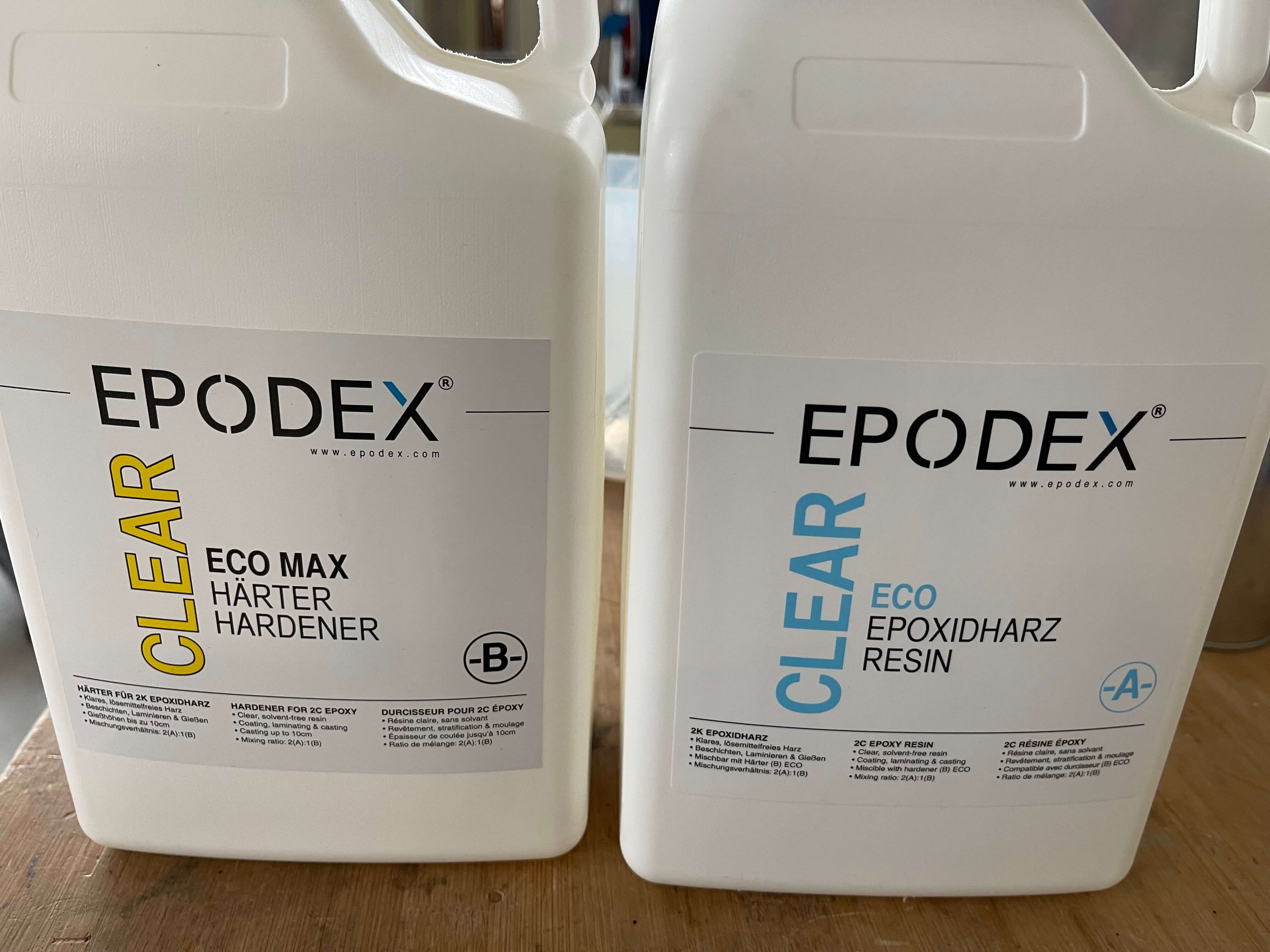

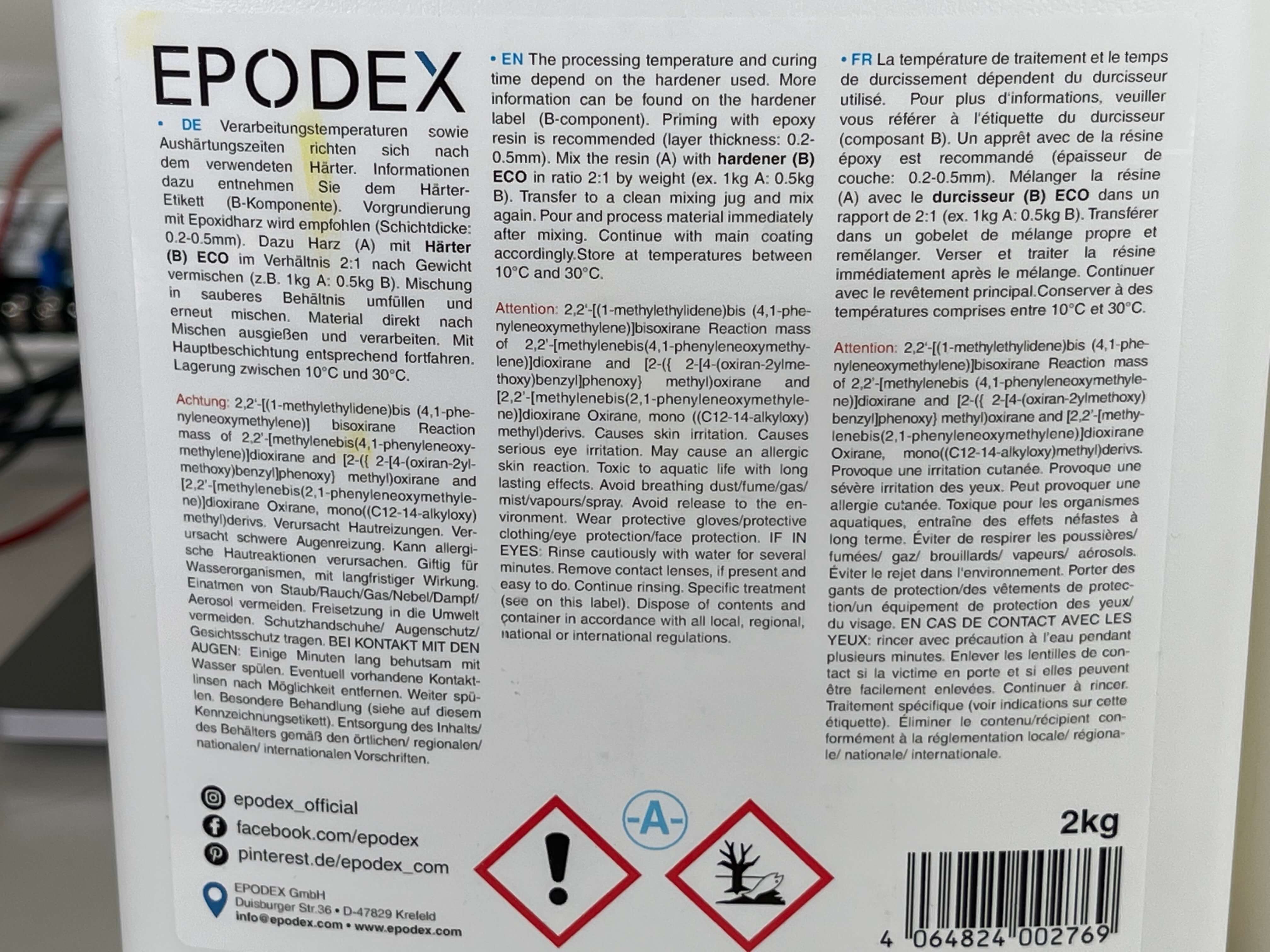

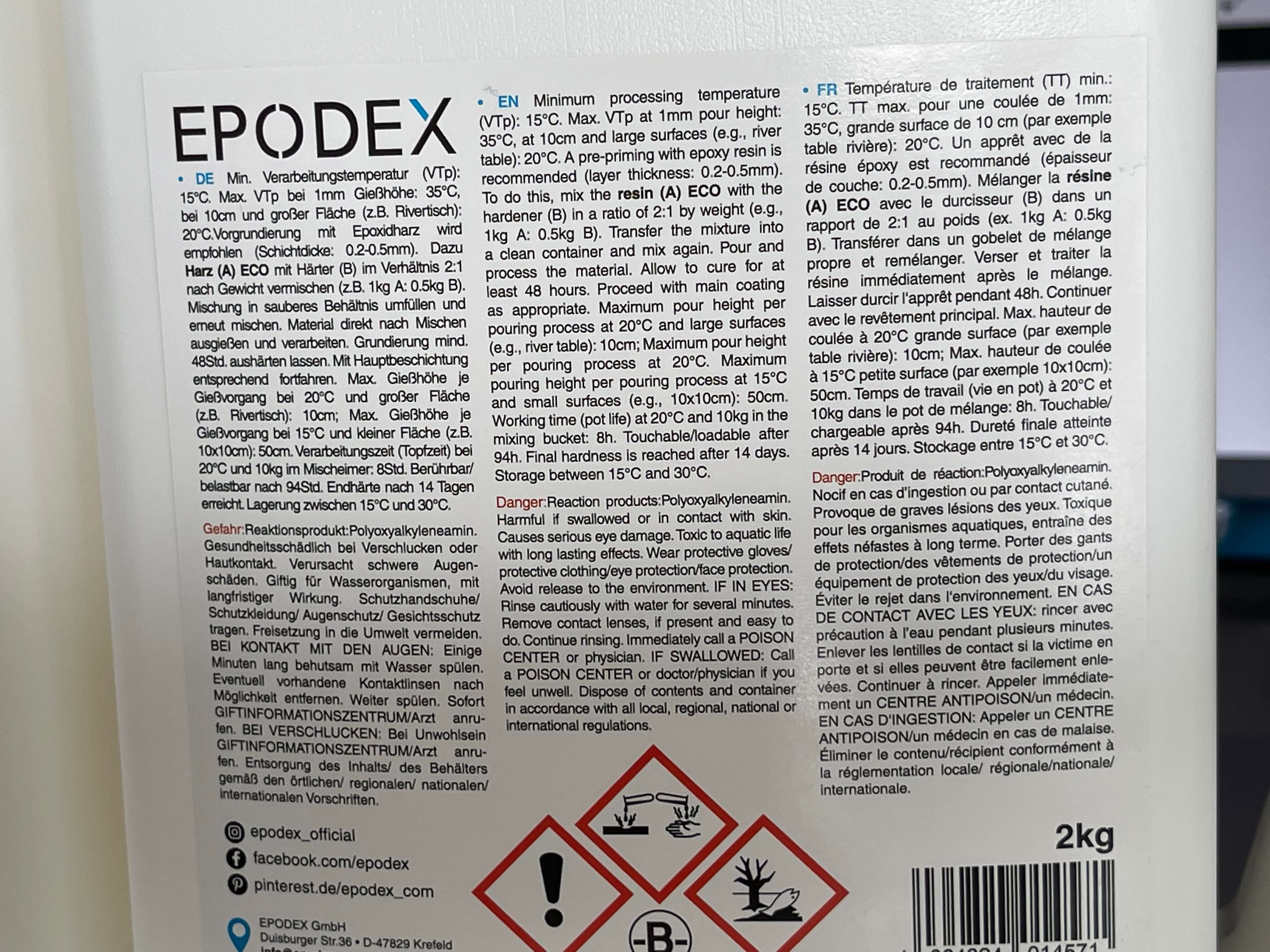

This resin is sourced from a local vendor and sadly has no safety datasheet online. We have however summarized the most important data points for this resin below. We used the EPODEX CLEAR ECO resin together with the EPODEX CLEAR MAX hardener:

| processing temperature range using the EPODEX CLEAR MAX hardener | 15°C - 35°C (At 1mm pour height); 15°C - 20°C (at 10cm pour height and for larger surfaces) |

| Pot Life | 8 hours, touchable/loadbale after 94 hours |

| Curing Time | Full vulcanization - 7 Days, final hardening stage after 14 days |

| Storage | Locked up, between 10°C and 30°C |

Safety instructions and warnings according to the webpage:

A Component Danger: Causes skin irritation. Causes serious eye irritation. May cause an allergic skin reaction. Toxic to aquatic life with long lasting effects. Avoid breathing dust/fume/gas/mist/vapours/spray. Avoid release to the environment. Wear protective gloves/eye protection/face protection. IF IN EYES: Rinse cautiously with water for several minutes. If possible, remove contact lenses. Continue rinsing. Dispose of contents/container in accordance with local/regional/national/international regulations.

B-Component Danger: Harmful by inhalation, in contact with skin and if swallowed. Causes serious irritation of the skin and serious eye damage. May cause an allergic skin reaction. Harmful/Toxic to aquatic life with long lasting effects. Avoid release to the environment. Do not breathe dust/fume/gas/mist/vapour/spray. Wear protective gloves/ protective clothing/ eye protection/ face protection. IF ON SKIN (or hair): Take off immediately all contaminated clothing. Rinse skin with water/shower. IF INHALED: Remove person to fresh air and keep comfortable for breathing. IF IN EYES: Rinse cautiously with water for several minutes. If possible, remove contact lenses. Continue rinsing. Immediately call a POISON CENTER/doctor. IF SWALLOWED: Call a POISON CENTER/doctor if you feel unwell. Keep locked up. Dispose of contents/ container in accordance with local/ regional/ national/ international regulations.

We also used the opportunity to use coloured and or metallic pigments inside the epoxy and hardener mixture. According to the manufacturer the amount of colour the user has to add to the mixture is as follows:

- Colourpigments (metallic, neon and glow in the dark): ca. 1,5%

- transparent colours (with exception of white black and grey): 60 drops

- transparent black, white and grey: 20 drops

- semi-transparent colour (with exception of white): 40 drops

- semi transparent white: 60 drops

- RAL colours: 1%

- Glitter: ca. 1%

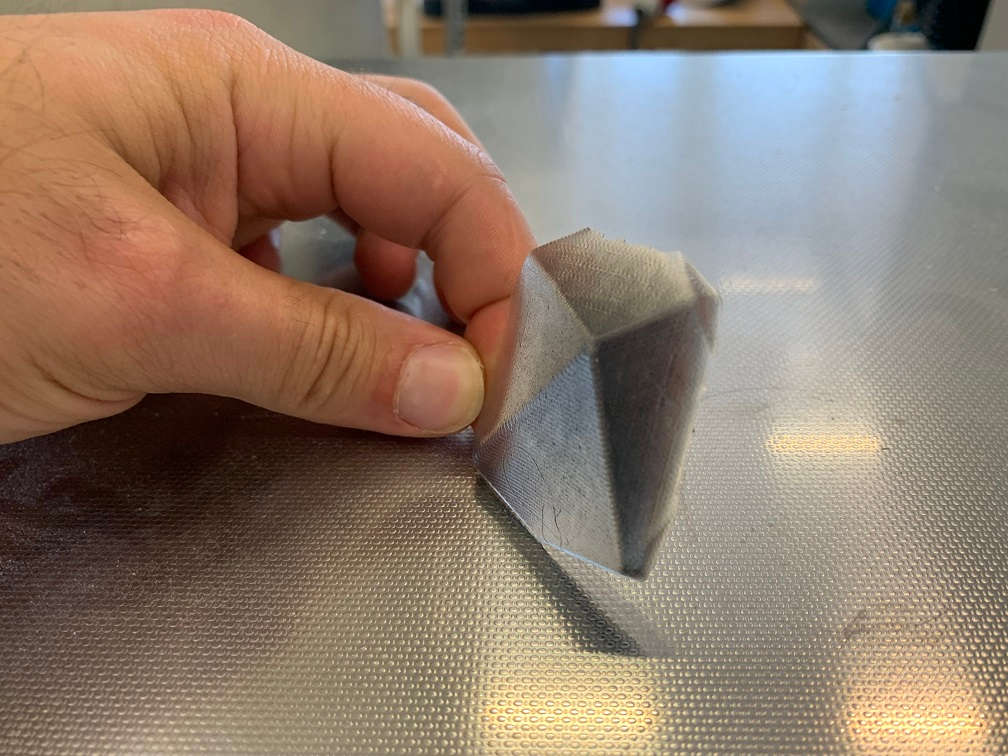

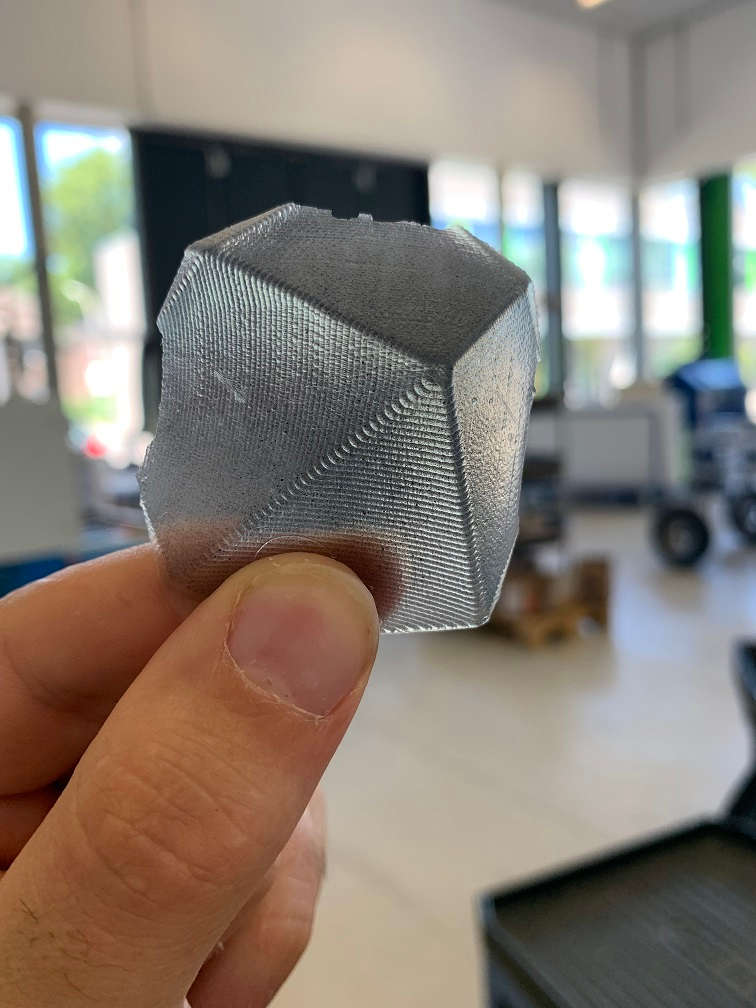

For my final resin cast I wanted to use the metallic pigments, so we did a test cast with one of the molds we had sitting around at the lab. The result can be seen here: