In this week 06 we worked in groups to test our 3D printers and then everyone had individually printed their object that they modeled. I am with two colleges.

We have two 3D printers in our lab and the software I use for modeling is SolidWorks 2020. Formlabs Form3 and Sindoh 3DWOX1.

Form3 Formlabs printer.

3DWOX1 Sindoh printer.

Work Group

Let's test the design rules of 3D printers.

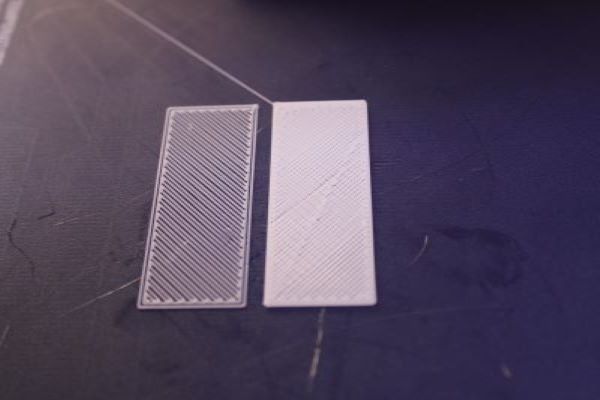

We will compare the results of the two printers at the same time. The minimum printing per layer of 3DWOX Sindoh is 0.05 mm and its maximum is 0.4 mm. On the other hand, the Form3 is fixed by default at 0.05mm. We tested our first print by printing two plates, one of which is 0.4mm thick and the other 0.2mm with 3DWOX. In the settings of the 3D printer we have chosen a layer of 0.2mm. We chose not to print with support, which greatly reduced the printing time, which was 45min, now 7min. I didn't know how, but I liked it. The one printed in 0.2mm came out in a grid and the one in 0.4mm is very flexible. It was impressive.

We modeled different model of object which we wanted to test the precision of angles, holes, friction clearance and finally see the conditions under which we can print without support.

The precision of the angle.

When I look from 100 degrees the filament drools and the angle is not printed well. so from this angle down you need a support.

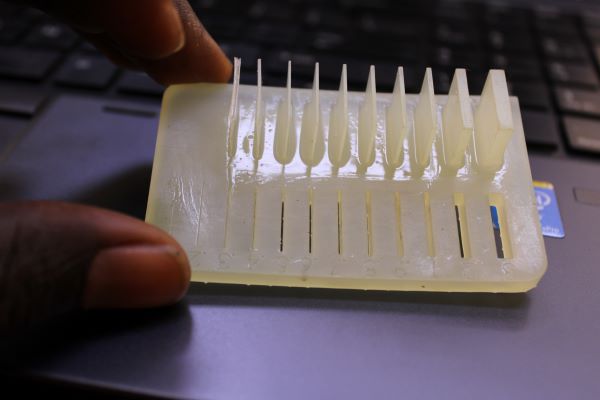

Hole precision and vertical print thickness.

Accuracy of holes and thicknesses. The 3DWOX printer can print a rectangular hole of 0.4mm. Below that it is blocked. It is able to print a wafer vertically from a thickness greater than or equal to 0.6mm .

As for the Form3 Formlabs, it prints a rectangular hole greater than or equal to 0.4mm. But the printing of the thickness goes up to 0.3mm.

Checking

Hole accuracy with 3DWOX printer is less accurate. this is a 2mm wide rectangular hole and this is what we measure after printing 1.96mm.

Accuracy of holes with Form3 printer not very as accurate. this is a 2mm wide rectangular hole and this is what we measure after printing 1.98mm.

Accuracy of thickness with 3DWOX printer. this is a vertical plate with a thickness of 0.6mm. The result after printing is 0.68mm. I don't know why it was exceeded.

As for the Form3 Formlabs, it prints a rectangular hole greater than or equal to 0.4mm. But the printing of the thickness goes up to 0.3mm.

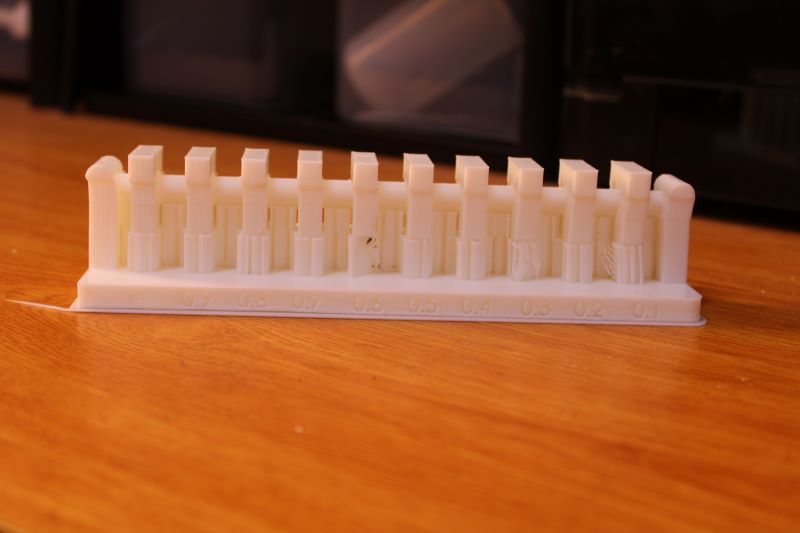

Friction play on the shaft.

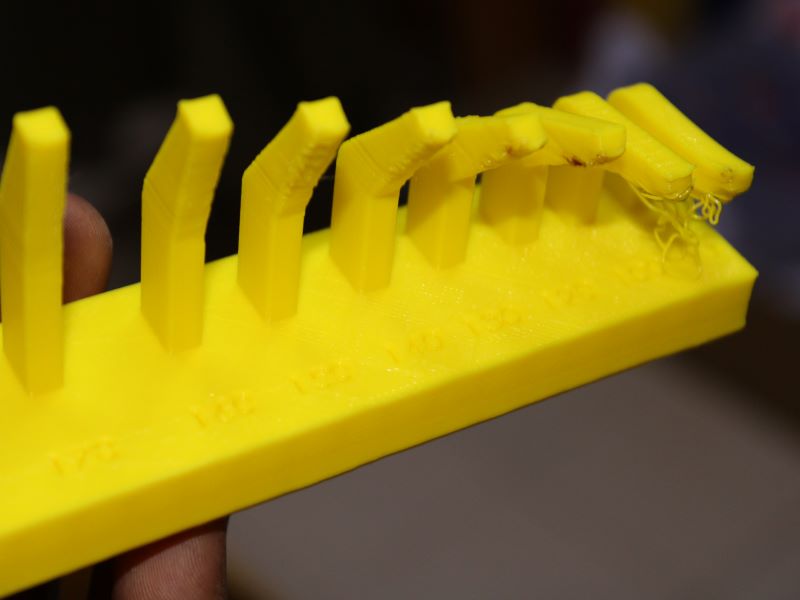

We have made several sets of friction ranging from 1mm to 0.1mm. The result is a tight fit from 0.2mm to 0.1mm. But a loose fit from 0.3mm to 1mm, so these elements are mobile on the 'axis.In the printing parameters of this test, we added the support. The quality of the printing was not to your liking, the cause the filament was finished during the printing, this caused the shift (when we look at the piece).

.JPG)

stl file

With support

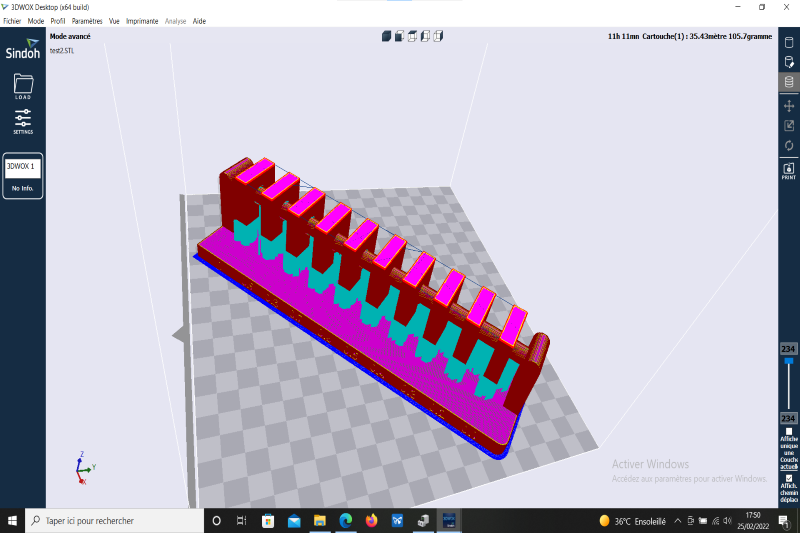

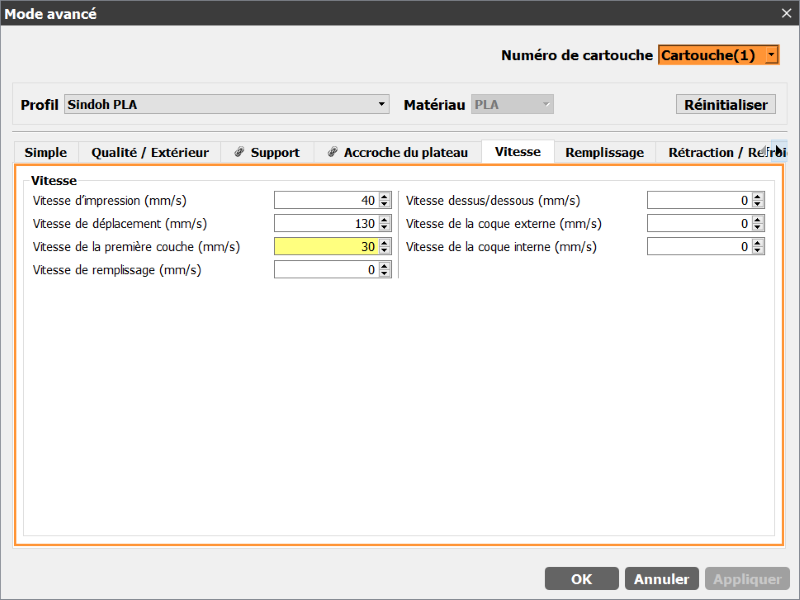

Test of the different parameters to see the printing time of the same object.

We have changed different print parameters to see the print time but it is relative to the print quality, the print speed. The print speed, one of the important parameters, the closer its percentage is to 00%, the more the print time increases considerably, hence the print quality is also high. The speed of movement, the more it increases the more the printing time decreases. Printed with support also increases the printing time.

.PNG)

Individual mission

Design and 3D print an object.

In this individual part I worked on my own project. I made an object that cannot be printed subtractively. I printed it without a support. there is a void at the foot of the room and whose upper base is wider than the one below. So we can not print this piece in a subtractive way.

This object is a prototype that I am developing. For more purposes it will allow me to detect my veins. I would take advantage of this part to correct my mistakes.

.JPG)

.JPG)

Scan an object in 3D, try to prepare it for printing.

I'm going to scan an object and try to print it.

I first installed the XYZscan Handy software.

Open the software.

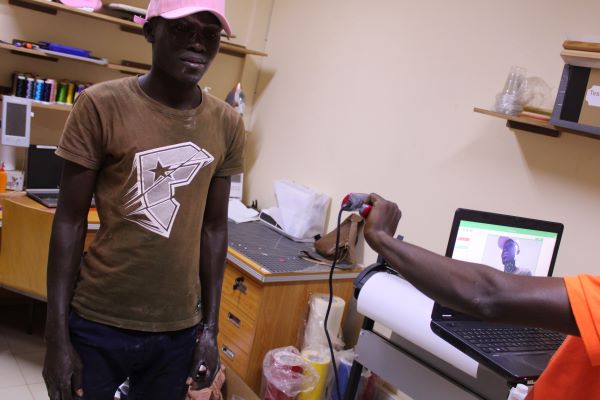

The scanner cannot detect the black color, so to scan we met powder on the object.I used XYZprinting 3D Scanner.

I scanned my head, I powdered my head. Then I backed up the file..

.JPG)

.JPG)

I imported the scanned file I printed it twice with different settings with support.The difference between these two is that the 0.10mm one is not smooth, but the 0.05 one is perfectly smooth. in addition, the 0.10mm one had finishing errors such as small holes on the back.

One is printed with a thickness of 0.10mm per layer and a printing speed of 40mm/s. The printing time is 5h12min.

The other a layer of 0.05mm with a printing speed of 30mm/s. the printing time is 10h13min.

Note that without support the printing time is 2h49min.

Learning Outcomes

Identify the benefits and limitations of 3D printing.

Print an object you've modeled,

I finished the modeling, I export the file to stl file,

Not all objects can be printed without a support as a T-shaped object,

The design method and production process of 3D printing.

There I will model an object with my computer,

Allowing us to do rapid prototyping and allows us to save both time and money,

Then I used 3DWOX's software for printing. Indeed I open the software and I import the stl file. I place the parts well in the tray. In the settings I chose the thickness of the slides 0.2mm.la printing speed to 30%. The printing time is 7h33min,

Finally I generate the G-code, I save in the key of 32G. I connect the key to the printer and I choose my object to print,

It should be noted that the file known by the 3D printer is the G-Code,

Demonstrate how scanning technology can be used to scan objects.

There are several possibilities of technologies to digitally have the shape of an object in 3D. With a scanner you can scan an object and print it; with the photogrammetry system you can scan an object,

Stl for polygonal shapes. Use in 3D modeling,

Not all objects can be printed without a support as a T-shaped object,

Problem and Problem solving

Problem.

The first problem: the nozzle of one of the 3DWOX printers is clogged,

Problem two encountered: two stops of the printer due to the lack of filament in progress. Then stop printing without cause, unfortunately we could not identity the problem. But we were able to restart it,

Problem three encountered: one of the 3DWOX printers can no longer dash the filament of the cartridge. In fact, the filament bends inside the cartridge when loading is started,

Problem four encountered : the fan of the washer device does not turn.

Problem solving, we start with the easiest problem to solve to save time.

Formlabs Scrubber Maintenance

After printing the object in the Formlabs Form3, we have to wash it with another device that I call the washer. Indeed after the last uses there was not enough alcohol, the device uses alcohol for washing. The object has left resin at the bottom of the tank, and as its duration the alcohol is evaporated. The resin bonded the fan with the tray. So we dismantle it to do the maintenance. We dismantled the fan, in its poles there are magnets. Then it is cleaned with alcohol and also the bin. In fact the fan rotates with the help of a magnetic field because of the magnets that are located in these poles.

3DWOX maintenance: clogged nozzle

The nozzle is clogged, a needle passed through the hole of the nozzle was used. We pushed so that the filament that remained inside comes out and with the help of a screw turn we could remove it,

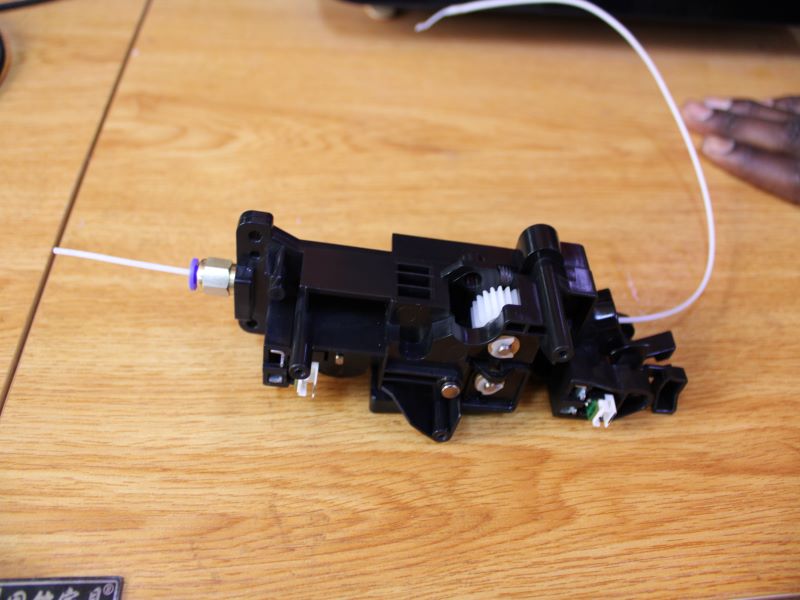

Maintenance of the 3DWOX whose filament bends

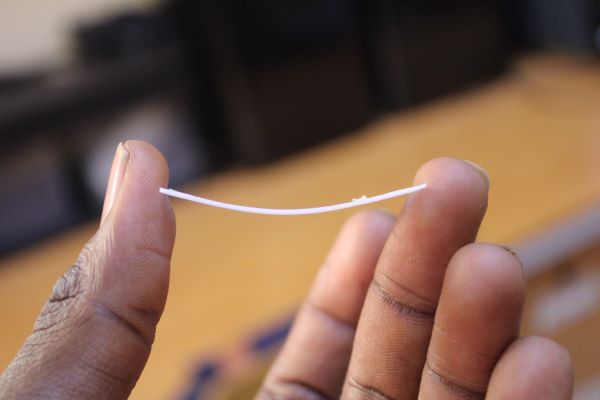

When you want to load the printer with the filament, it folds inside the cartridge. In addition, it was found that the gear that drives the pinion of the cartridge is blocked. We have dismantled the part where the engine unrolls the filament brings out the box or passes the filament. We put lubricant on the axes of the gears. Now his turn out well. We made the example of going from the filament inside and it comes out as usual. After reassembly the same problem is the. We put him aside so that he would not take up all our time. We will plan for most to intervene on it

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)