17. Wildcard week

This week assignment is to design and produce something with digital fabrication process that is not covered in other assignments

My plan is to design airplane with (in SolidWorks) and produce it with composite manufacturing. I will use fiberglass and epoxy resin for its skin. This aircraft wing will later be used in my project since my final project is design and produce subsonic wind tunnel for testing the performance of and behaviour of model aircraft.

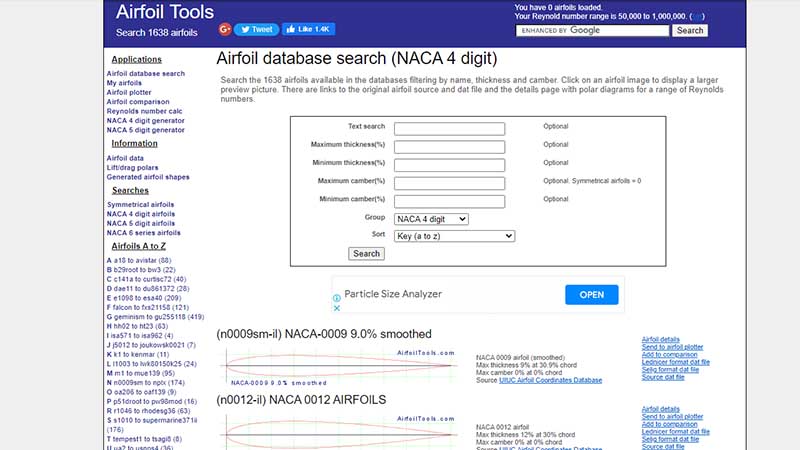

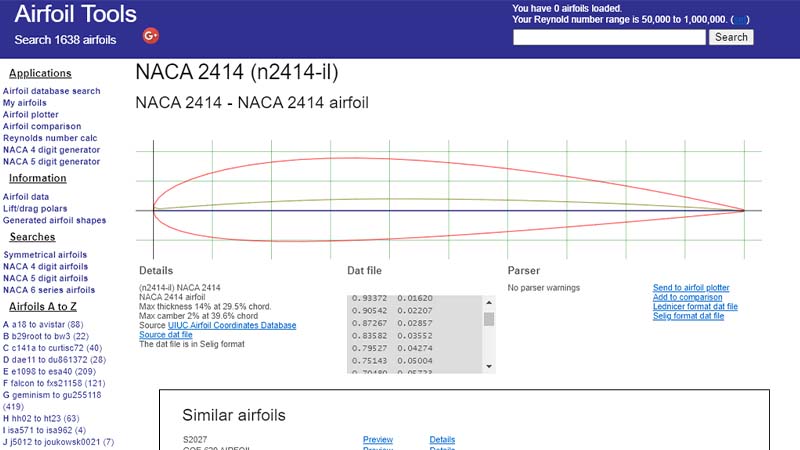

I started my my searching the convenient airfoil from NACA to get some data.

I specically downloaded NACA 2414 airfoil. It has maximum thickness of 14% at 29.5% chord.

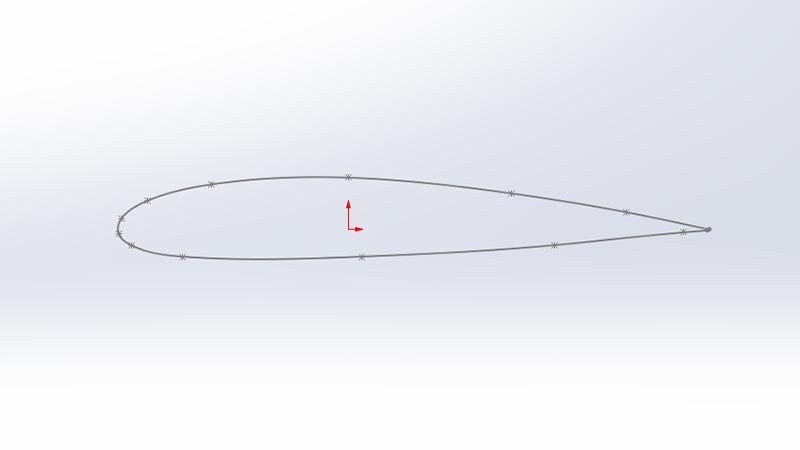

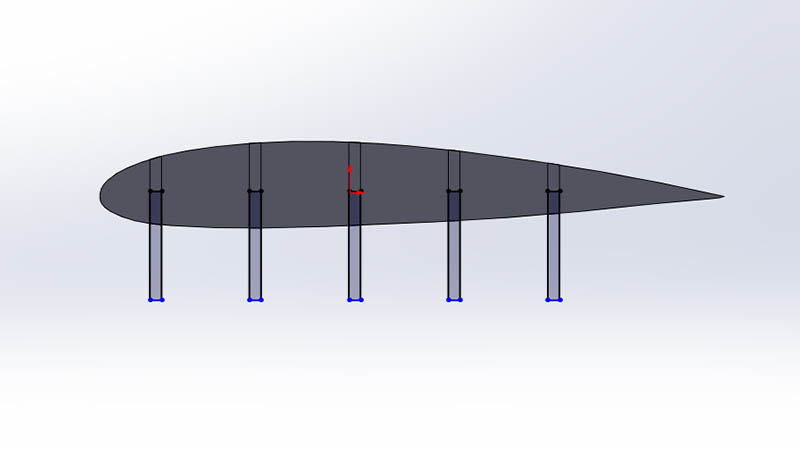

To imoprt its data into design software, you can either import its data (coordiname) or import image. I used sketch picture in SolidWorks get the reference and use spline tool to get the sketch.

Sketch I got

By extrude feature, I converted it into solid body.

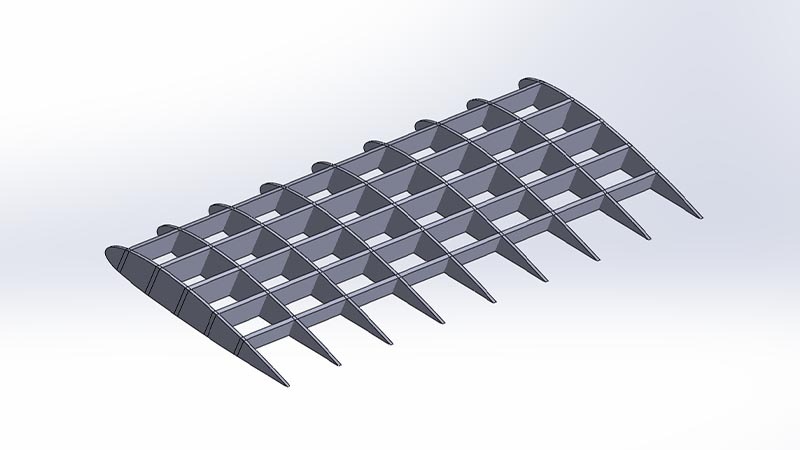

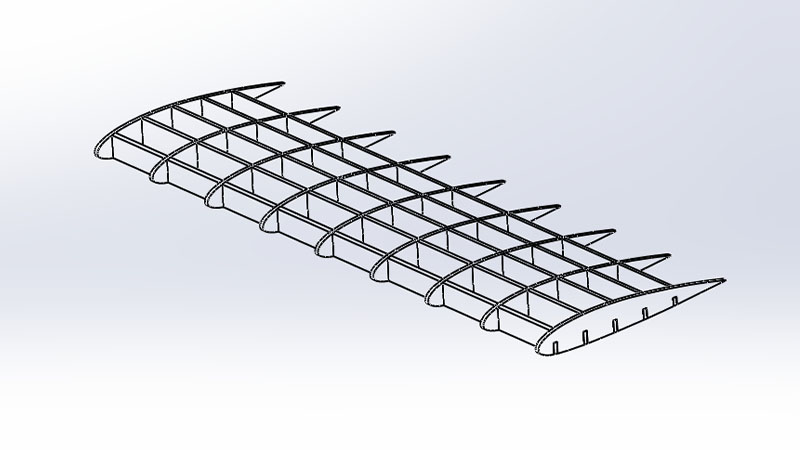

I used with split tool, I cutout ribs and spars struct ure. I am using SolidWorks multibody method instead of SolidWorks assembly. This process is relatively simple in designing iregular shape(s) compored to assembly.

Next process was to cut tabs so that I can assemble them easily.

Final design

I used laser cutter to cut all the parts. The material of the wing structure is 3mm MDF.

I covered the structure with thin sheet of cardboard (0.5mm) so that the epoxy will adhere easily.

I covered the wing with two layers of 0.5mm thickness fiberglass.

I used epoxy and its hardener. The ratio is 1:1. For measuring, I used volumetric measuring, I pouled 125ml of epoxy in one cup and that of hardener in other.

After measuring the two portions, I pouled them in one container and mixed the thoroughly for aproximately 5 minutes.

After mixing, I pouled the epoxy evenly arround the wing. I have to avoid skin contact with the mixure since it toxic and can cause skin issue. I took proper precaution measures. By wearing gloves and respiratory mask. I also did everything outside (open area). It advice to do it in a well ventilanted area.

After that, I set it outside (in the sun) for around six hours for epoxy to cure.

This is the final output