15. Mechanical design¶

Learning outcomes

-

Work and communicate effectively in a team and independently

-

Design, plan and build a system

-

Analyse and solve technical problems

-

Recognise opportunities for improvements in the design

Like the previous weeks , student are expected to complete two (2) categories of weekly assignment.

Mechanical Design

Group assignment:

-

Design a machine that includes mechanism + actuation + automation

-

Build the mechanical parts and operate it manually.

-

Document the group project

Individual assignment:

- Document your individual contribution.

Machine Design

Group assignment:

-

Actuate and automate your machine.

-

Document the group project

Individual assignment:

- Document your individual contribution.

Group Assignment¶

For our Group assignment we had to design machine & automate its components and document.

The Group Assignment page is as follow Link:

Group Members:

-

Terrence Carew

-

Christopher Proute

-

Nervene Bhagwandass

-

Marvin Holloway

Machine description:

Automated Cookie Cutter

For this assignment, my group designed and built an automated cookie cutter. The machine uses an actuator that pushes a cookie cutter unto a circular conveyer which the cookie dough is placed. The cookie dough is cut to shape, the actuator retracts and the conveyer turns with another piece of cookie dough. The cookie cutter shapes can be switched with different shapes.

This project entails both digital and manual fabrication processes. These processes include:

-

2D design and Laser cutting

-

3D design and 3D printing

-

Electronics design and production

-

A bit of reverse engineering

Individual assignment:¶

I was assigned to:

-

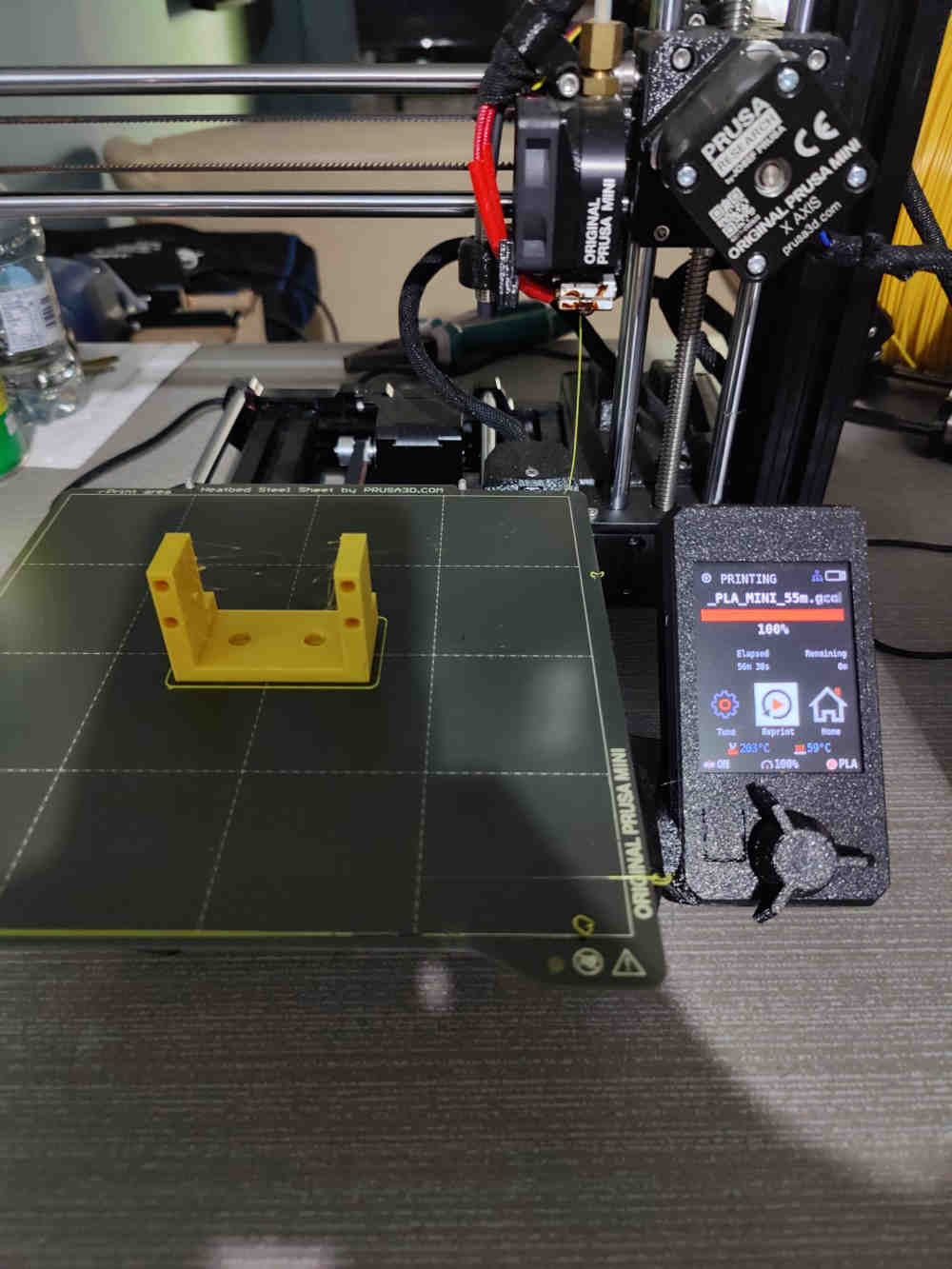

Design several servo motor mounts for the Hitec HS-422

-

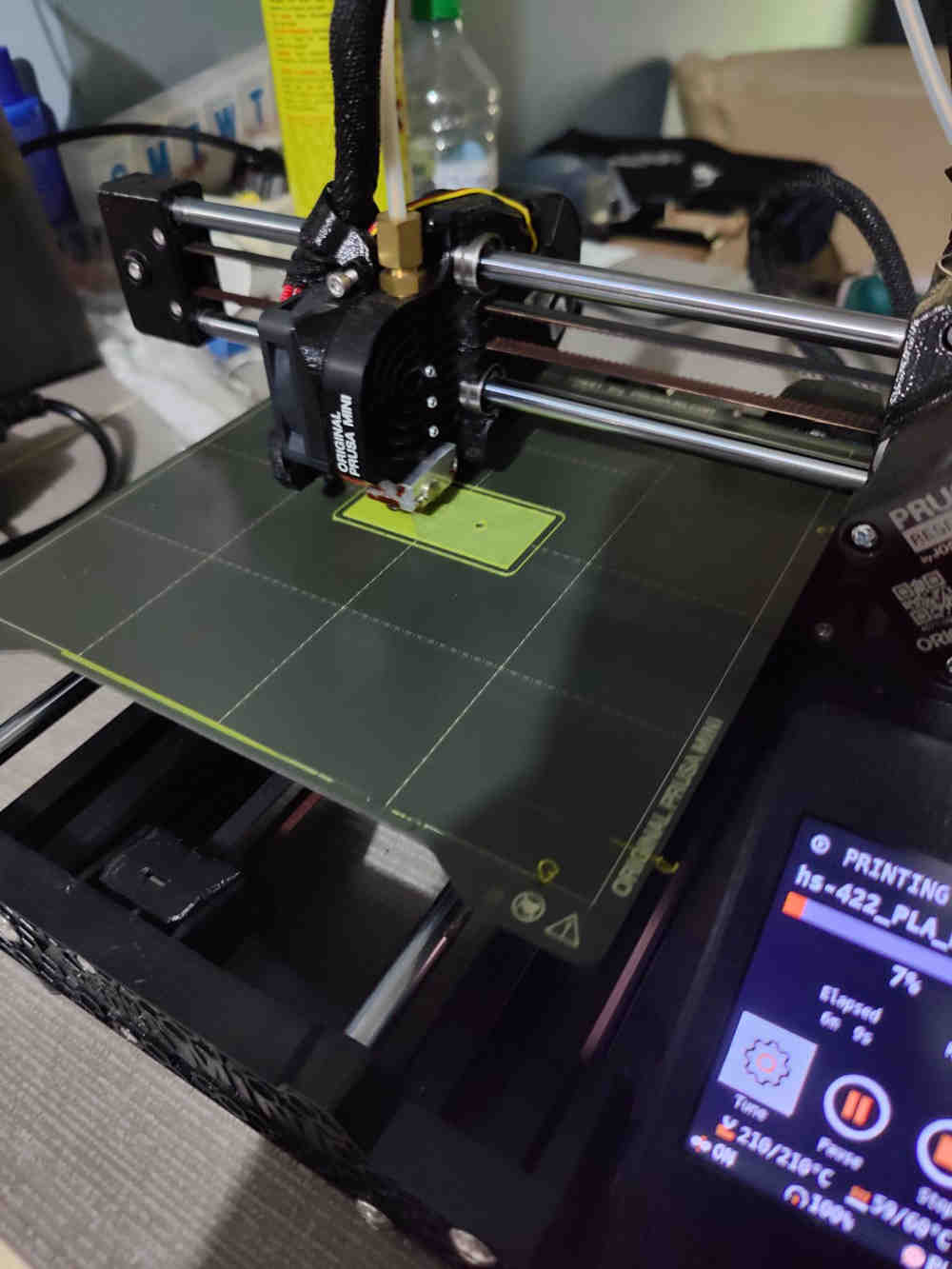

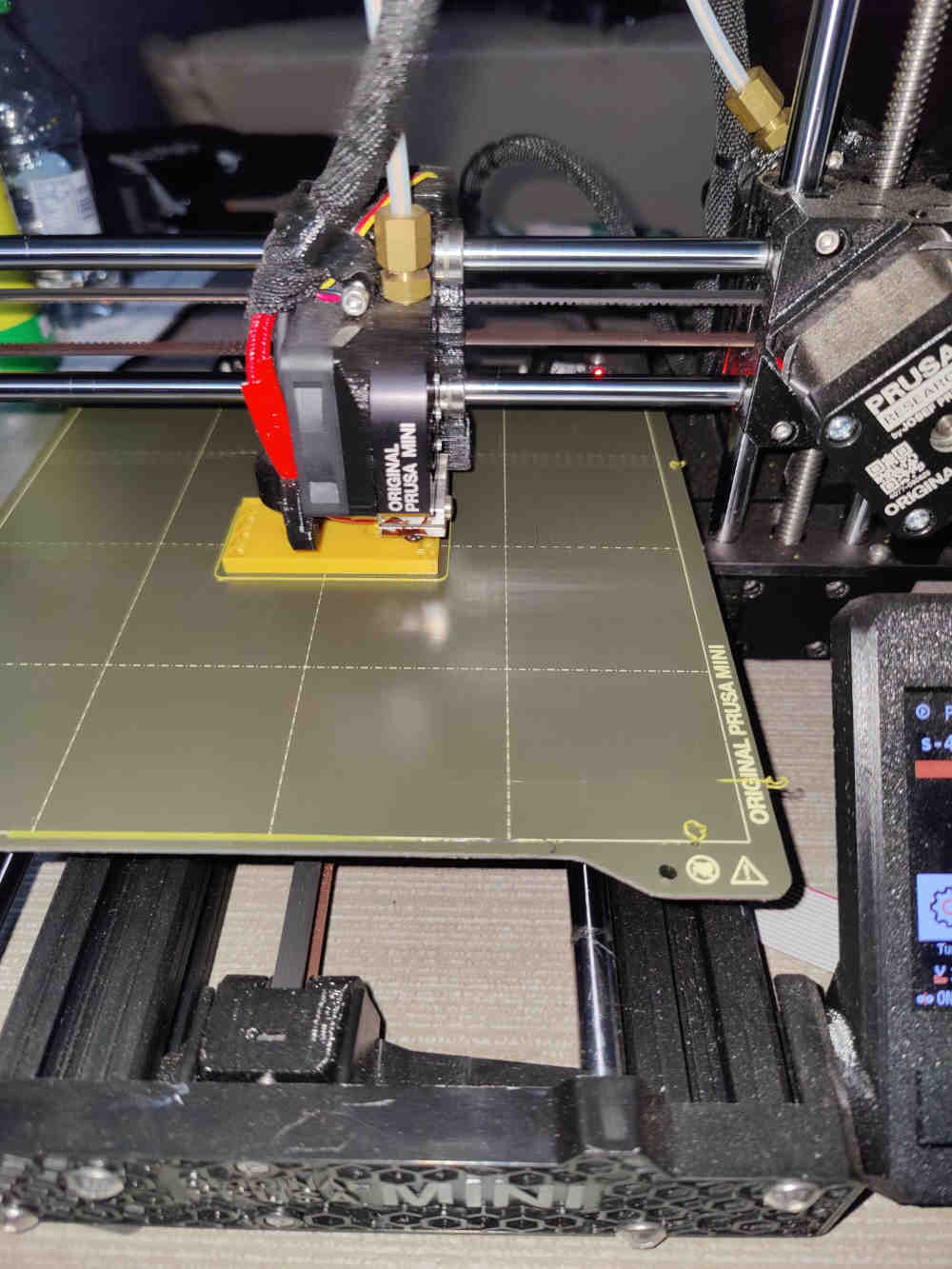

3d print servo motors mounts for the Hitec HS-422

-

Design stamp

-

3d print stamp

3D Designing and 3D Printing the Servo motor Mounts¶

Software tools used for 3D design was Tinkercad

HS-422 90 Degree Mount

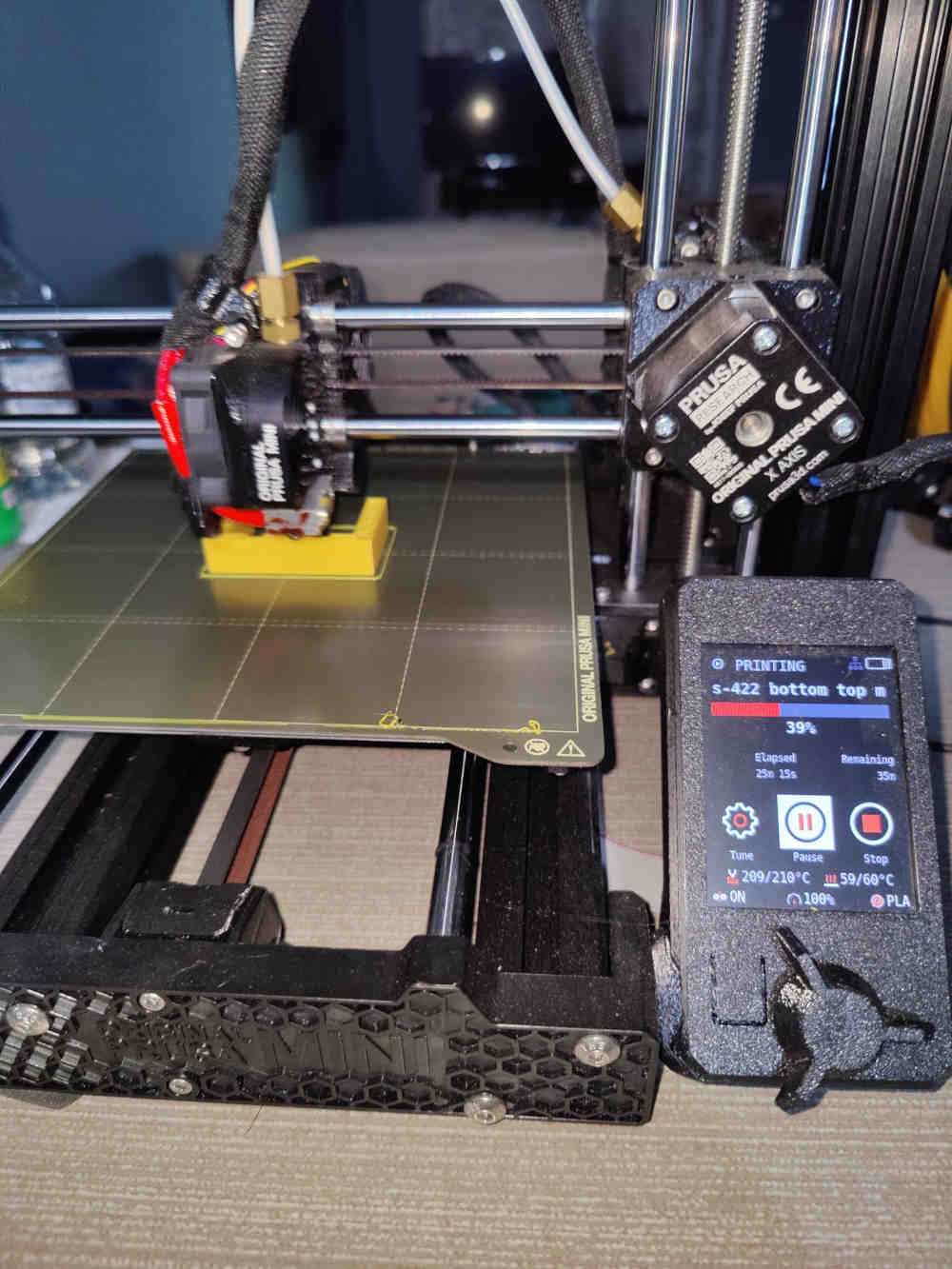

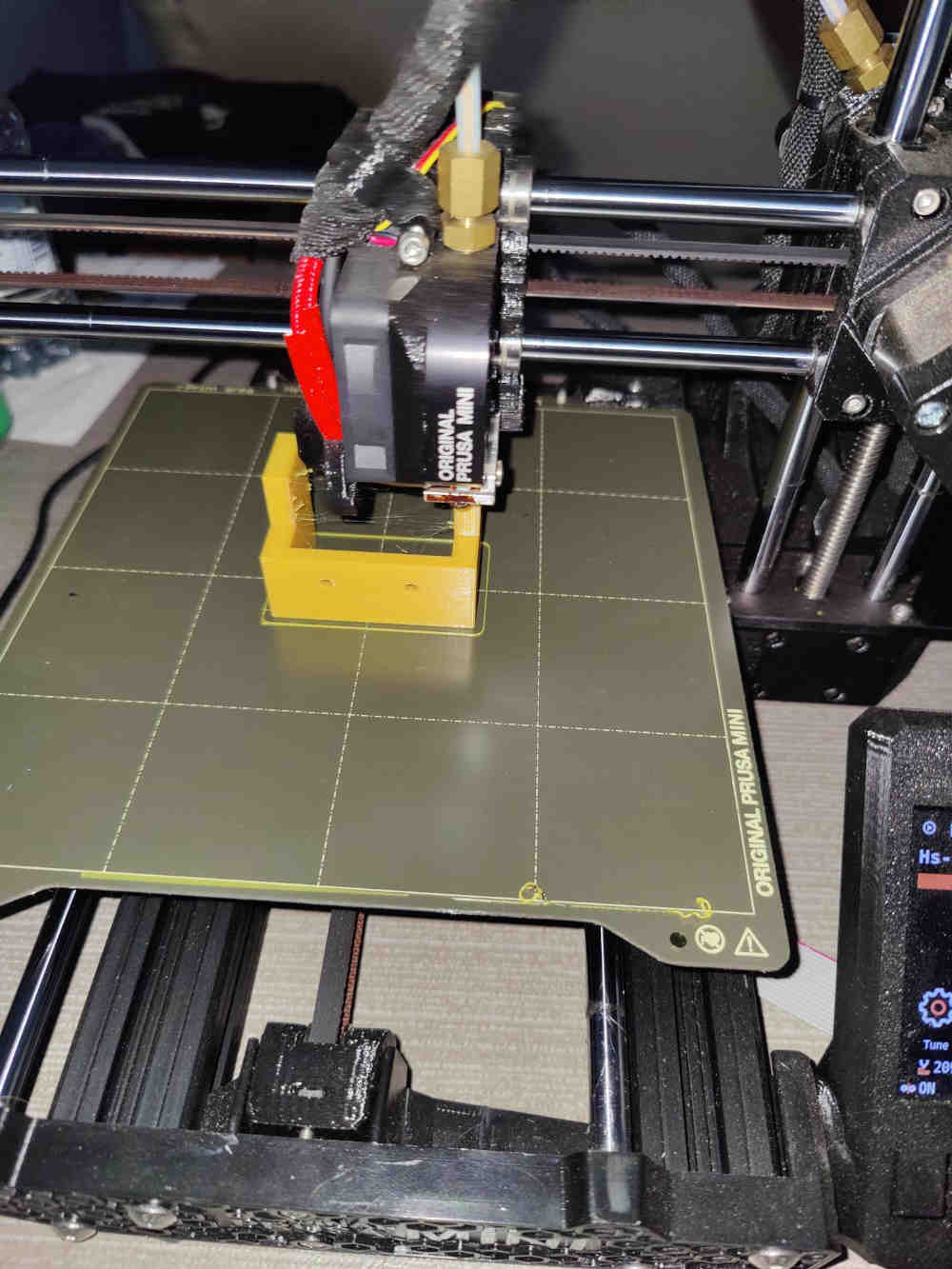

HS-422 90 Bottom Top Mount

STL HS-422 90 Degree Mount Download file

STL HS-422 90 Bottom Top Mount Download file

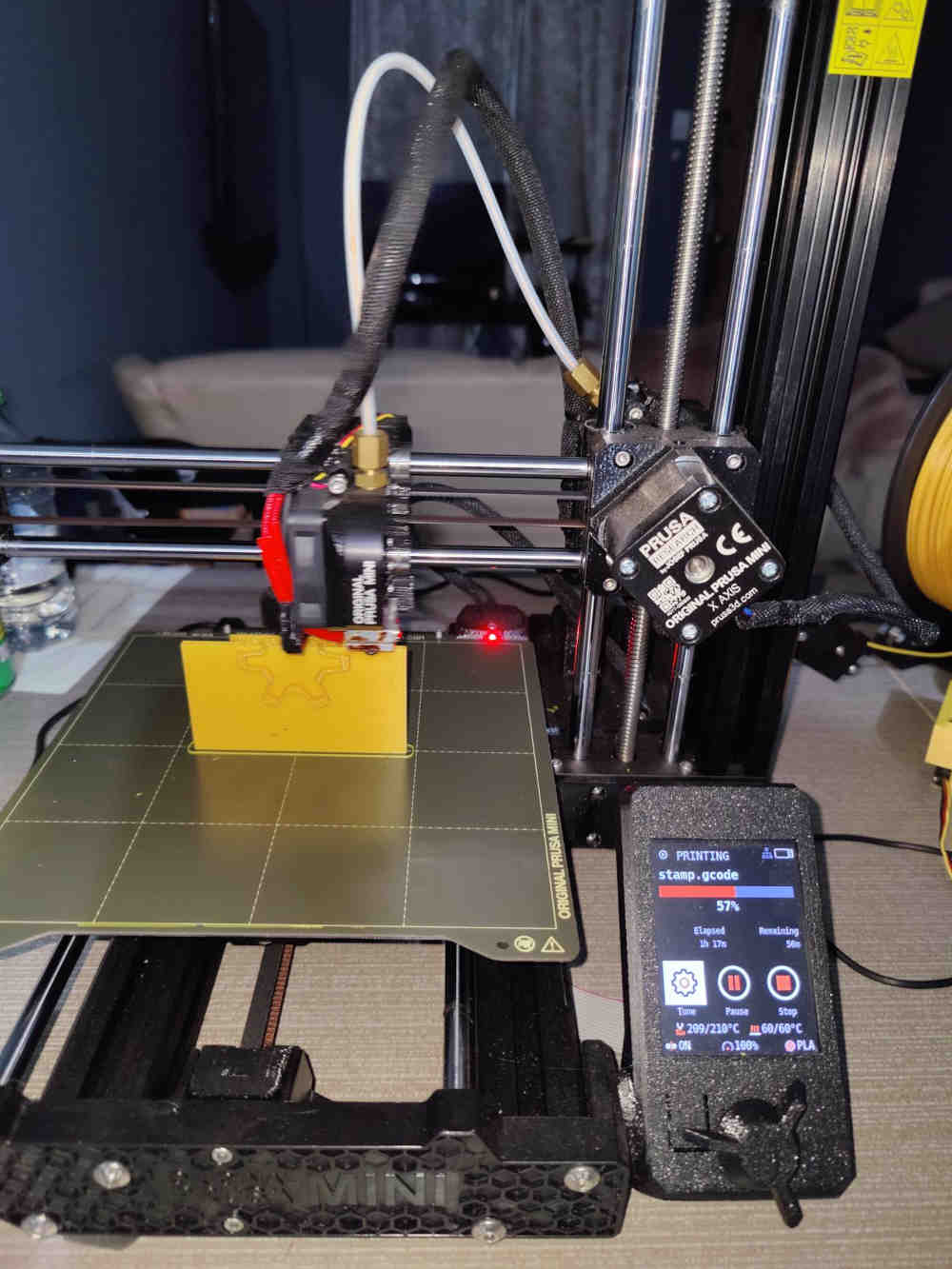

Note: gcode files are for Mini Prusa

Gcode HS-422 90 Degree Mount Download file

Gcode HS-422 90 Bottom Top Mount Download file

Both Servo Motor Mounts

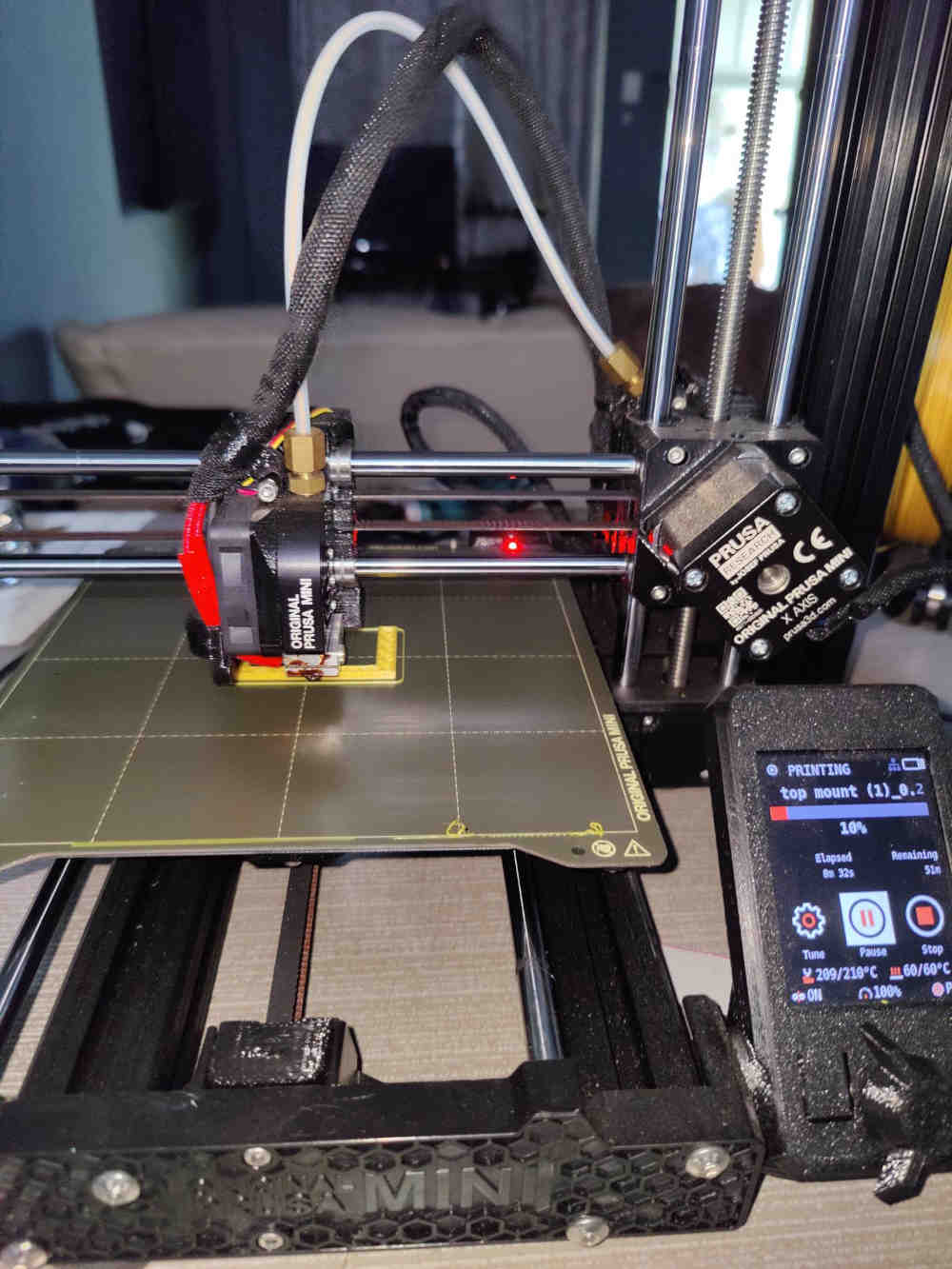

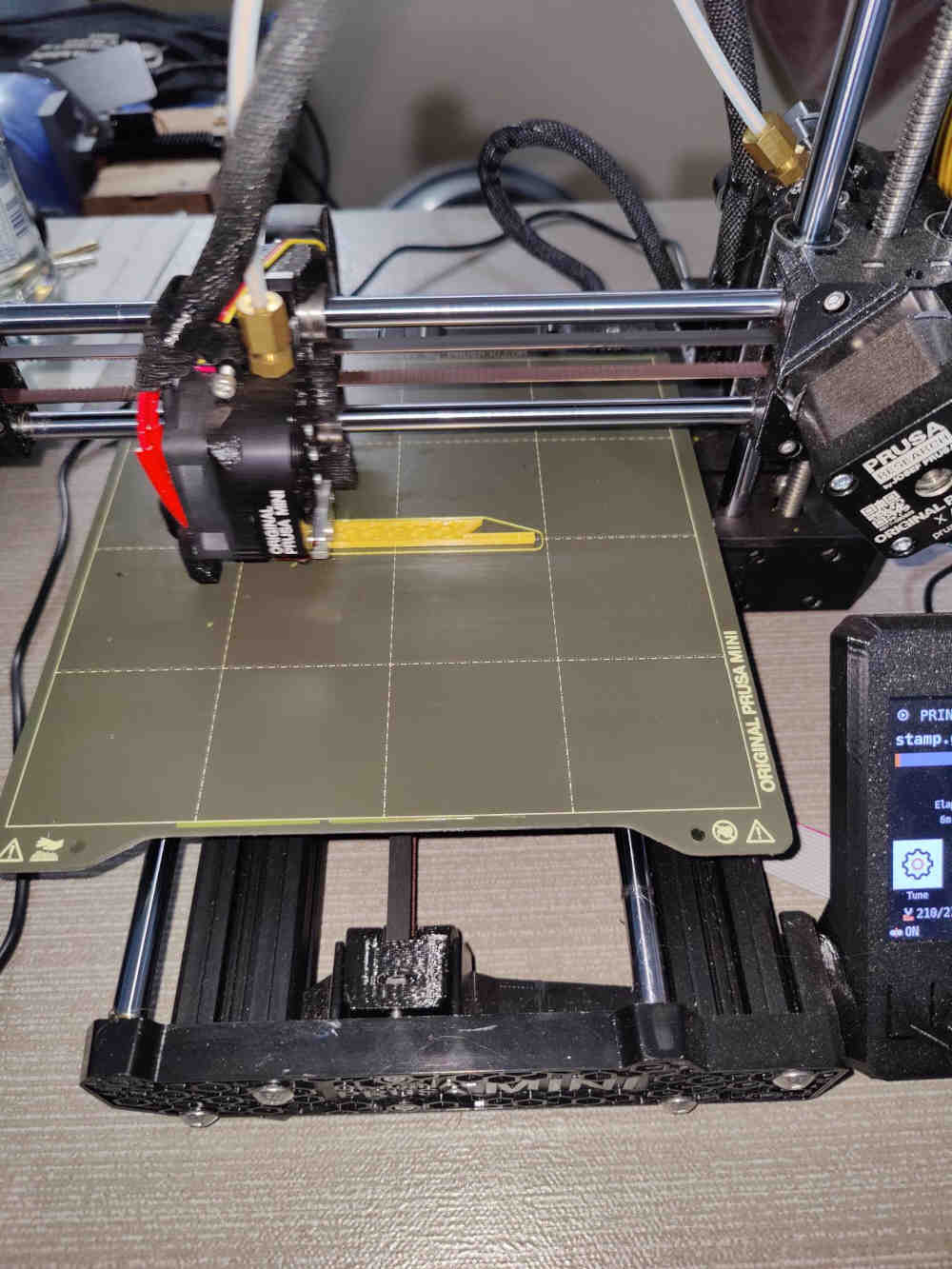

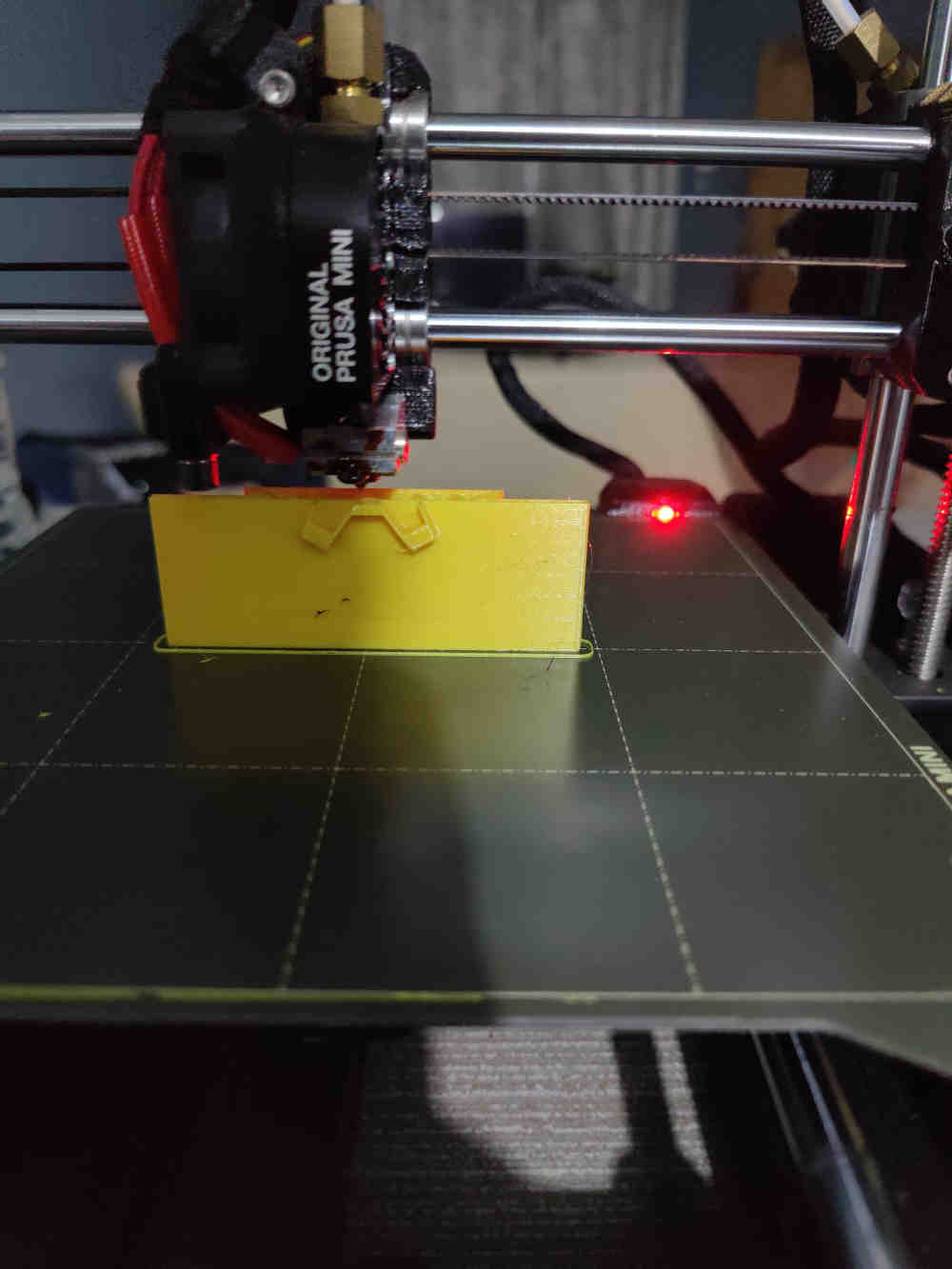

3D Design and 3D printing the Stamp¶

Again Tinkercad was used for 3D designing & Prusa Slicer software and a Mini Prusa was used for 3D printing the stamp.

Note: gcode files are for Mini Prusa