3D Scanning and Printing | Group Assignment

3D Scanning and Printing

Group Assignment

Task

This week we had to do some testing on our 3D printers to figure out their limits. In our Fablab, we have a Creality Ender-3 V2, a Creality Ender-3, a Prusa Mini+, a Sindoh 3DWOX1, and an Ultimaker S5. Aaron decided to test the Ender-3 V2, Leen the Sindoh, and Roland the Ender-3.

Testing

The test files we used are the ones provided on the Fab Academy website:

Creality Ender-3 V2

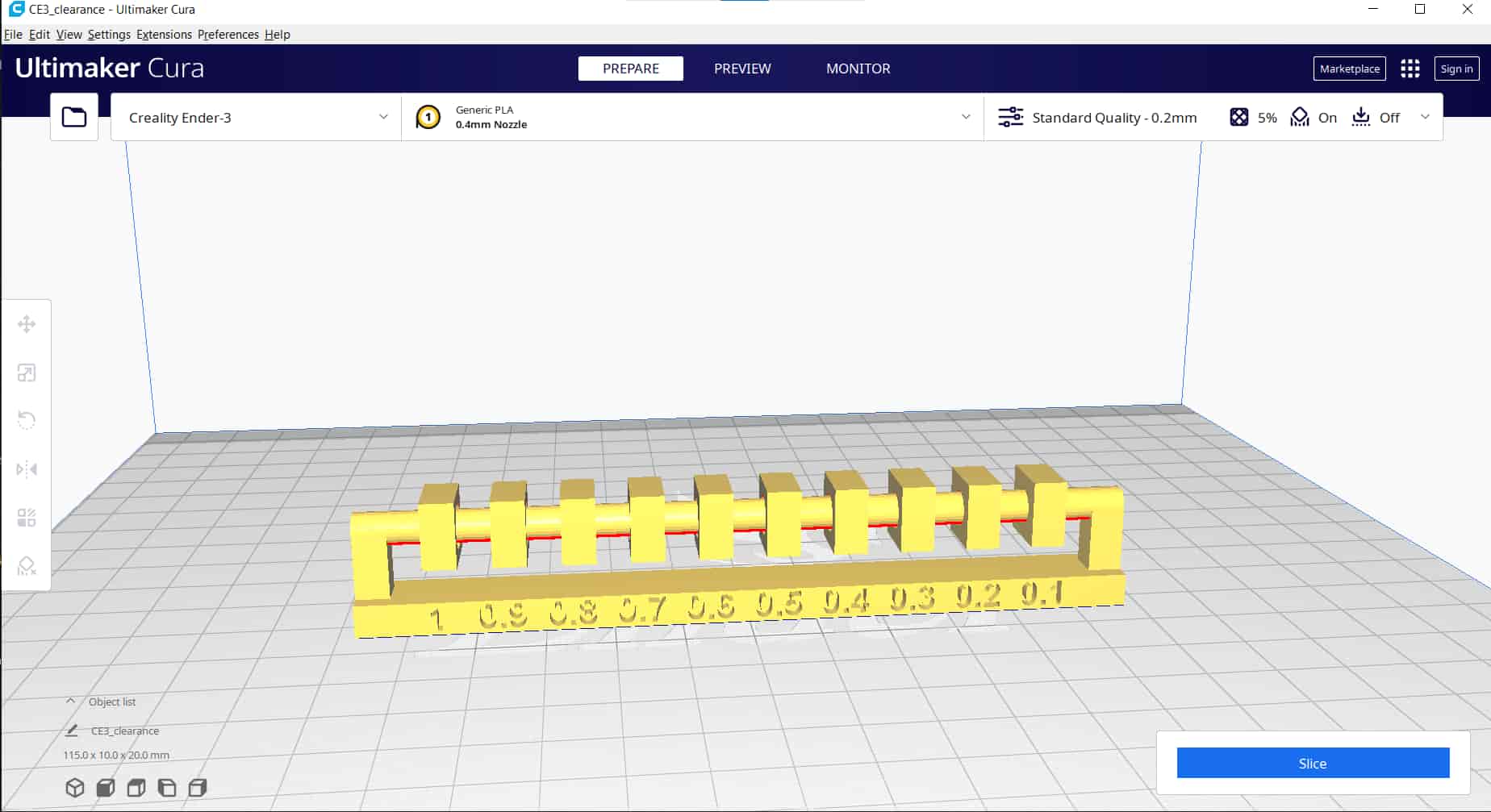

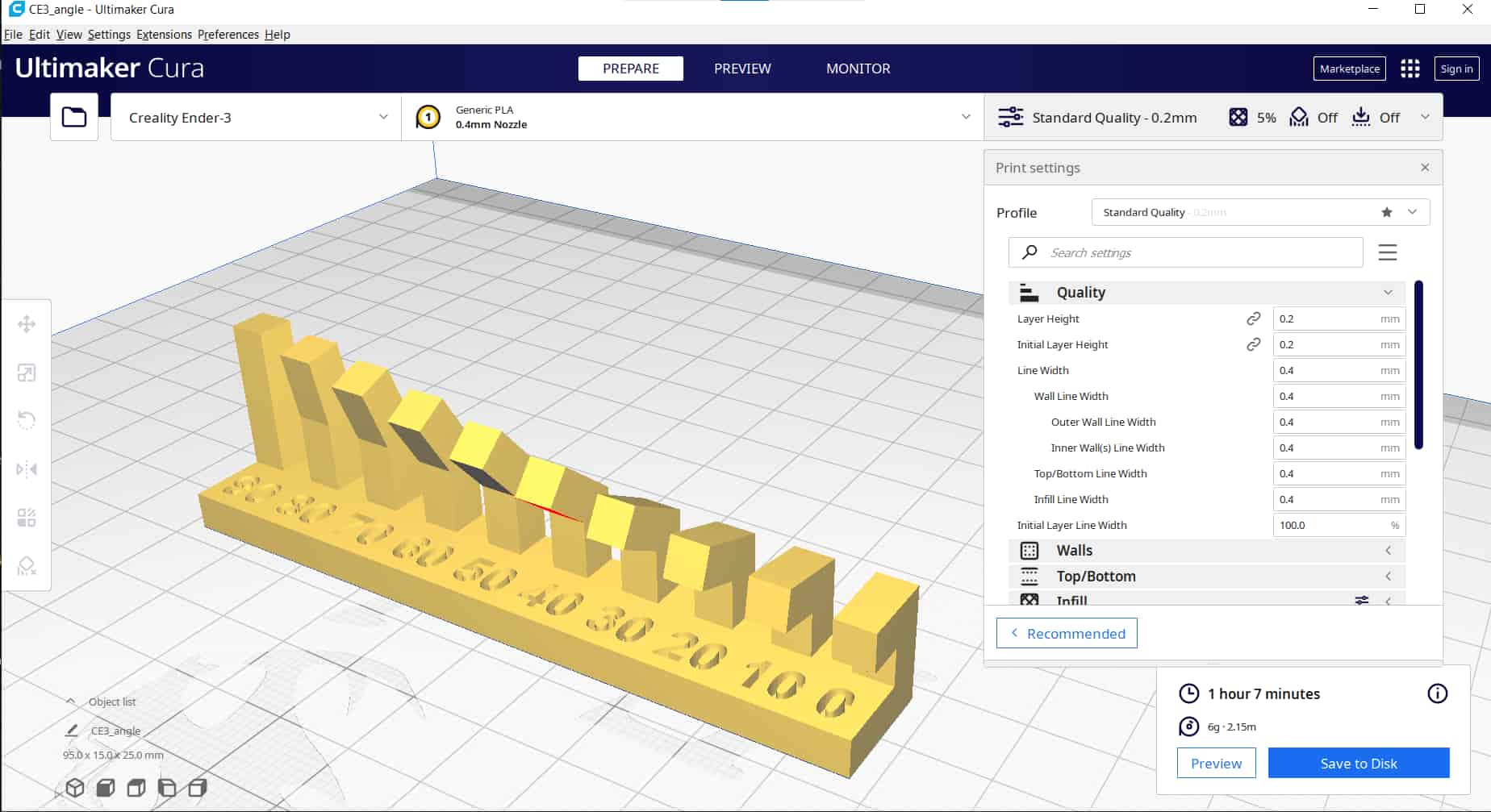

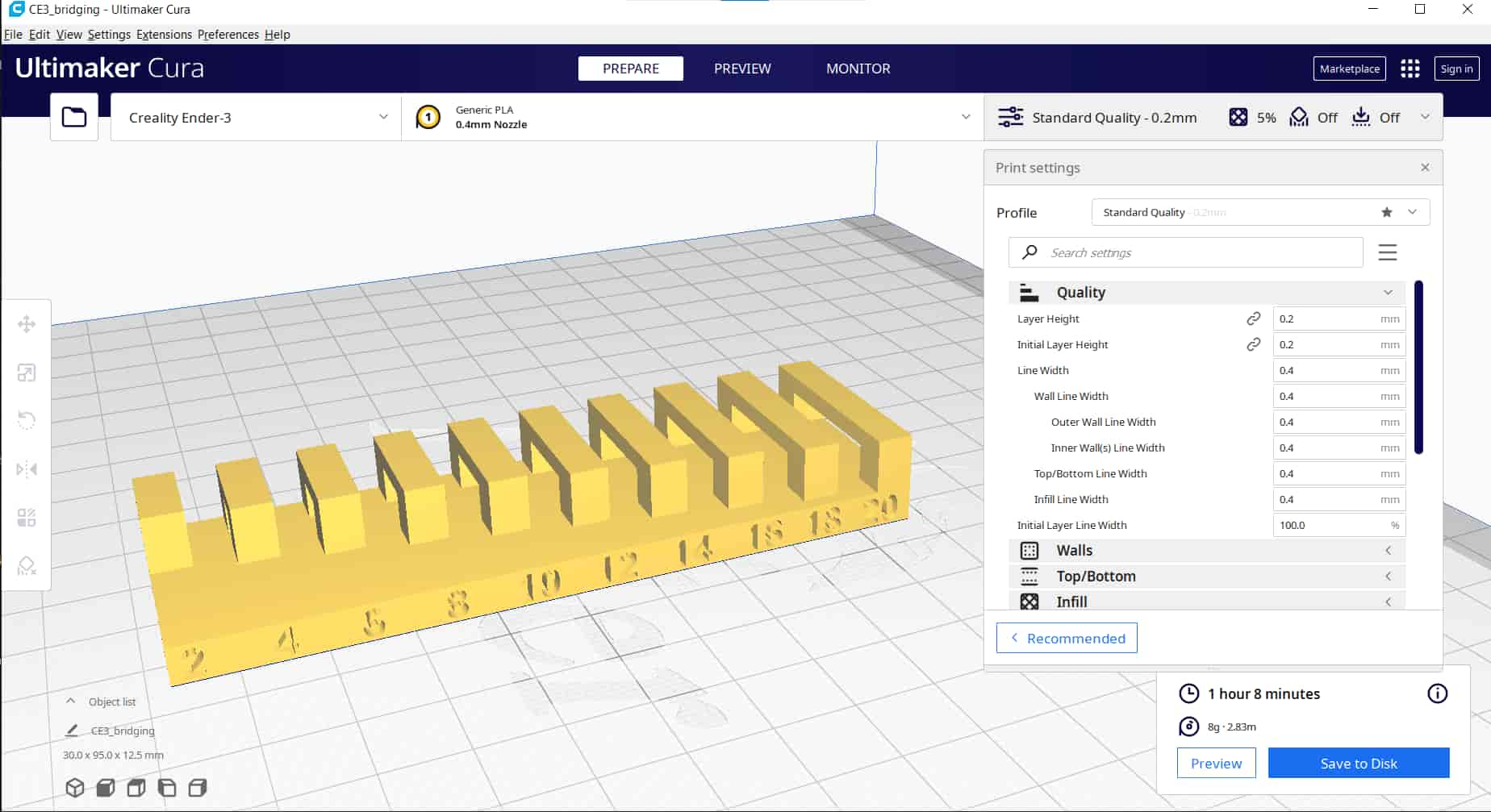

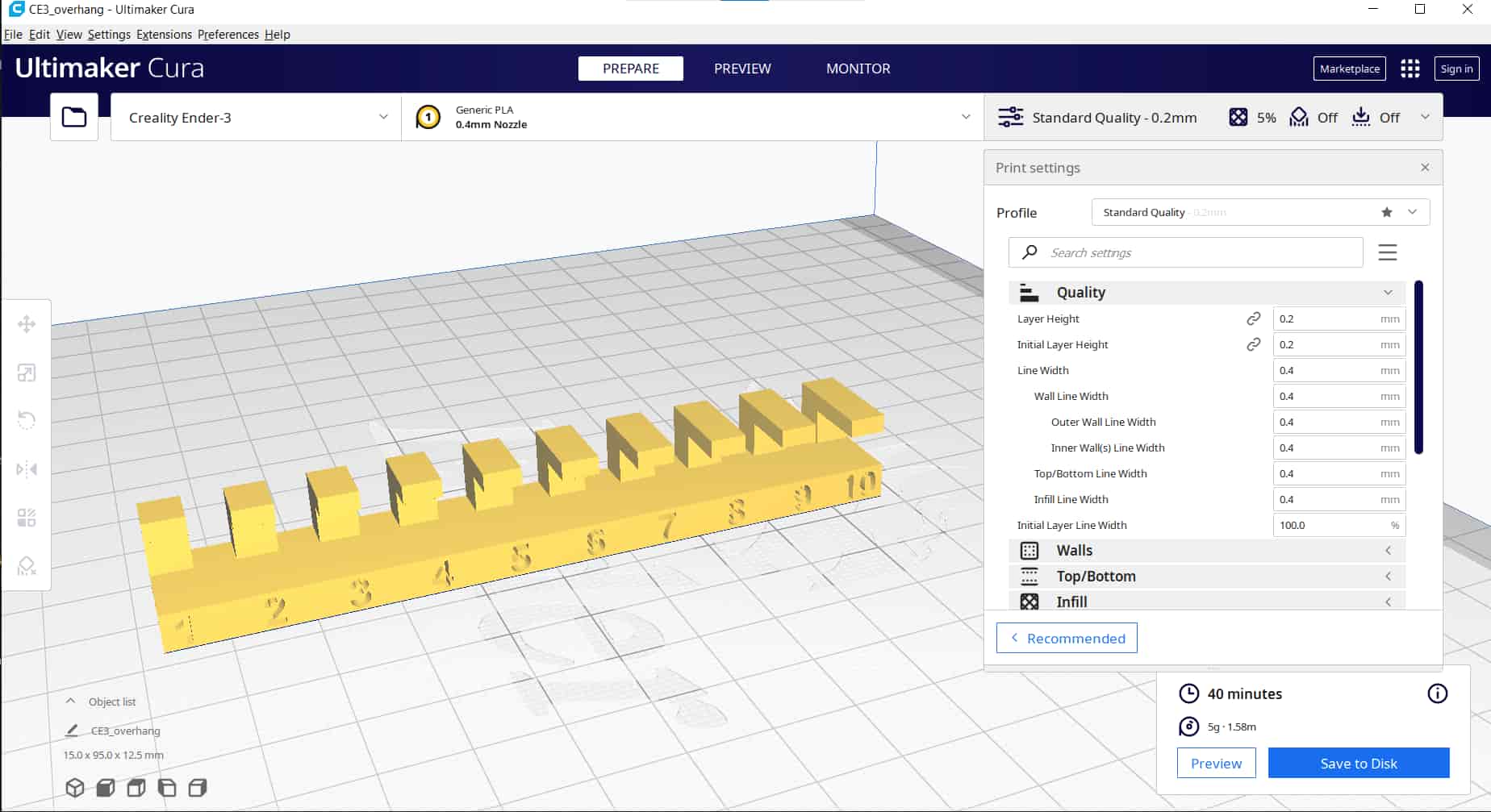

We first imported the STL file to to the Ultimaker Cura slicer and changed the Infill to 5%:

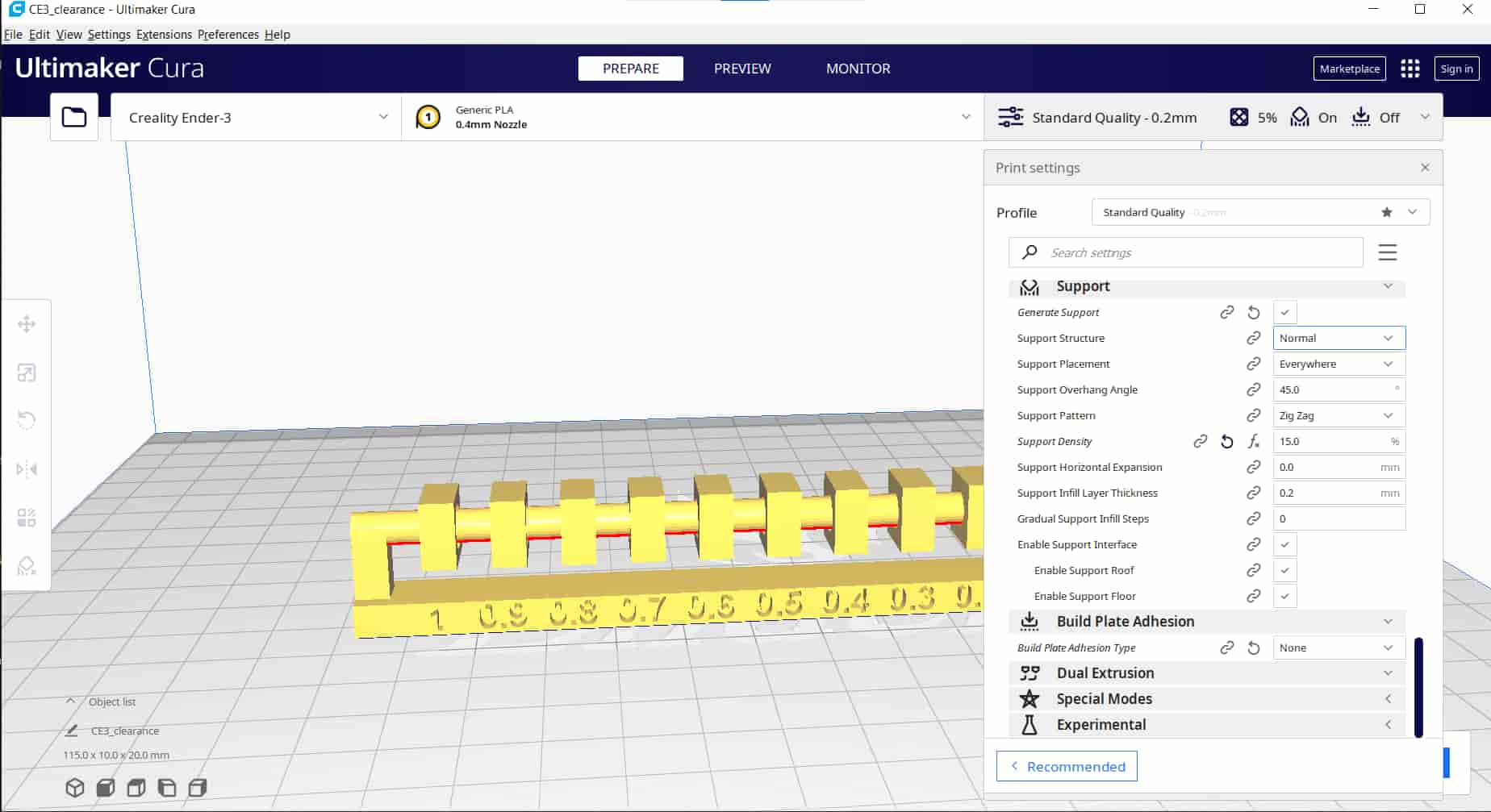

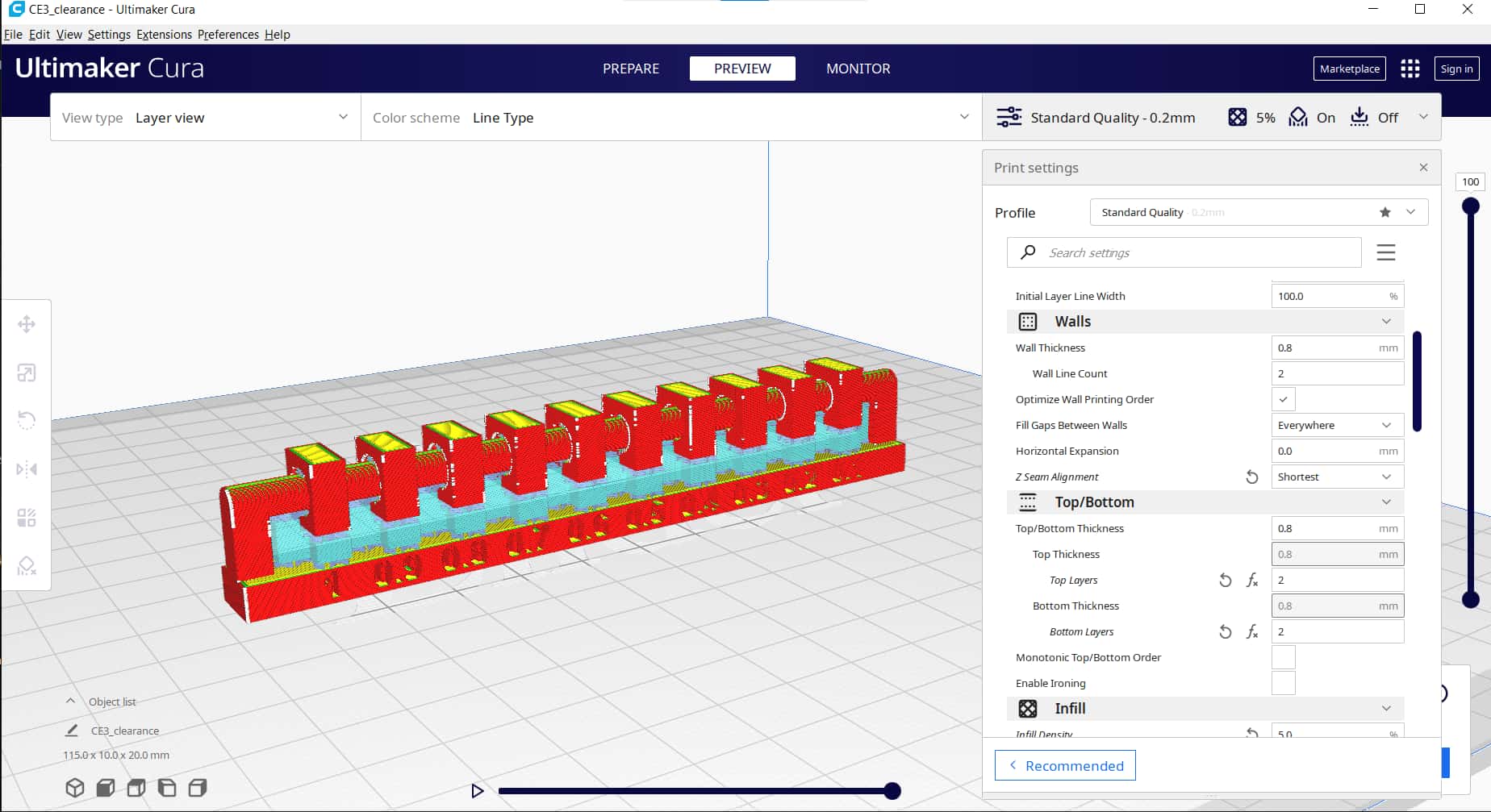

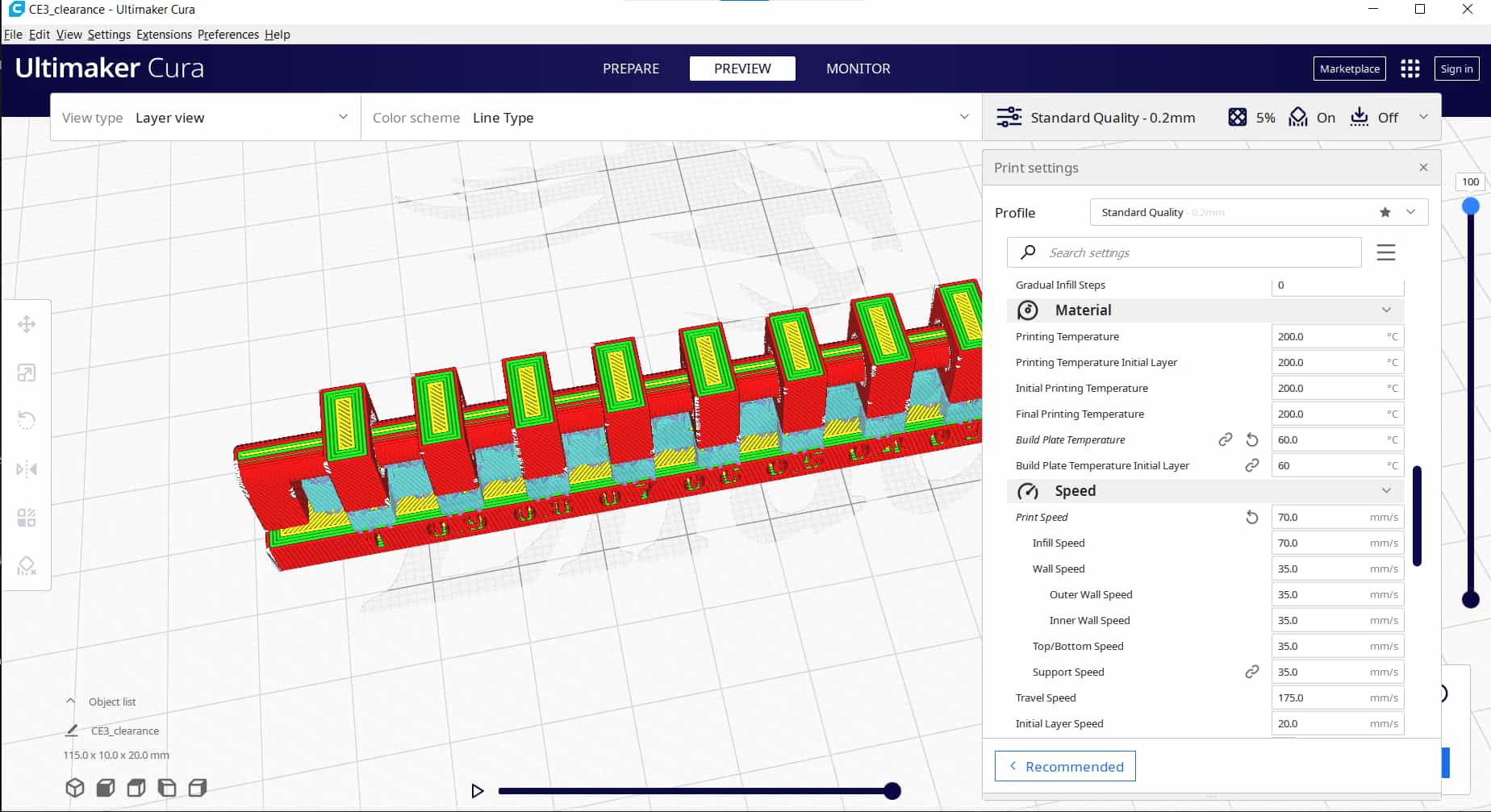

And then changed the settings of the Support tab to add support to the Clearance print.

But we kept the other settings according to the profile Standard Quality.

For the unsupported tests, we kept the settings as they are except for the Infill (5%).

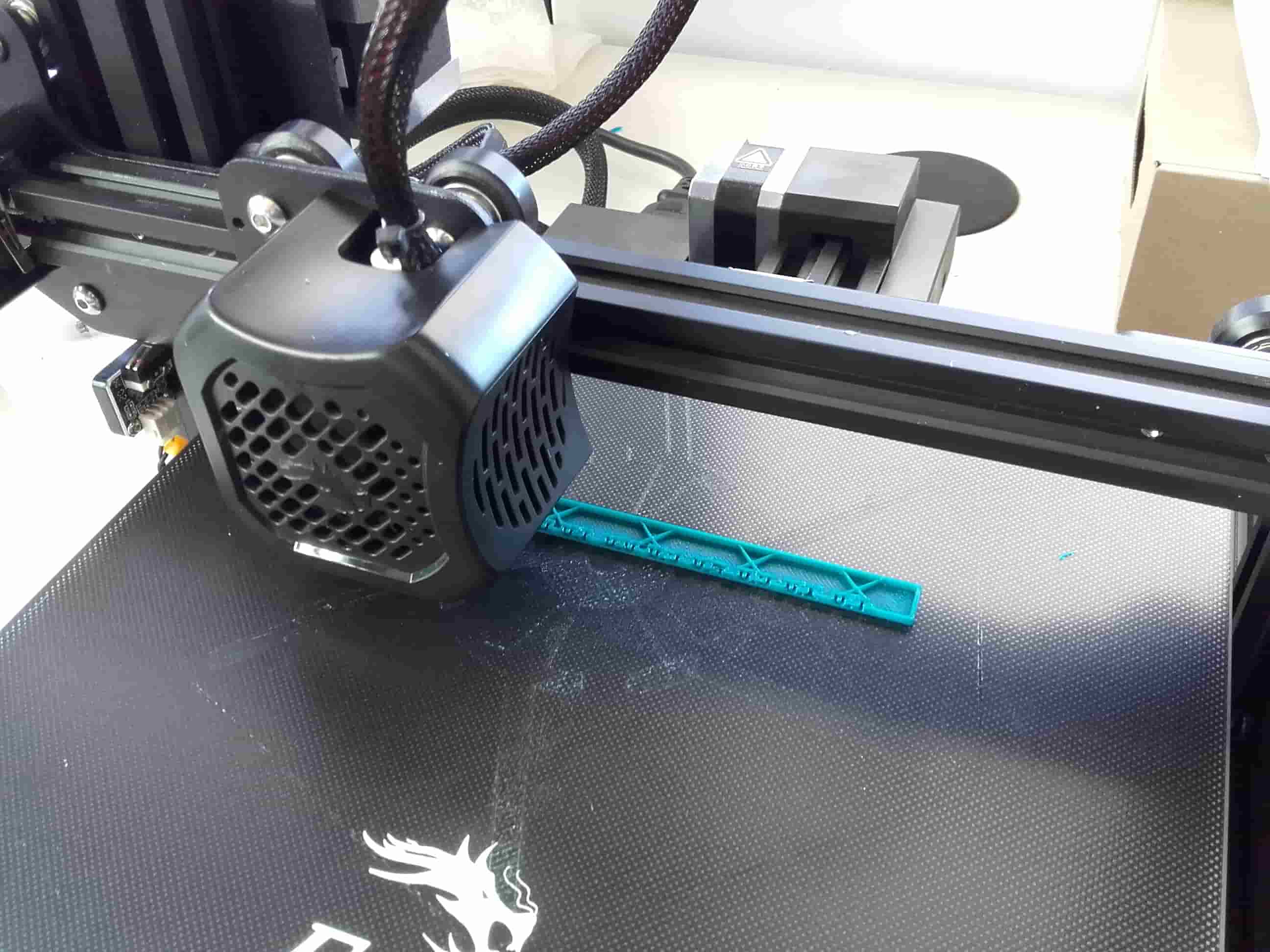

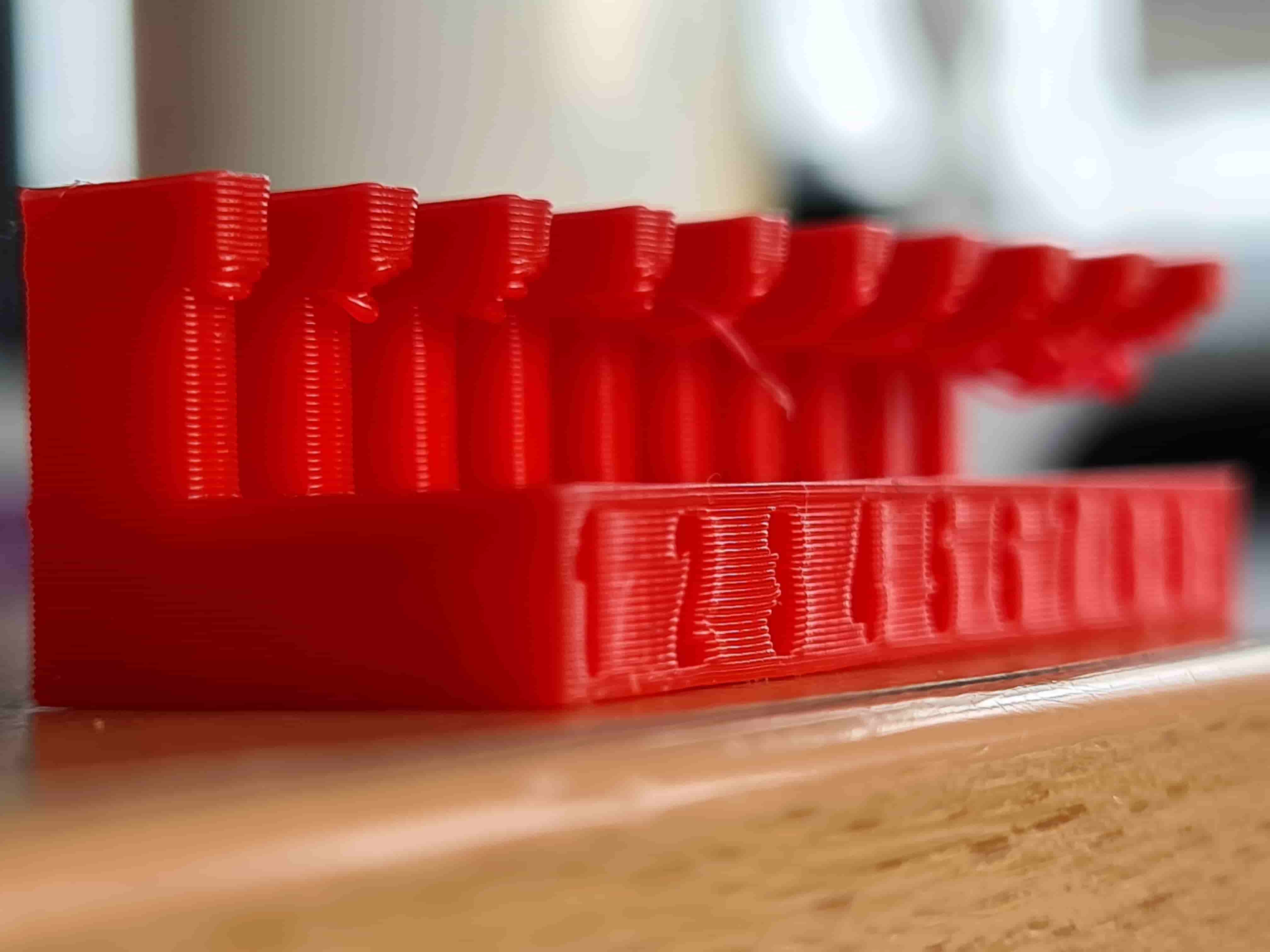

Here is the printer in action:

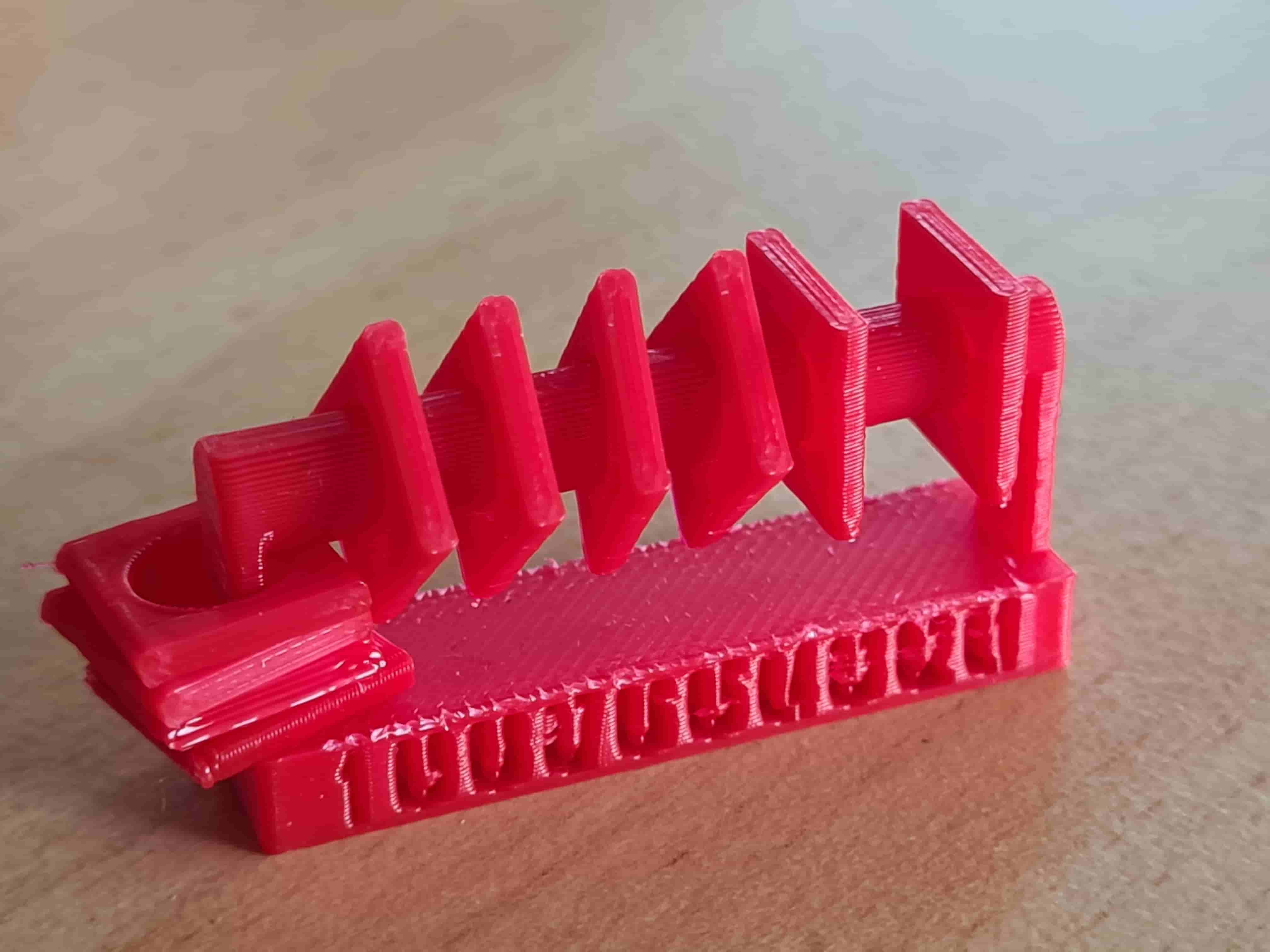

And here are the tests:

Sindoh 3DWOX1

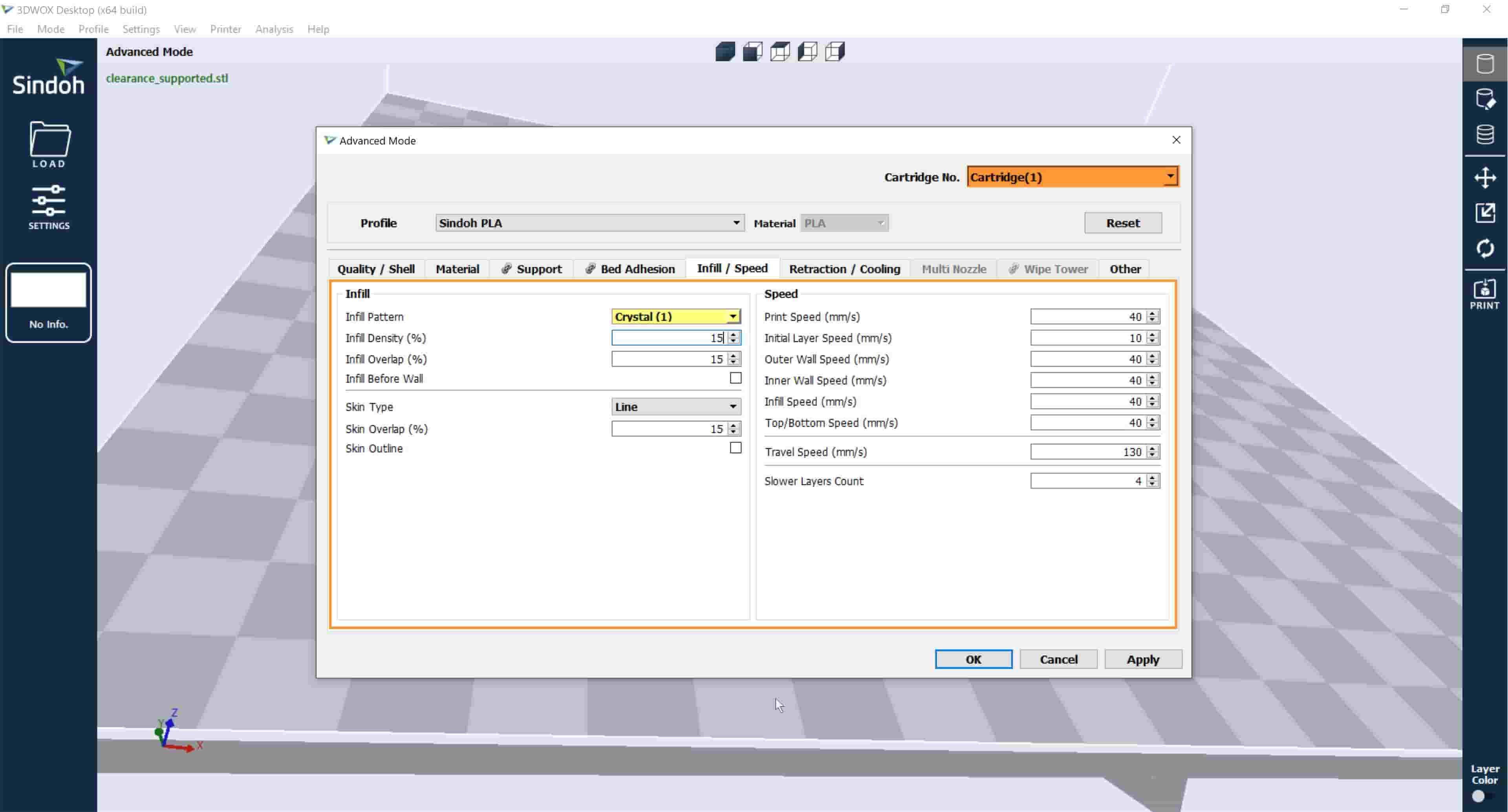

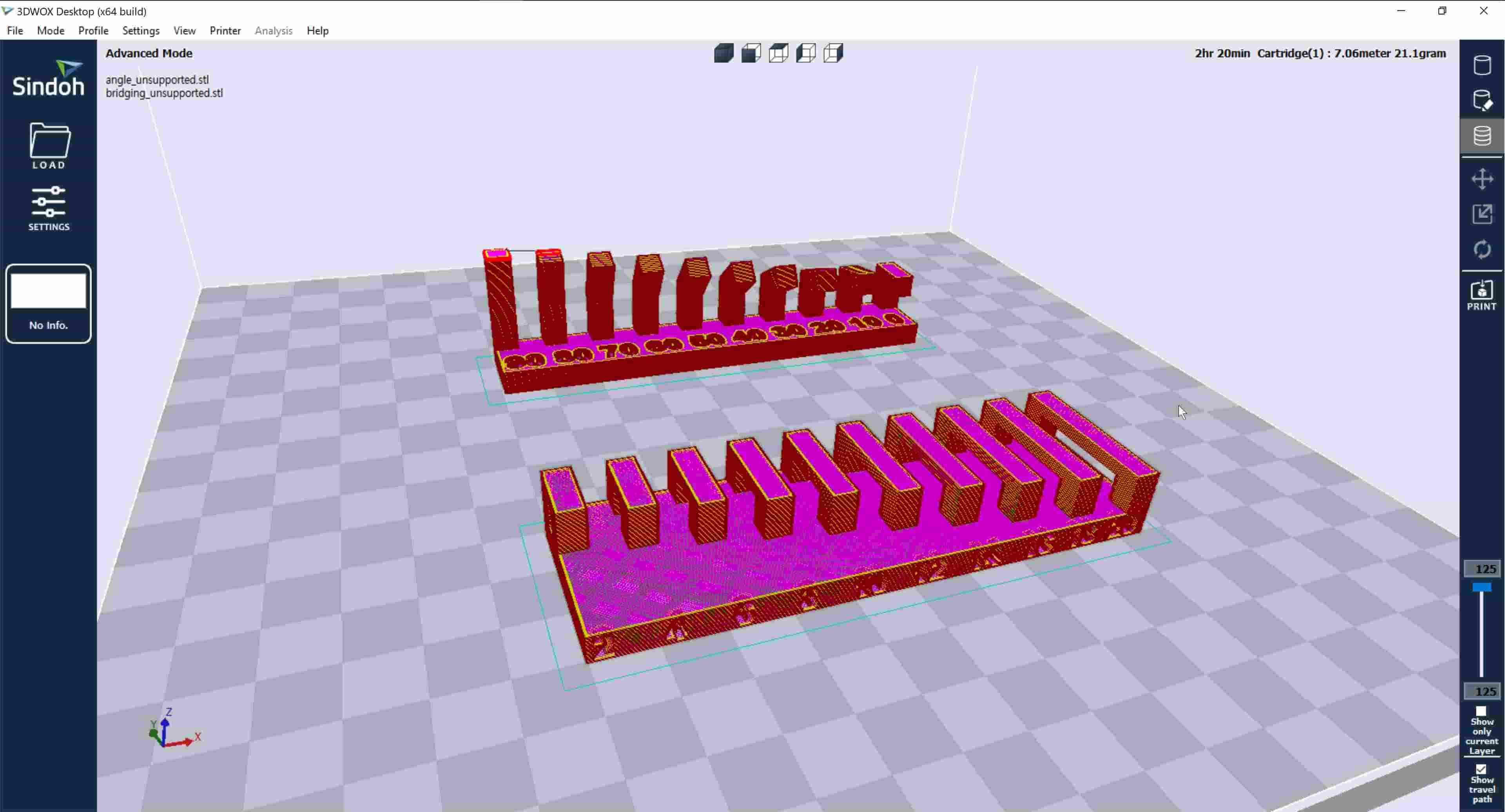

The workflow here is very similar to the one described above. We first imported the STL files to the Sindoh slicer, set the infill, and only setup the clearance test to have supports.

-min.jpg)

-min.jpg)

And the infill of the unsupported files is 15%.

-min.jpg)

Here is the printer in action:

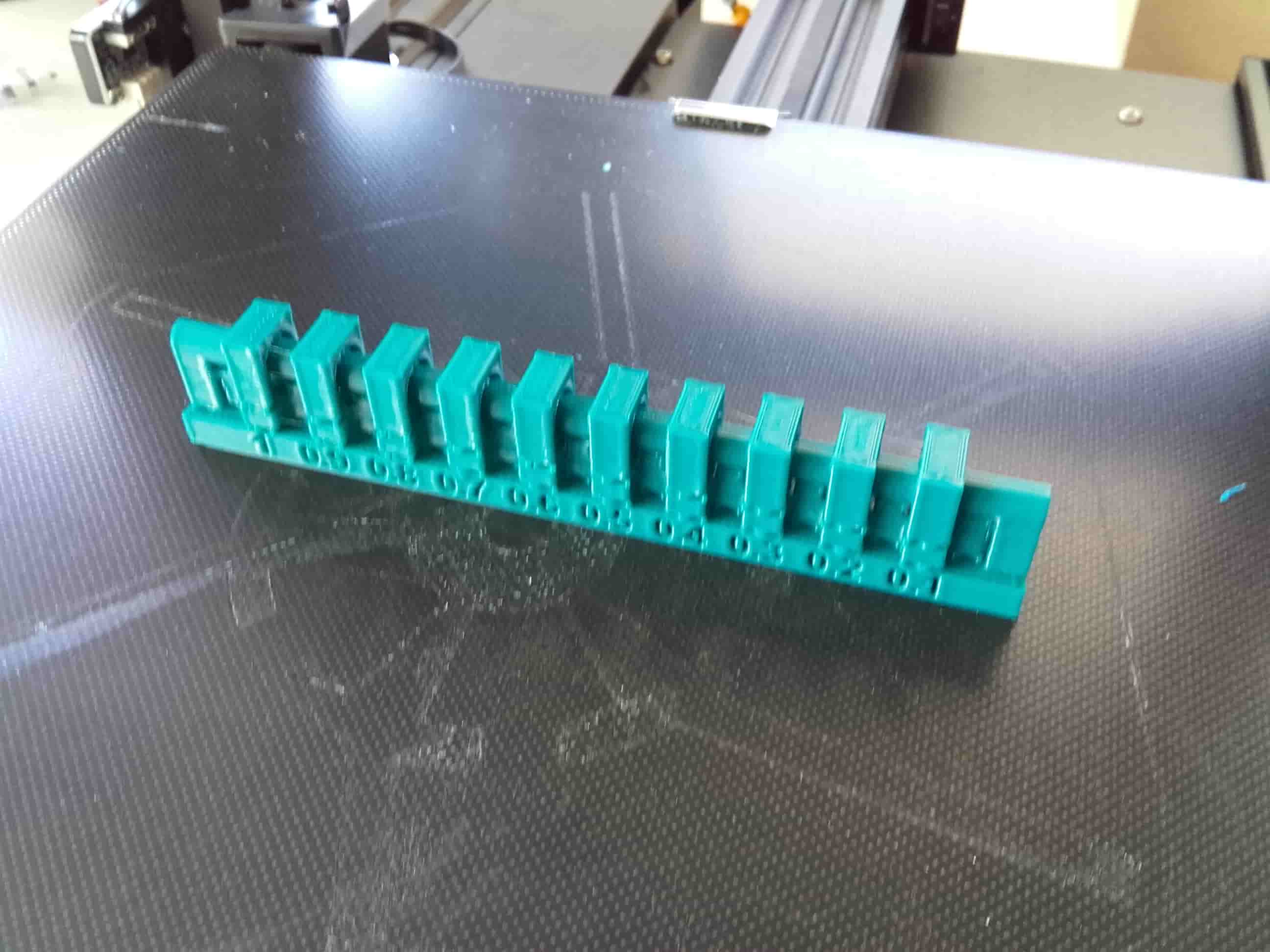

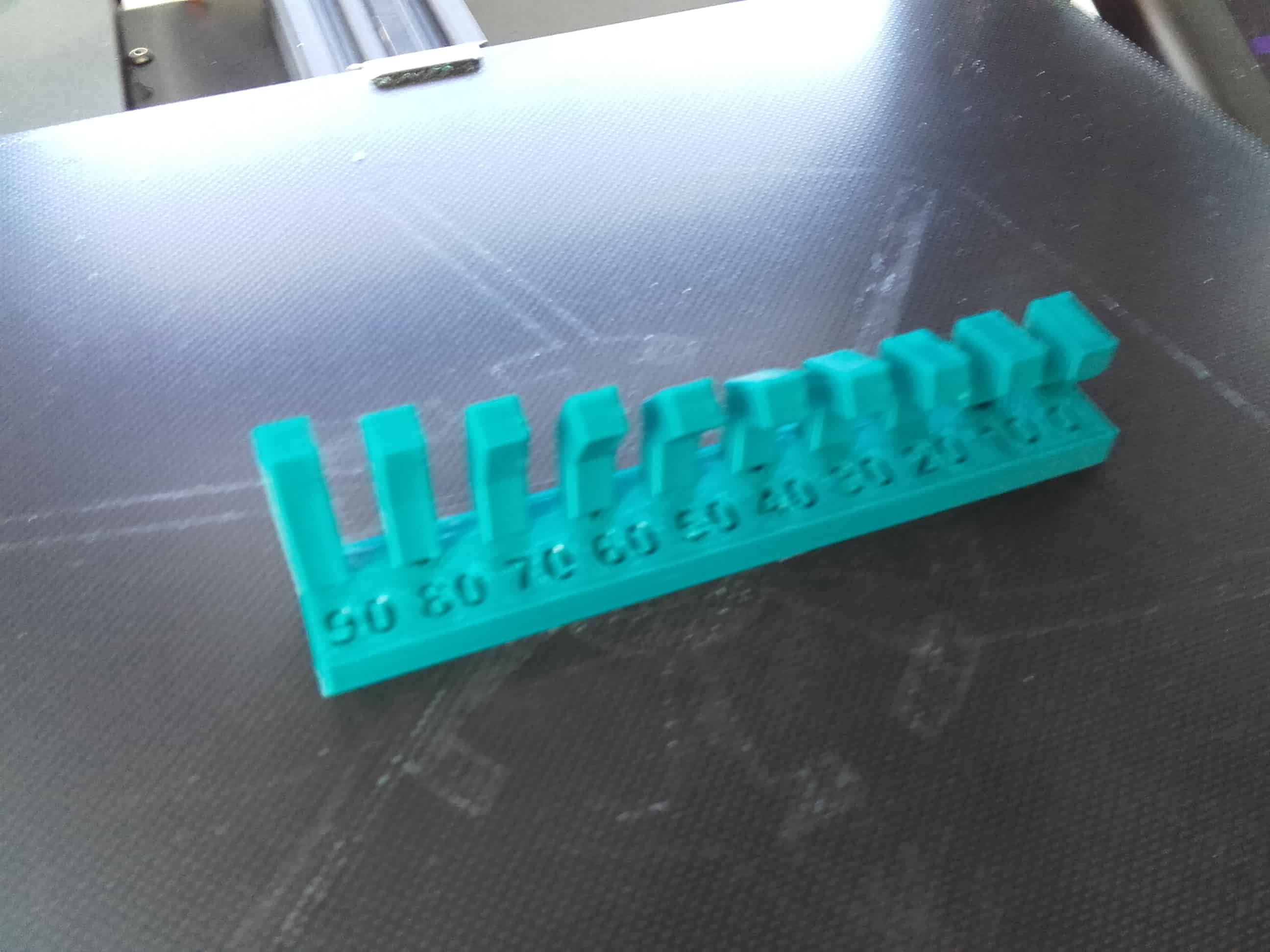

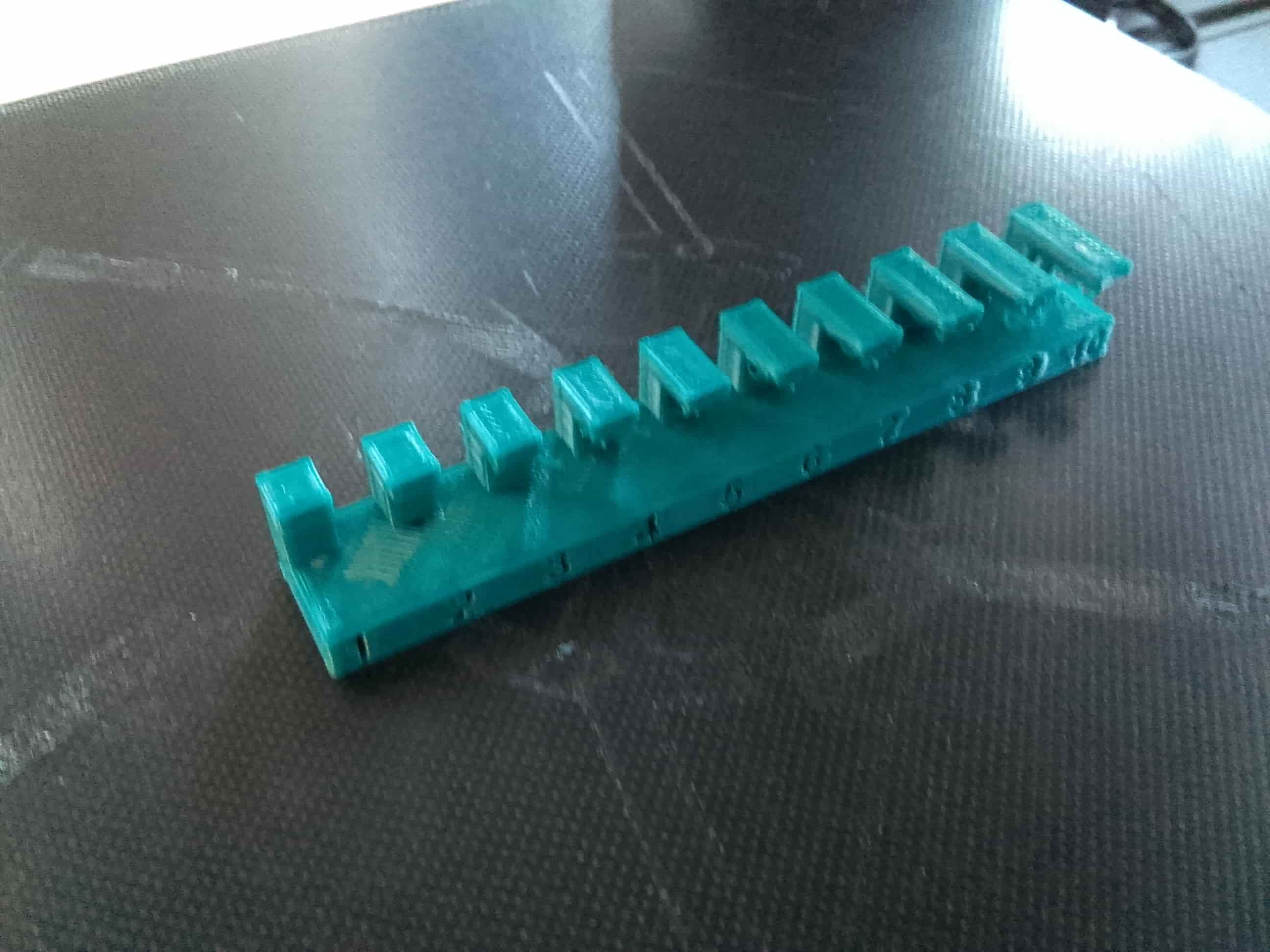

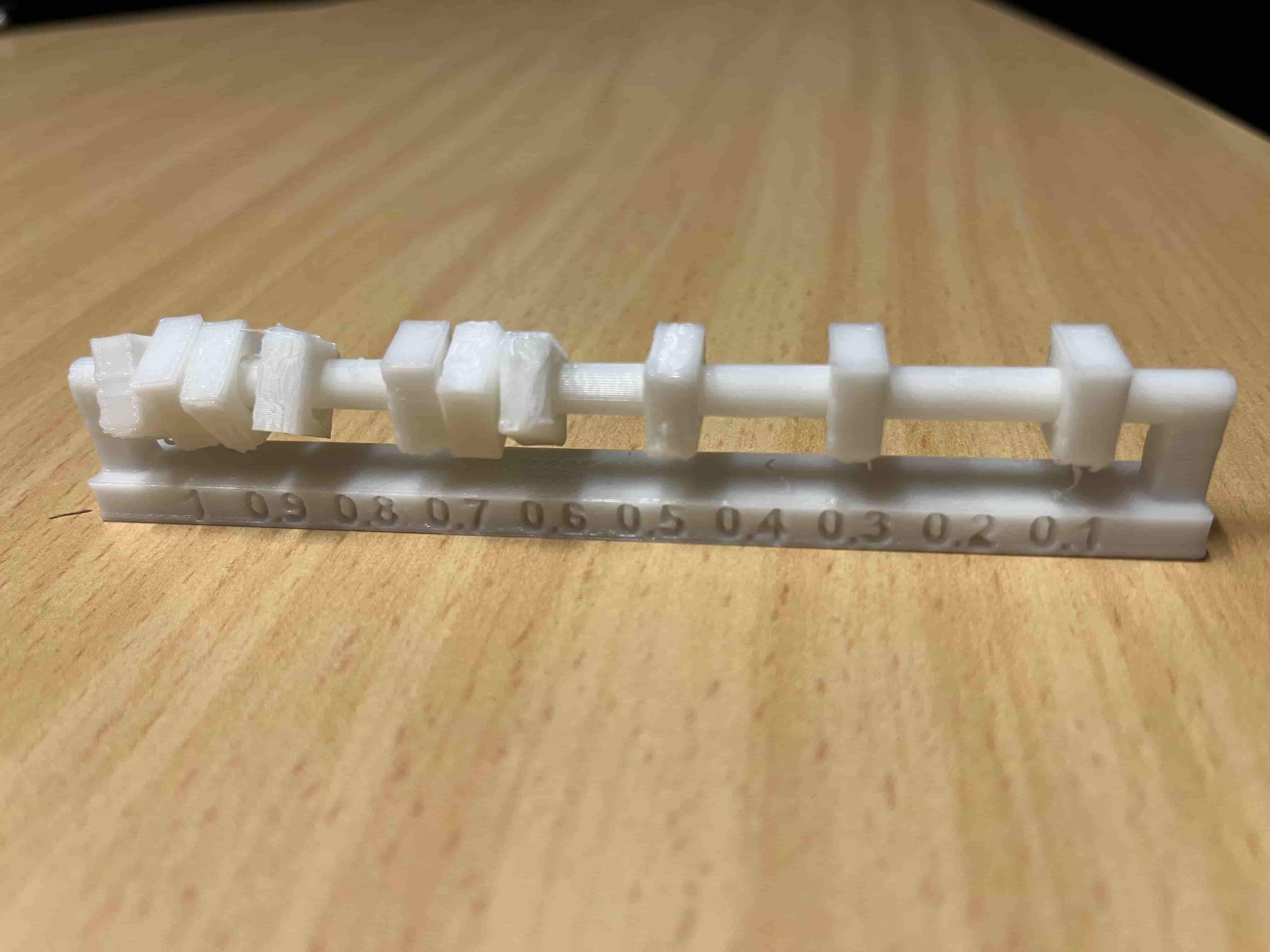

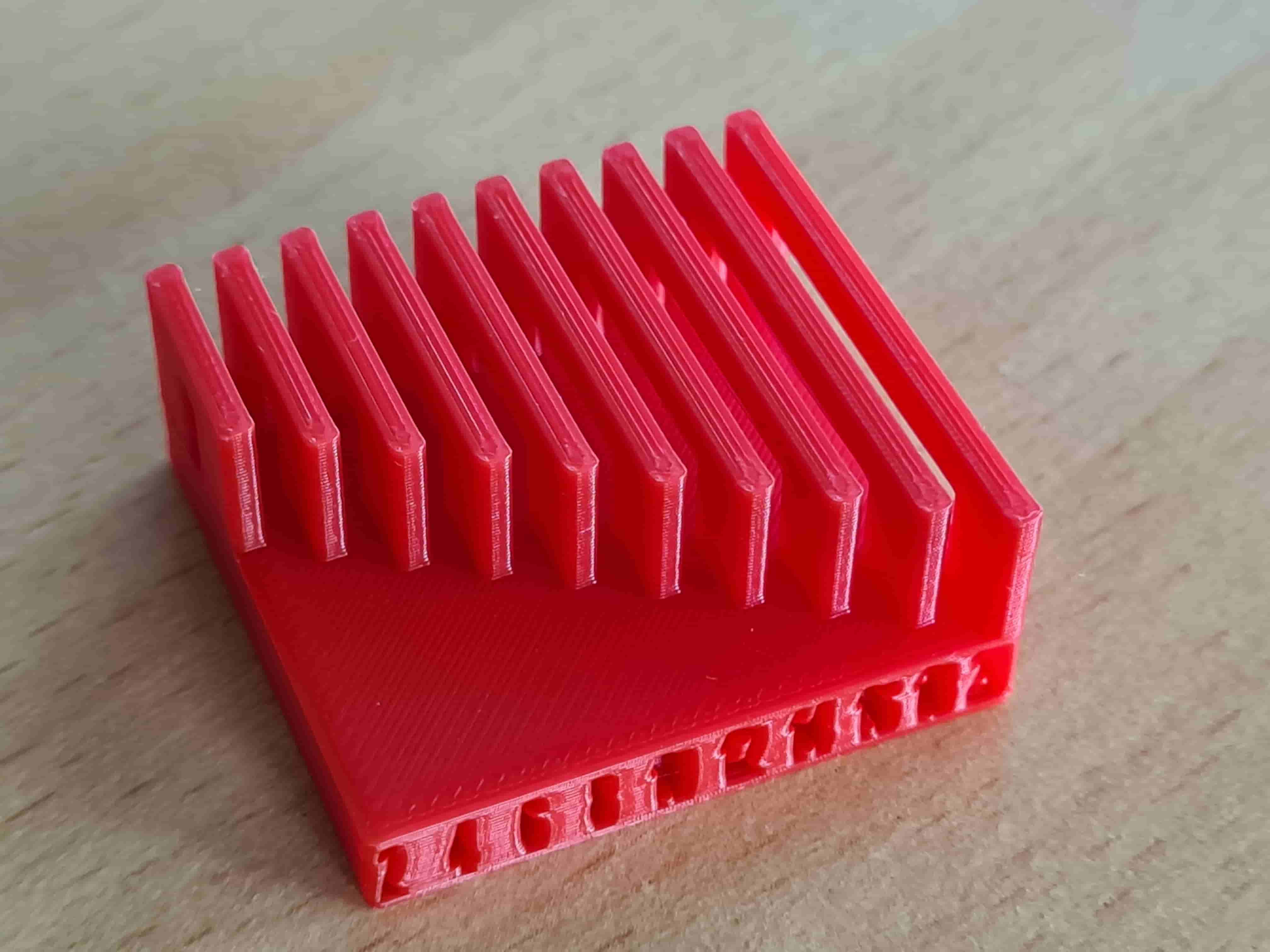

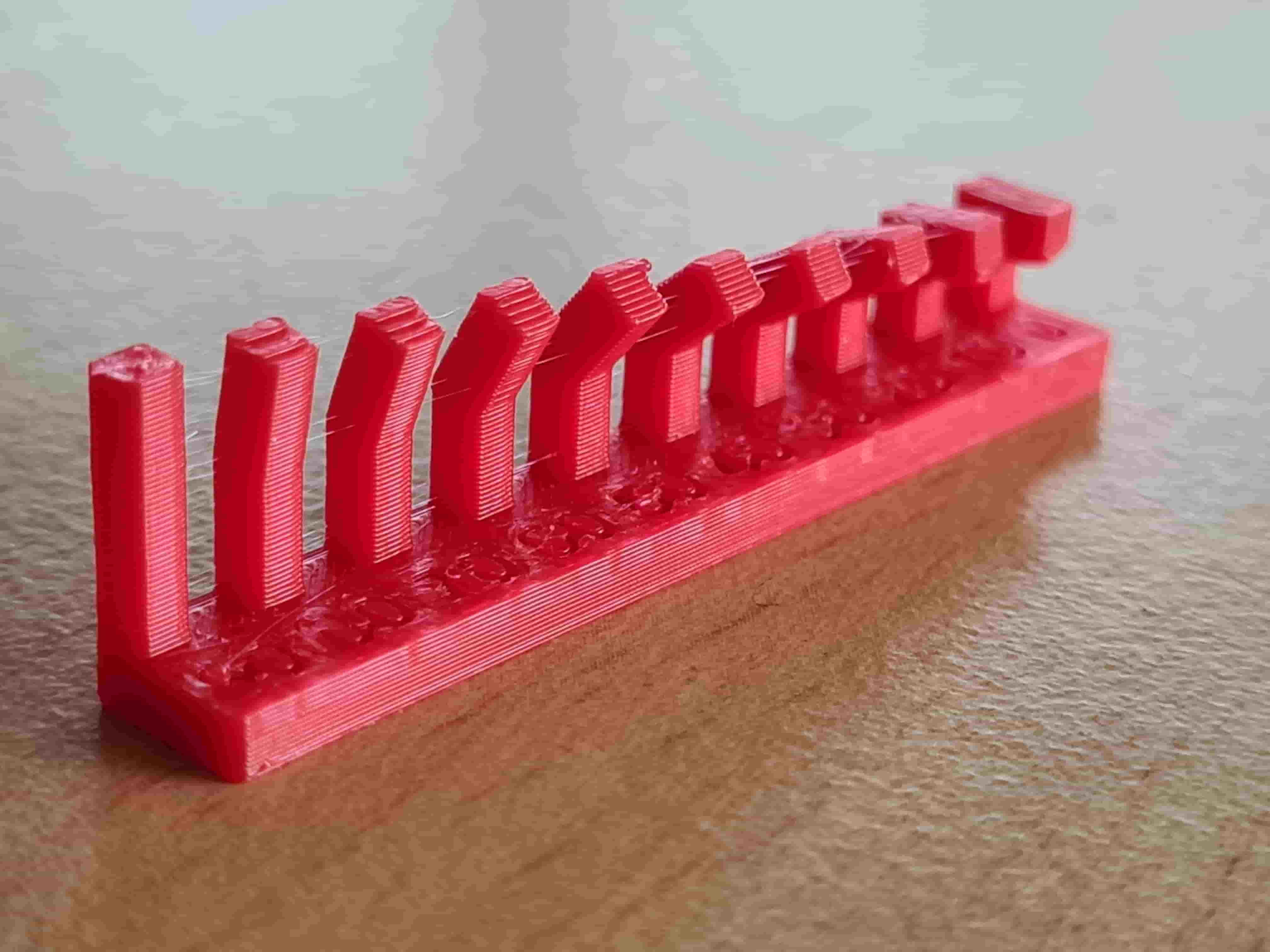

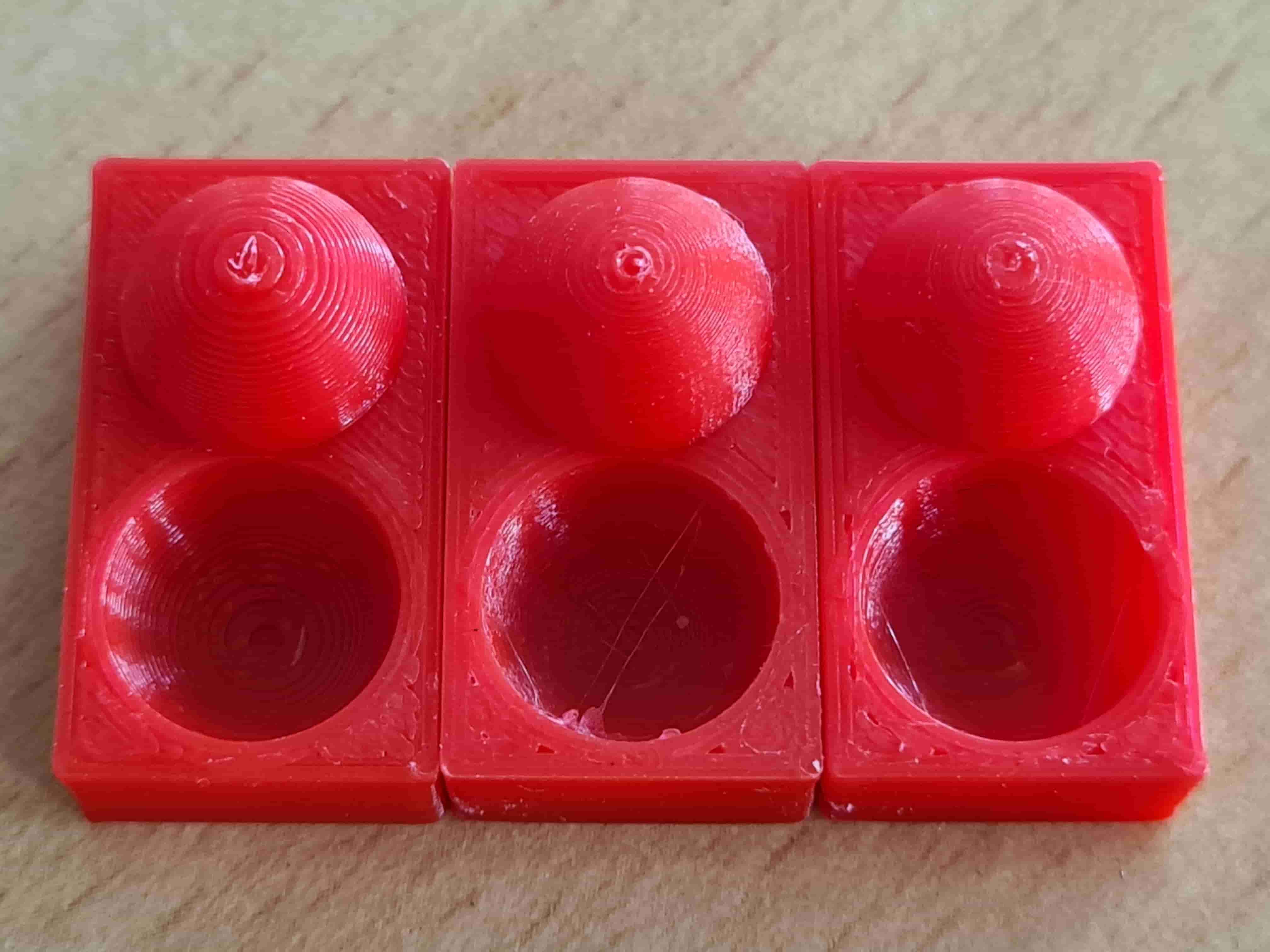

Here are the tests:

Creality Ender-3

The workflow here is also similar, except for that we used the Prusa Slicer instead. Here, the standard settings of 0.2 mm layer height and 20% grid infill were used, and the support for the clearance test were automatically generated by the software.

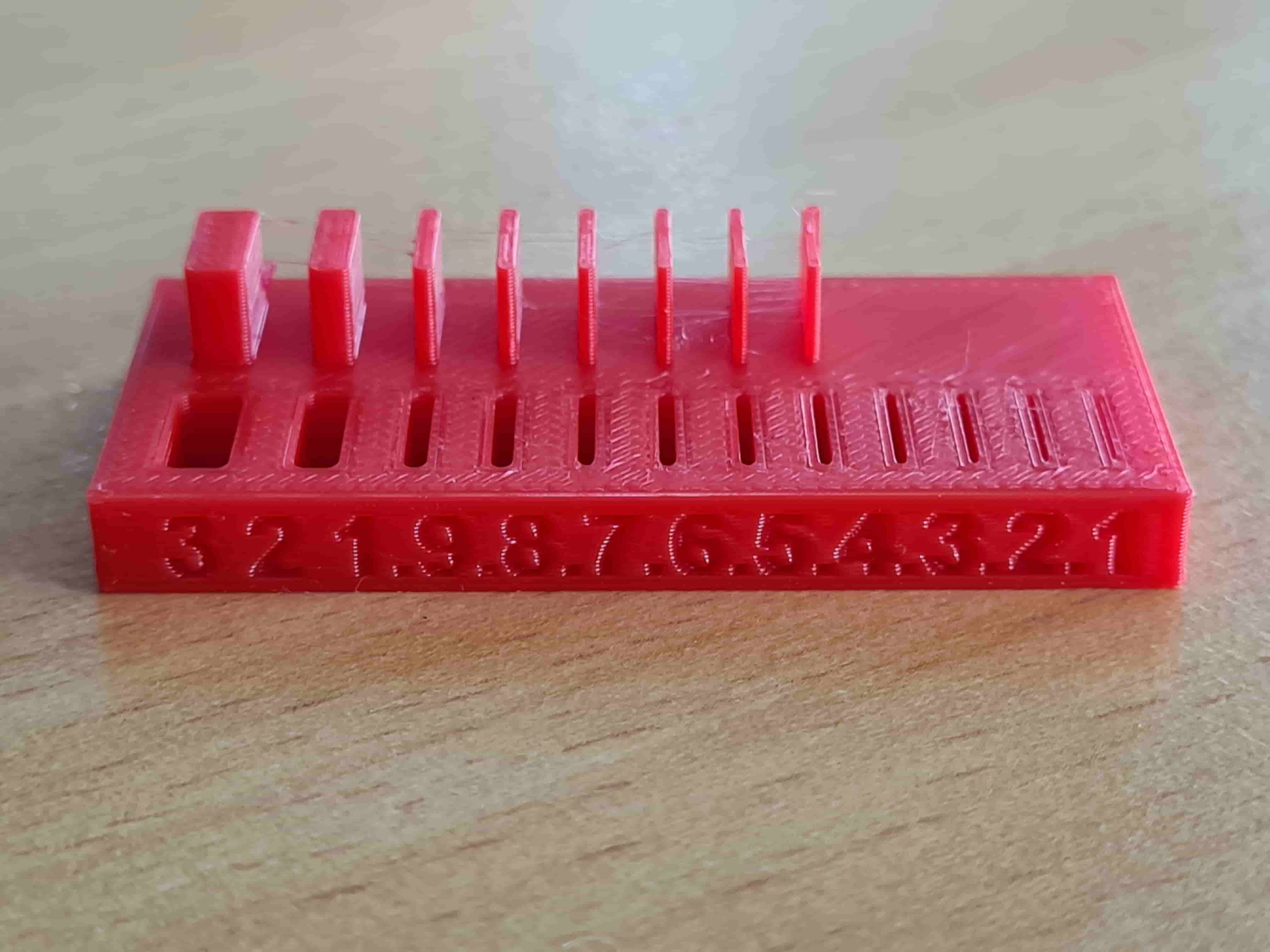

Here are the tests:

And some extra tests:

Results

Acceptable print quality table:

| 3D Printer | Supported Clearance | Unsupported Angle | Unsupported Overhang | Unsupported Bridging |

|---|---|---|---|---|

| Ender-3 V2 | 0.3 mm | 20° | 2 mm | 16 mm |

| Sindoh 3DWOX1 | 0.2 mm | 30° | 1 mm | 12 mm |

| Ender-3 | 0.2 mm | 20° | 1 mm | 16 mm |