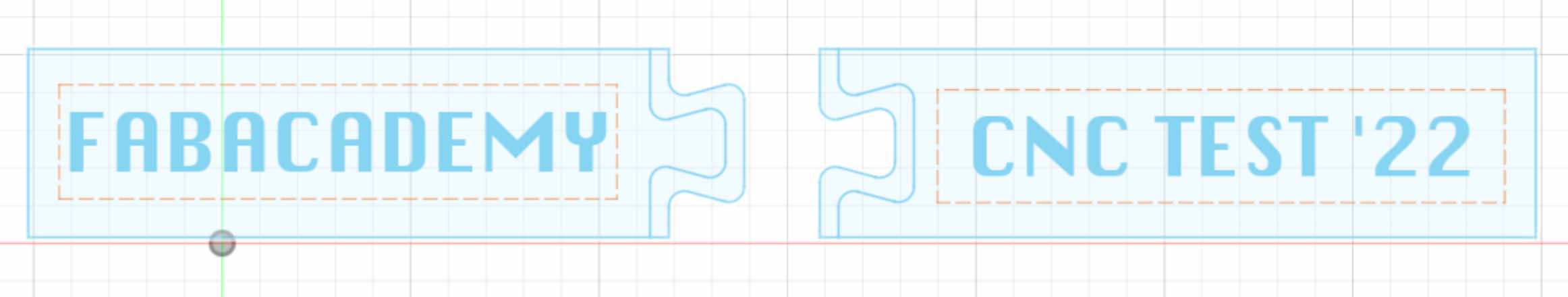

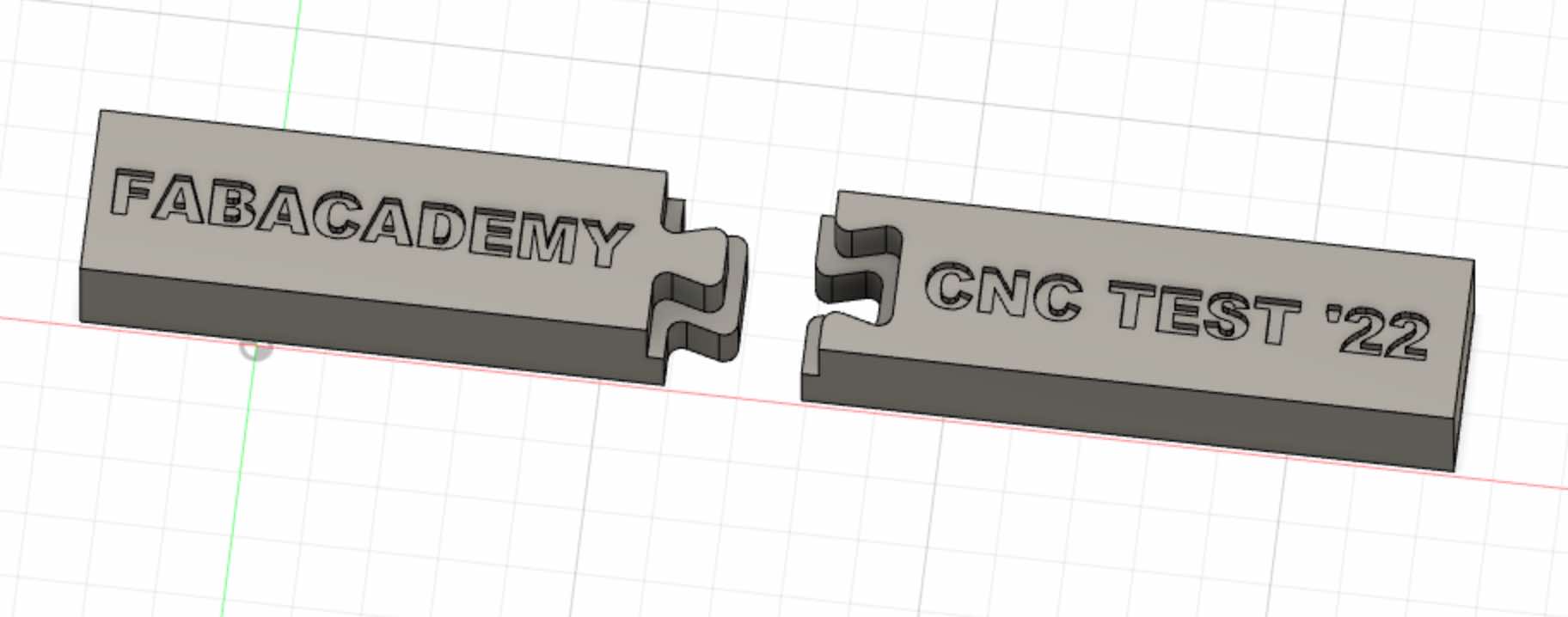

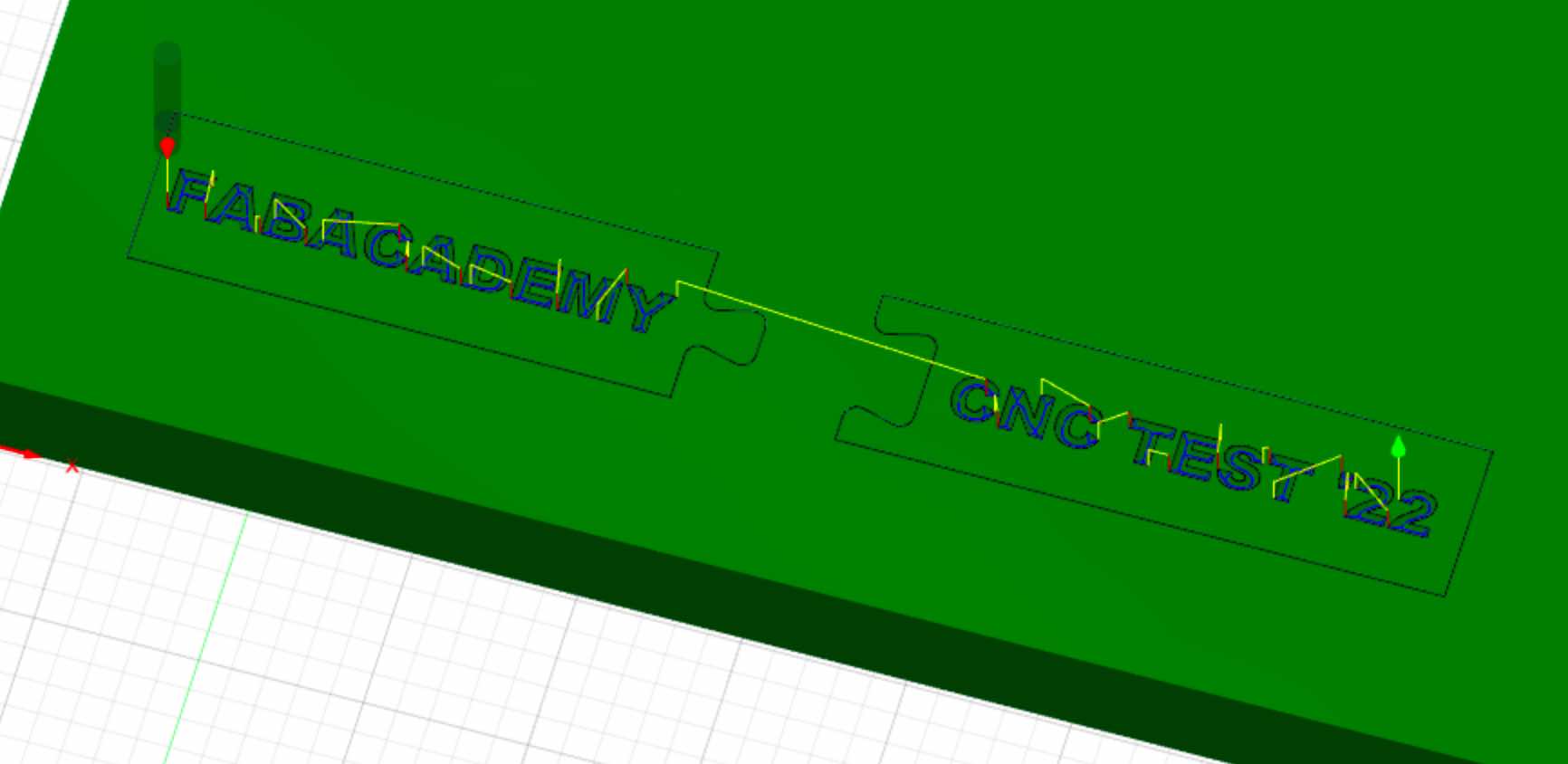

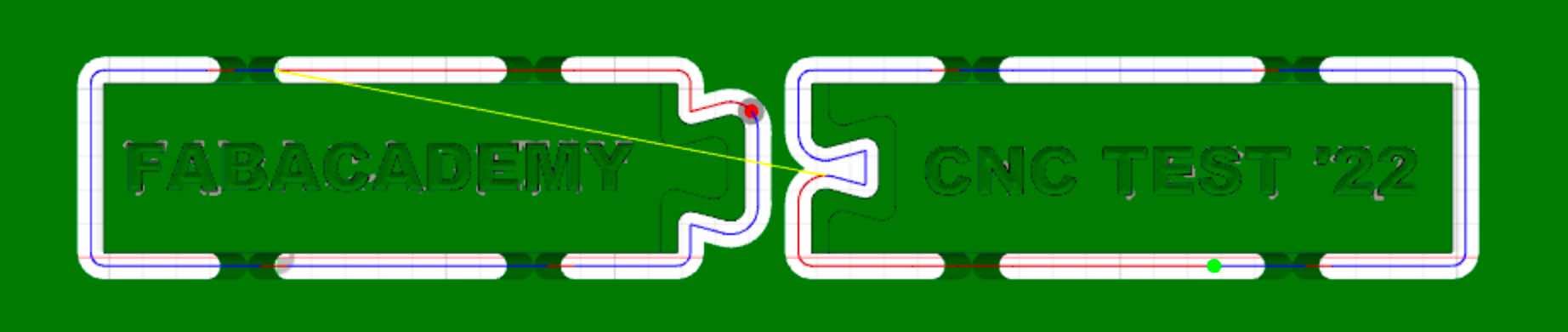

For the group assignment of this week we decided to download a joint from Jochen Gros Library. We choose this to try the tolerance, interferences, speed, tools etc. To do that we used a piece of waste material, a piace of wood with a thickness of 20 mm.

We uploaded the file on Fusion 360, and once we edit it, we can move on the manufacturing part.

In this case we are going to use several types of processing:

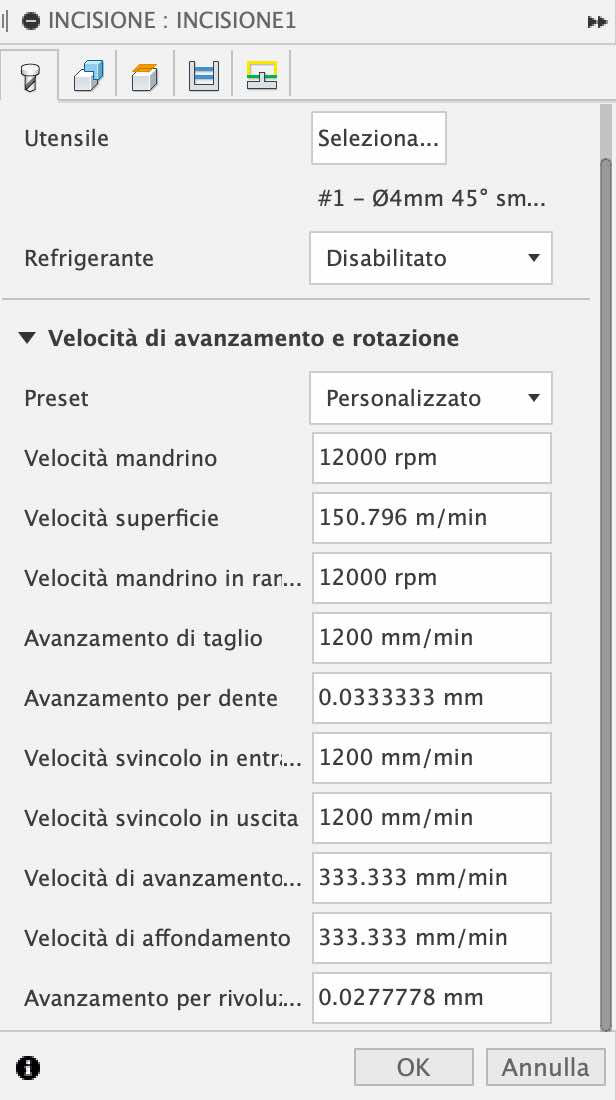

- Engraving: to engrave the writing on both pieces we will use a 45 ° tip as can be seen in the settings below.

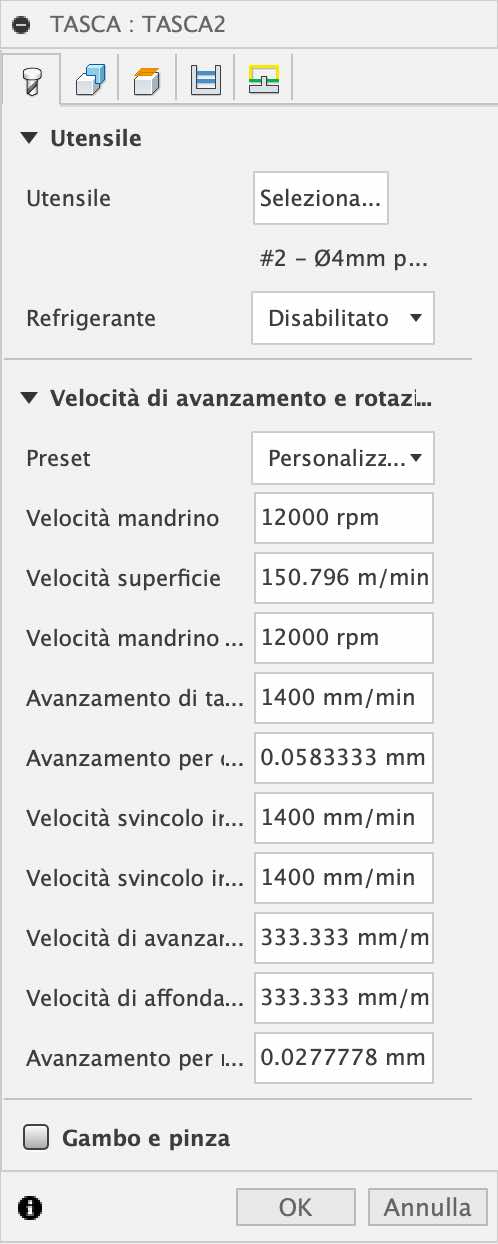

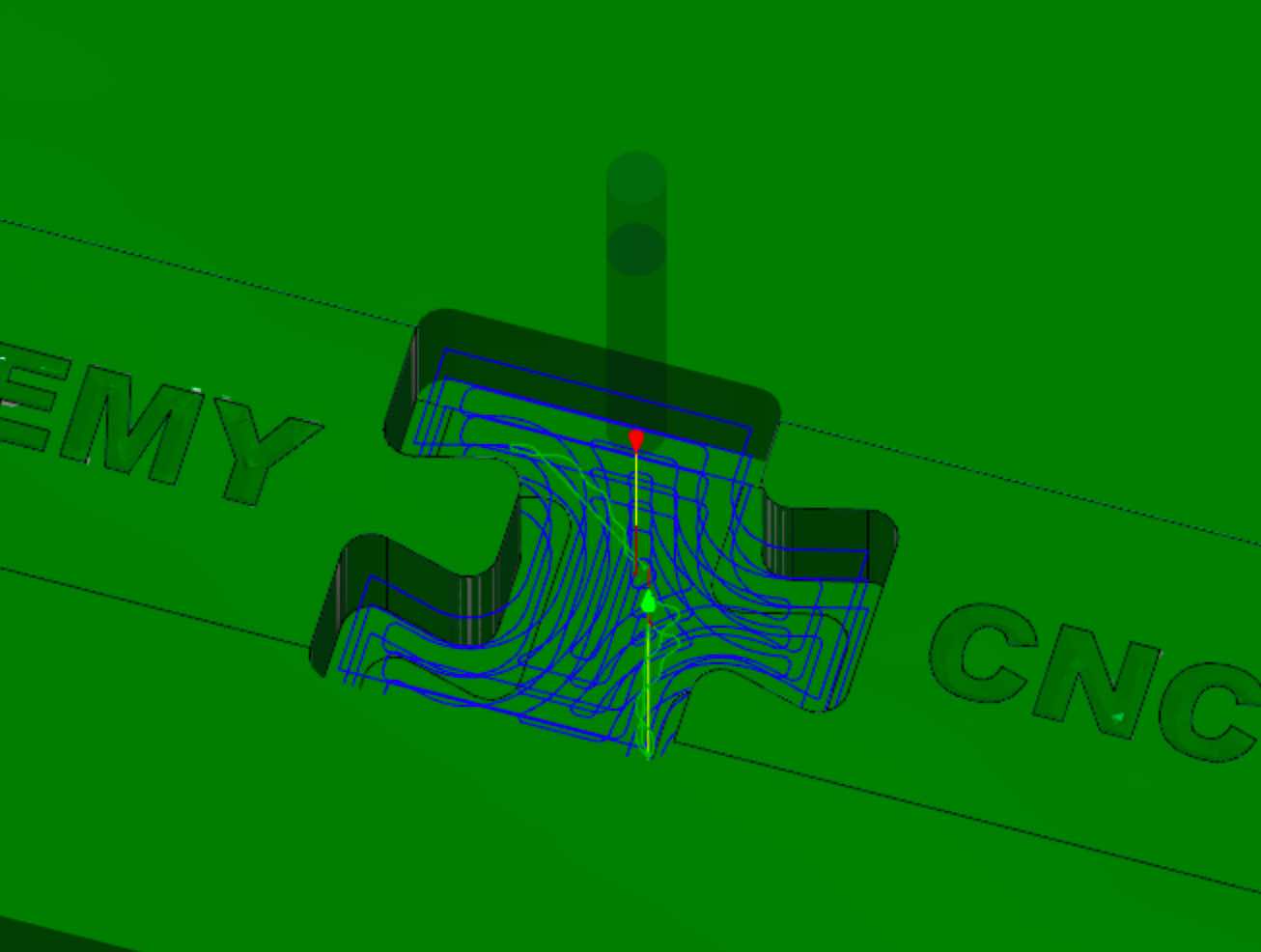

- 2d pocket: to create the joints on both sides we will use a 4 mm tip as you can see in the images

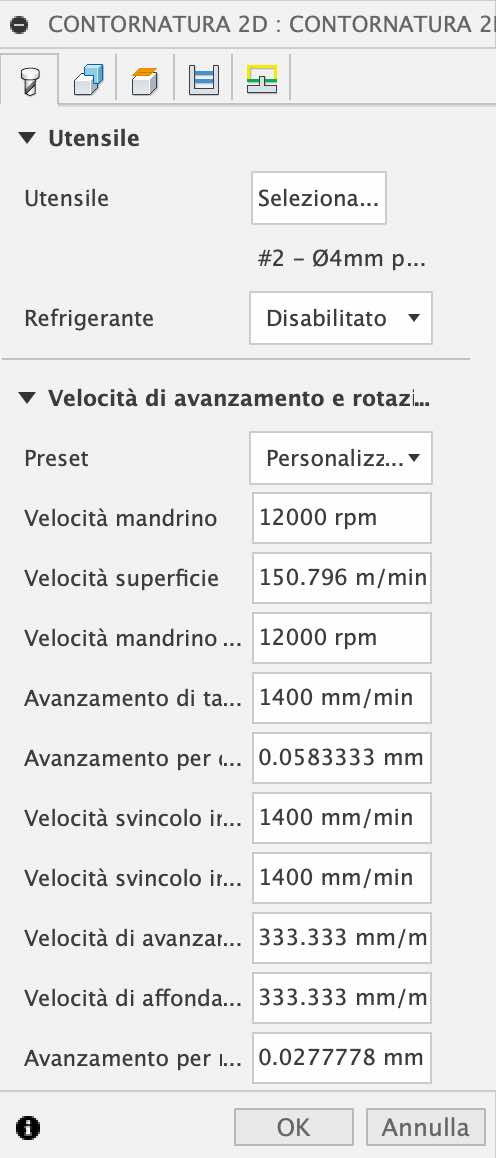

- Contouring: to outline the object we will use the same 4 mm flat tip, we will also create tabs to ensure that pieces of wood do not fly during milling

At this point we can download the gcode for the shopbot and start milling. We will have a processing for the engraving and another for the pocket and the contour, so we will have to do a tip change after the first processing.

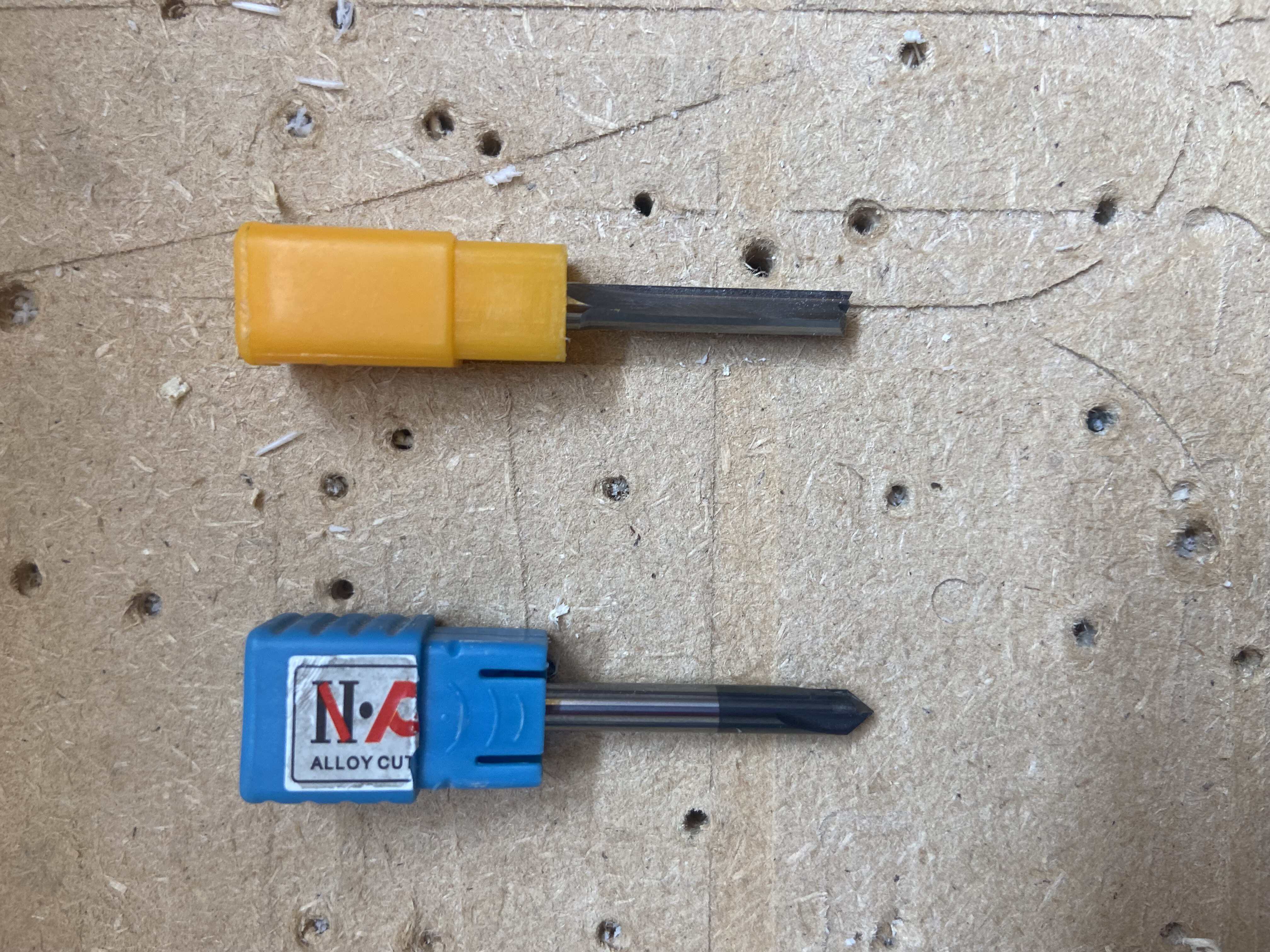

The tips we are going to use are:

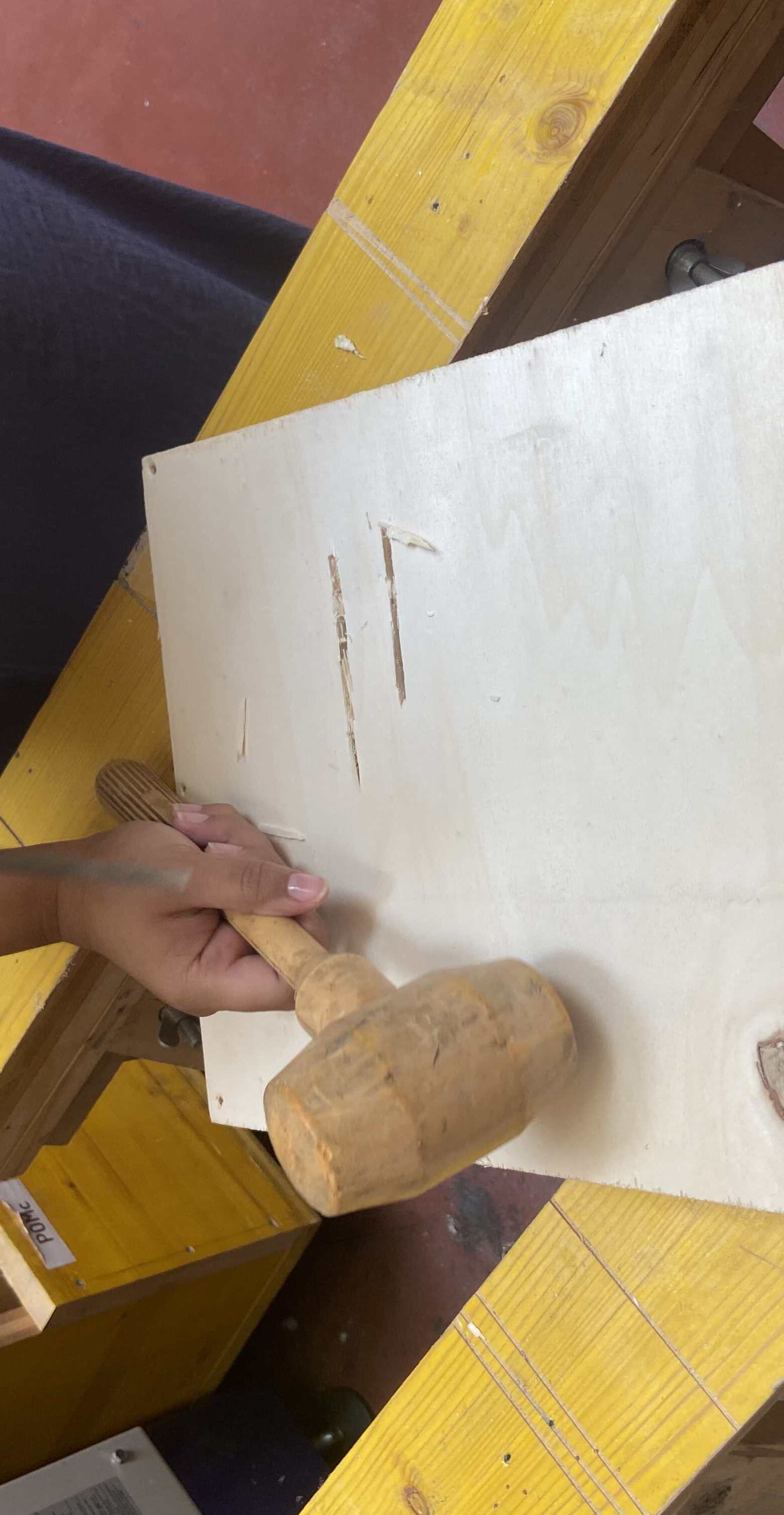

This is the result, after removing the tabs with a hammer and chisel and after having sanded it.