Wildcard Week

Assignment requirements:

Individual Assignment

- Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it.

Learning outcomes:

- Demonstrate workflows used in the chosen process.

- Select and apply suitable materials and processes to do your assignment

Assessment criteria

- Documented how you made your creation.

- Described problems and how you fixed them.

- Included your design files and 'hero shot' of the result.

Practice

G-code writing

- This week I was interested in exploring a machine a didn't use before, so for a practice Follwing this tutorial I learned more about G-code with Moiz we tried a simple G-code on the small CNC router machine.

- We used the small desktop router machine we have in our lab.

- Also we had a 25mm diameter end mill so we decided to use it but without rotating the spindle.

- we wrote the Gcode manually in a text file and used open builds control software to simulate it, we tried to use some special Gcodes but the machine didn't accept it so we went with the easy way to set the coordiante of each point it will travel from and to.

- Code: G-code

Individual Assignment

Machine & Tools

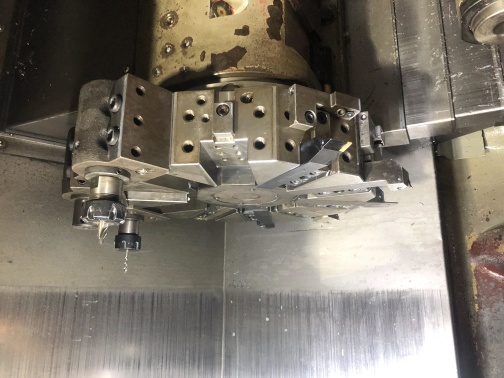

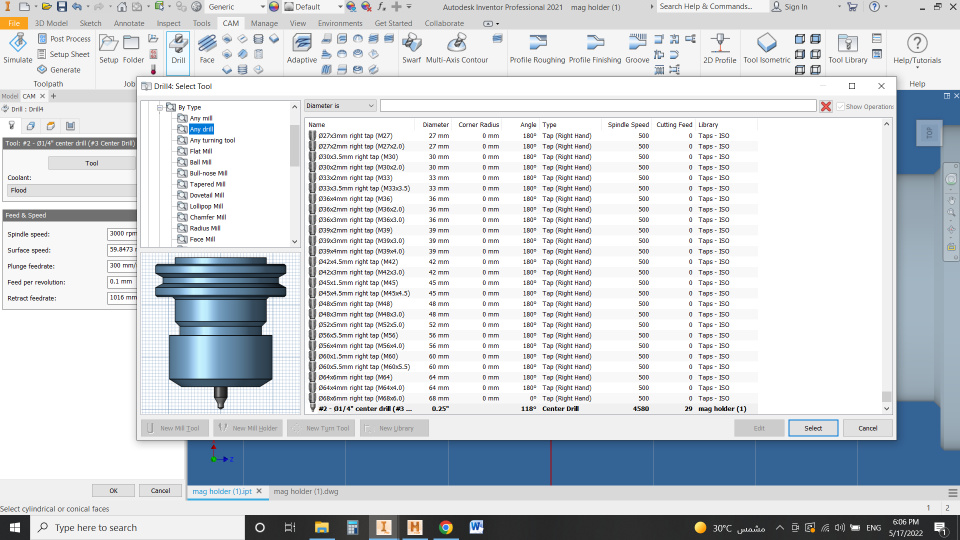

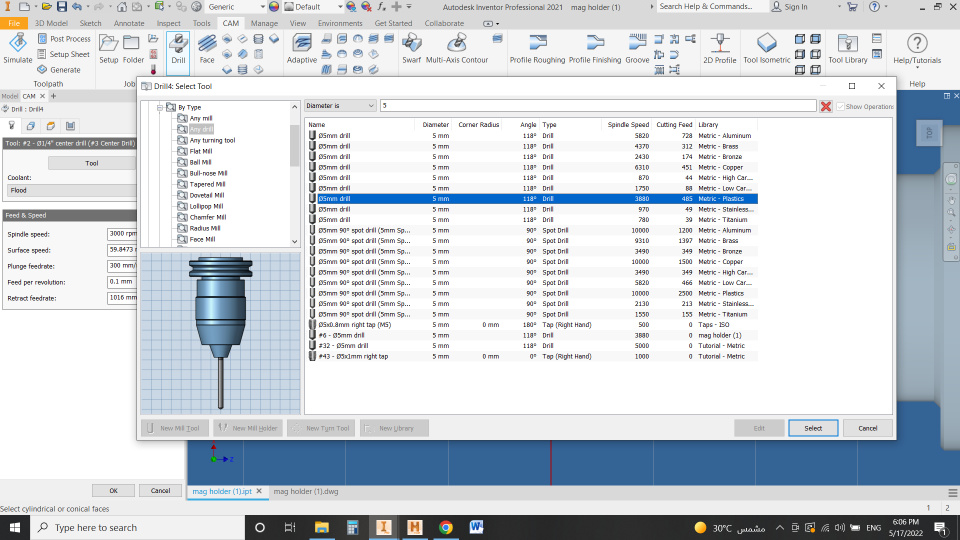

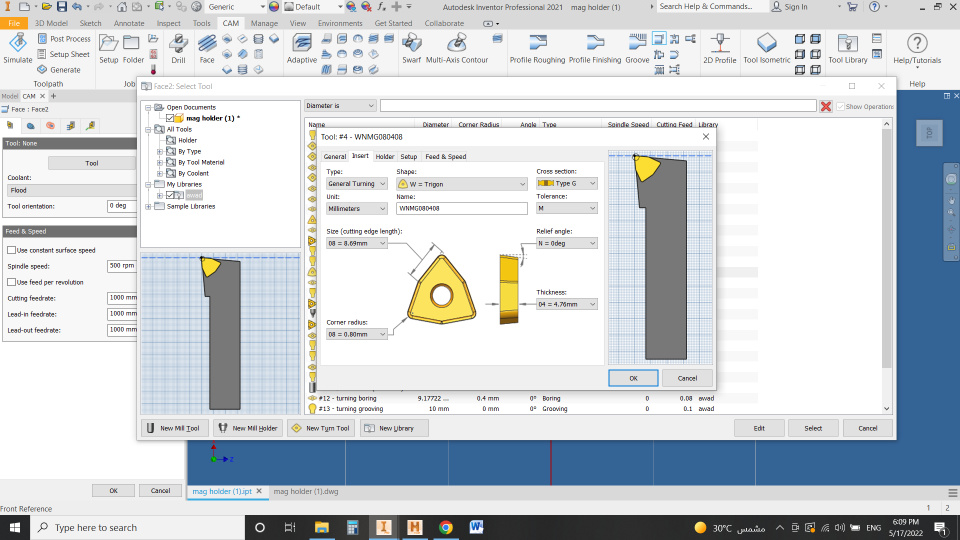

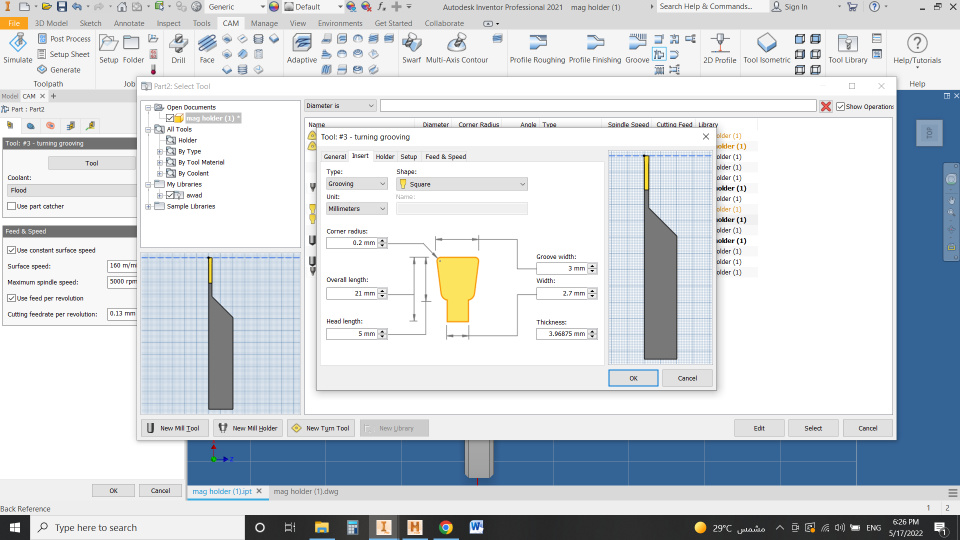

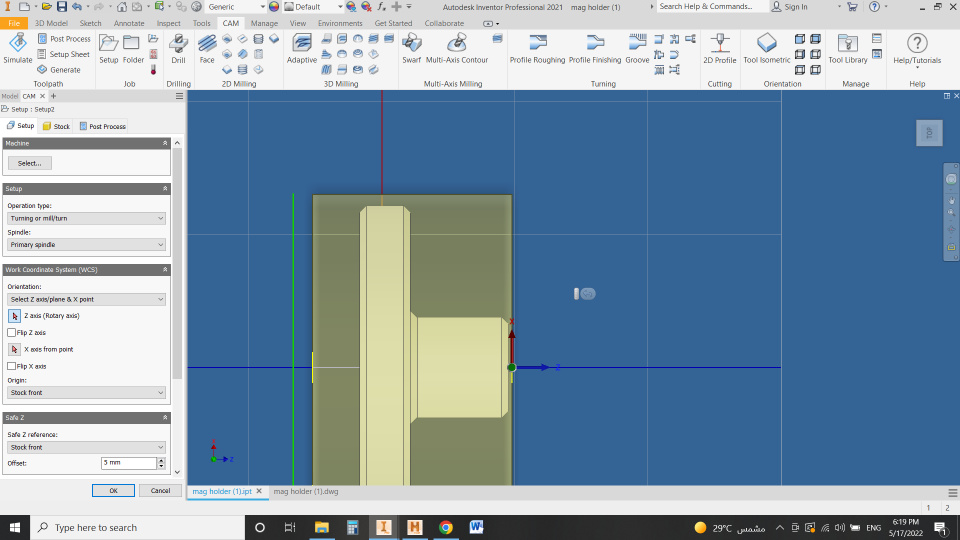

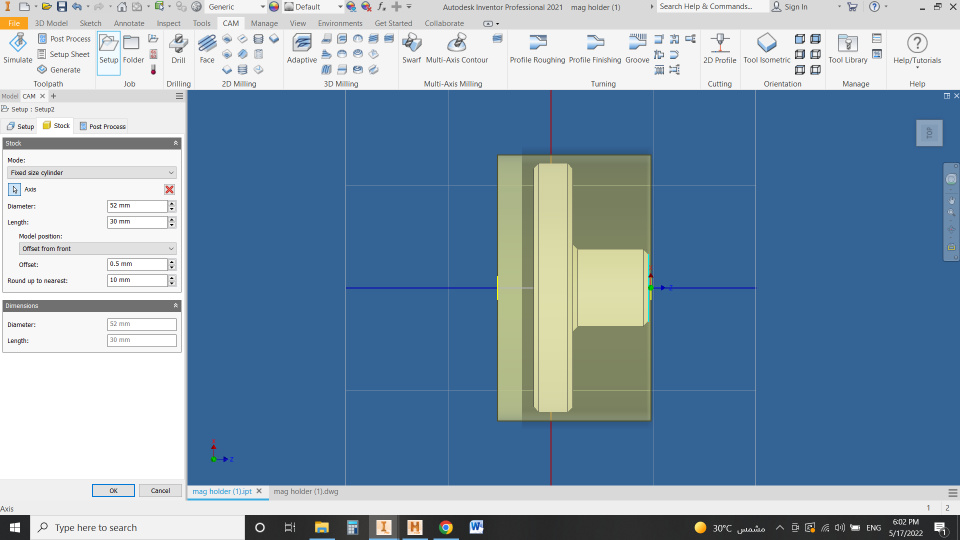

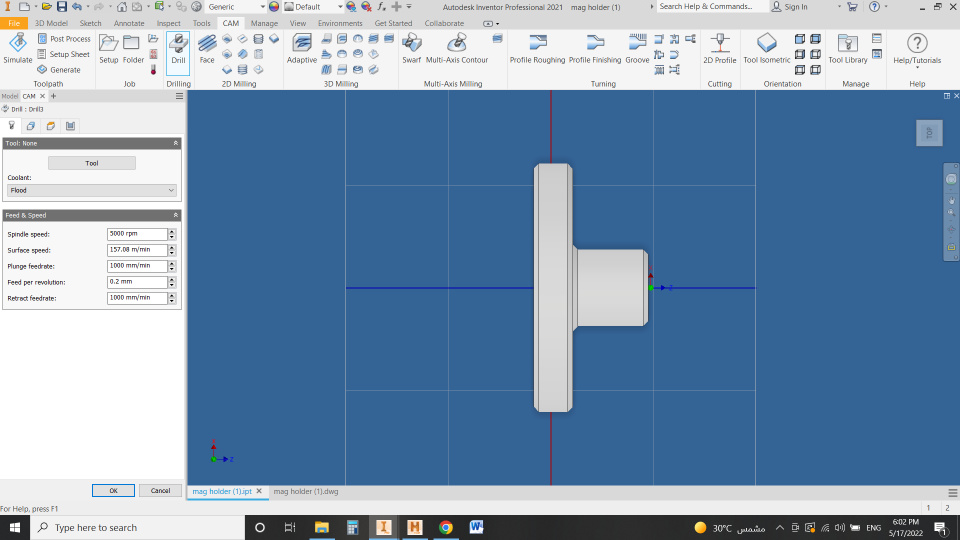

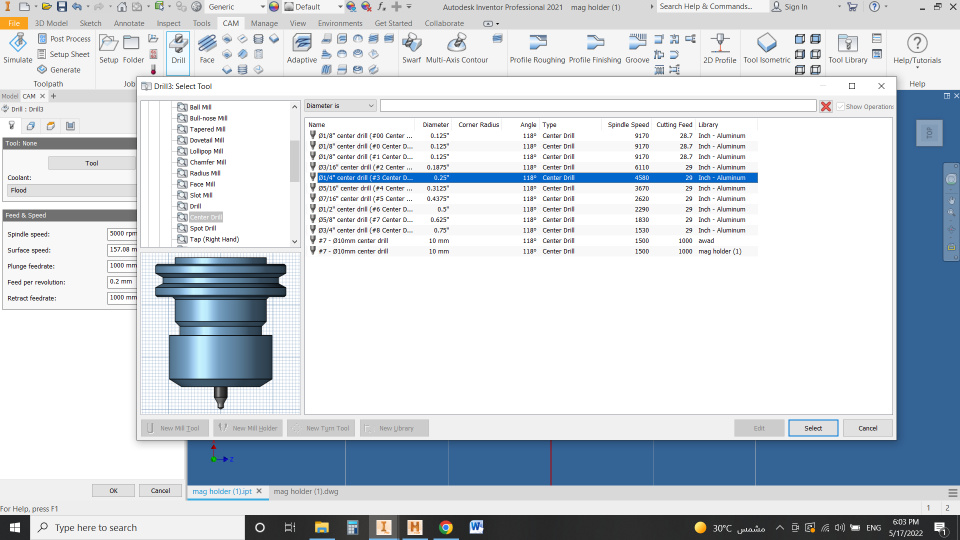

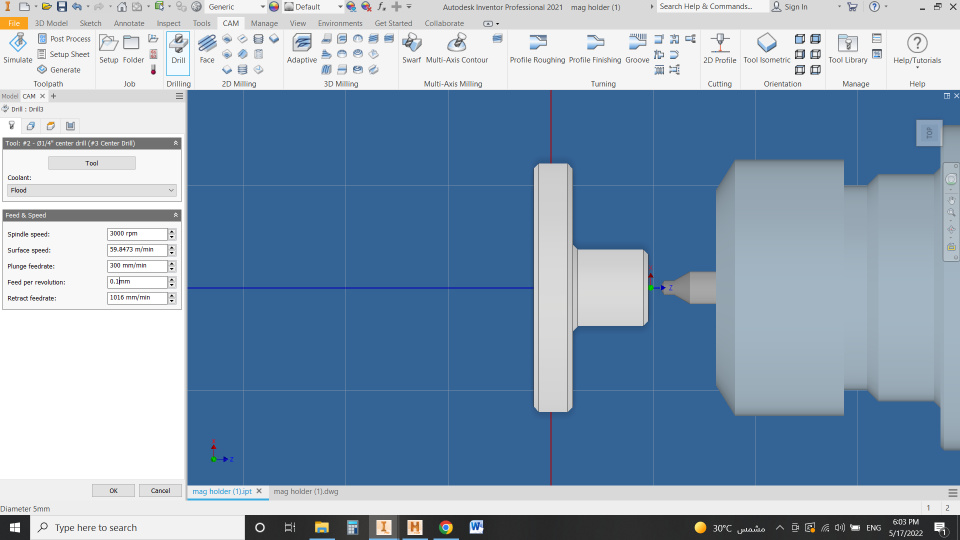

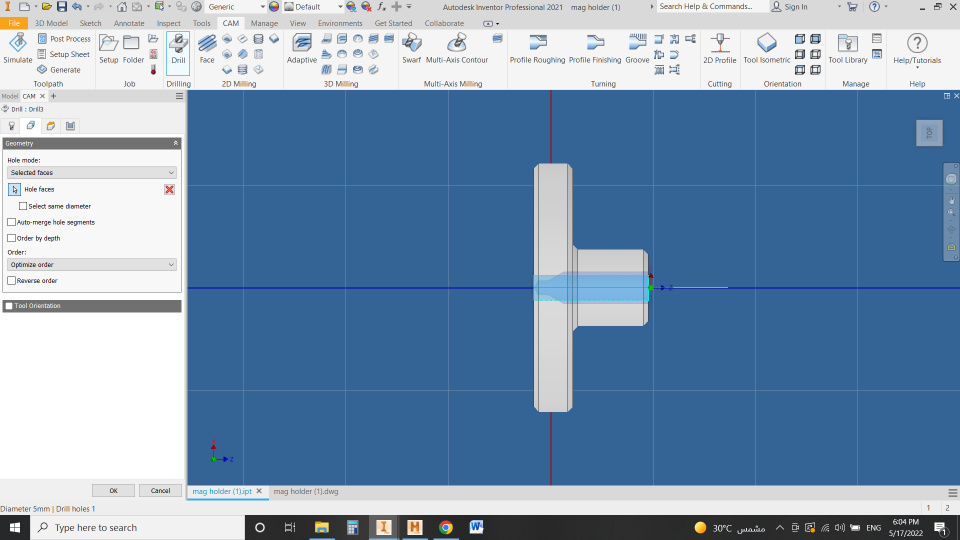

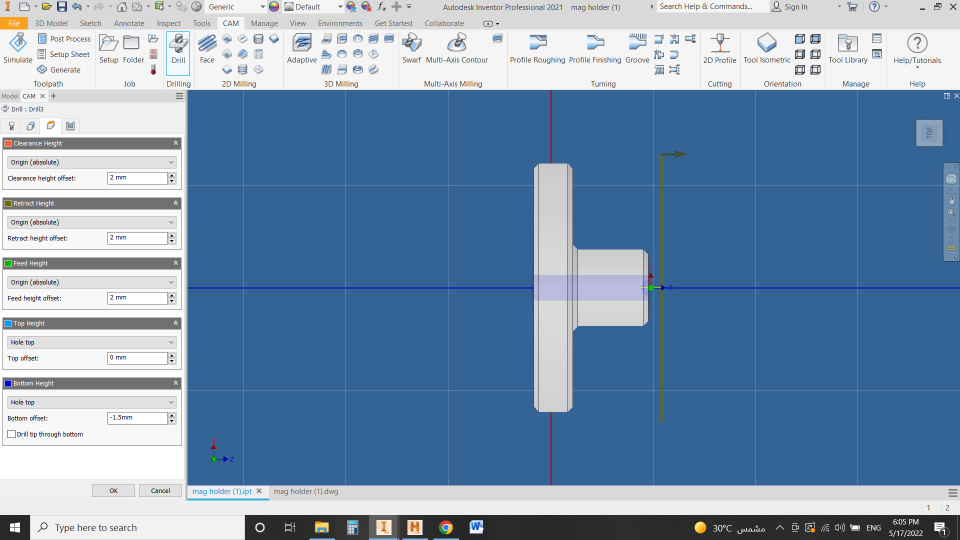

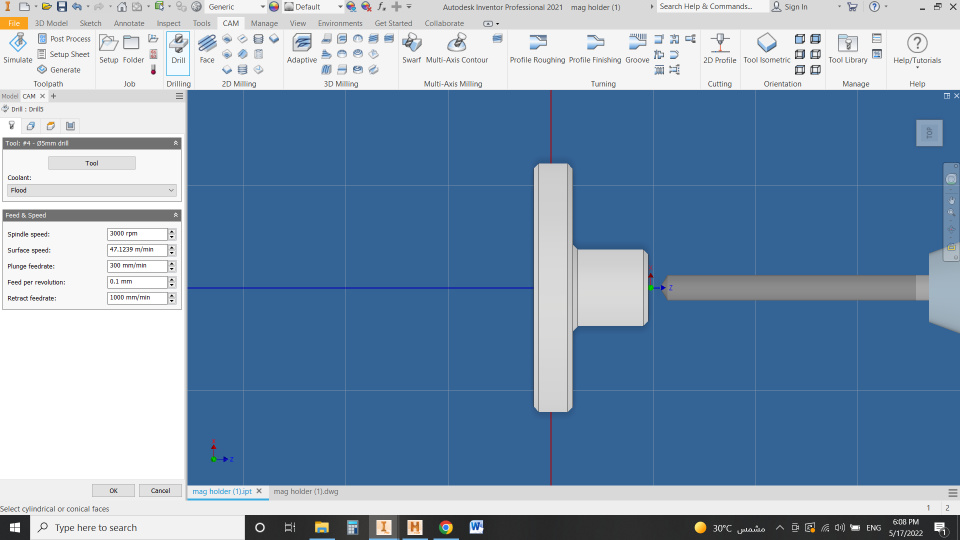

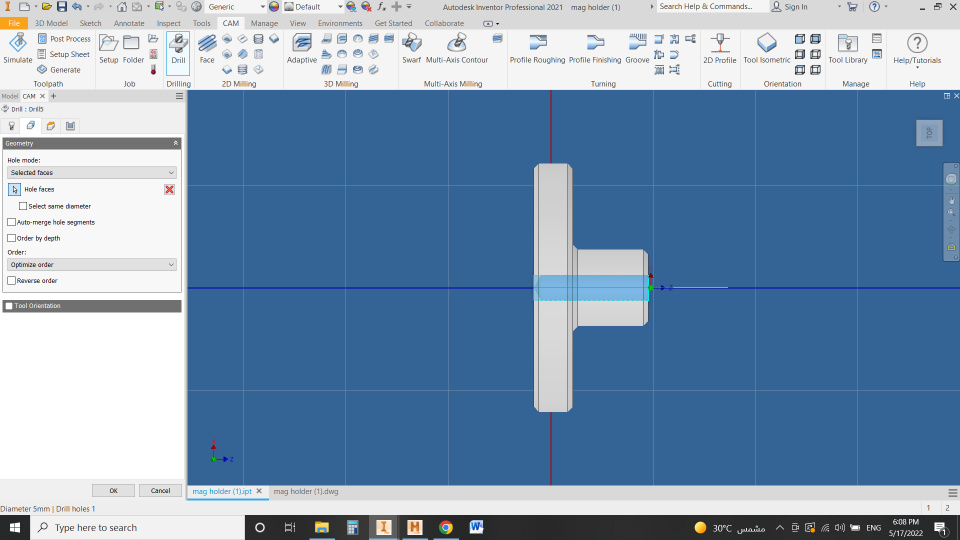

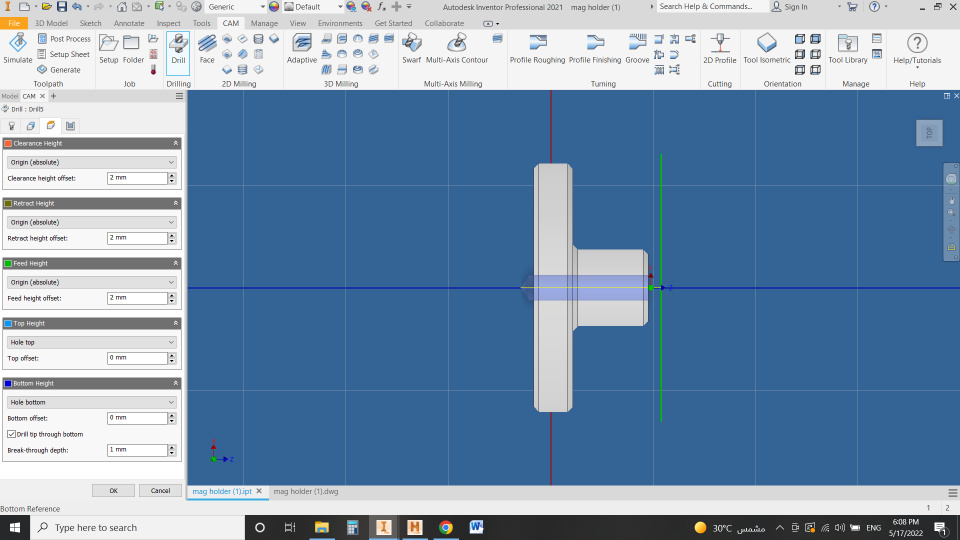

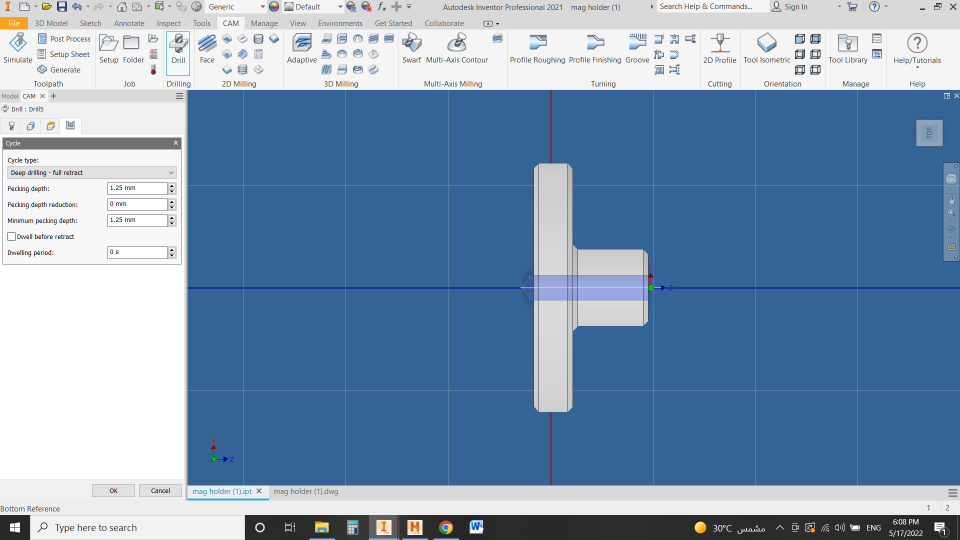

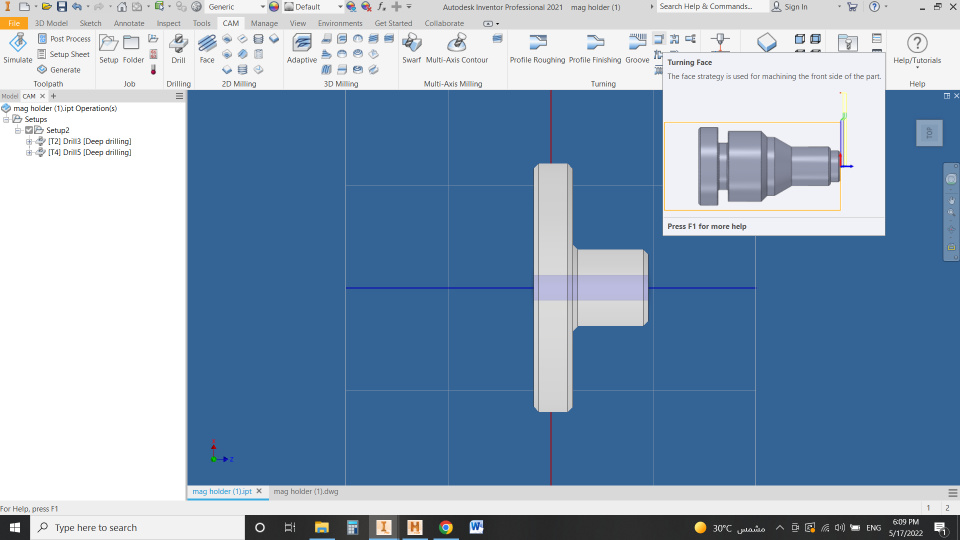

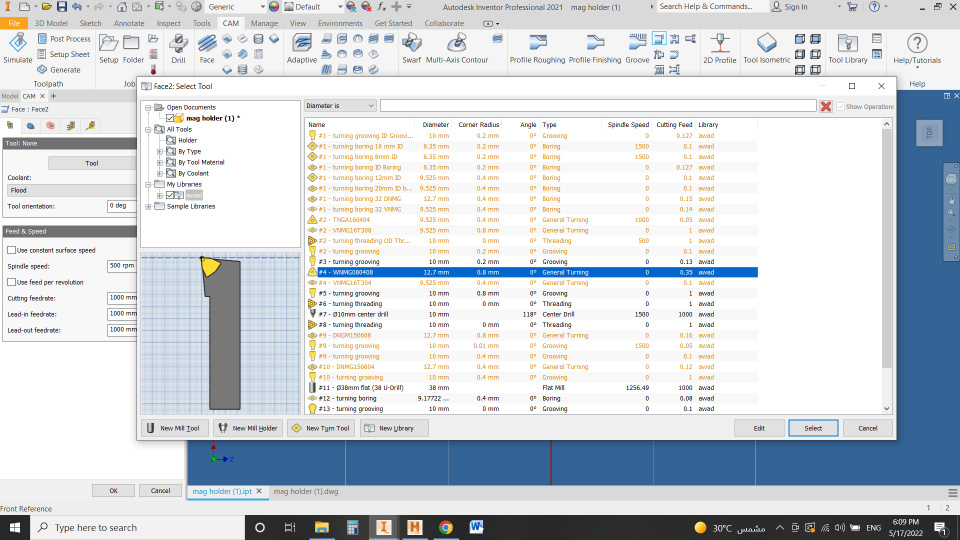

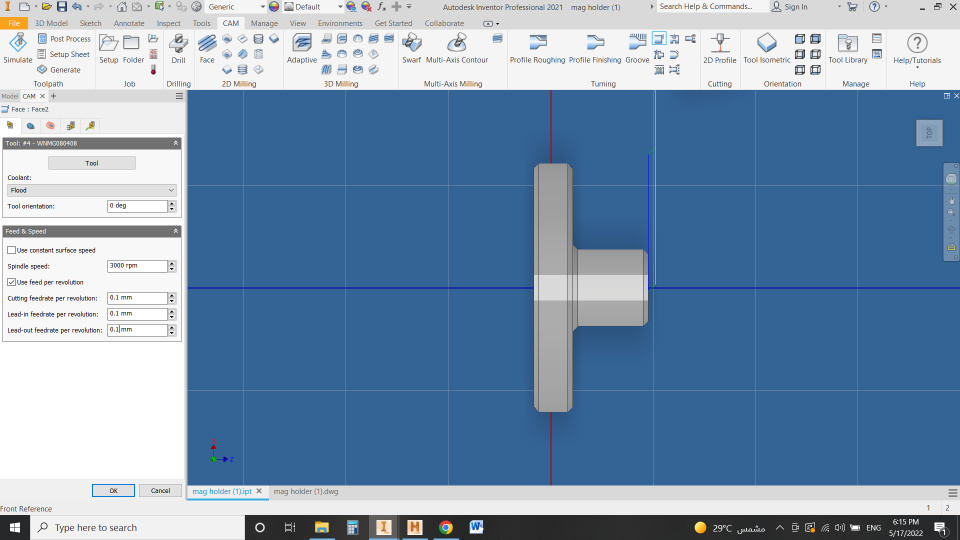

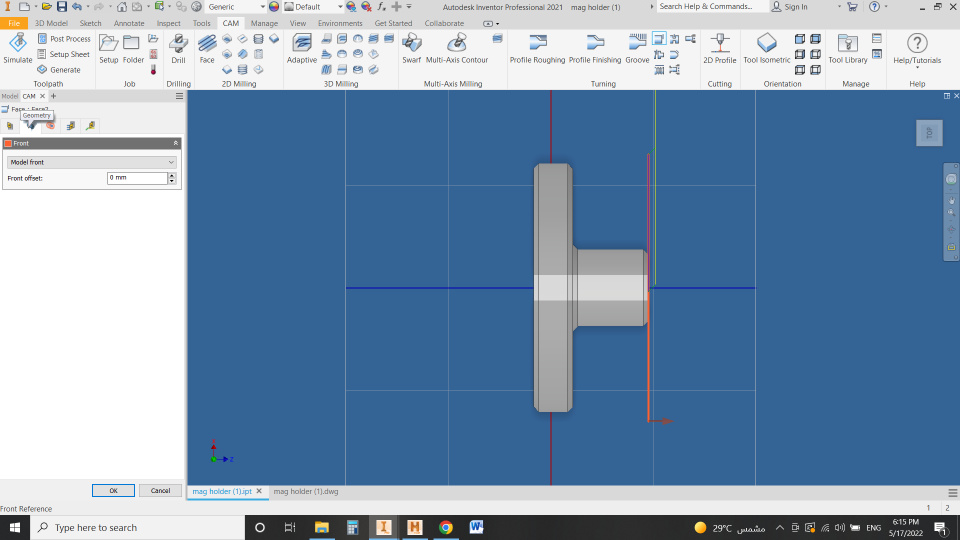

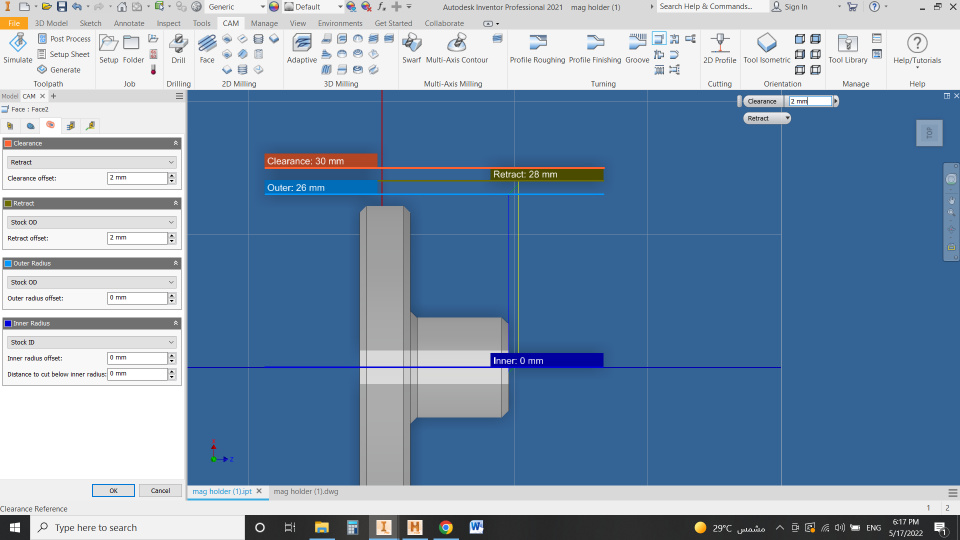

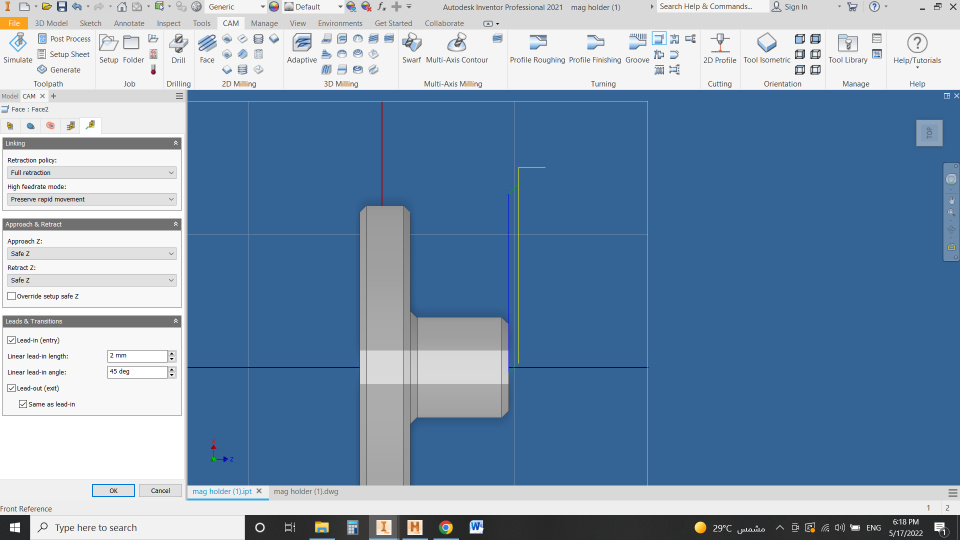

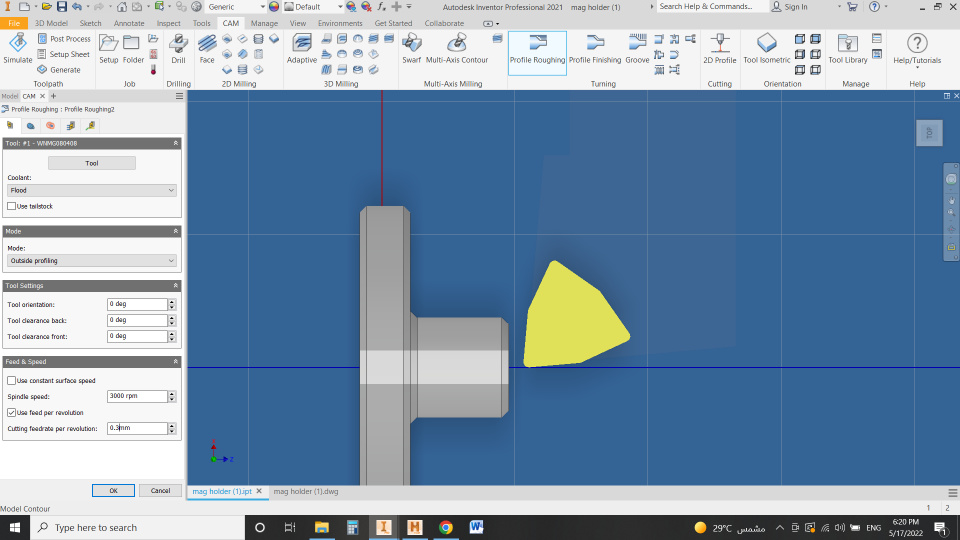

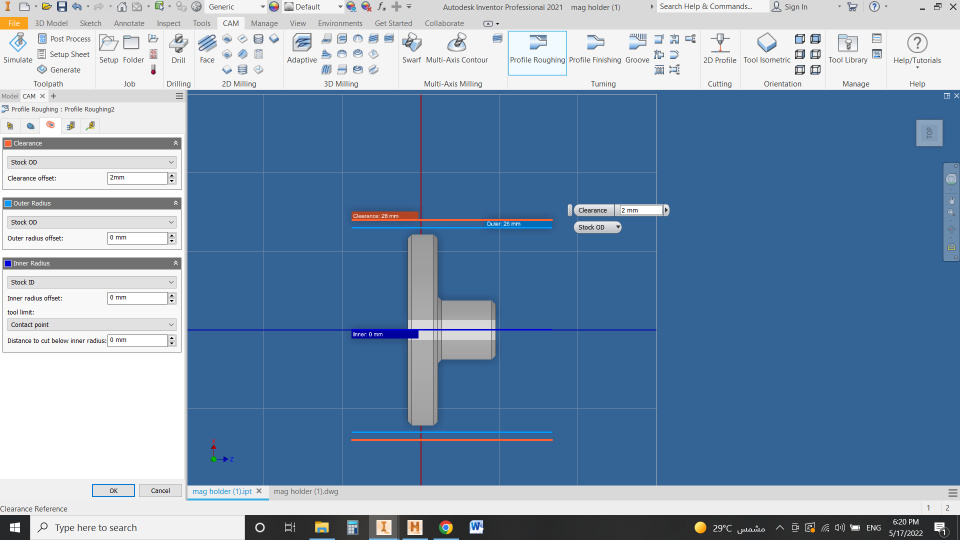

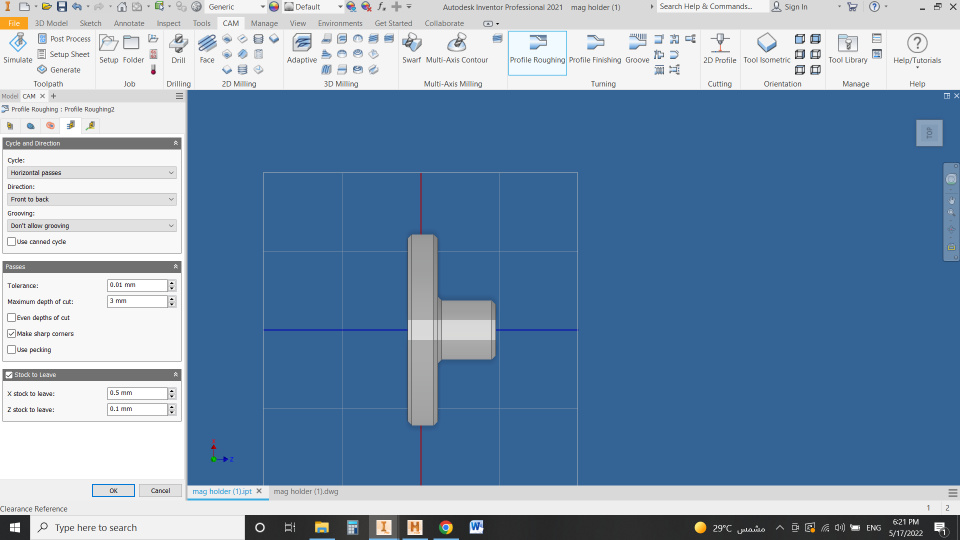

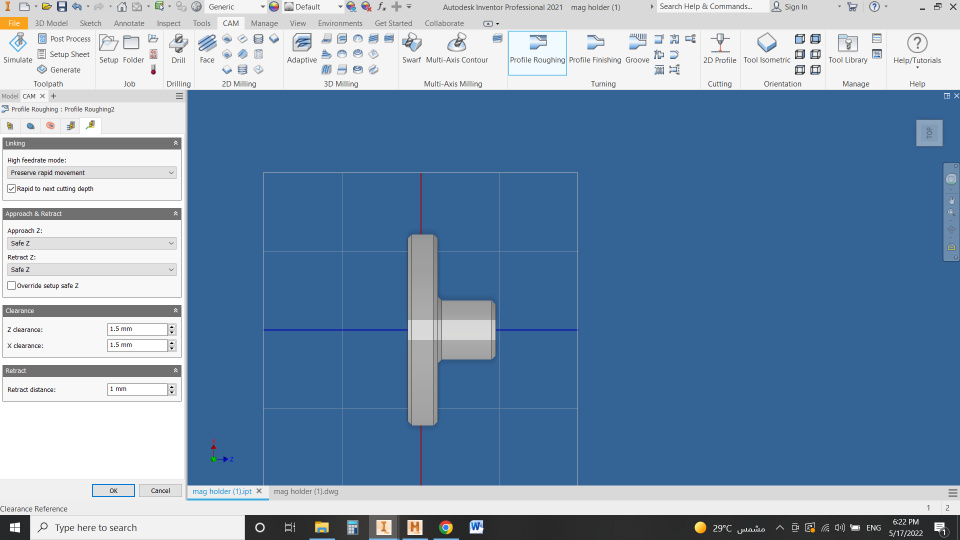

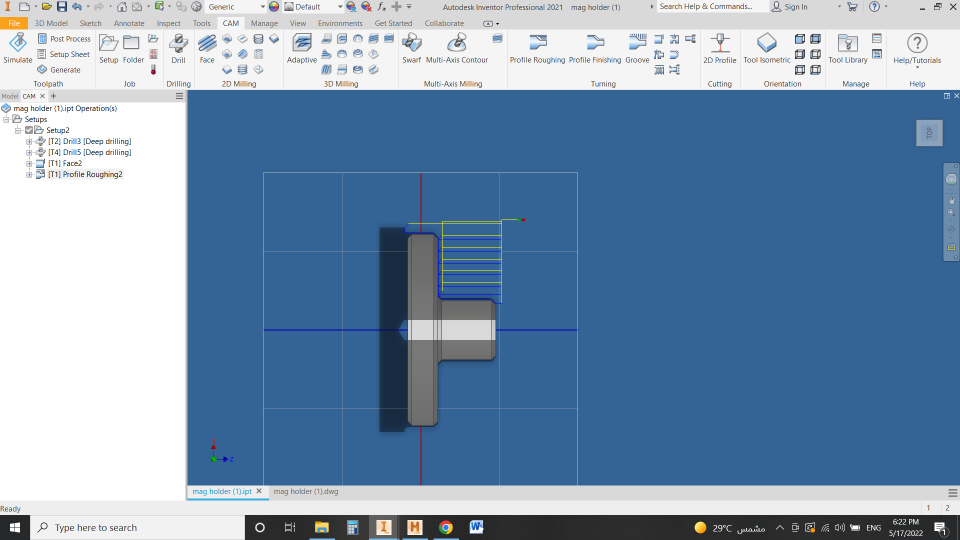

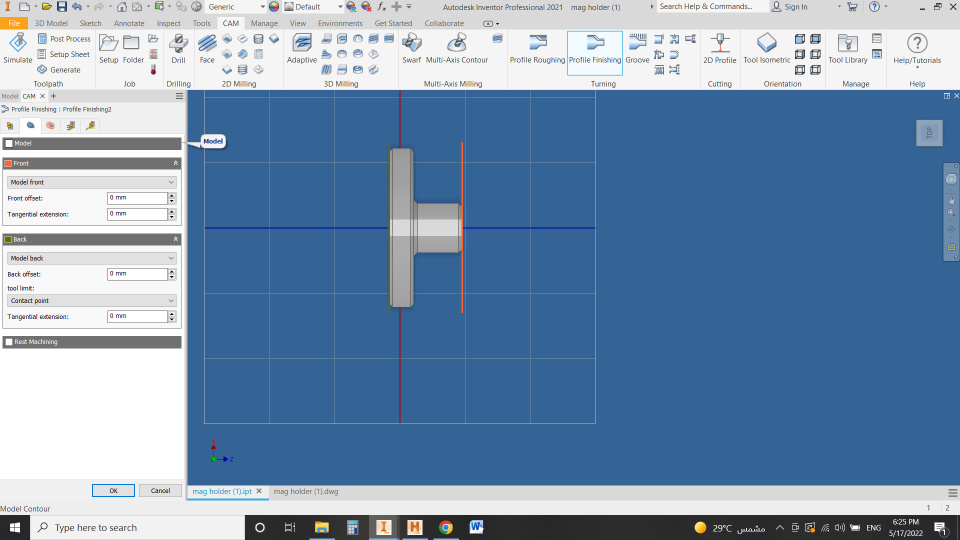

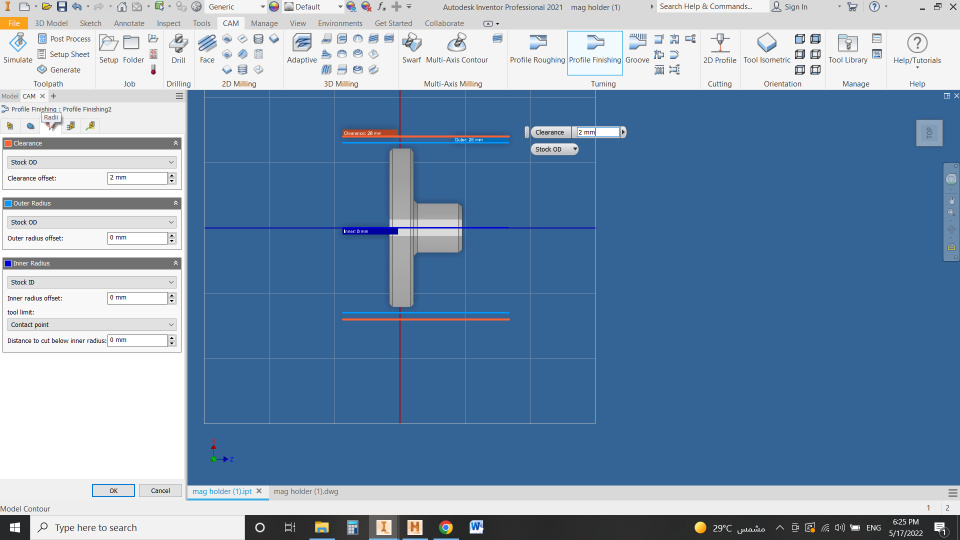

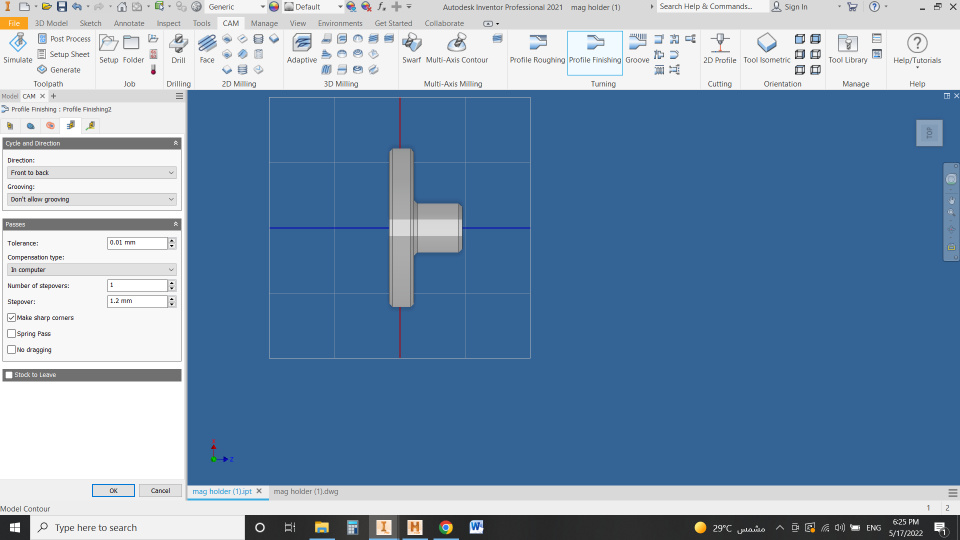

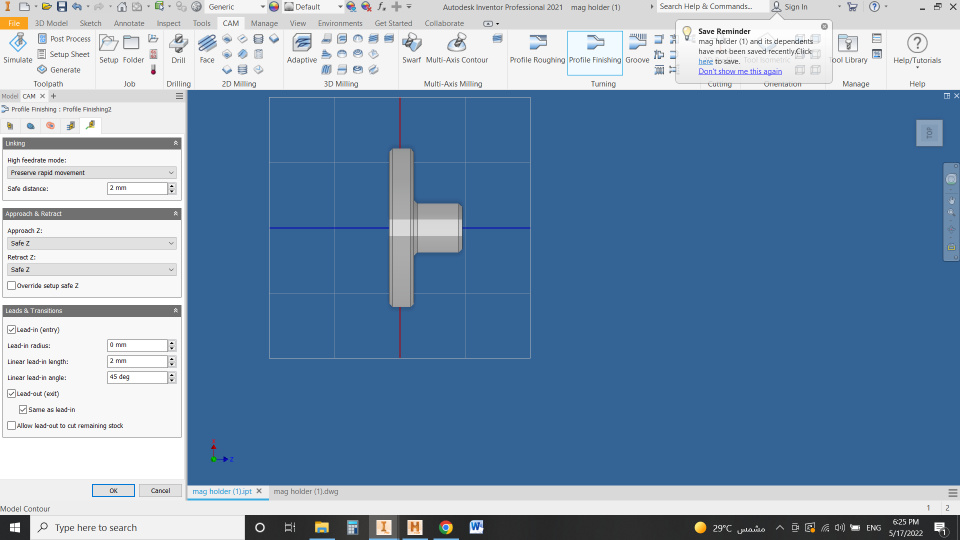

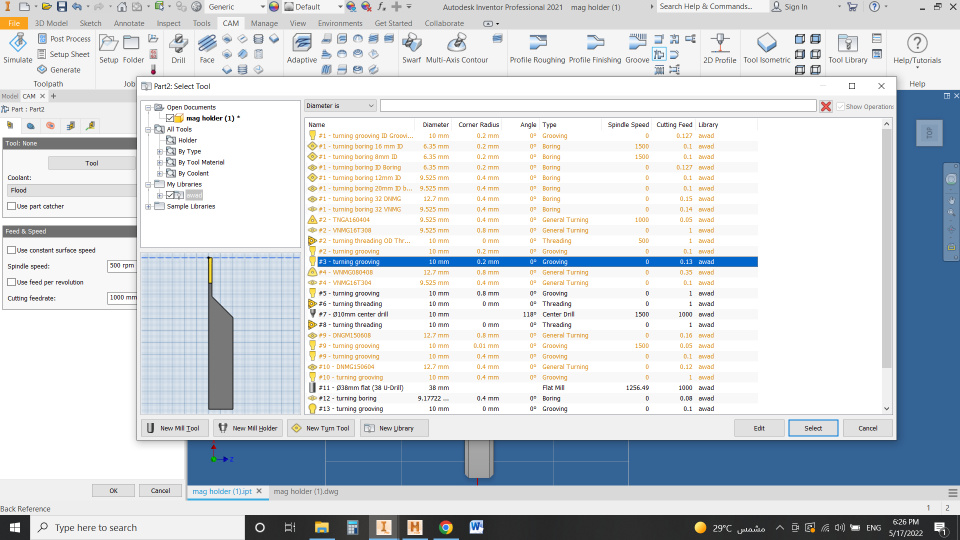

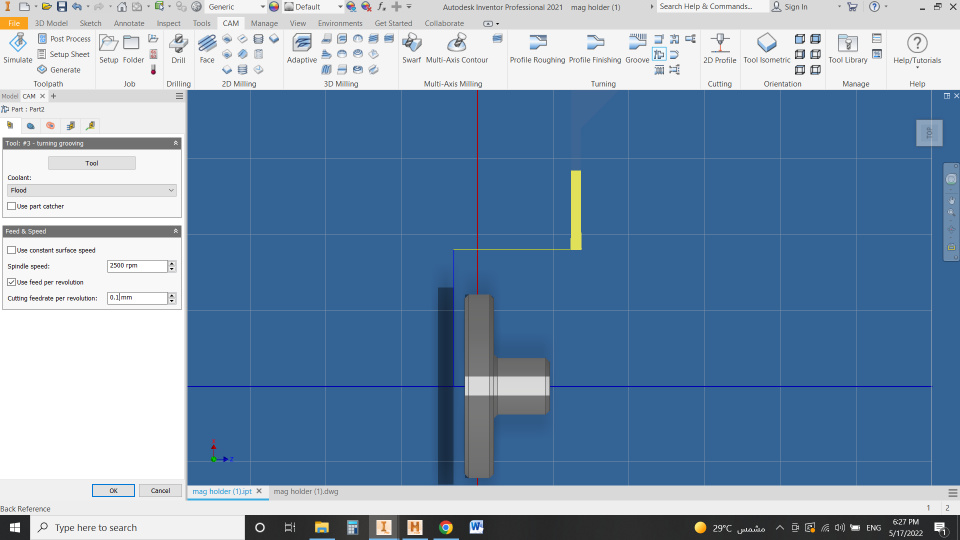

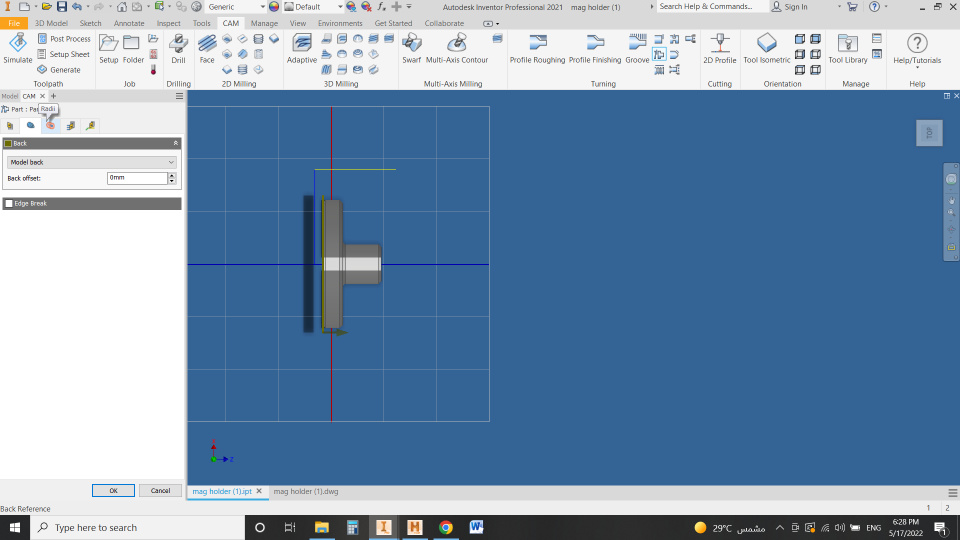

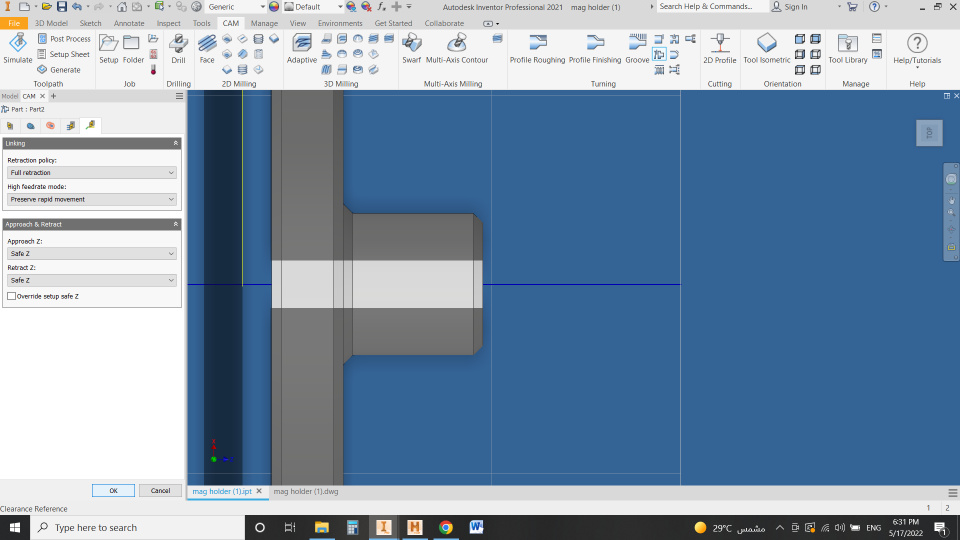

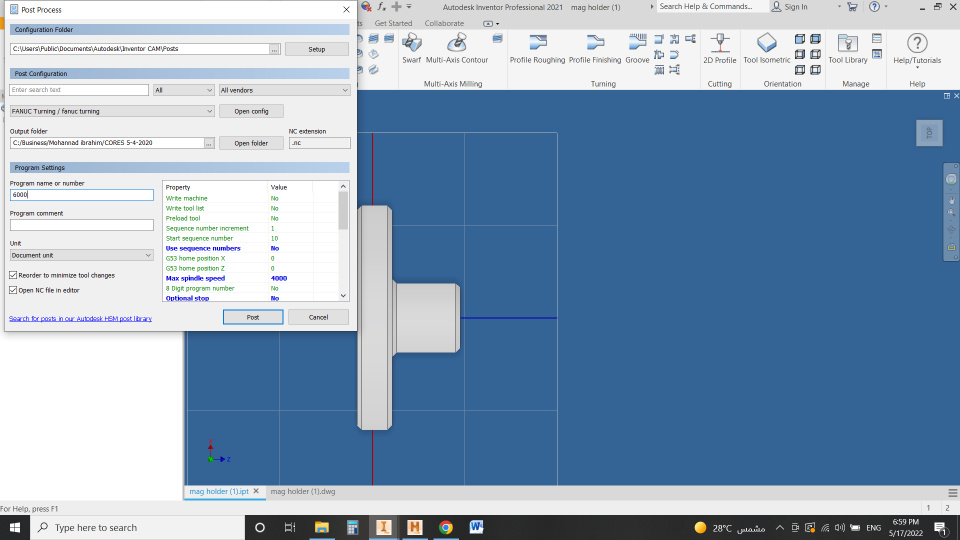

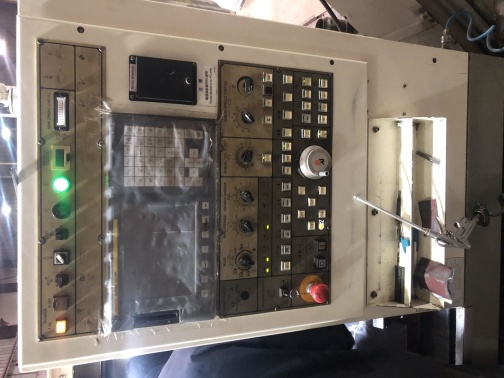

Thanks to my friend Mohammed Awad who gave me access to his turning machine I was able to learn more about CNC turning.