Task to be carried out this week

Lab's Safety Traning

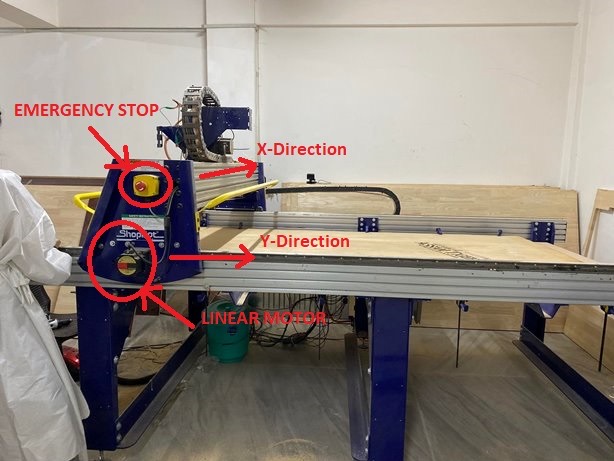

For this week;s assignment we had to make something big using the CNC machine. The CNC machine in out lab is the shopbot ---. Before we bagan operating the machine, we were briefed on some safety rules when inside the shopbot room. Some of the safety rules were as follows;

Runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for shopbot

The CNC machine available at our lab is the shopbot.Shopbot is a 3-axis with a bed dimensions of 4x8 feet. It also has two emergency switches to turn off the machines if issues occur.

The macine can be used to cut wood, plys, sofe alumnium etc.,.

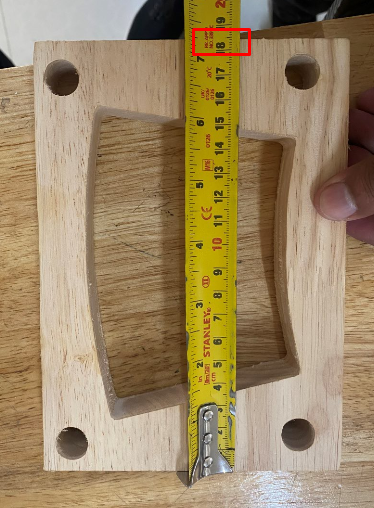

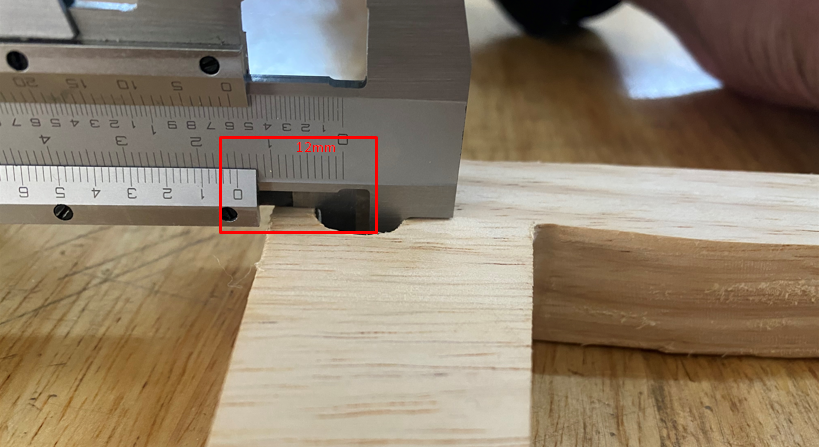

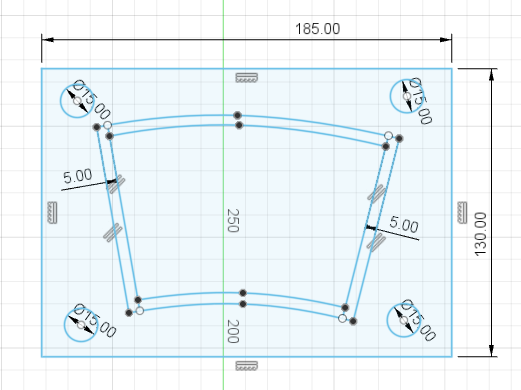

To check the runout, fixtures, alignment, feed etc., we made a simple design and cut it using the CNC machine at our lab. We made a simple parametric design incorporating strating cuts, holdes and curve cuts.

The design files and the machine cutout are shown below;

In the design files the dimensions mentioned were as follows;