Week 10/11 Mechanical Design and Machine Design

This week we have to make a machine that includes mechanism, actuation, application.

This week was much challenging and interesting week for us, So this year we were 6 participants in the super fablab and we were divided into two groups (Three Girls Vs Three Boys) for machine making.

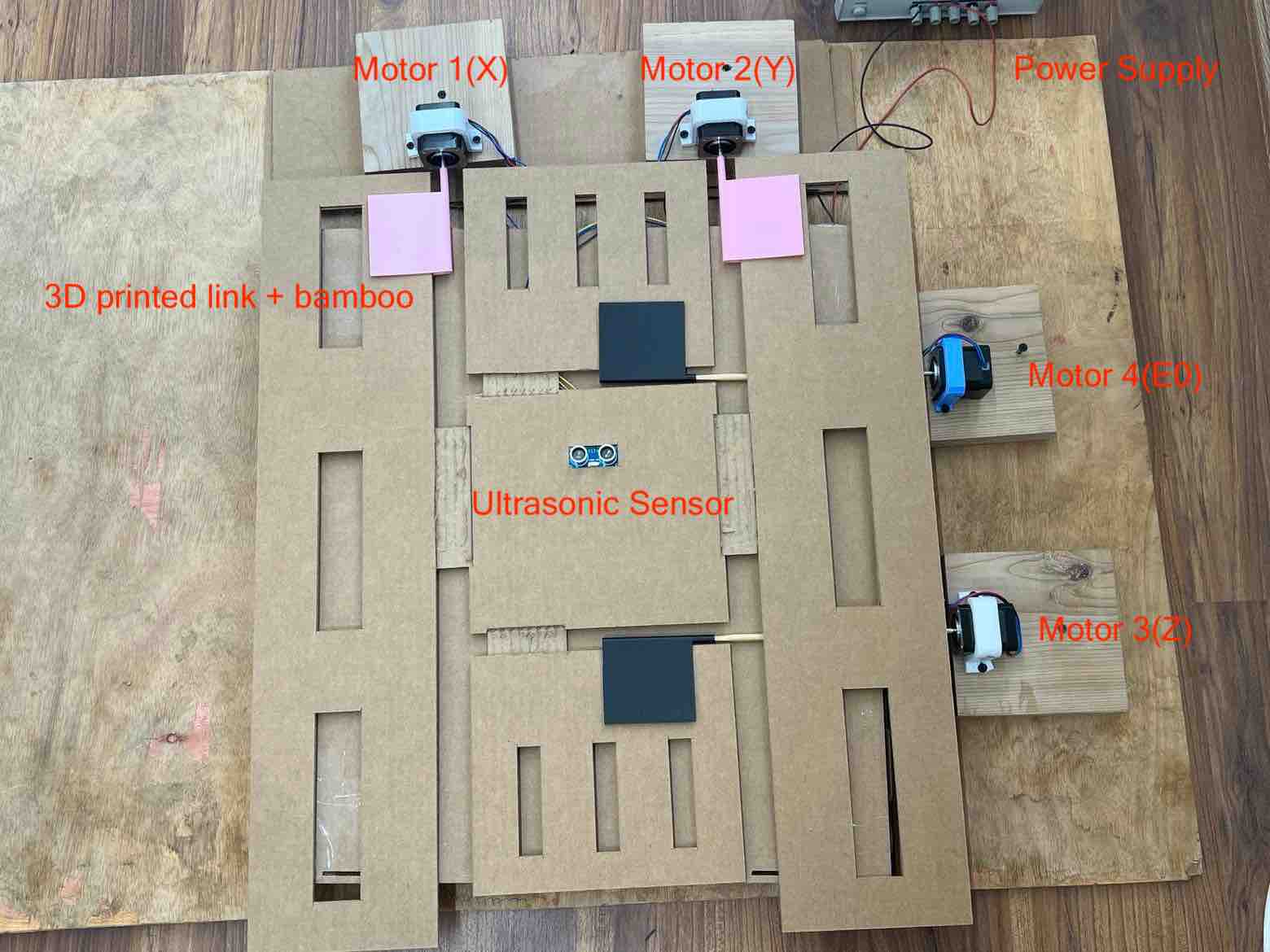

For machine making week, as Mr. Thinley already have an idea so we all agree with his idea and started to work our plan which is to make T-shirt folding machine using motors and detection sensors. In this machine we have used Arduino Mega, Ramps 1.4 Shield, Stepper Motors and the Cardboard.

Link for Group Assignment: Link

Individual Assignment

Document the group project and your individual contribution.

From this week we were divided into two groups: Boys Group and Girls Group.

I am in Boys Group and our group consist of 3 members. 1. Mr. Thinley Wangchuk 2. Rinchen Dorji 3. Tempa Dorji.

The IDEA OF THE MACHINE: As mention earlier our group decide to make a T-Shirt folding machine.

Components required to make the machine:

T-shirt Folding Machine:

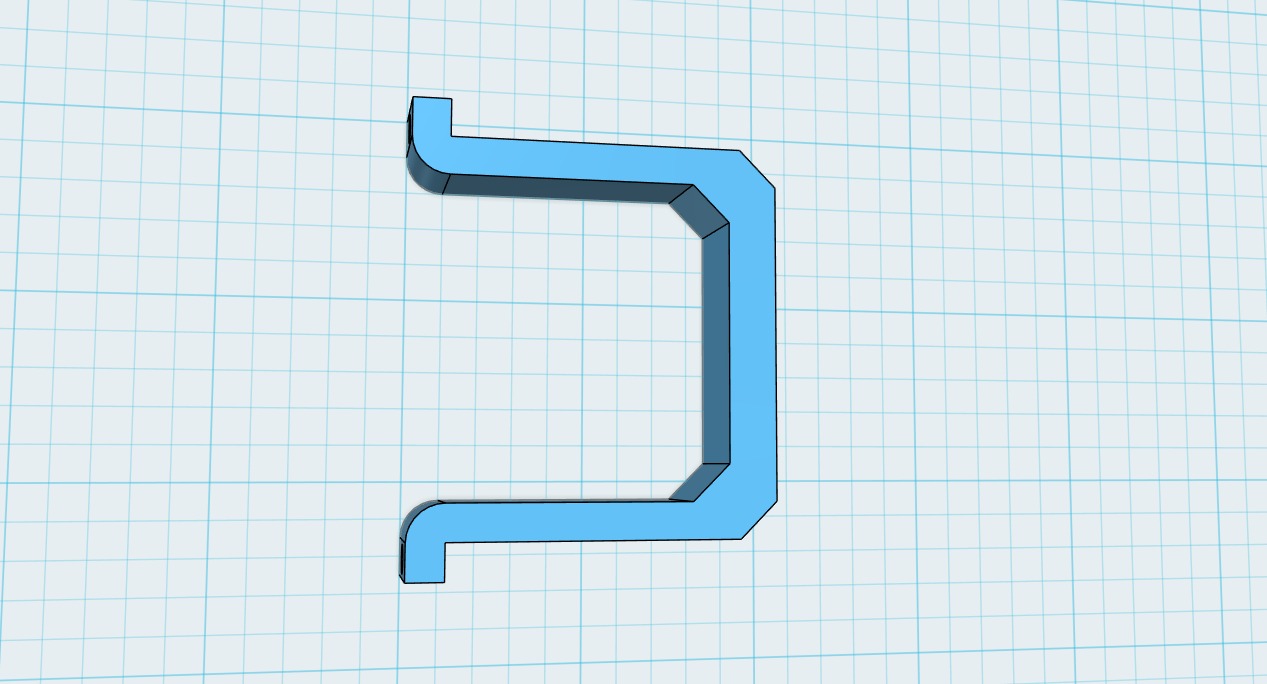

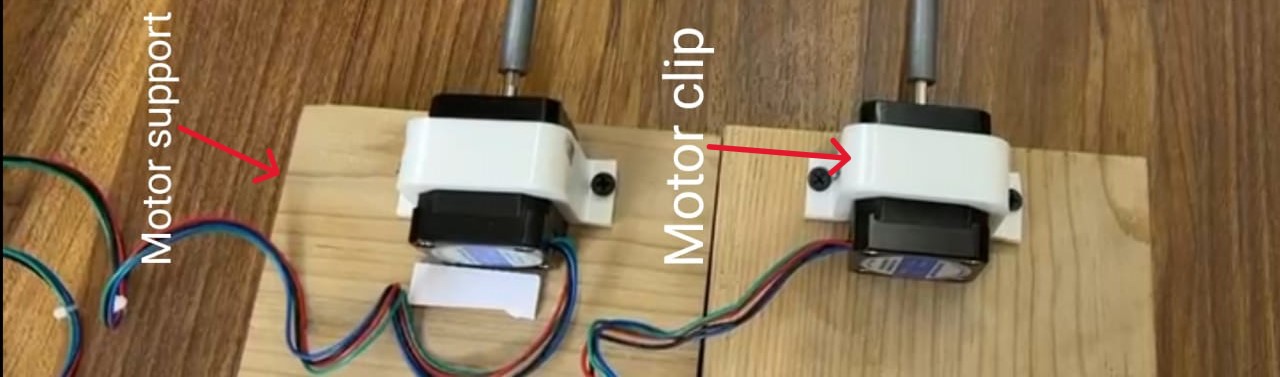

This week me and Richen have start beginning work with 3D design for the Machine. So in our machine we are using motor and for that it need wing support to spin with a motor. And also need motor support and base. In this we worked together: For motor base, we have got a wooden support from the lab and has been cut down into three pieces with same length and height. As thinely mention we thought to make a clip to give a support to motor. So we started to design in fusion 360.

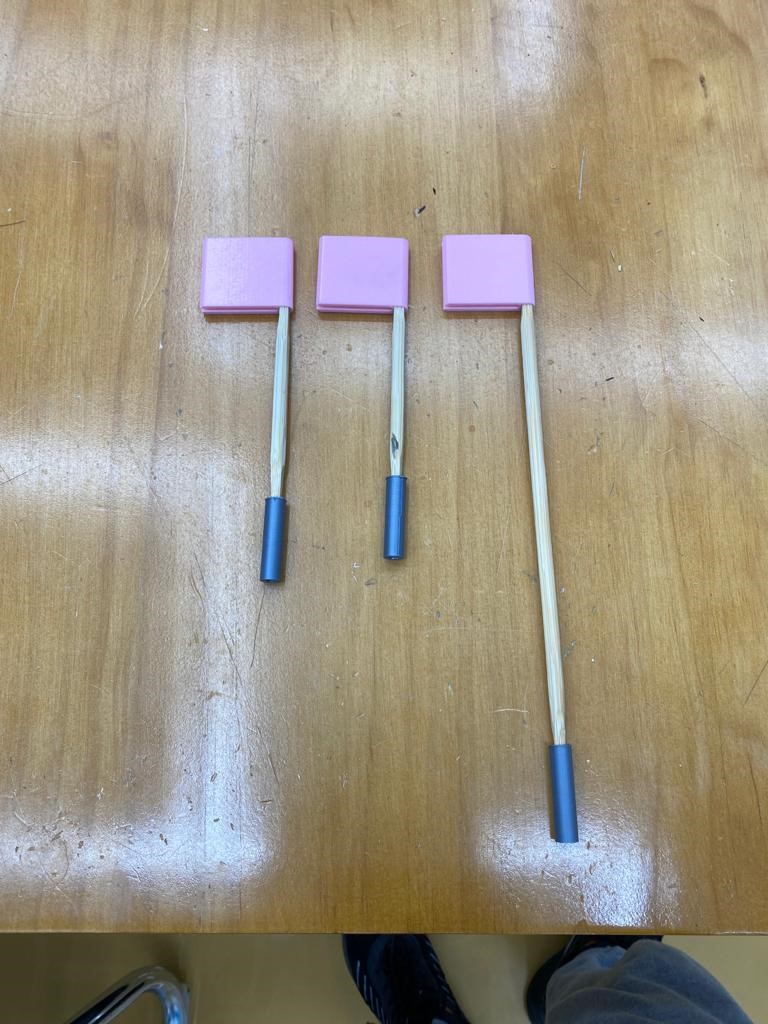

Secondly we started with designing wing support for the motor to spin with the object for our machine. So Rinchen start to design in fusion 360 and I start to begin work wing stand with bamboo.

Our First Design progress:

After our 3D printing and physical work has been done, then we try to fix in our motor and try to spin the object with the help of motor but unfortunately our design wing was too small to spin with the object. So again we re-design the wing by increasing the length, Height and thickness so that it can carry object and to spin smoothly.

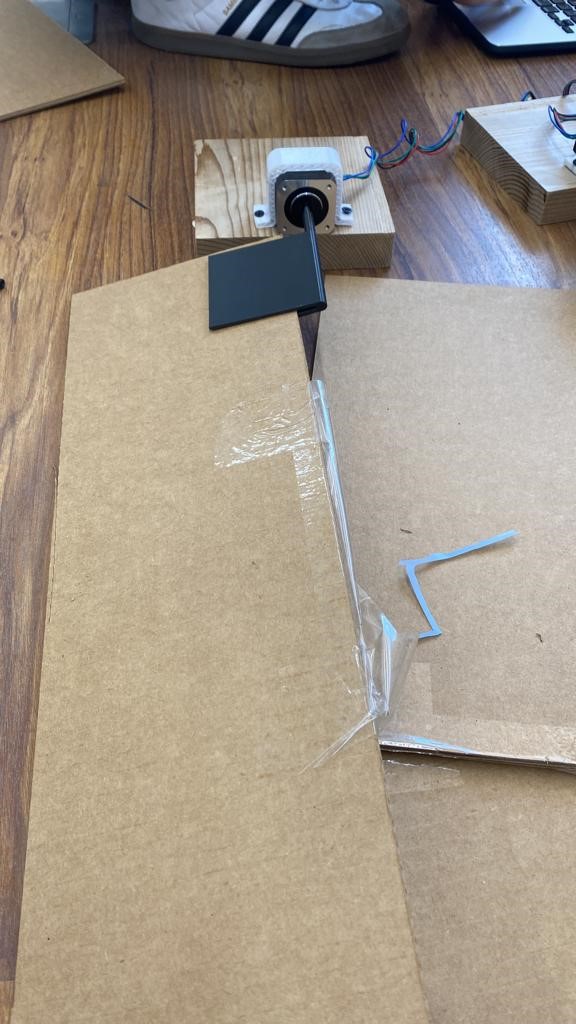

Now we have fixed the wings to motor and the object to test, finally it worked and was functioning well and good so before arranging all the motors and wires we thought to design the machine base out of cardboard. So Rinchen and I start working with the machine base.

Conclusion

In this whole project on machine making was very stressful and also got more experience too. This ideo was brought by oue group leader Mr.Thinley, so for me this idea was amazing for me as i will learn more from this project. I am really grateful to my team leader and members to work with this idea.

In this project, firstly we have improve the physical pars to how it works and how it will do. So with that we worked very effective and with good process. Secondly, we face more issue with the electronic parts, as the motor cant move our body parts which is made by acrylic pieces so we try with Cardboard to work it smoothly.

Due to time constraints, we could not design well on the machine looks so we used a ultrasonic sensor to senses a shirt and its moves to fold it. Lastly, we could have done more work on the torque calculations since we initially underestimate the weight of the acrylic.

What you learnt from this project?

From this project I have learned more:

Final design

>

>