4) PCB fabrication workshop

Using the PCB pictures from this reference to create process file .rmlUsed Files

| Files | Link |

|---|---|

| Traces | Download |

| Outline | Download |

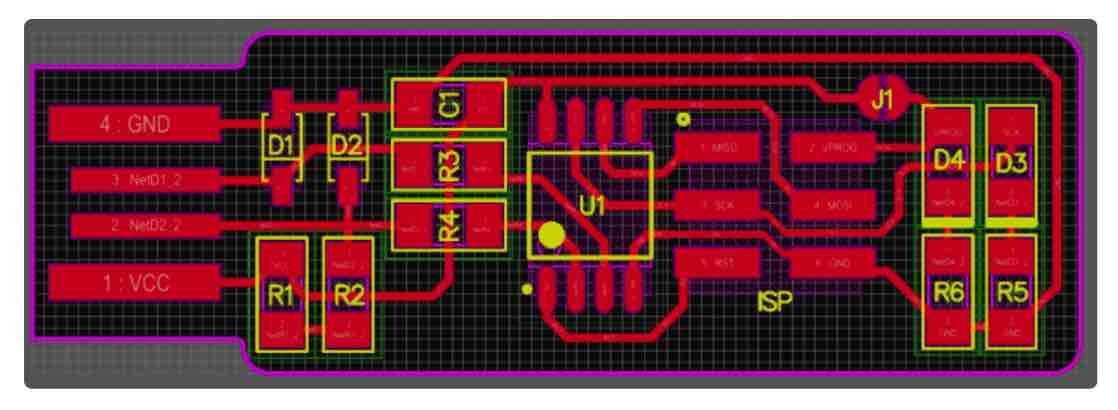

4.1) PCB Design and preparing

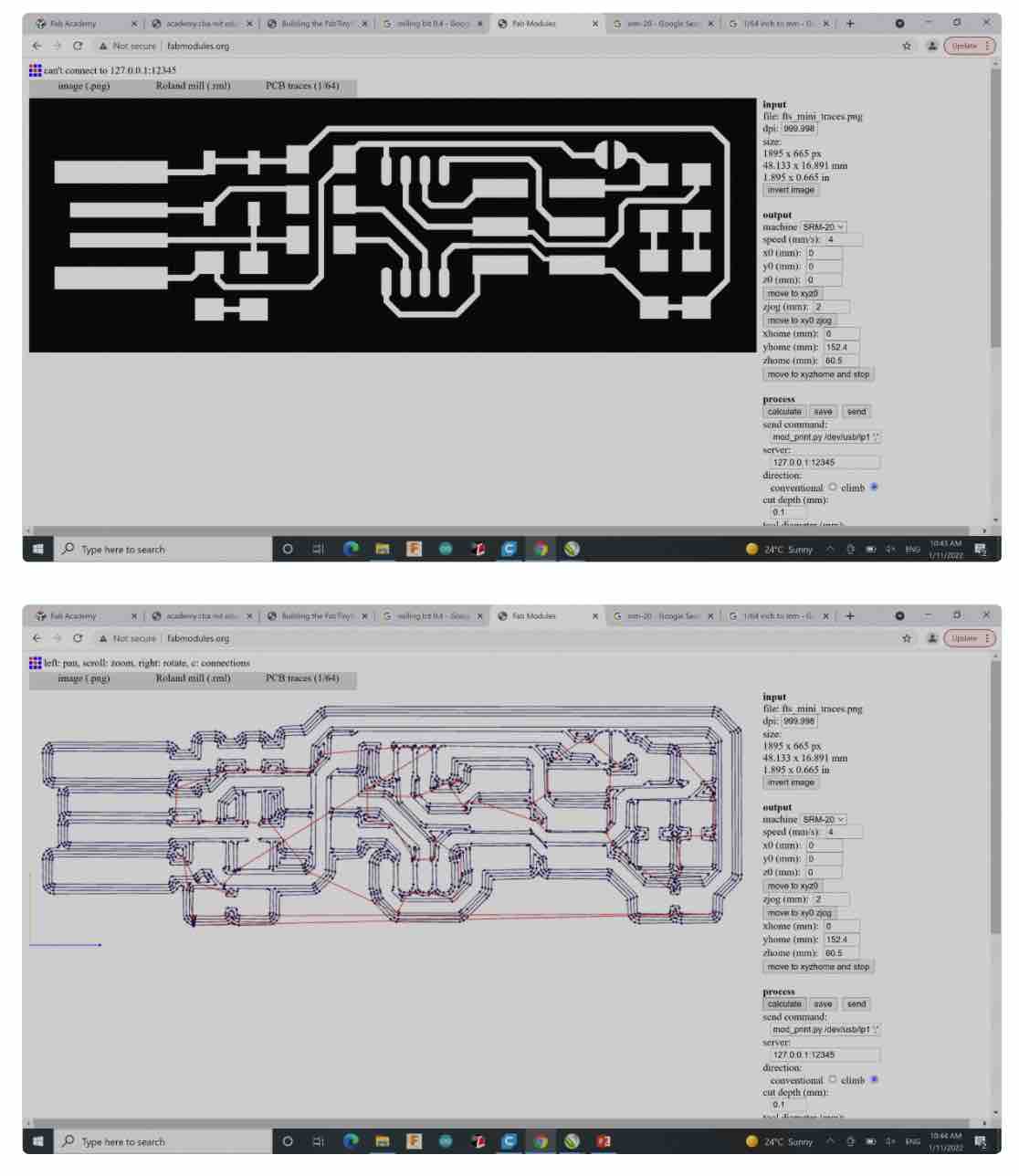

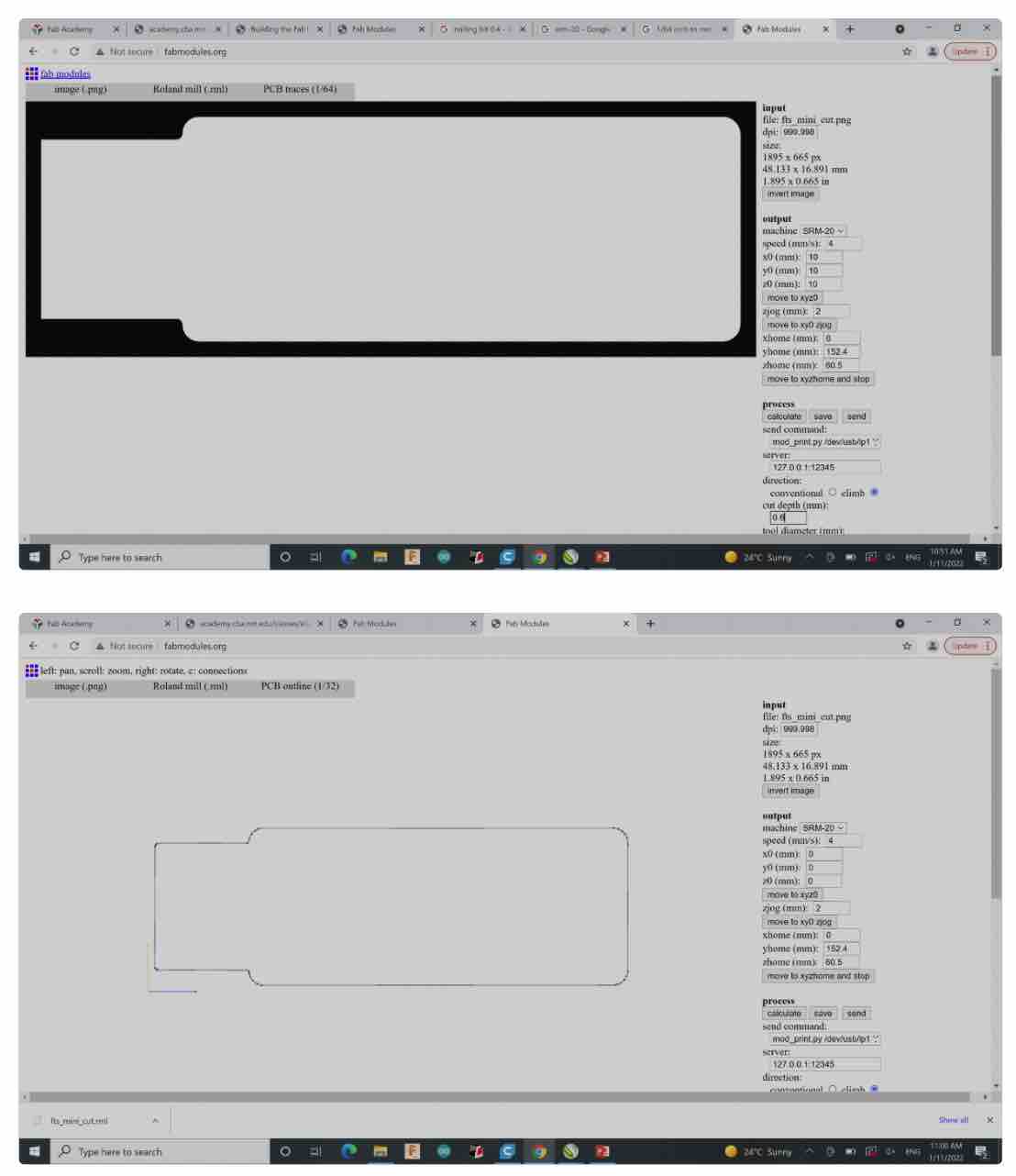

Using the Fabmodules to convert image to G-code for the milling process.Steps:

**Traces**

**Outline**

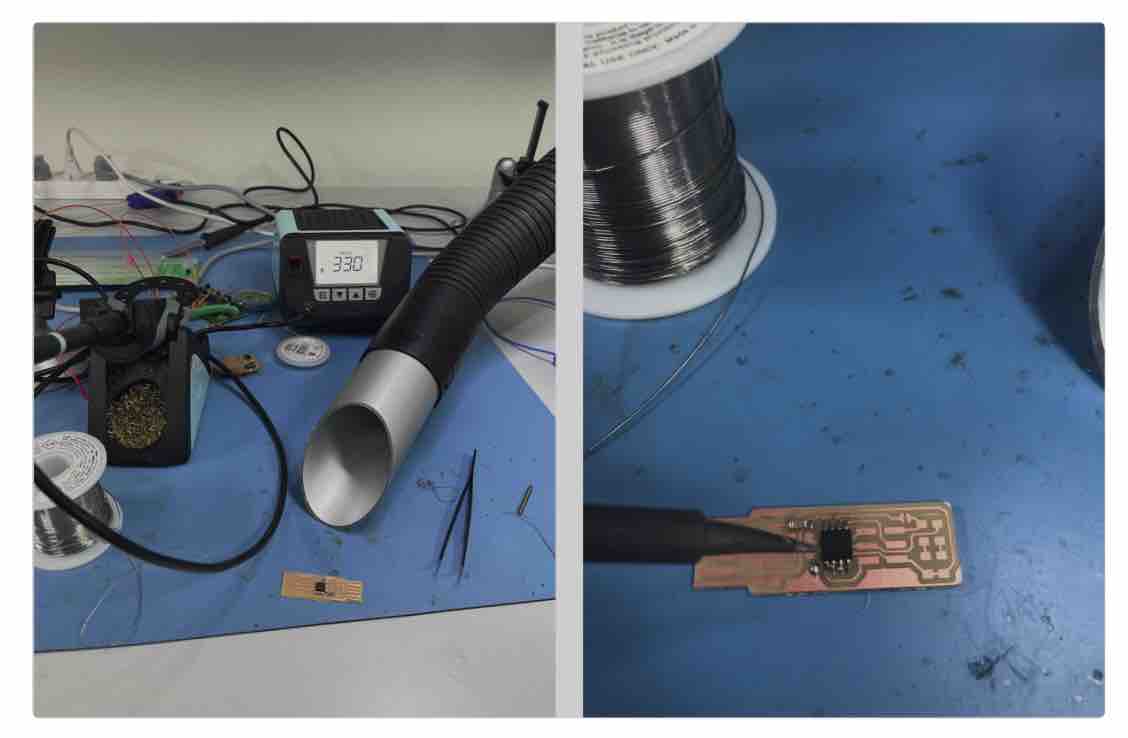

4.2) PCB fabrication

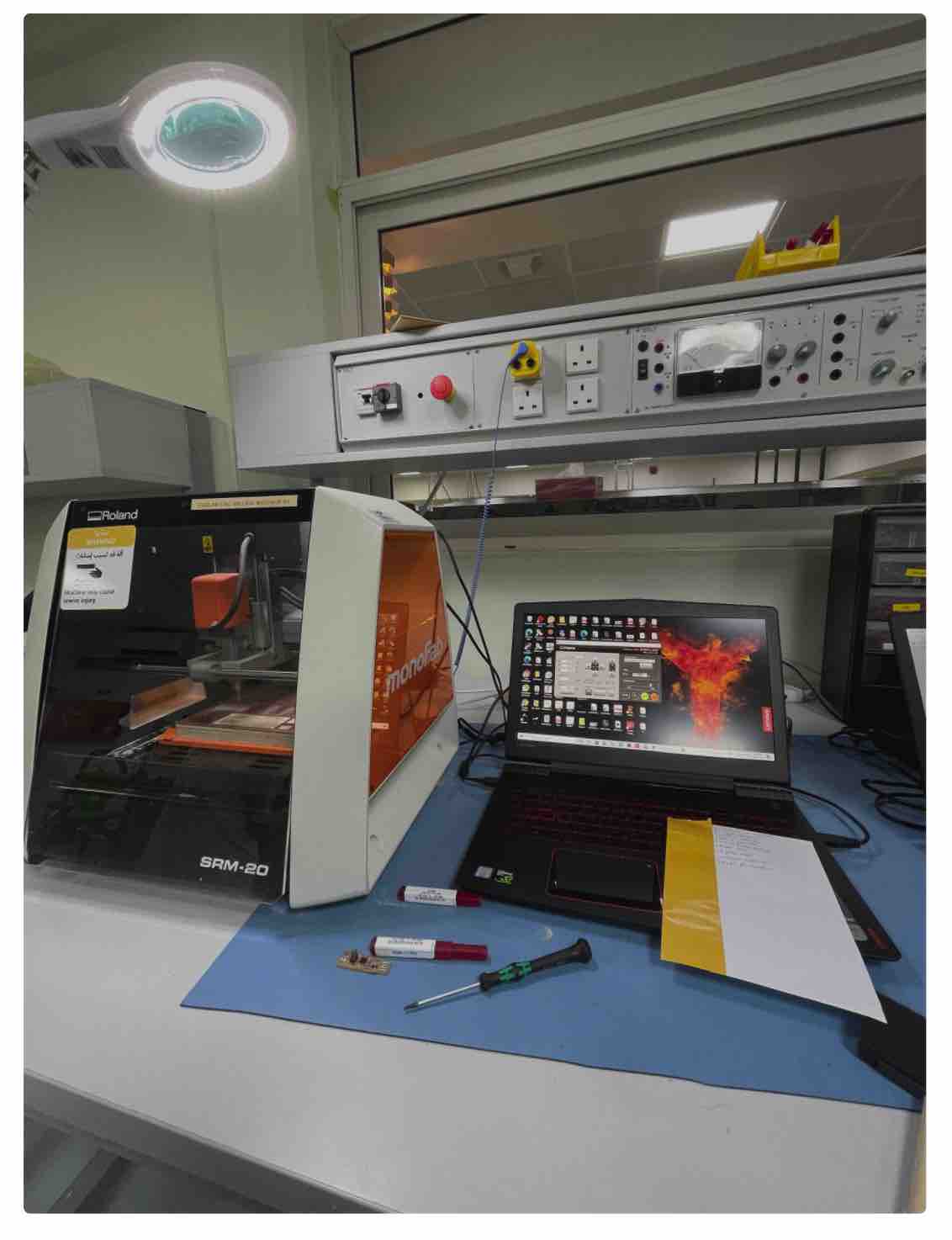

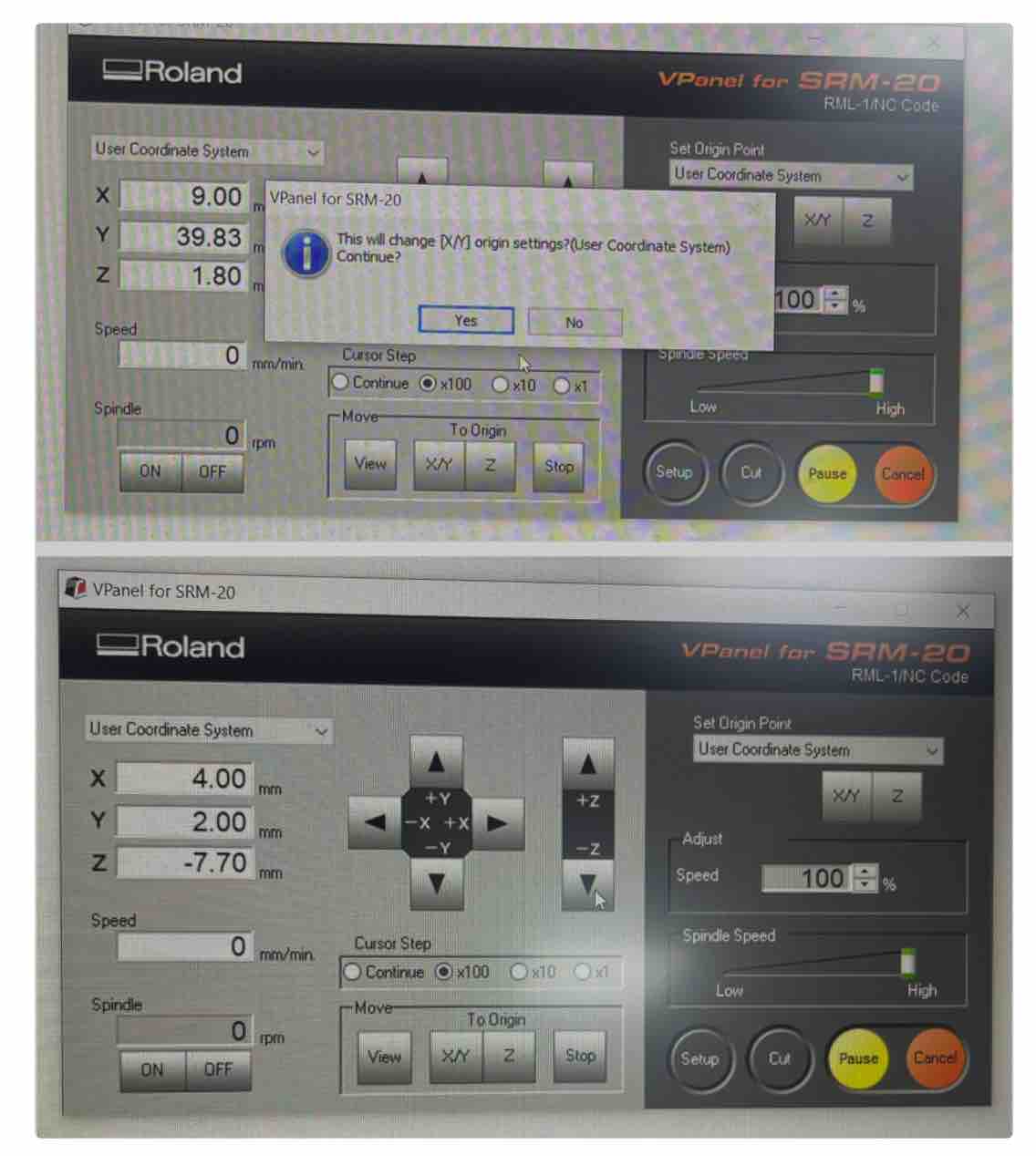

Used machine: monoFabUsed software: VPanel

Process: Milling

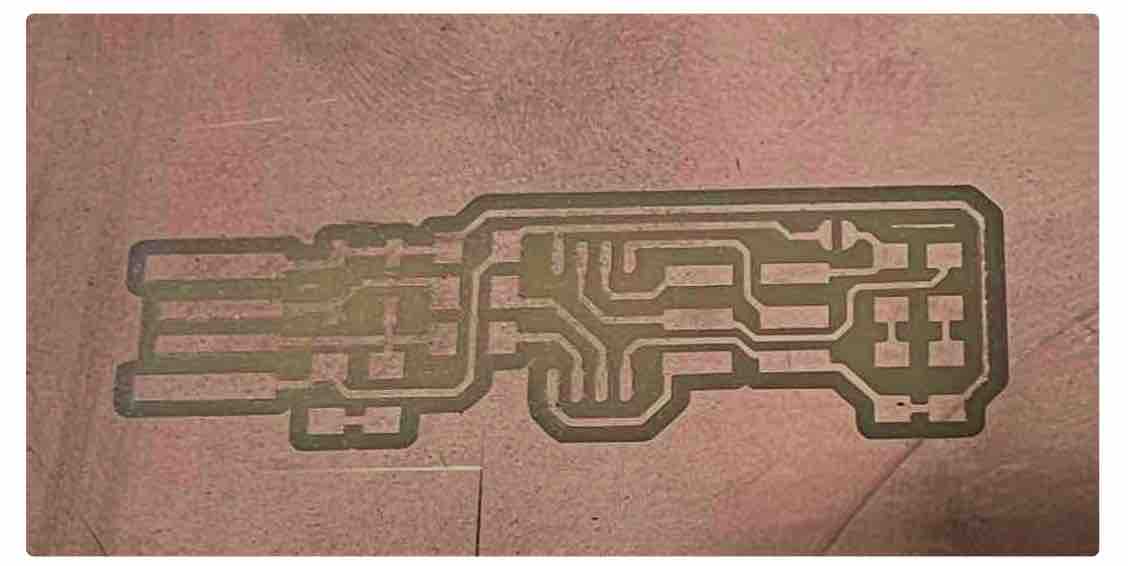

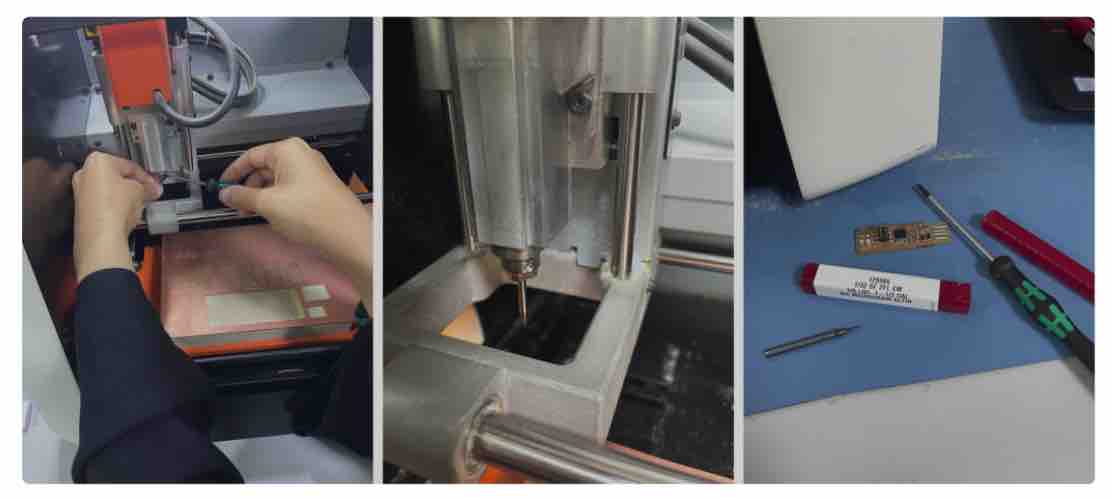

Mill bit used: 1/64 for traces; 1/32 for outline

**Workplace**

**Setup - Leveling**

**Milled PCB traces**

**Attach and Replace Mill bit**

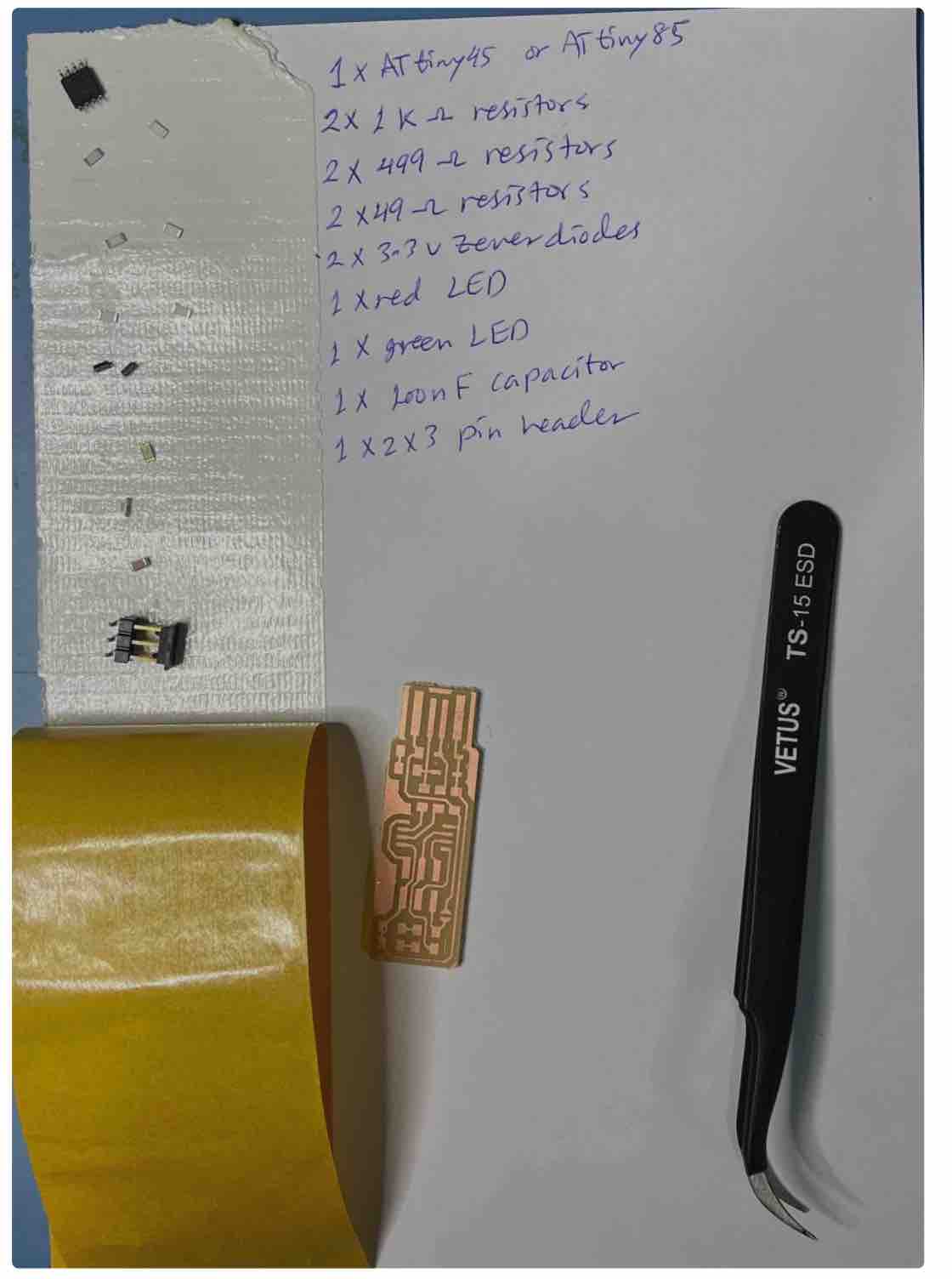

4.3) PCB Assembly

**Components**

2x 1kΩ resistors

2x 499Ω resistors

2x 49Ω resistors

2x 3.3v zener diodes

1x red LED

1x green LED

1x 100nF capacitor

1x 2x3 pin header

**Soldering area**

**PCB board**

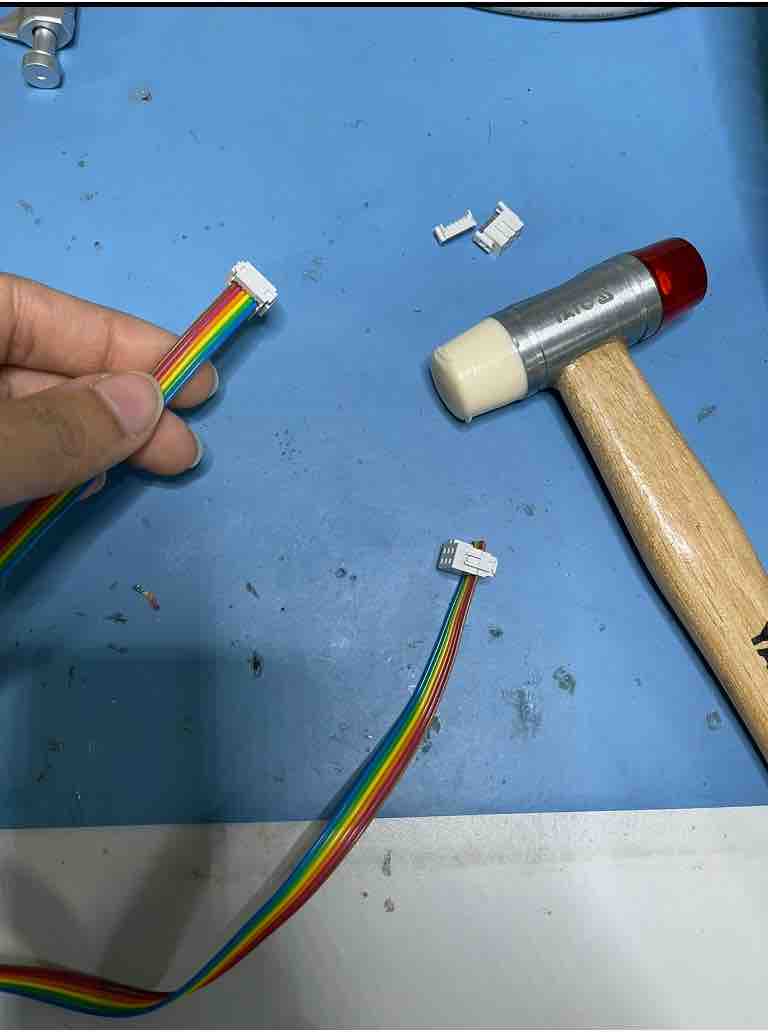

Update 21/01/2022:

Ribbon wire:

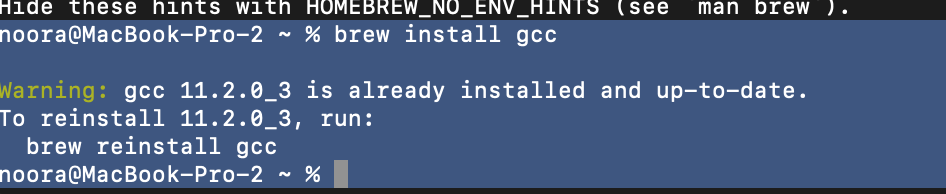

Update 06/02/2022

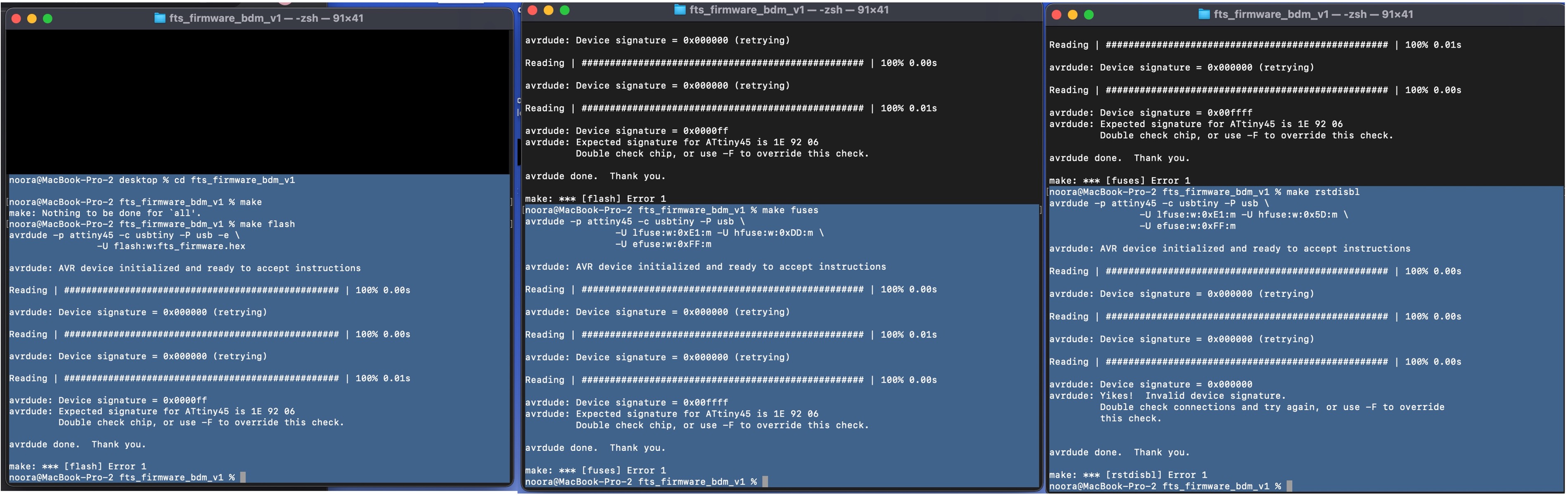

Programming:

Steps:

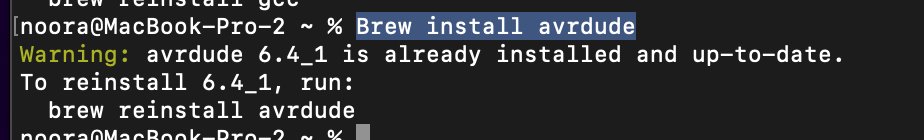

1) Open terminal and past the following command to install Homebrew:

ruby -e "$(curl -fsSL https://raw.githubusercontent.com/Homebrew/install/master/install)" 2) Install avr-gcc toolchain

brew tap osx-cross/avr brew install avr-libc brew install avro-c brew install gcc

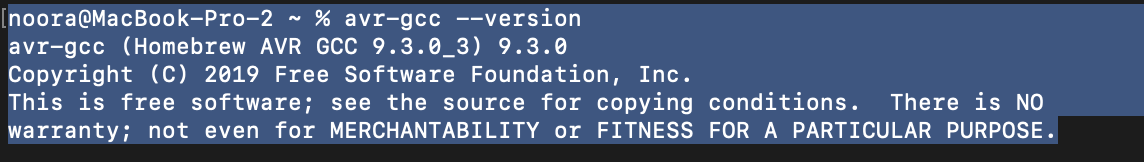

brew install binutils brew install avrdude  Last step is checking avr-gcc version; by typing the following command:

Last step is checking avr-gcc version; by typing the following command: avr-gcc –version  3) firmware

3) firmwareUsing terminal to navigate the fts_firmware_bdm_v1 folder, and run

make In order to create this file (fts_firmware.hex)

4) Using USBTiny to program my PCB: