Computer Controlled Cutting

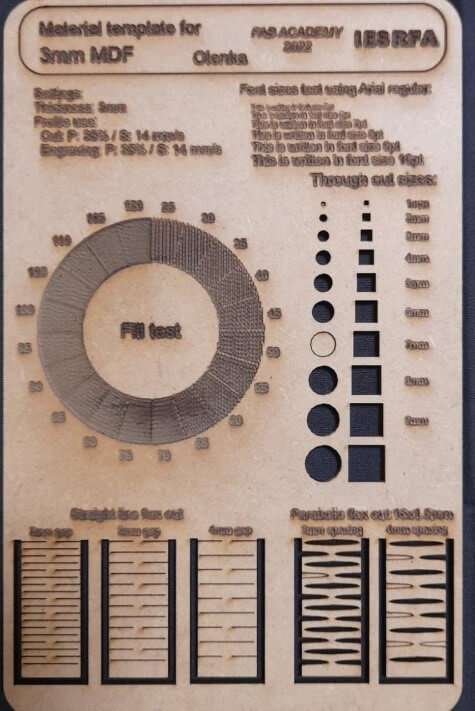

LASERCUTTER

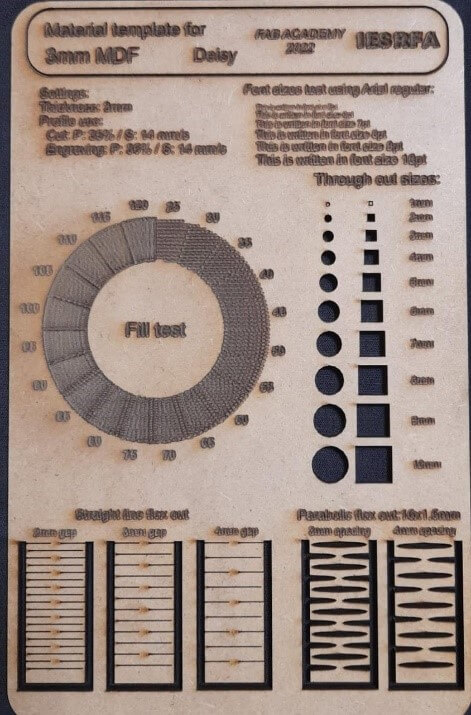

Group Assignment

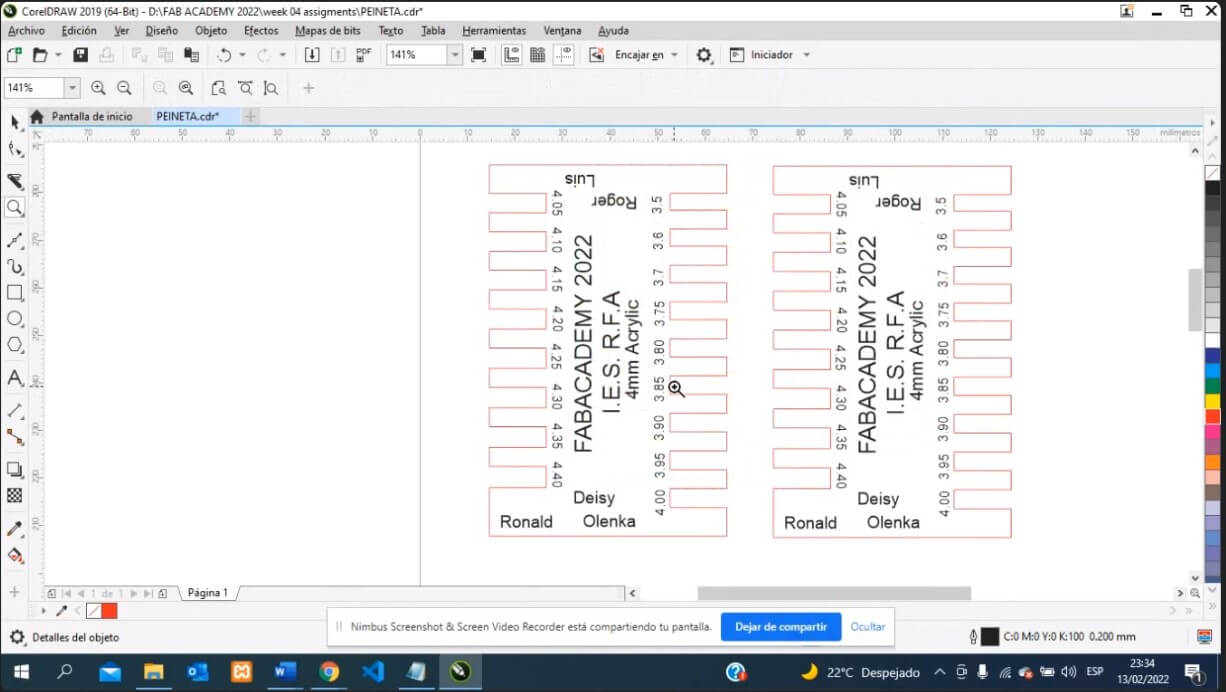

This work was carried out by the team made up of teachers from the I.E.S. “REPÚBLICA FEDERAL DE ALEMANIA”, which is detailed below:

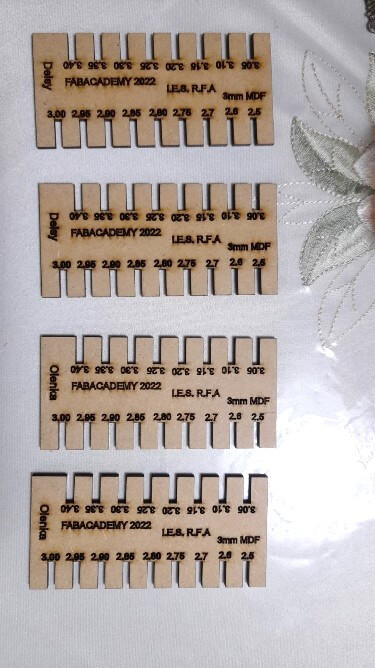

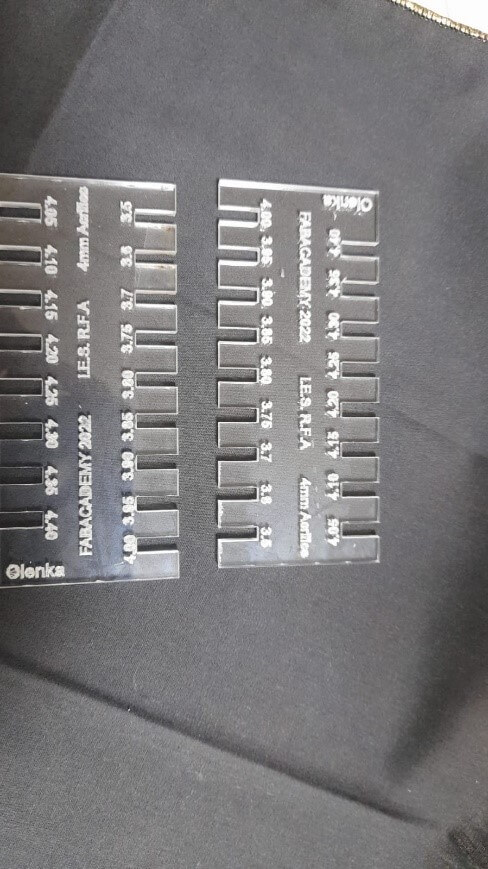

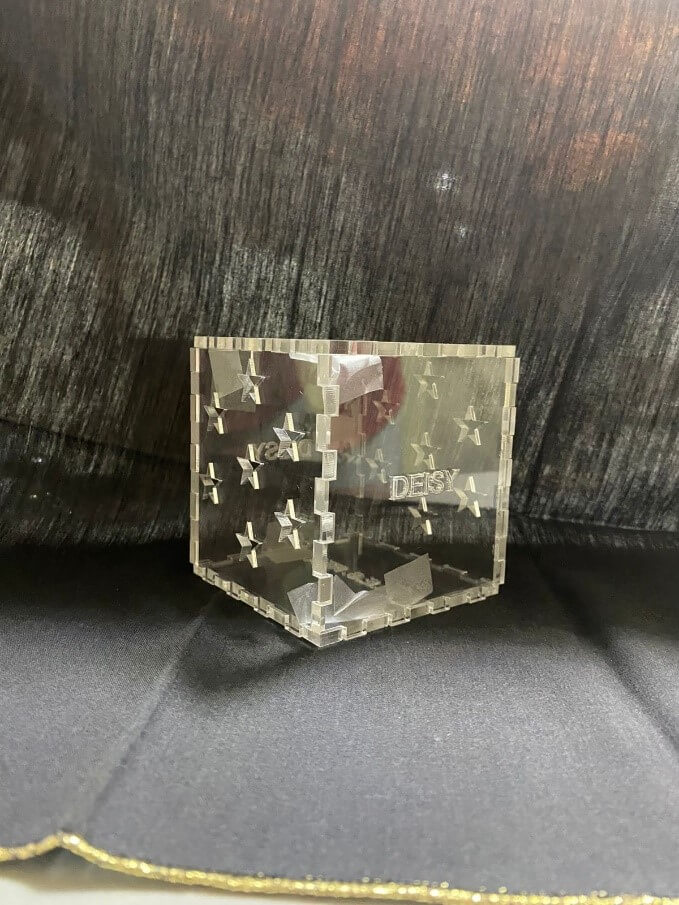

- Eng. Olenka Odar Jiménez

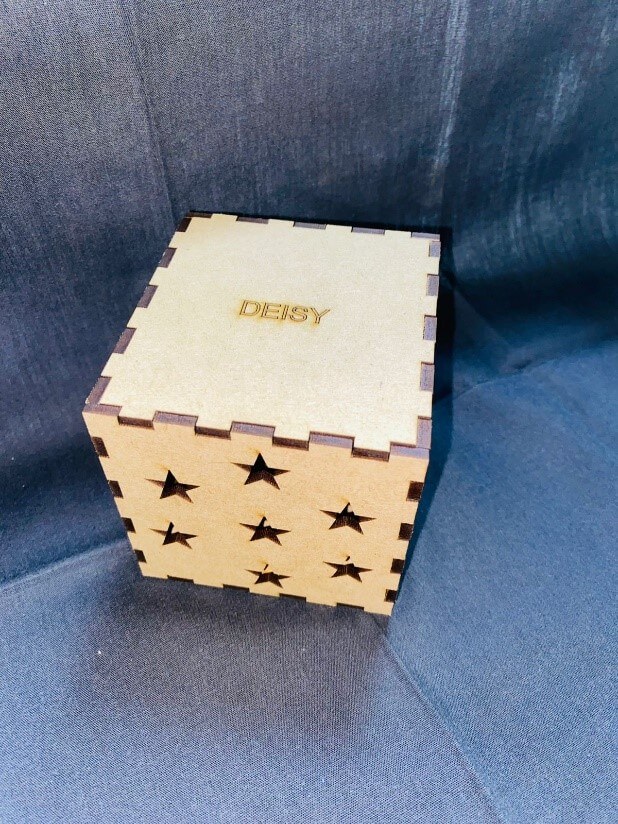

- Eng. Deisy Olguín García

- Eng. Roger Zavaleta Lozano

- Eng. Luis Montalvo Soberón

- Técnico Ronald Villar Gonzales

We still do not have a Fab Lab implemented in our institute, so we looked for places where we could carry out our assignments; Although we were limited in the time we could use the machines, we were able to carry out the activity.

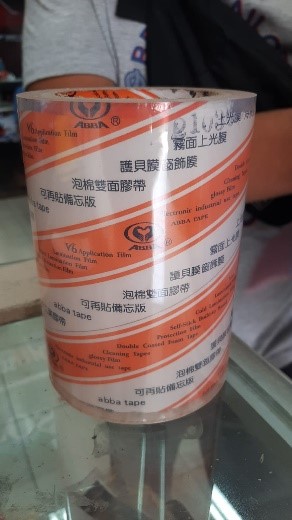

Laser cutting

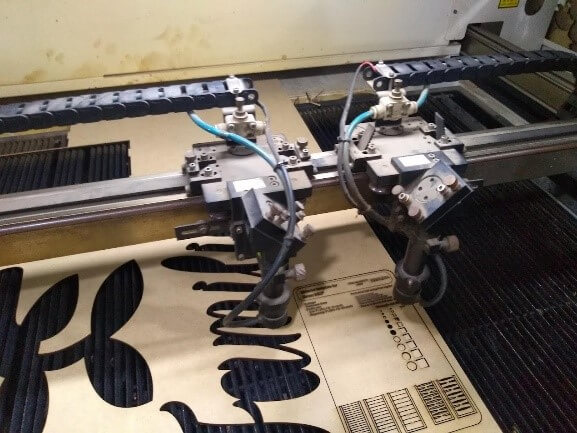

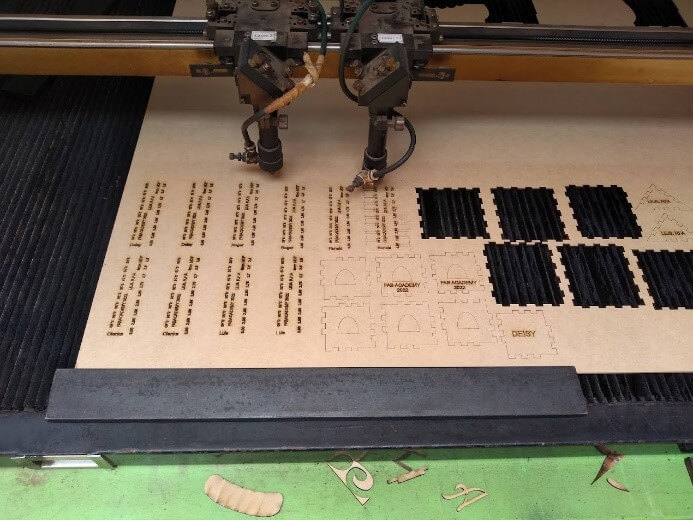

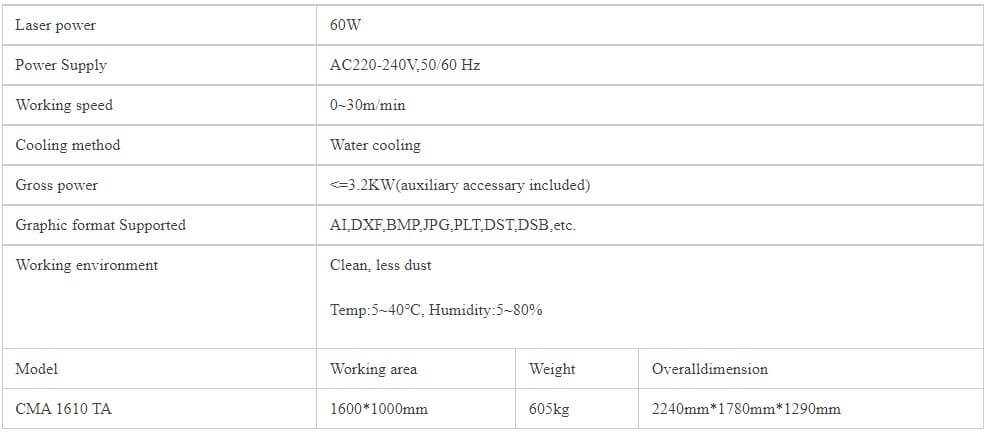

Laser Cutting Engraving Machine CMA 1610 TA, has 2 Tube Laser with power 1 Tube 80 watts. 1 Tube for 1 Head. Can be used 2 Tubes for 2 Head at a time, can also 1 Tube 1 Head is On.

Mark: Hans Yue Ming

Model: CMA 1610 TA

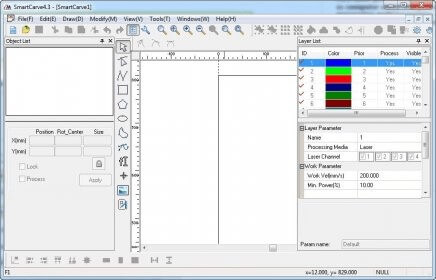

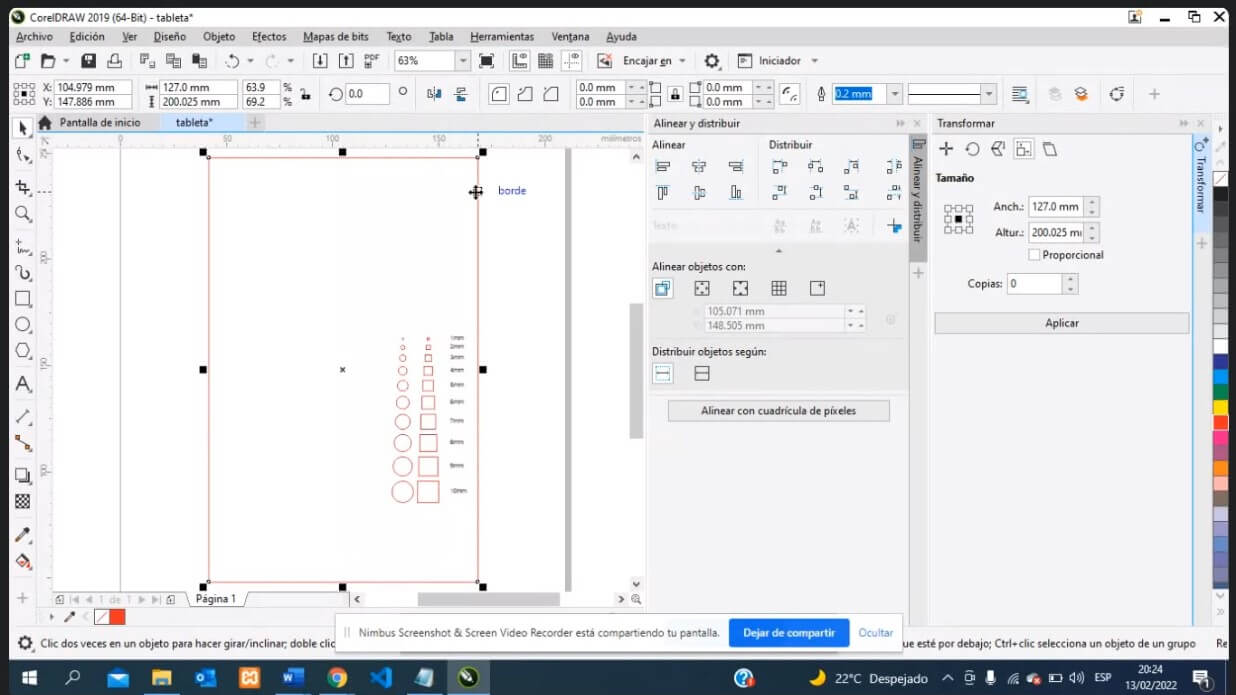

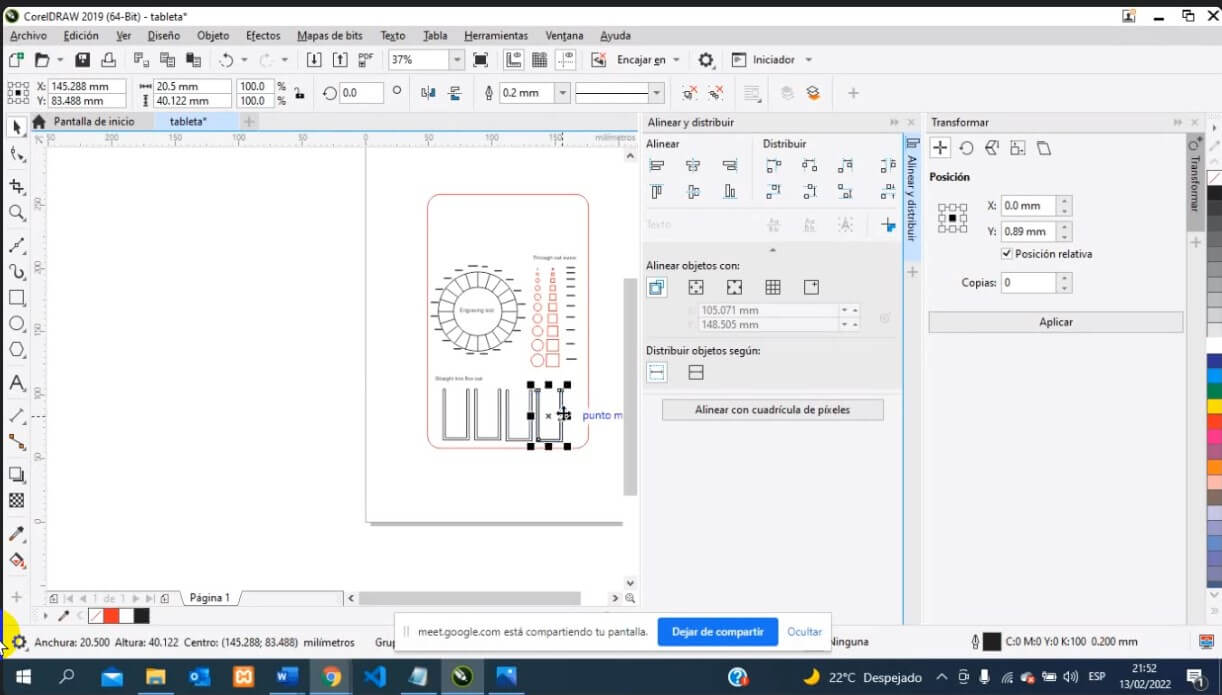

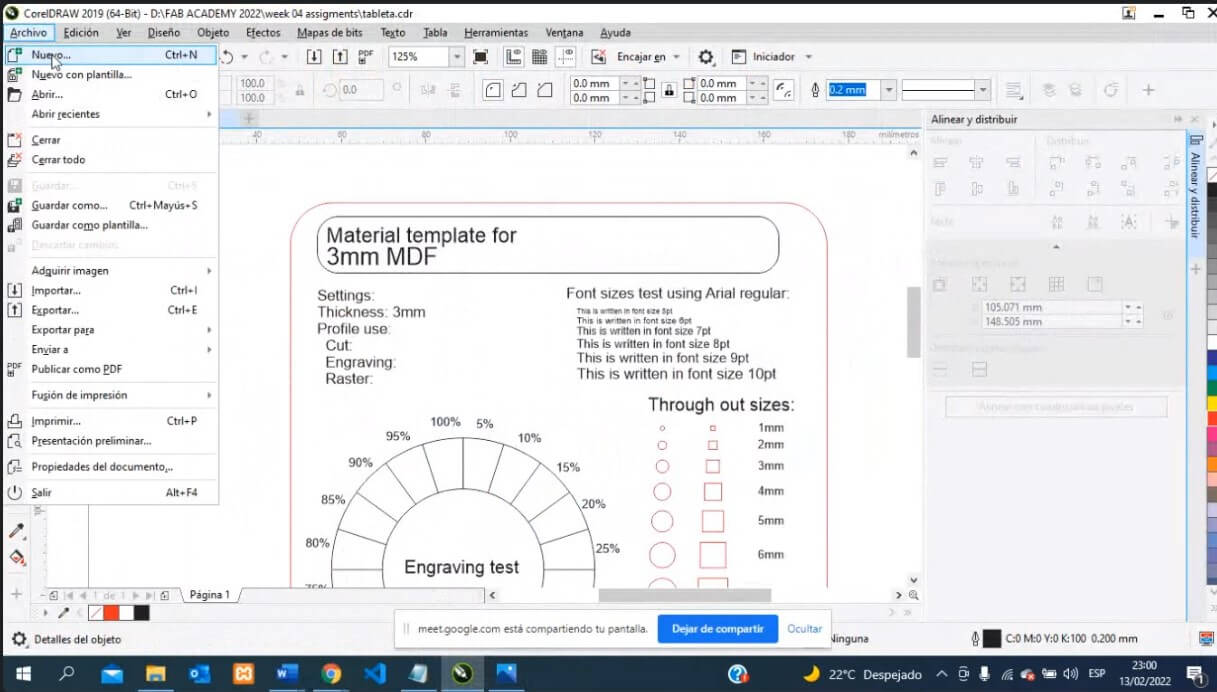

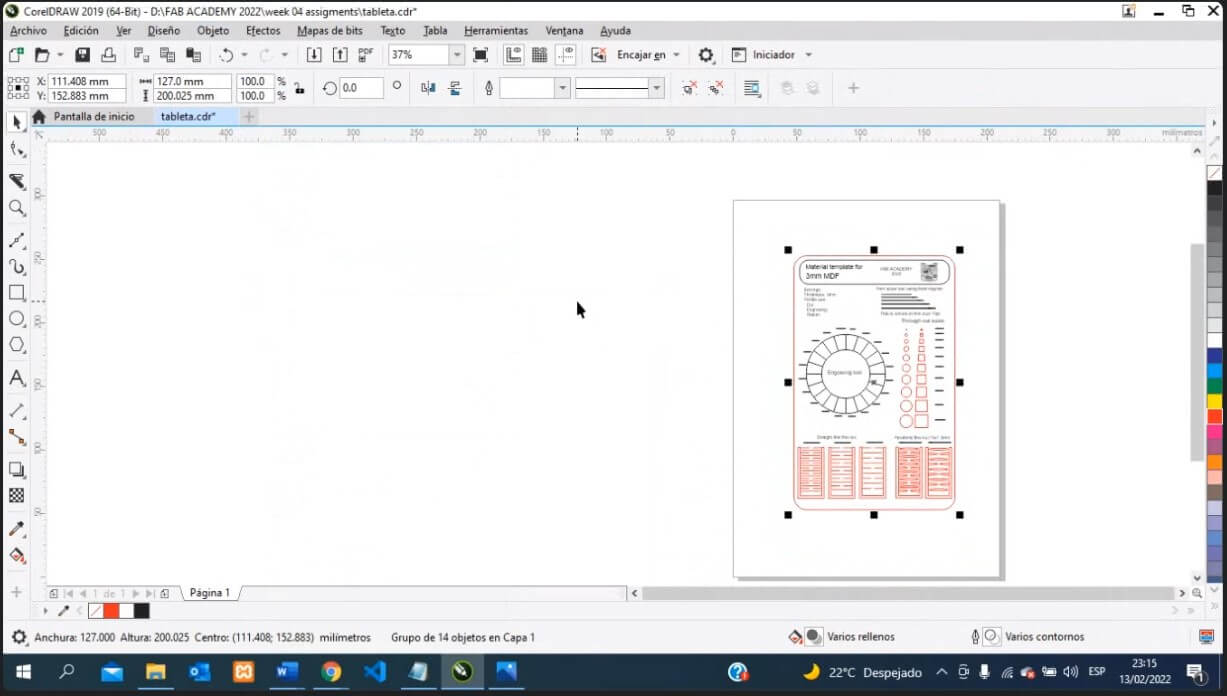

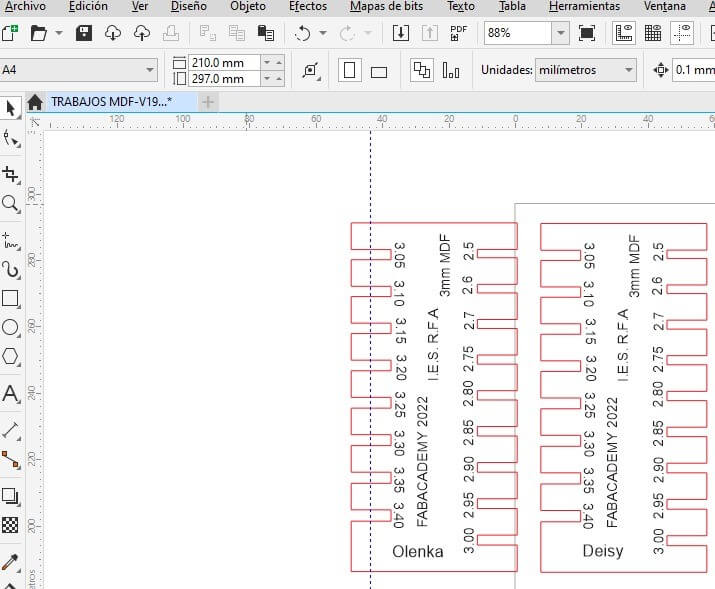

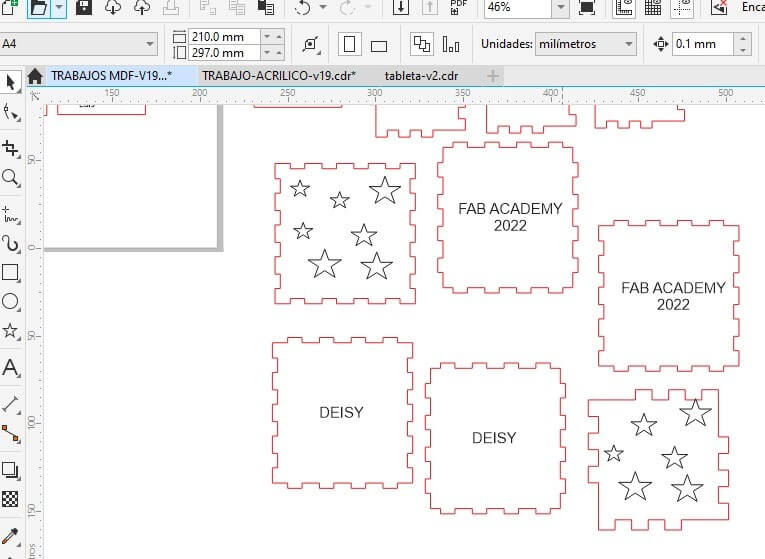

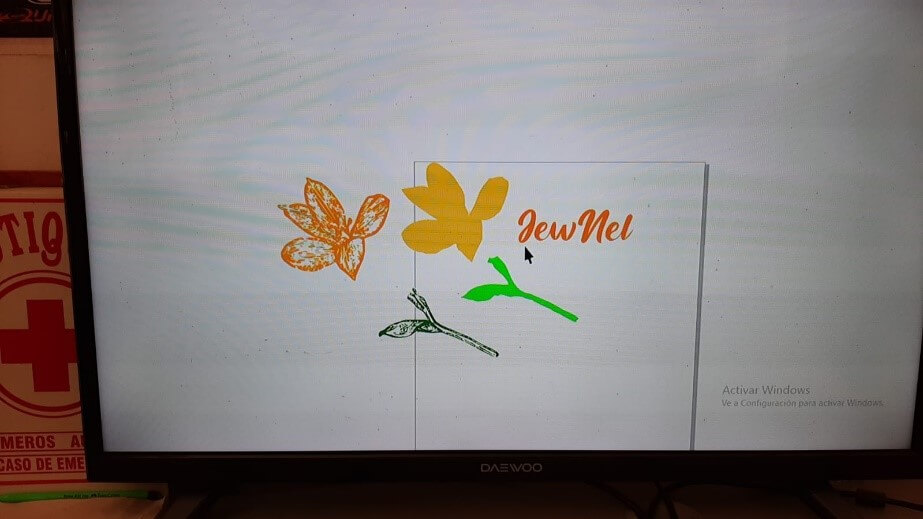

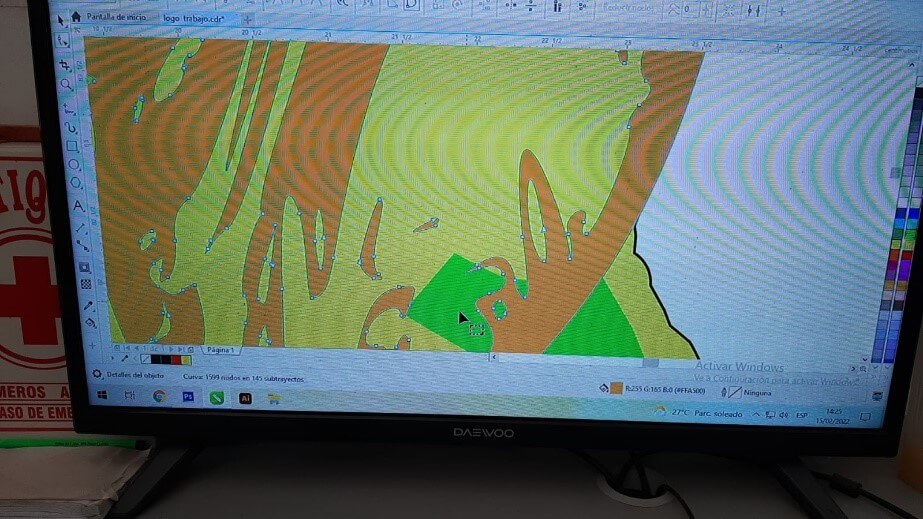

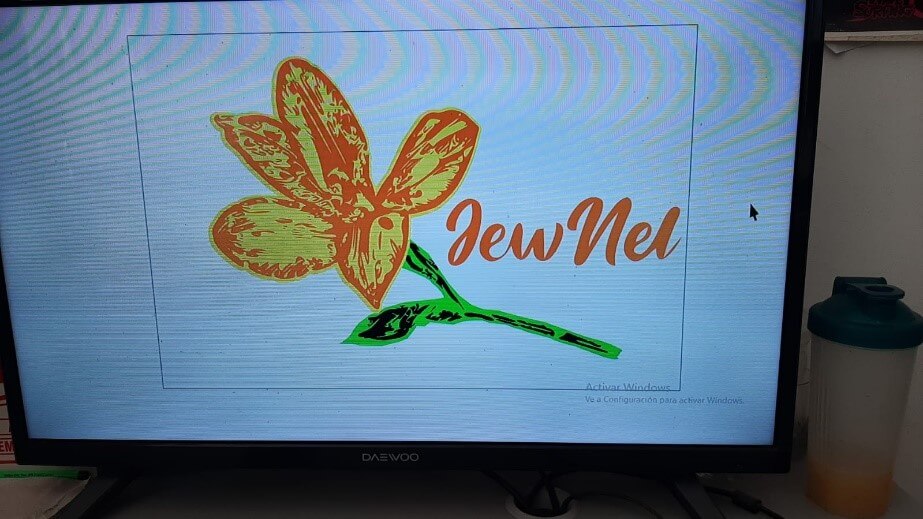

Software: Corel Drawn + SmartCarve4.3

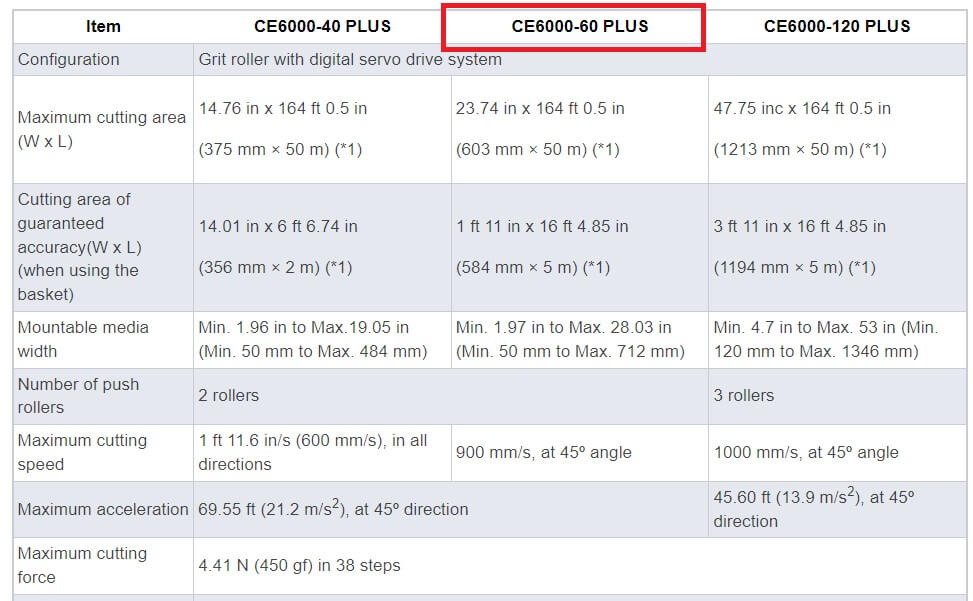

Technical Parameter

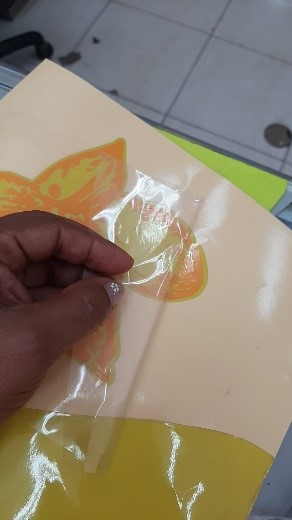

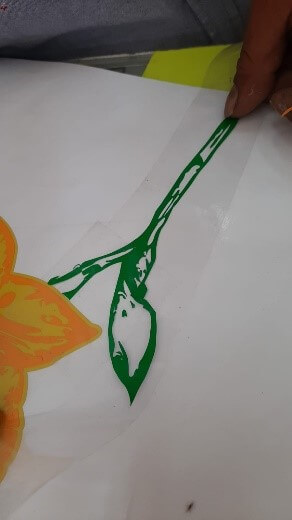

Some photos of the machine that was worked on: