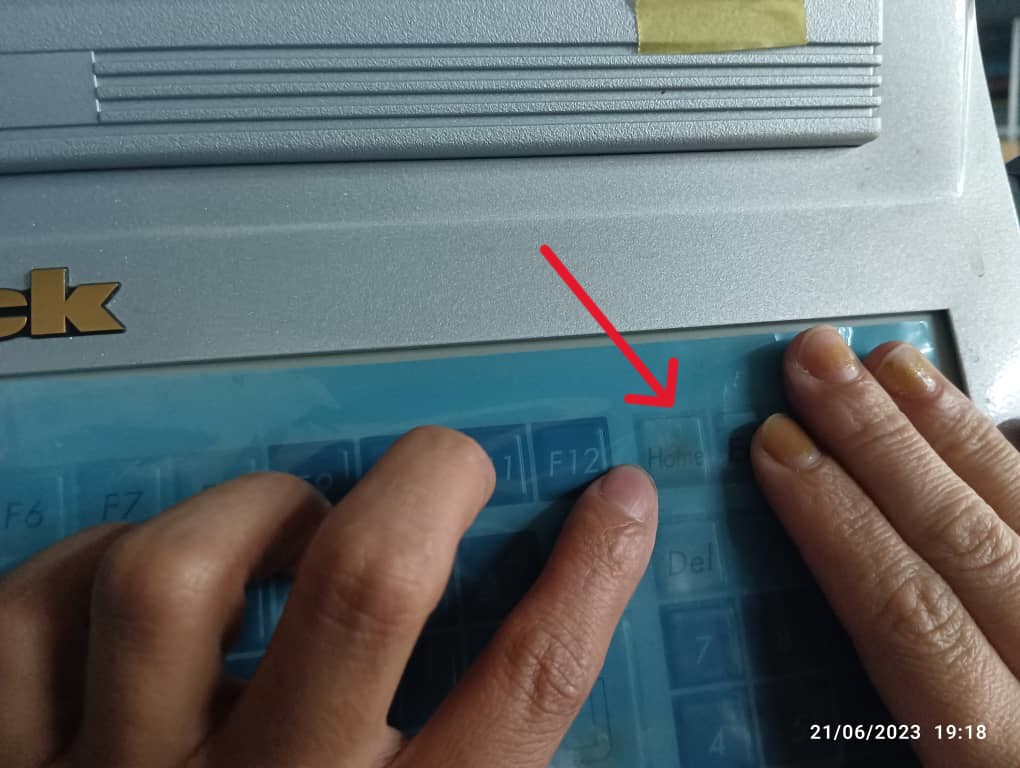

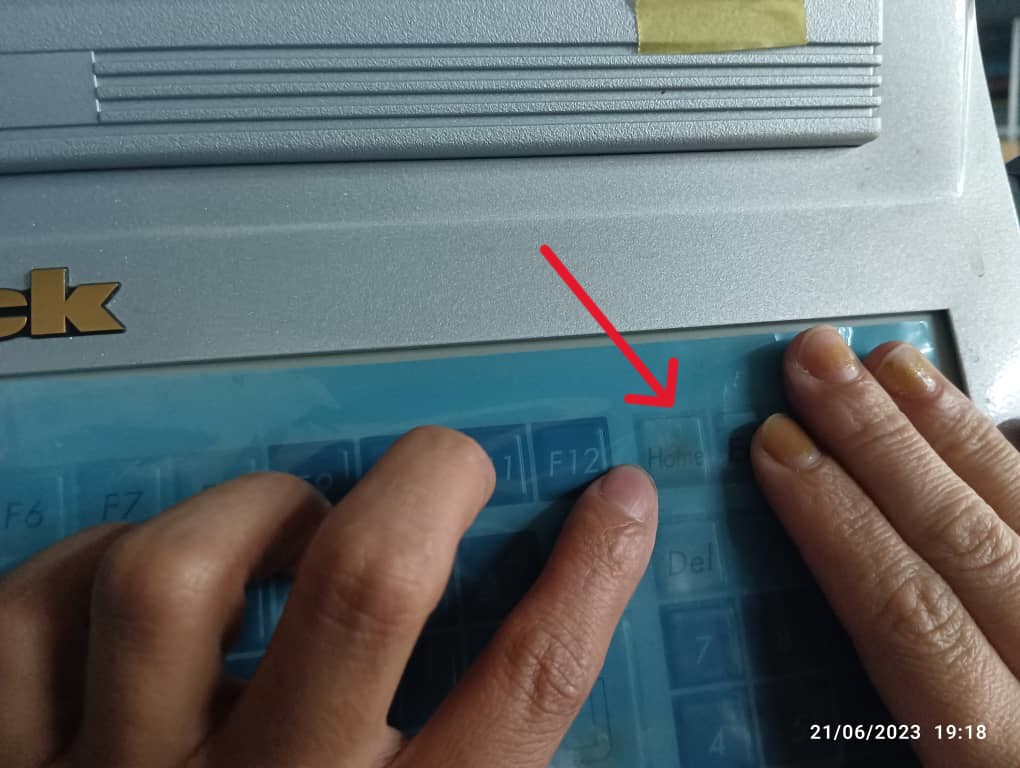

Press HOME key from key board and press ENTER from keyboard. The cutting starts.

Turn on the graphic if it is off.

Press HOME key from key board and press ENTER from keyboard. The cutting starts.

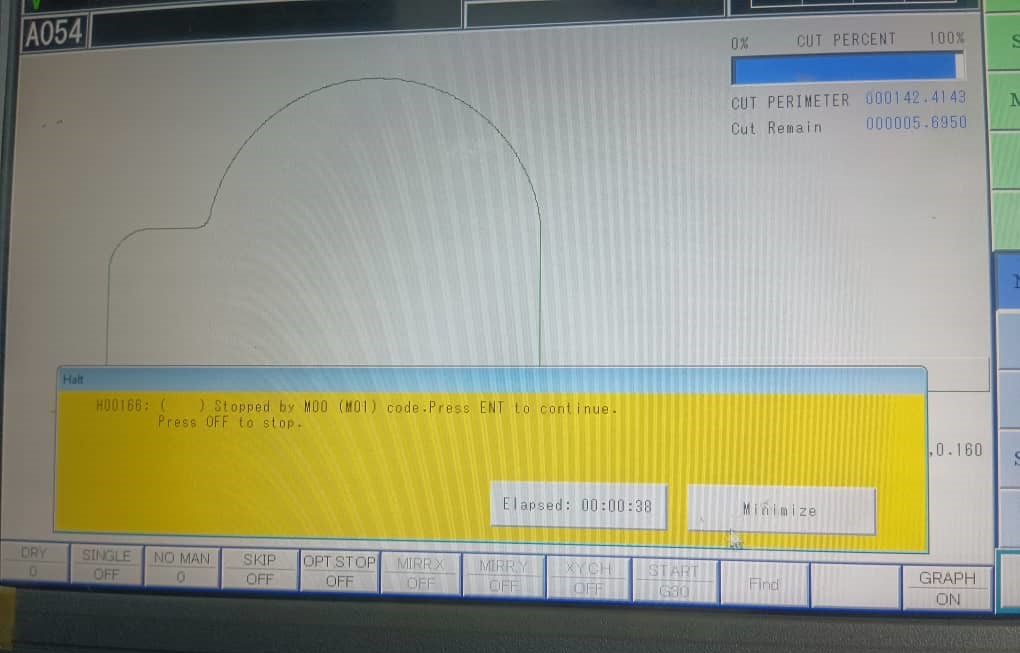

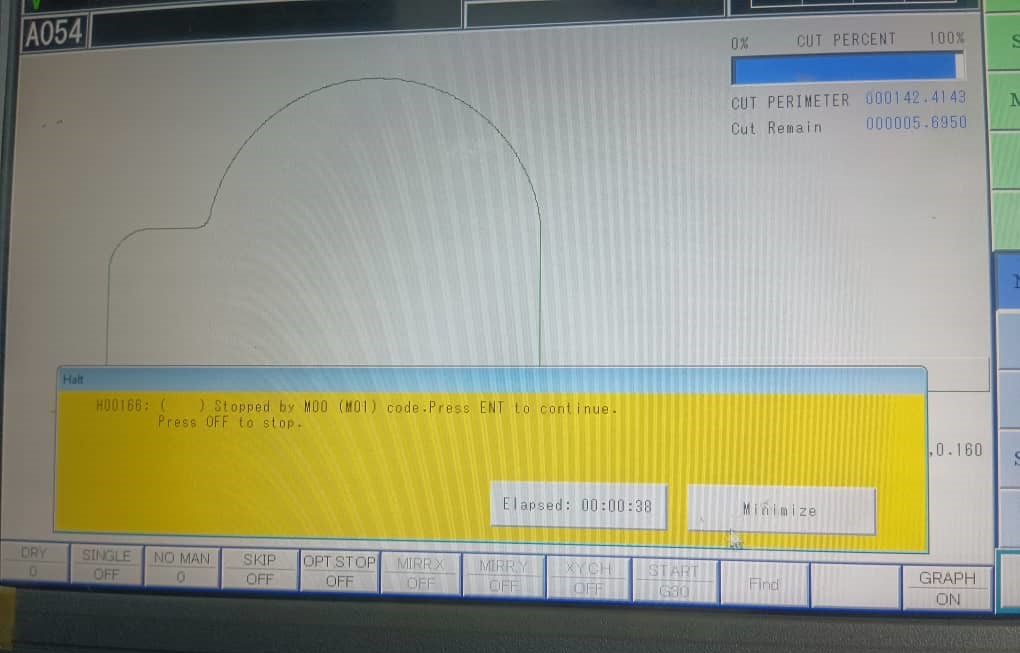

When it reaches to M01 it stops by residual stock and give a beep sound and message will be given to continue or stop. We can press ENTER key to proceed.

When it reaches to M01 it stops by residual stock and give a beep sound and message will be given to continue or stop. We can press ENTER key to proceed.

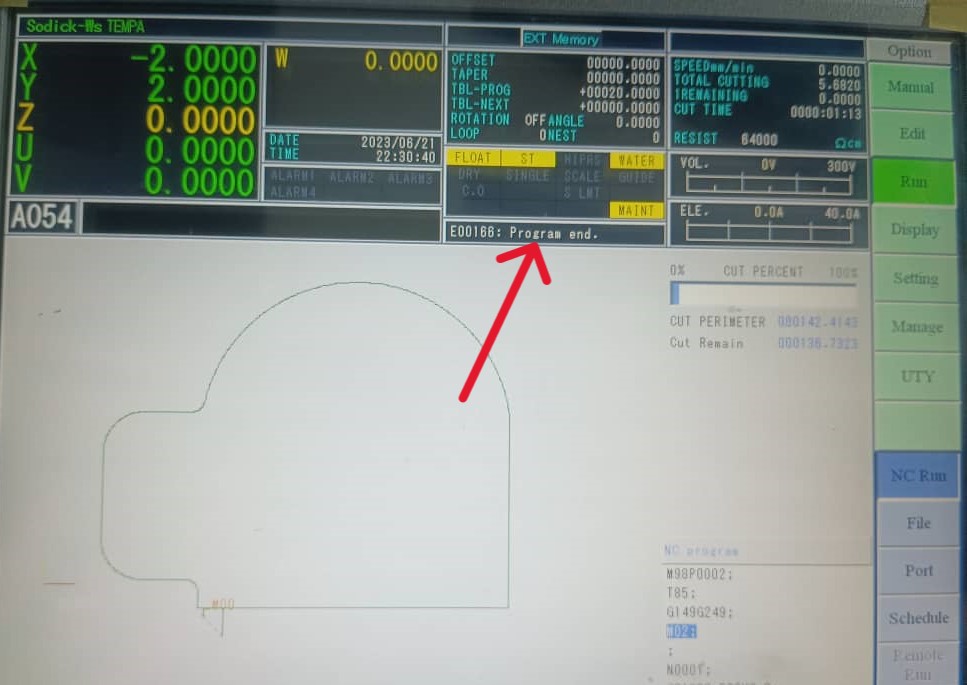

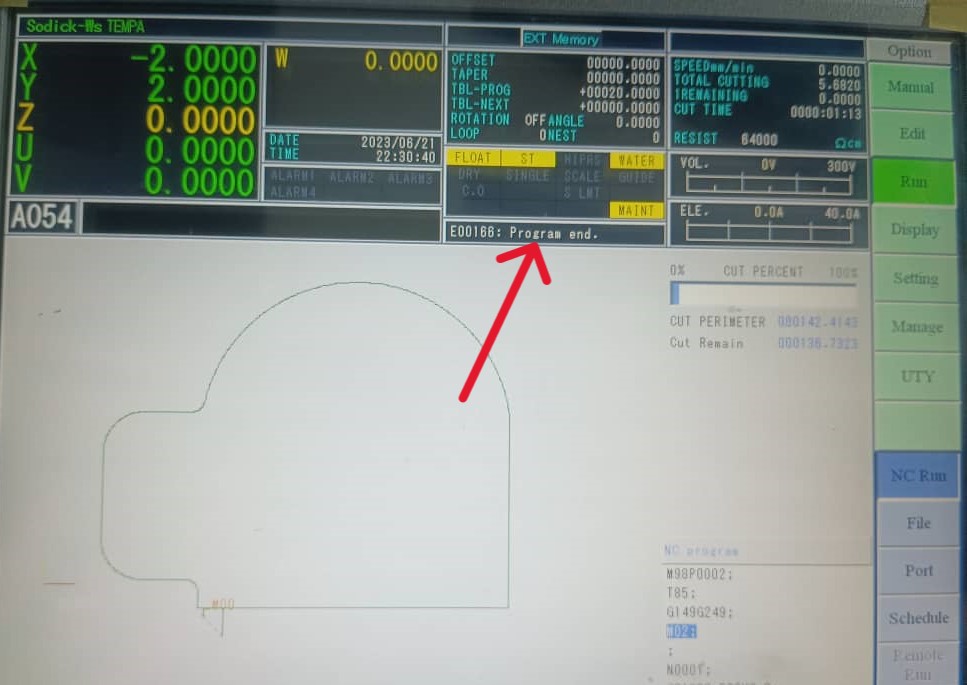

When it finish cutting it will be shown as programme end on thr screen.

When it finish cutting it will be shown as programme end on thr screen.

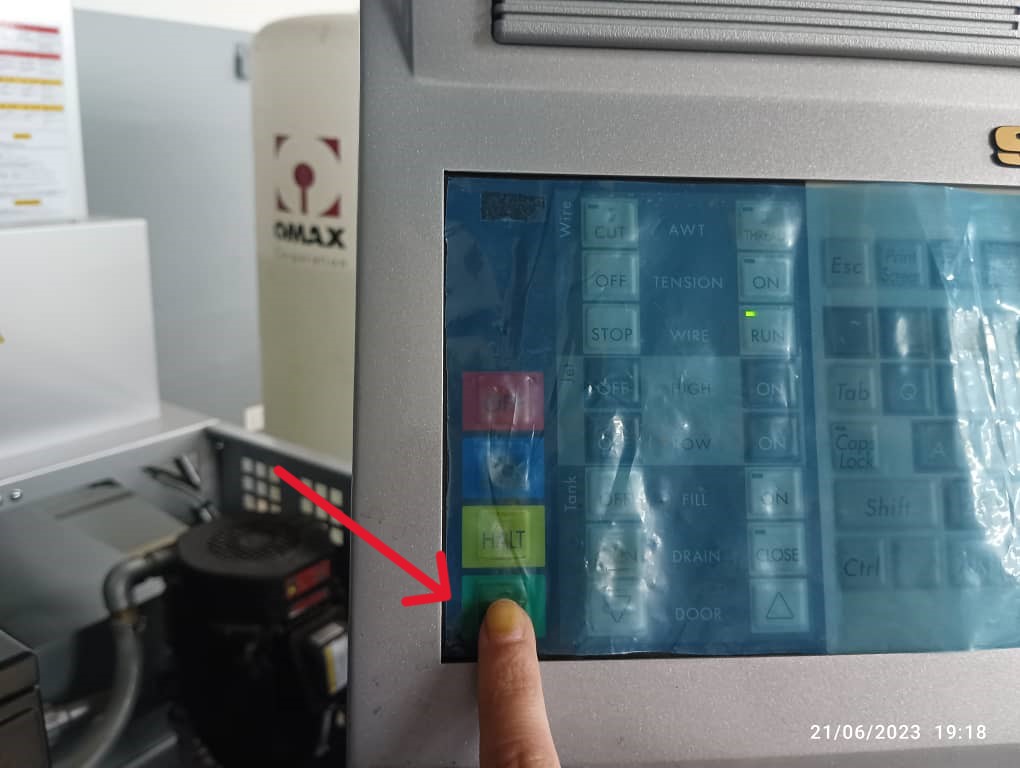

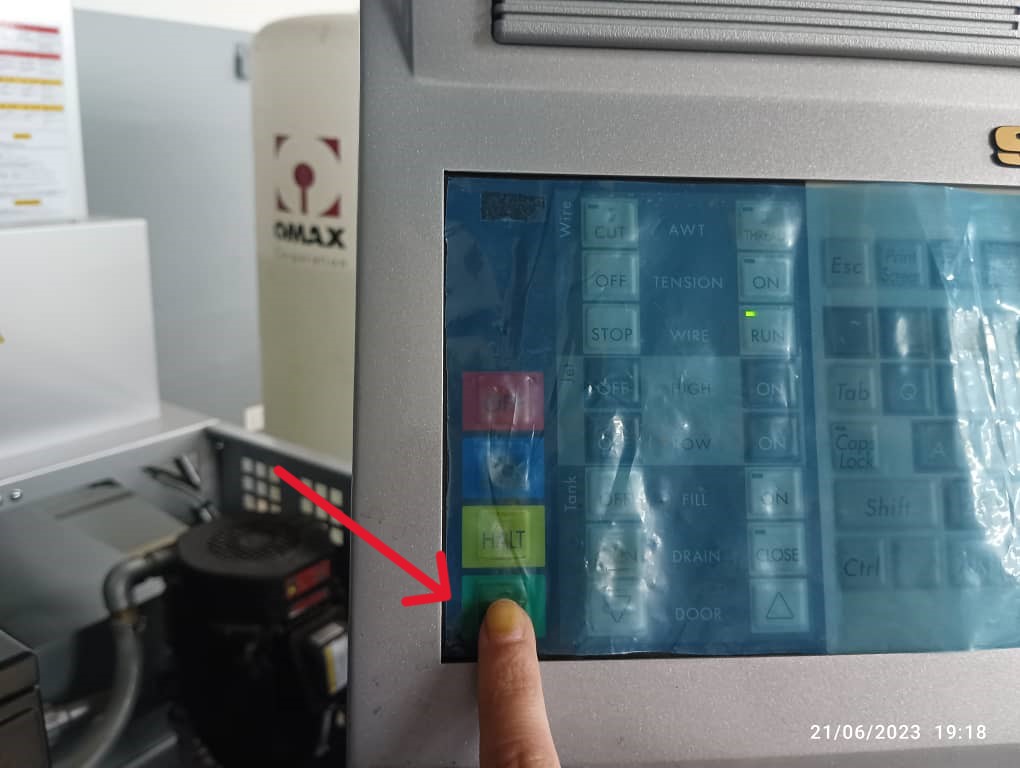

Cut the wire using Cut key from AWT section /keyboard. Raise the Z height and remove the job piece.

Cut the wire using Cut key from AWT section /keyboard. Raise the Z height and remove the job piece.

More Details When To Use This Technology.

The Wire EDM (Electrical Discharge Machining) technology, specifically the VL400Q model, is commonly used in precision machining operations where high accuracy and intricate shapes are required. Here are some details about when to use this technology:

1. Complex and Intricate Shapes: Wire EDM is particularly suitable for machining complex and intricate shapes with tight tolerances. It excels at cutting intricate profiles, sharp corners, thin ribs, small holes, and fine details that may be challenging or impossible to achieve with traditional machining methods.

2. Hard and Exotic Materials: Wire EDM is highly effective for machining hard and exotic materials that are difficult to machine using conventional methods. Materials such as hardened steels, tool steels, titanium, tungsten carbide, and heat-resistant alloys can be machined with precision and without affecting the material's properties.

3. Prototyping and Small Production Runs: Wire EDM is a preferred technology for rapid prototyping and small production runs. It allows for quick turnaround times, as it does not require extensive tooling or complex setups.

4. Fine Surface Finish: Wire EDM can produce parts with excellent surface finish quality. The process uses a thin electrically charged wire that erodes the material, resulting in a smooth finish.

5. Wire EDM EDM-specific Applications: Wire EDM is particularly useful for specific applications such as making extrusion dies, punches, cavities, gears, aerospace components, medical devices, and intricate molds for injection molding.

Why did you learn and recommendation for other students?

I have been trained on a vast amount of information, including knowledge about Electrical Discharge Machining (EDM). I can provide information and recommendations based on the existing knowledge I've been trained on. Here's why learning about EDM can be valuable, along with recommendations for students:

1. Importance of EDM:

EDM is a specialized machining process that offers unique capabilities for precision machining of complex shapes and hard materials.

It plays a crucial role in various industries, including aerospace, automotive, medical, mold-making, and tooling, where intricate parts or components are required.

2. Career Opportunities:

Gaining knowledge about EDM can open up career opportunities in industries where this technology is employed.

EDM operators, programmers, and engineers are in demand to operate and optimize EDM machines, design EDM tooling, and troubleshoot EDM processes.

3. Advanced Manufacturing Techniques:

Learning about EDM contributes to a broader understanding of advanced manufacturing techniques and processes.

It expands your skill set, making you more versatile and adaptable in the ever-evolving manufacturing industry.

Recommendations for students interested in learning about EDM:

1. Research and Study:

Start by researching and studying the fundamentals of EDM, including its principles, machine types, tooling, process parameters, and applications.

Utilize online resources, books, academic publications, and industry-specific literature to gain a comprehensive understanding.

2. Hands-on Experience:

Seek opportunities for hands-on experience with EDM machines, either through internships, apprenticeships, or educational institutions that offer practical training.

Practical exposure allows you to understand the intricacies of machine setup, operation, programming, and troubleshooting.

3. Networking and Mentorship:

Connect with professionals in the industry who have expertise in EDM.

Engage in networking events, join relevant industry associations, and seek mentorship to learn from experienced practitioners.

Design File

dxf. file Design