Week's goals:

1- Individual assignments2- Group Assignment

Used Software:

1. CorelDraw2. Autodesk Fusion 360

3. Roland CutStudio

4. Universal Laser System interface

Used Machines:

1. Universal Laser Systems Machine2. Roland vinyl Cutter model CAMM-1 GS-24

Individual assignment - Laser cutting

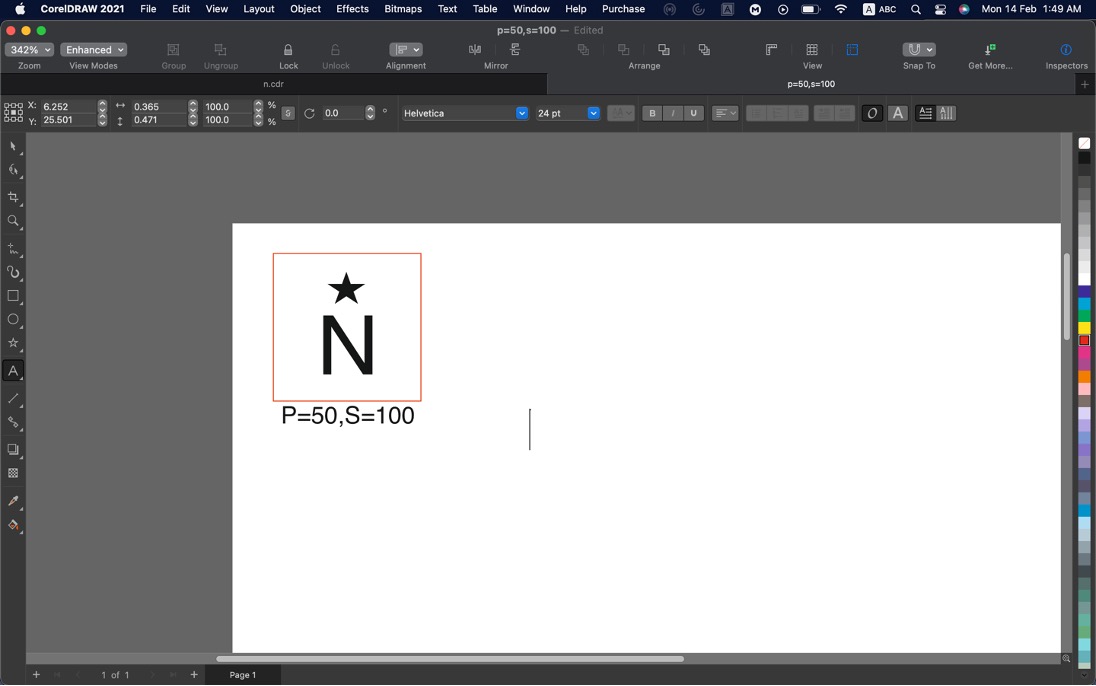

First task was done during the pre-fabacademy and it was about design, lasercut, and document a parametric press-fit construction kit.Using the CorelDRAW software to create my design to be produce. I inspired my design from sheikh Zayed poem. This is the created initial design:

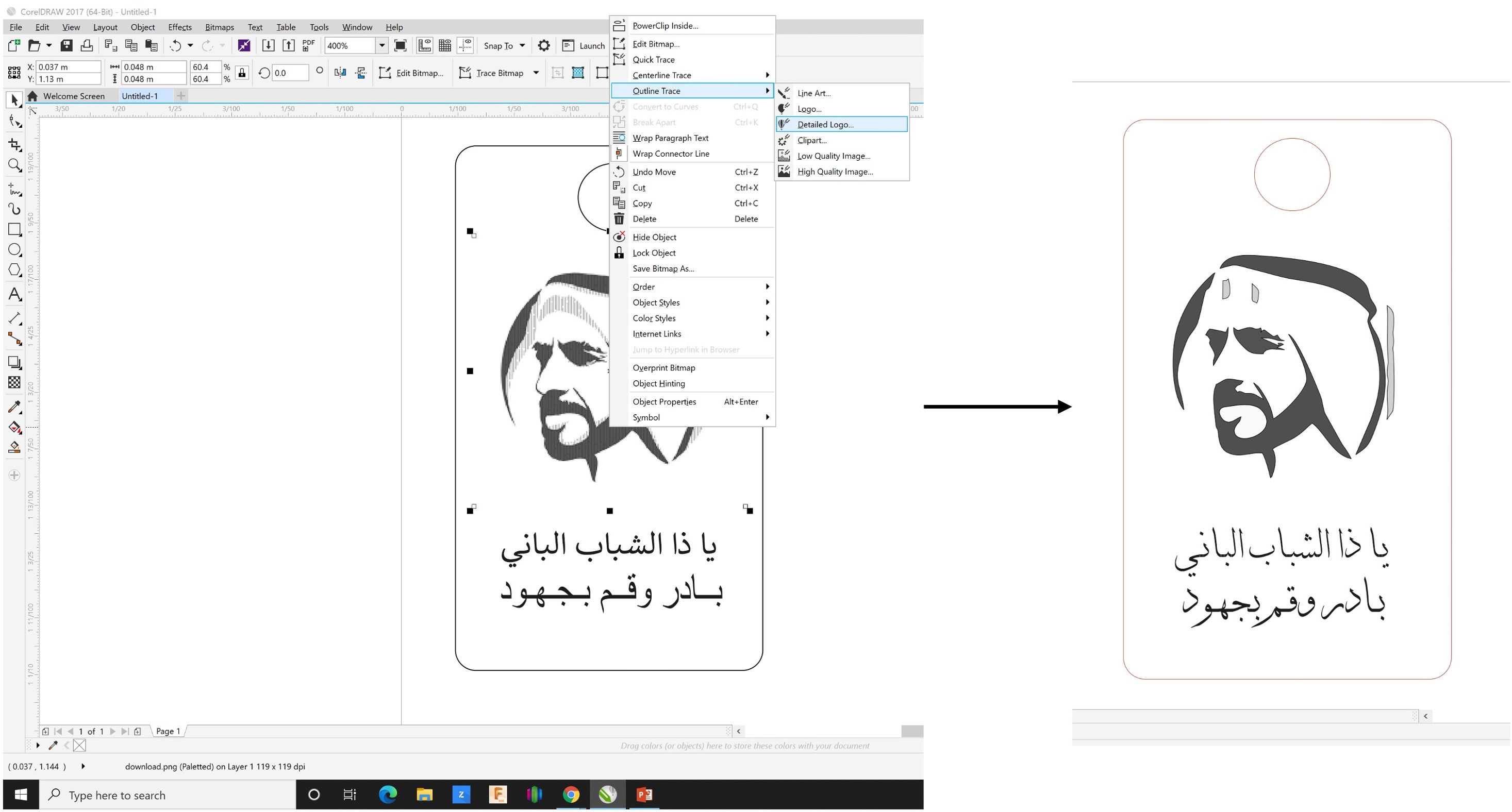

Setup used before cutting the part; right click on picture and select detailed logo; then select image and delete the white background.Also, the last thing of the setup to check is color the outer lines in red which means to be cutted, and black color for engraving which will be for the image.

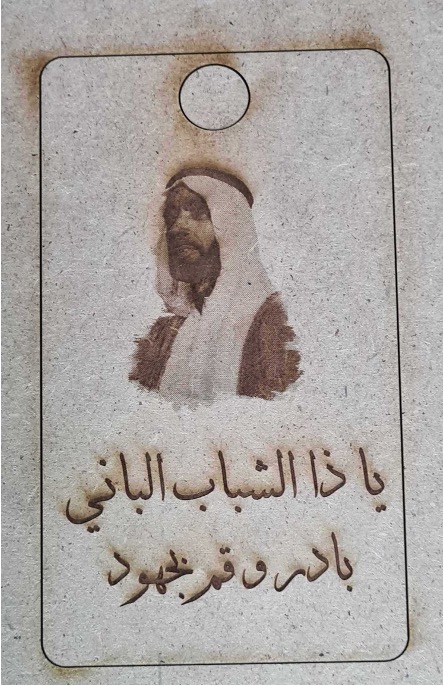

I used a diffrenet image and then used the laser cutting machine to produce the part (using MDF wood sheet) auto setting in the software. The final cutted part is shown in this picture:

Finally, this is a video shows the cutting process for my design.

Second task is to do the press-fit kit.

Third task is to cut something by using vinylcutter.

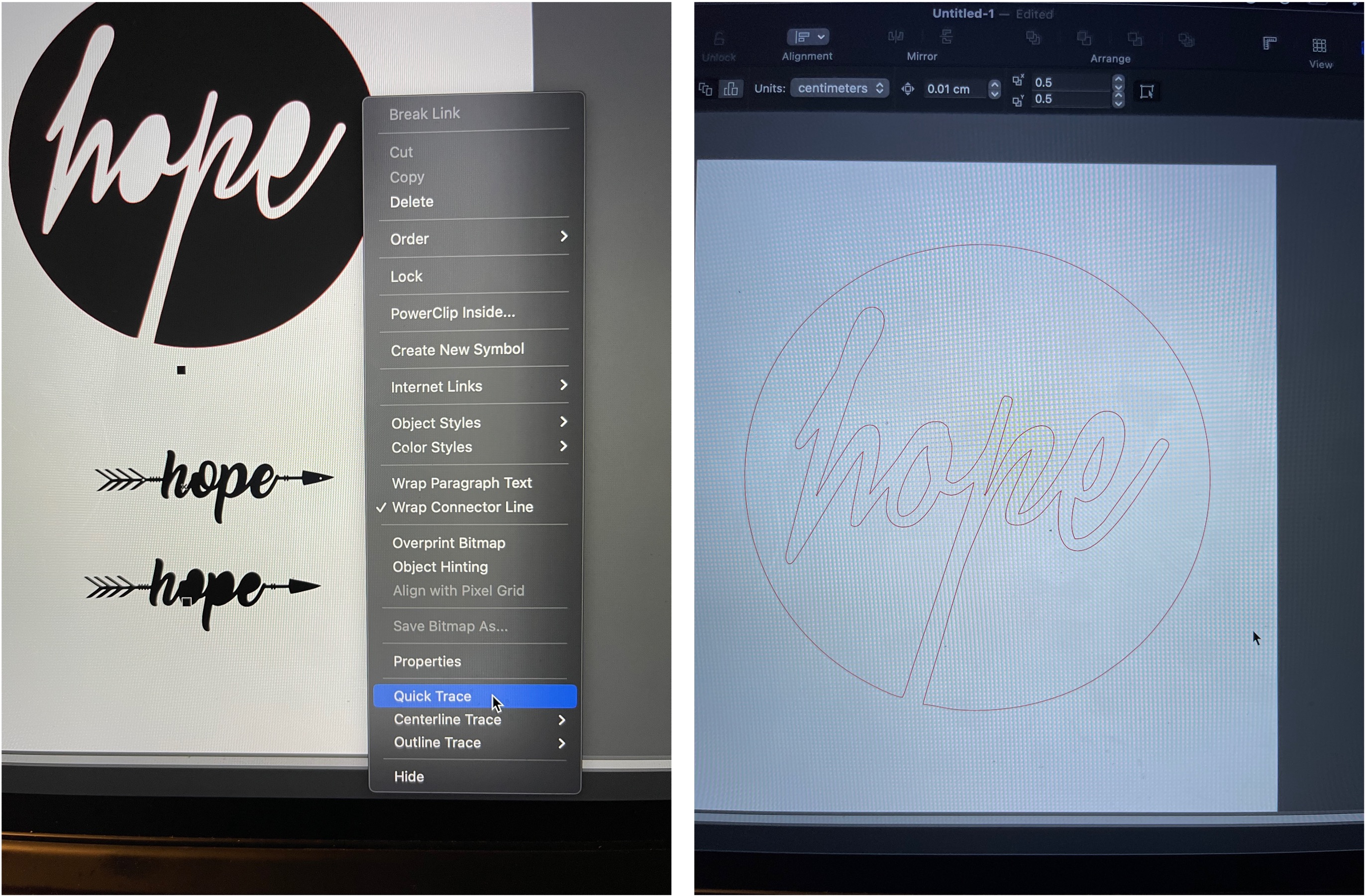

I searched for png format pictures that I want to create as a sticker. I used corelDRAW to edit and convert the picture into a vector in order to cut it in using the vinyl cutter machine.

Group assignment:

For this group task we have to characterize the variables (power, speed, kerf, and joint clearance) of the laser cutting machines we have in the fablab for different materials. The main objective of this task is to test the cutting and engraving parameters in order to find the perfect setting for the testing material. I choosed this material (***), and test the cutting settings (Power, Speed and Kerf). In order to complete this assignment, I used this reference.Measuring kerf:

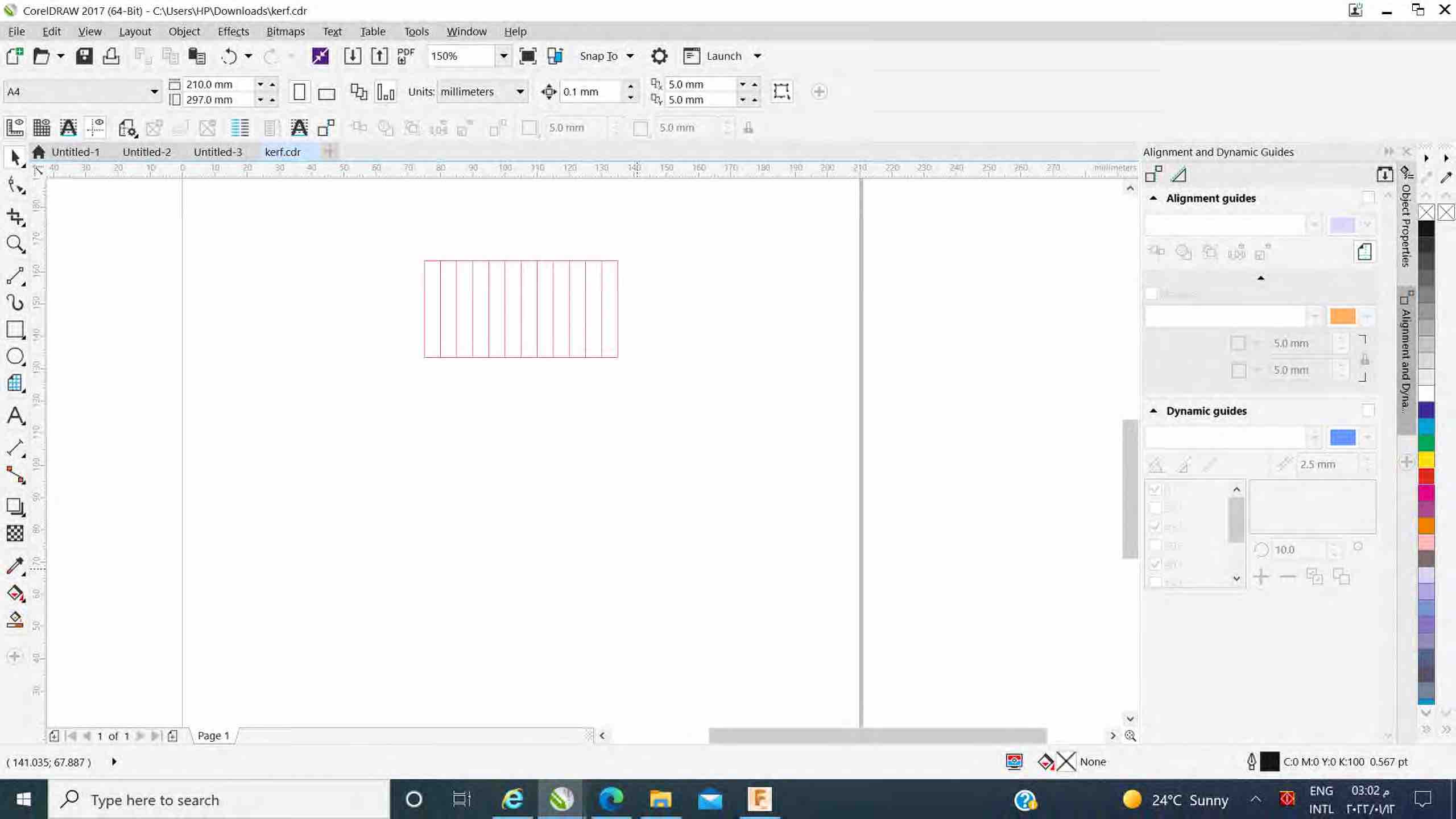

I used the corelDRAW software to design a rectangular shap with this dimensions LxW (60x30mm), and divide it to 12 equal pieces. To calculate the kerf; first I calculated the actual length for the cutted parts, and then used the following equation to calculate it:

To calculate the kerf; first I calculated the actual length for the cutted parts, and then used the following equation to calculate it:Engraving test:

I decided to make three trails by fixing the speed at 100%, and change power gradually from 50 up to 95%. This is the design that I will do the test using it: