Project Saturn

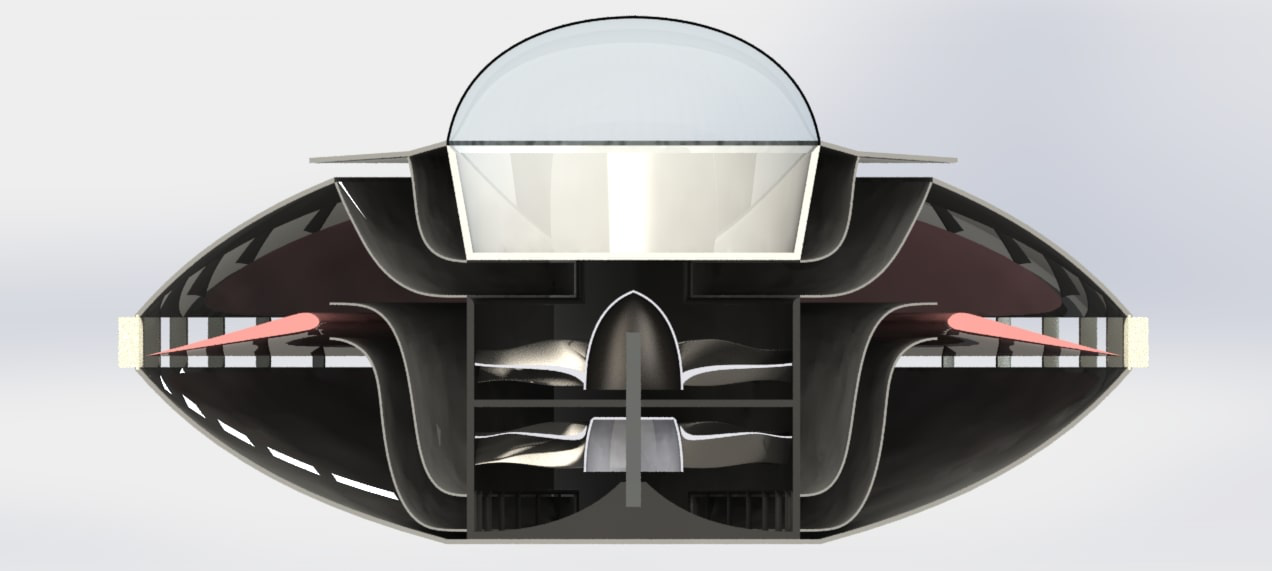

I pursued this project in both my bachelors and masters theses; the title of the project was 'Studying the Aerodynamic Behavior of a Circular Wing by Having a Radial Duct Blowing Air on It'. The main idea behind this project was to reverse engineer the concept of wings. In a conventional design, the wings are usually thrusted through the air to generate lift. Even in helicopters, the blades are spun slicing through air to create lift. However, doing the opposite, which consists of thrusting air along wings, may yield the same result, and therefore, could allow new wing designs. This phenomenon can be seen when testing scaled down aircraft models in a wind tunnel. In a wind tunnel, the model is rigged to the ground and connected to scales and computers. As the wind tunnel provides faster air flow, various forces, including the lift force, start to occur and increase. In this project, instead of using a wind tunnel, airflow is created using a centrifugal fan to thrust air along a circular wing.

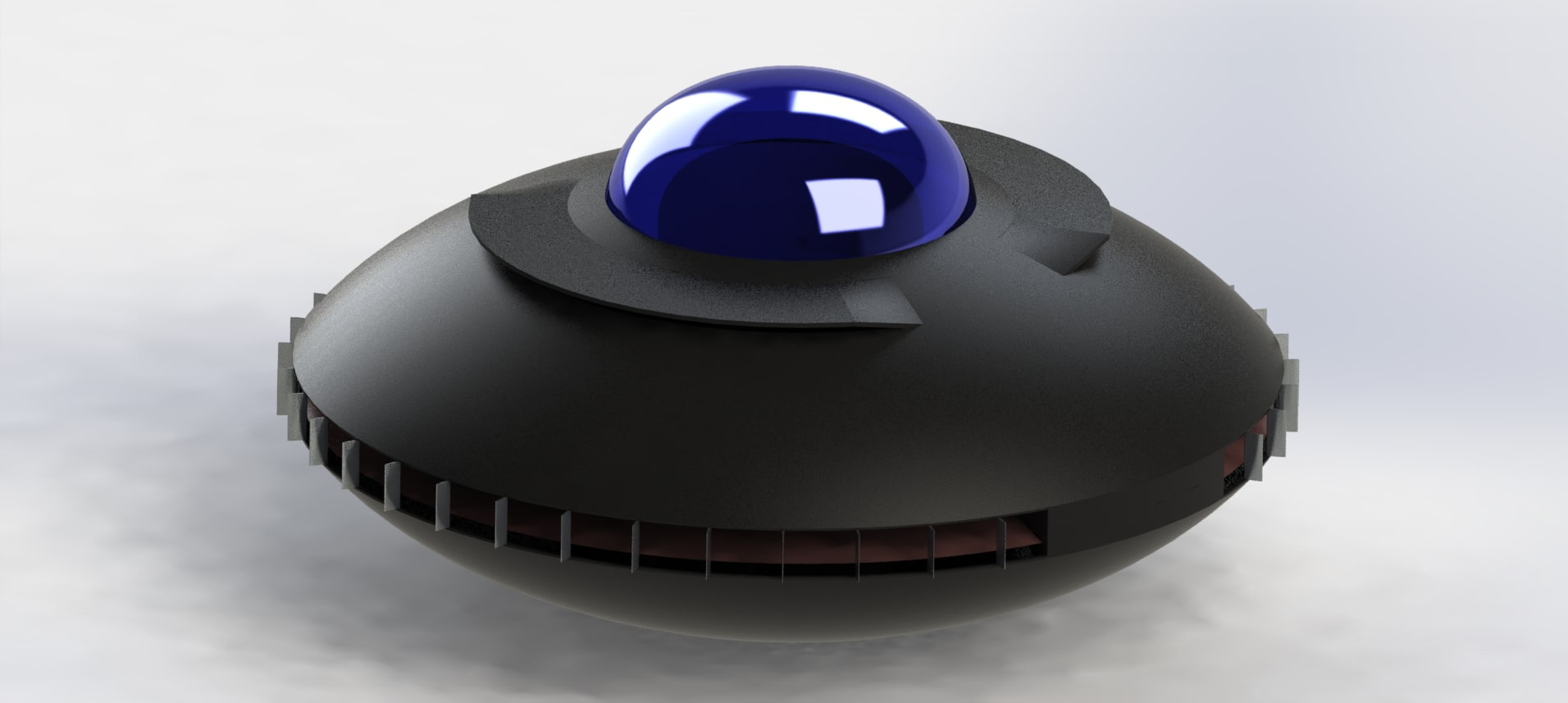

The aim of this project was to investigate a novel flying vehicle that is comprised of a stationary circular wing and forced air flow over its surface to understand its aerodynamic behavior. This project discussed a scaled down version of the actual size. The craft is scaled down 16 times to have a diameter of 0.25m. The objective of both research papers was to find a safer, more reliable, cost and energy efficient ways of aviation.

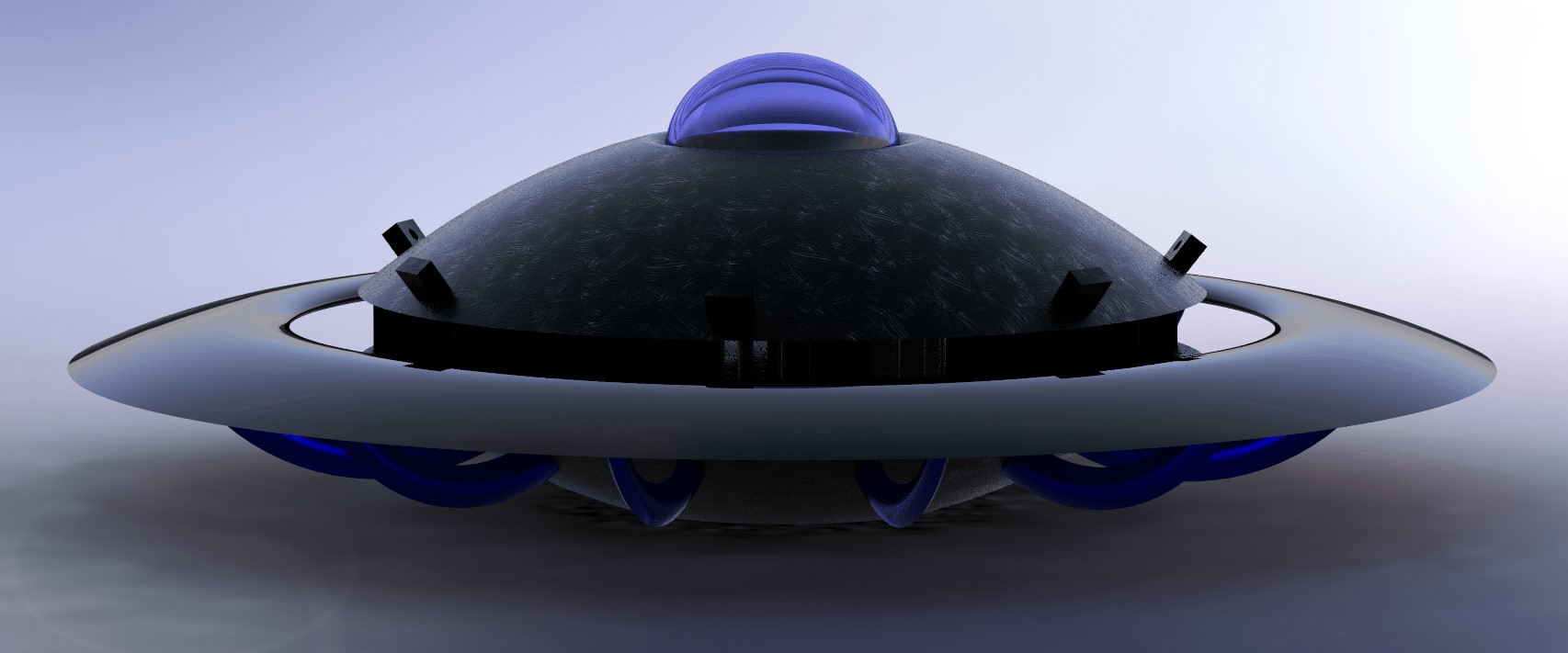

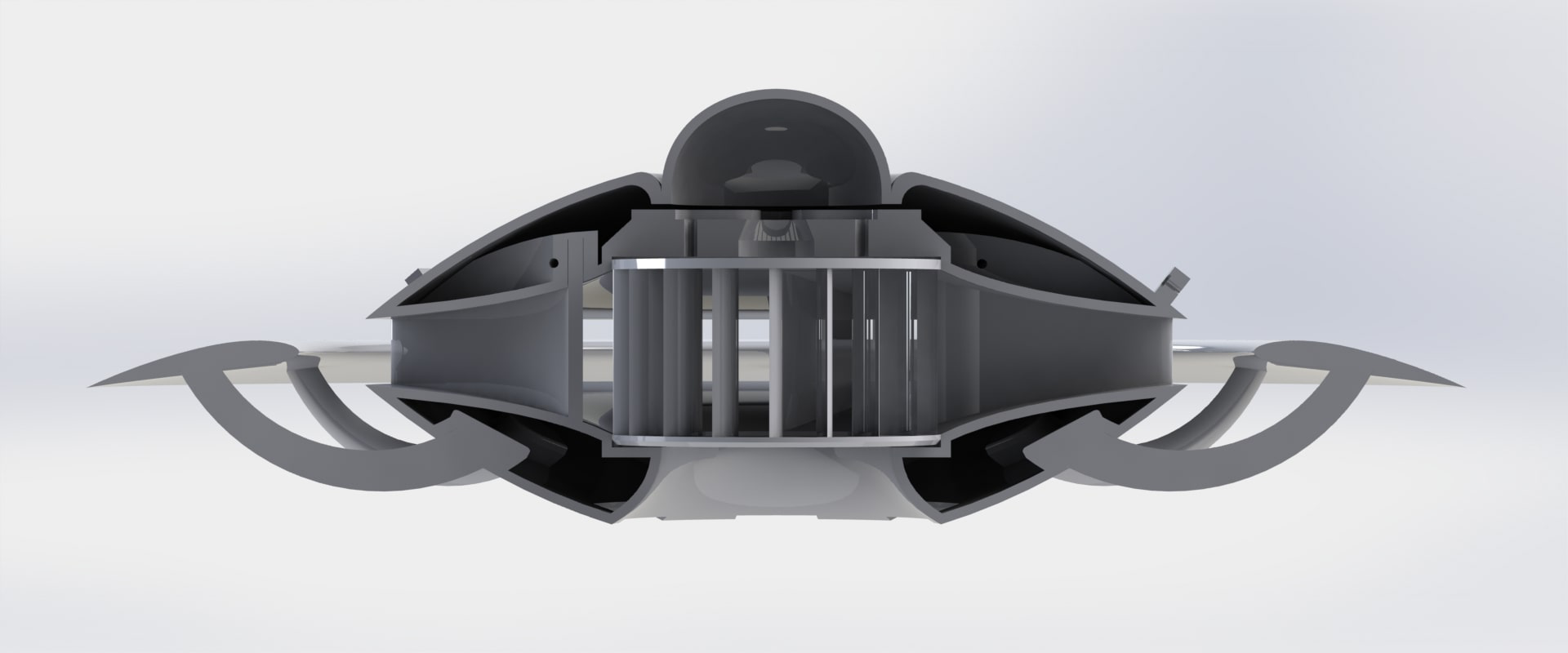

The following are images from my bachelors thesis.

The following are images from my masters thesis.

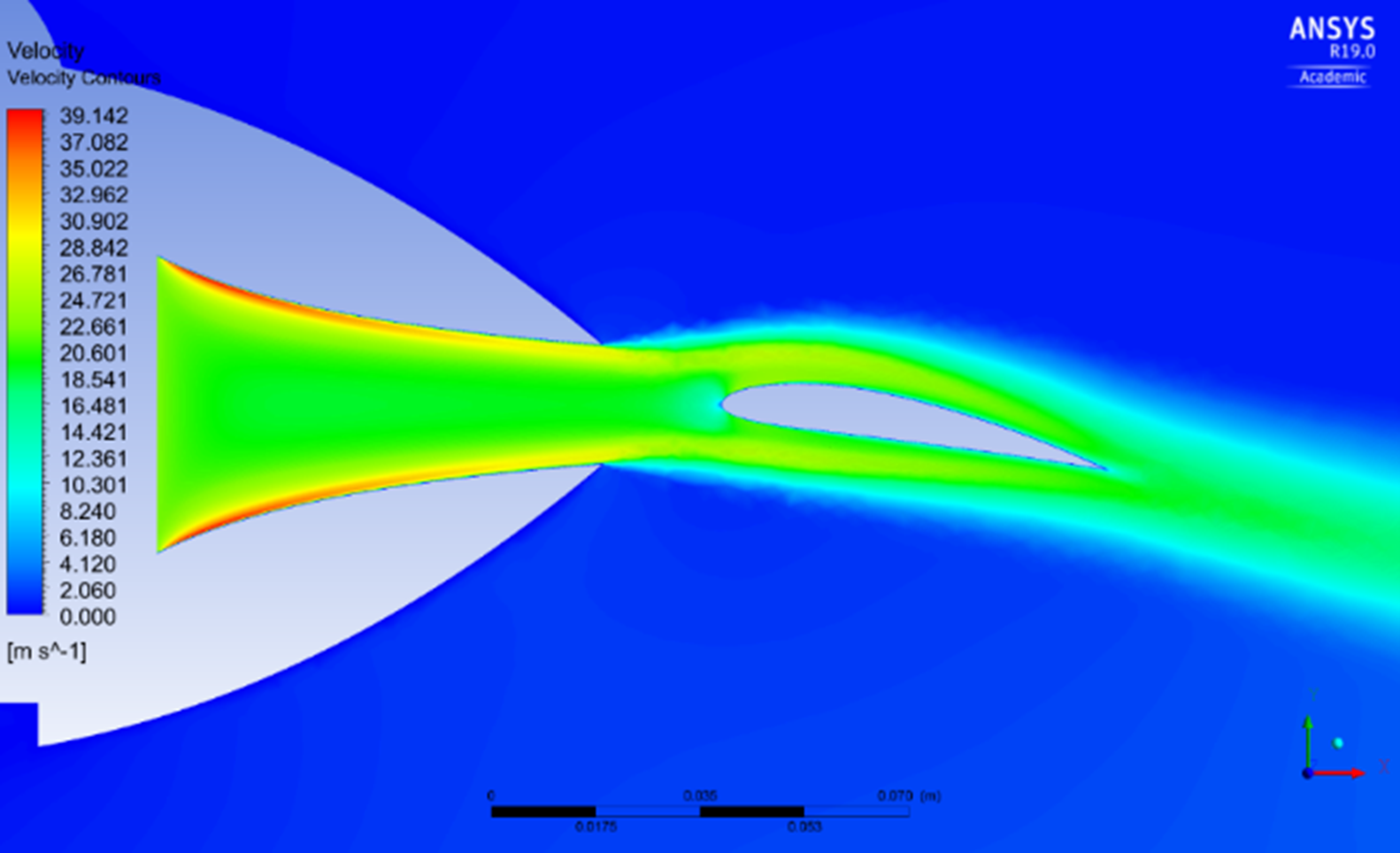

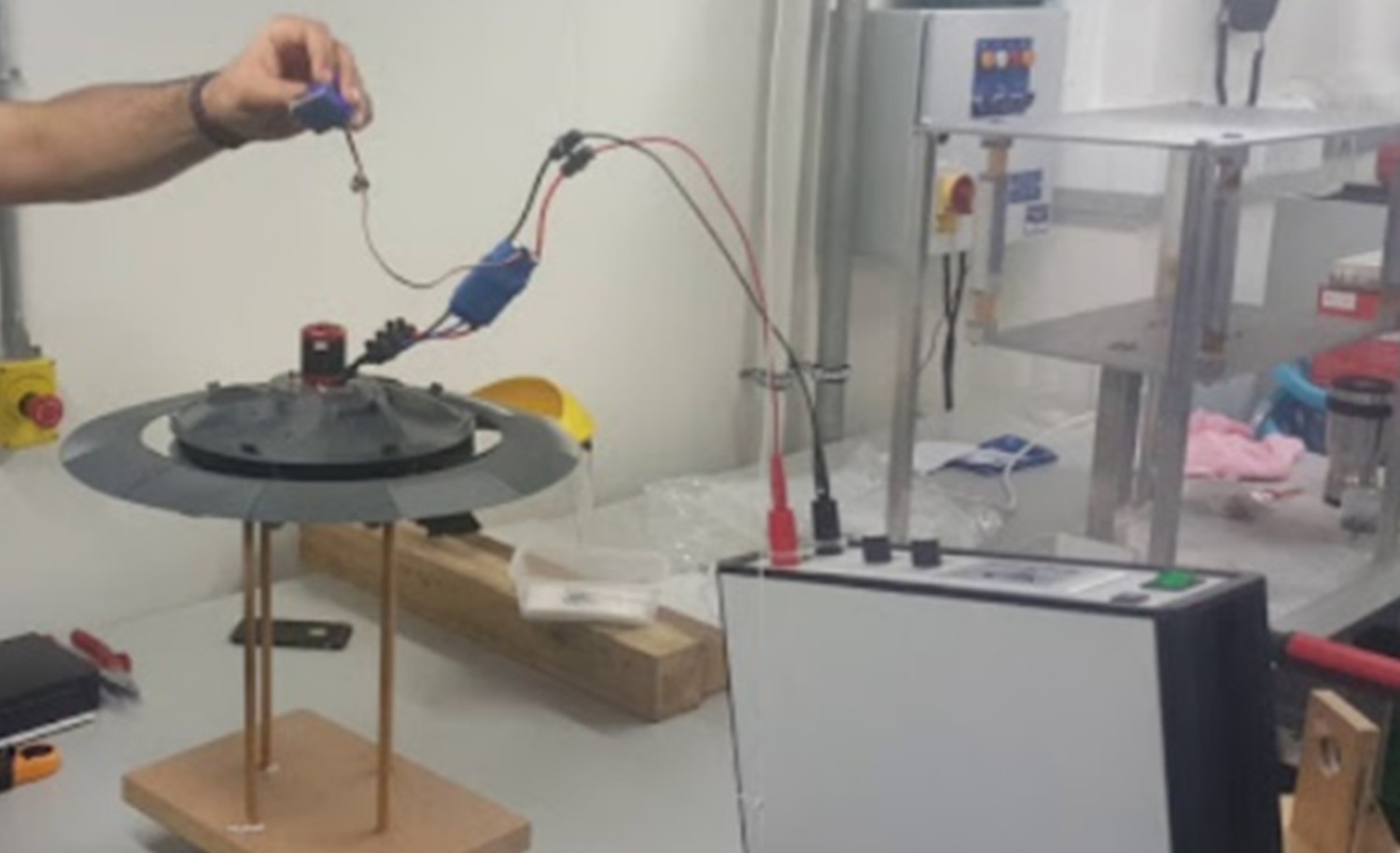

The following is a CFD image of the ducted circular airflow over the circular wing, and an image from the experiment.