What will it do?

It is an LPG Base Sanitary Napkin Incinerator. It will dispose of used napkins in an environment-friendly method by burning the pads using LPG burners and converting them into ash. The napkin Incinerator will be designed to ensure easy and safe disposal of napkins in a hygienic way.

Who's done what beforehand?

I design and developed the 1st version of the LPG Base Sanitary Napkin Incinerator(5 pads per batch) at Vigyan ashram during my internship. I mentioned it in my principle and practice week assignment. After me, my friend Chaitanya Lokhande took this work in his hand and started working on the vertical corner concept. Currently, I and Purnesh both are working on the 60-pad version of it.

First version POC.

1st fabricated version .

1st fully complete version.

What will you design?

As It is a big project I started thinking about it earlier.Thinking of a bigger version of the incinerator. I have to scale up every part.

- It will consist of a MS sheet metal chamber(considering ventilation for airflow ) as an enclosure with a chimney for the exhaust of hot gasses.

- I have to design a core unit at the center to hold 2 weld mesh baskets(each containing 30 pads) containing used sanitary pads for incineration.

- I have to design a vertical multiple burner system assembly at the core for the combustion of the pads at the center.

- I have to design a copper pipeline flow structure to supply LPG gas at burners.

- I have to design an Electrical actuator system consisting of an Ignition unit, gas solenoid valve and servo motor to control the LPG flow towards the Combustion system(burners).

- I have to design A control panel to operate the Machine.

- And finally an algorithm to control the continuous gas supply to a burner in such a way that it will perform pyrolysis and combustion simultaneously.

What materials and components will be used? Where will it come from? How much will they cost?

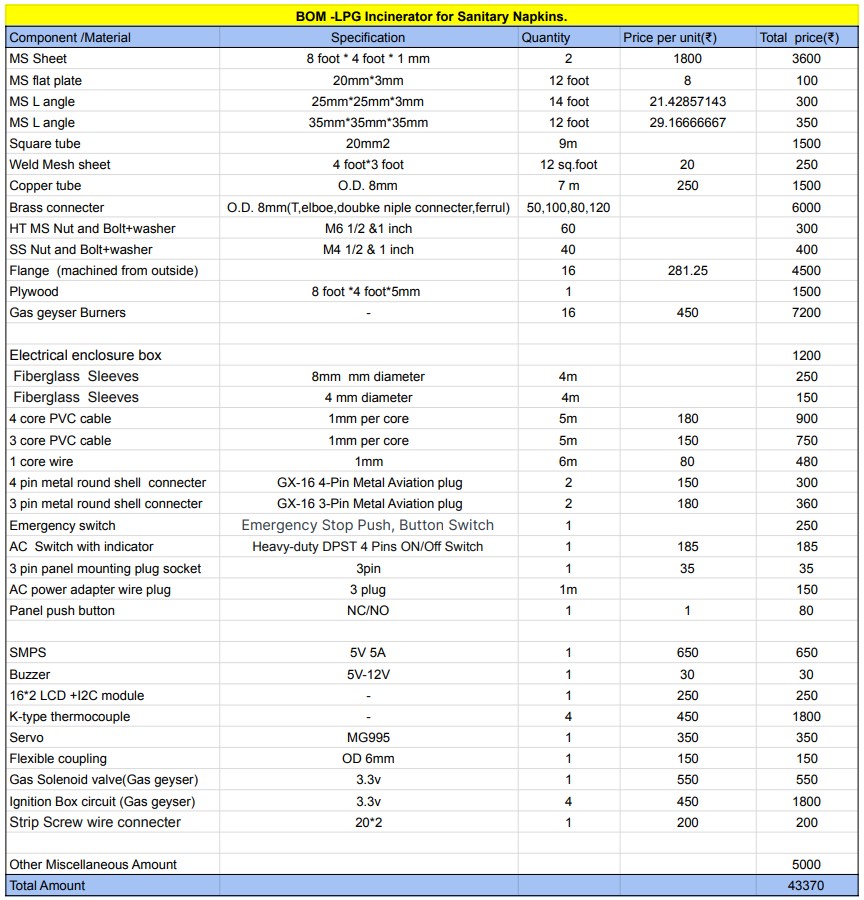

Following is the bill of material of LPG Sanetory Napkin .It almost caust around 43,370 ₹ in indian currency which will be almost about 548.98 USD.Most of the material was purchase from fames market of electronic in india pune Shukravar peth area some of the material such as Gas geyser Burners.We order from bangalore from a manufacturing company.I also perchess some matter from E-commerce website India-Mart and amazon to purchase Ignition circuit of gas geyser and etc.

BOM -LPG Incinerator for Sanitary Napkins.

What parts and systems will be made?

Following are the list of parts and system I will implement in final project.-

parts:

- MS sheet metal to make Enclosure Chamber ,Chimni ,ashtray and supporting structure of body.

- Plywood plate to inculcate the electronics from the hot surface and mounting components in the Control panel box.

- PLA for 3D printed Handal.

- Acrylic for making mounting frame for LCD display and 3 pin female plug on control panel.

- PCB Board from fiber copper sheet.

-

Systems :

- Multiple vertical Gas burberry system.

- Copper pipeline system to flow LPG gas.

- LPG gas flow system.

- Control Panel.

What processes will be used?

-

Fabrication processes in the workshop.

- Welding: Arc welding + spot welding machine

- Cutting :Cutter

- Grinding:Grinding machine

- Sheet metal bending

- Rebeting

- panting :Tool :Spray painting machine

-

Fabrication processes in Fab lab.

- Computer Aided Design:Tools: Solidworks Software -CAD design of Project.

- Computer Controlled Cutting: Tool: Laser Cutting-to cut small , Plasma cutting-to cut sheet metal for Enclosed chamber of incinerator.

- Electronics Production:Tool: Mods Project, Machine : SRM 20-PCB Milling of Final Board

- Electronics Design:Tool: Eagle PCB Design of Main Project board.

- 3D Printing:Tool- Factory works 3D printer to print Handle for control Panel.

- Embedded Programming:Tool: Arduino IDE-Programming to write and upload the program to the final project board.

- Input Devices:K-type thermal sensor to indicate high temperature of metal enclosure. Output Devices:Solenoid valve and servo motor to control LPG gas flow to the machine.

What questions need to be answered?

Did I choose the right project for the Fab Academy course ? Risky isn't it.

How will it be evaluated?

It will be evaluated on the basis of the following conditions.- All actuators are working properly including the ignition system, Solenoid valve, and servo to control LPG gas flow.

- Working of auto Ignition and Incineration process .

- Percentage of combustion of used pads into Ash as a byproduct.

- Minimum smoke output through exhaust.