Molding and casting

Group Assignment

review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them

extra credit: try other molding and casting processes

Individual Assignment

design a mold around the stock and tooling that you'll be using

mill it (rough cut + three-axis finish cut)

use it to cast parts

extra credit: use more then two mold parts

Group Assignment

Link for group assignment

Individual Assignment

Molding is a process to make a design of any hard object by compressing. Casting is melting of any metal and pouring in the design made by molding. Here is a youtube link to better understand. click me

Casting

Casting is an object made by pouring molten metal or other material into mold.

Design for molding and casting

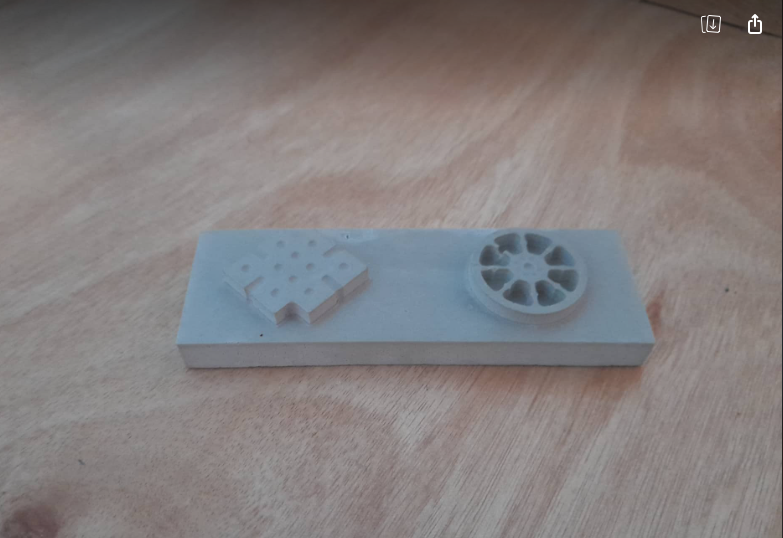

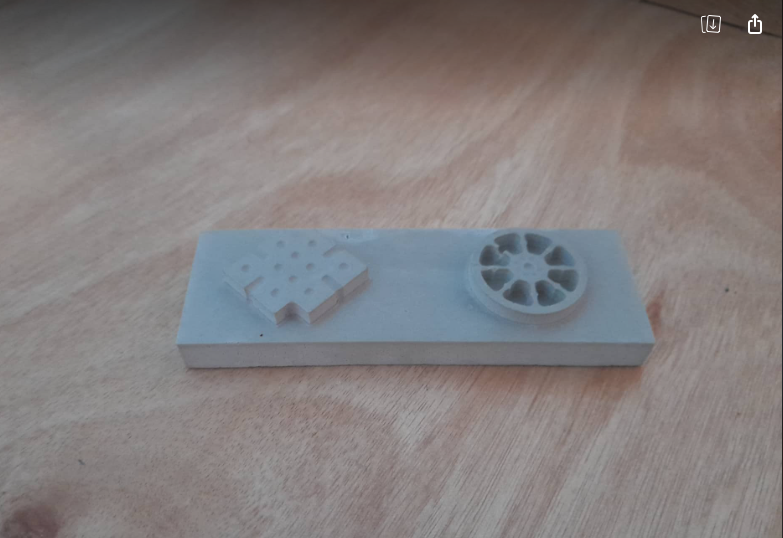

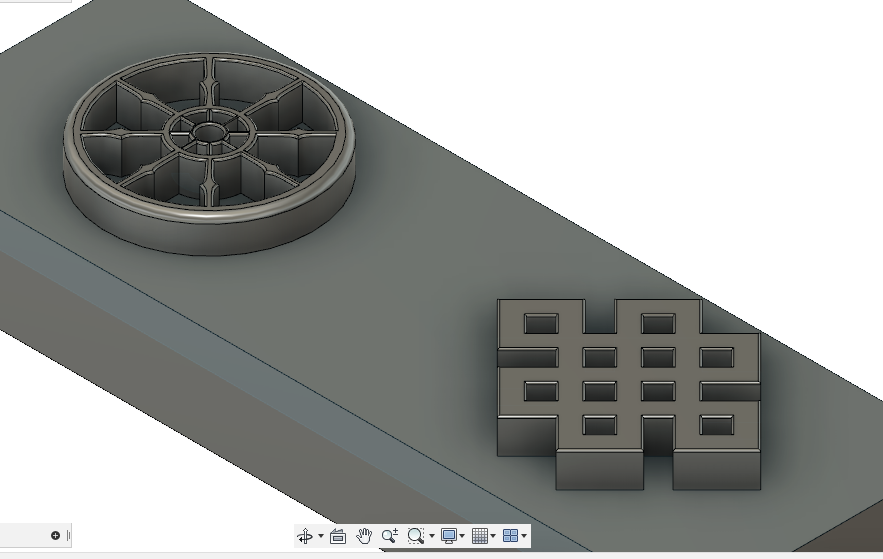

For molding and casting i used fusion360 to design. I have designed the wheel of dharma and endless knot.

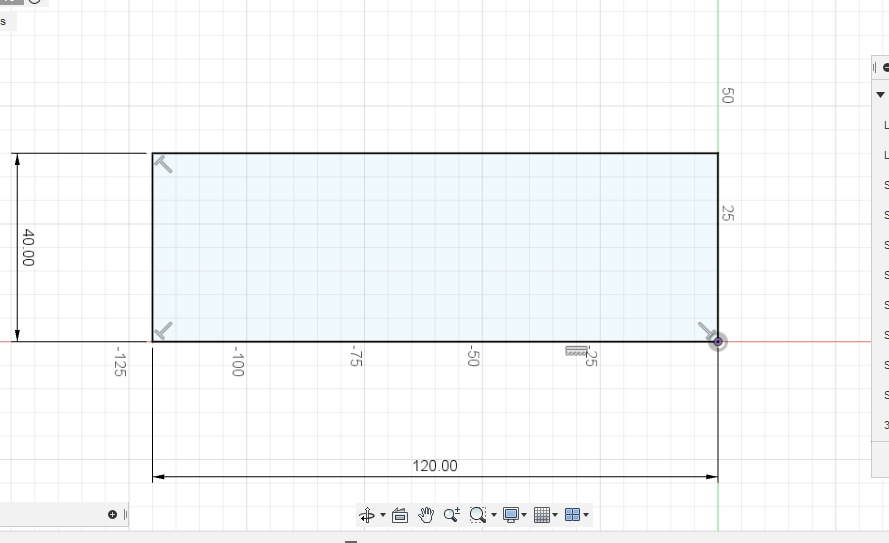

I drew a recctangle of width=40mm and length=120mm. Than i extrude 5mm.

I select a plane to sketch again. On top on plane I drew a sketch for wheel for dharma and endless knot.

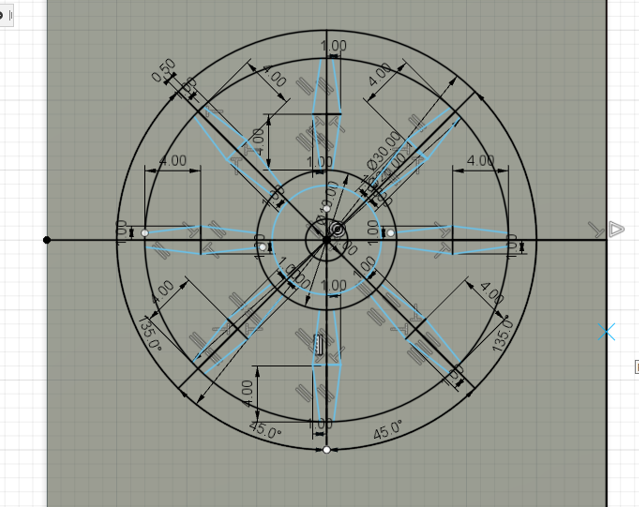

Wheel of dharma

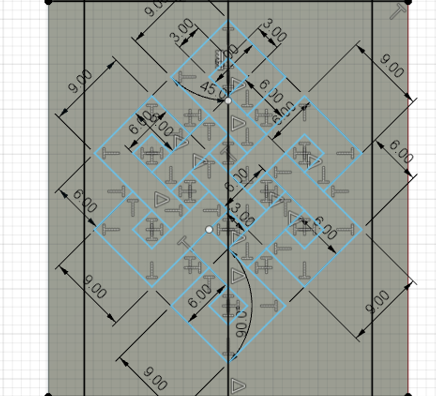

Endless knot

again i extrude 5mm on wheel and endless knot and export in .stl.

Medela Player

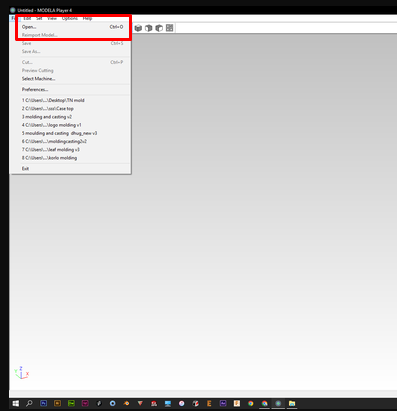

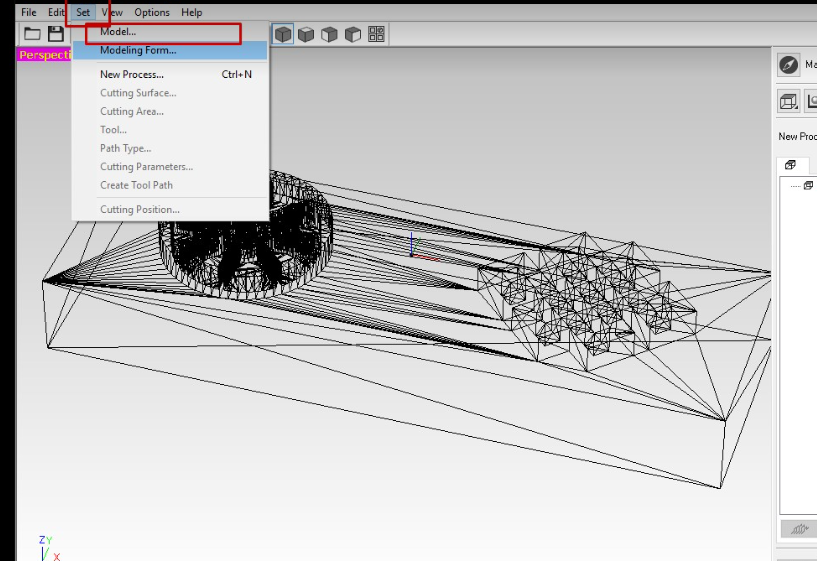

Open modela player software. click on file and open .stl file.

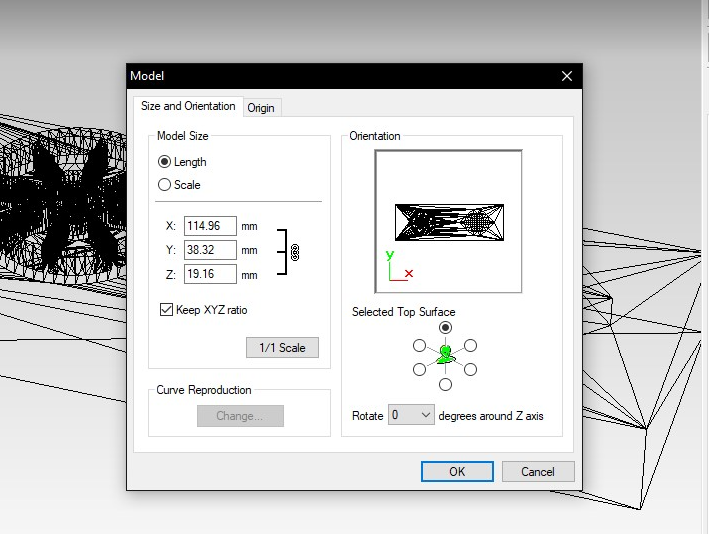

For size and orientation click on set and choose model. We can check the size- length, width and height of model

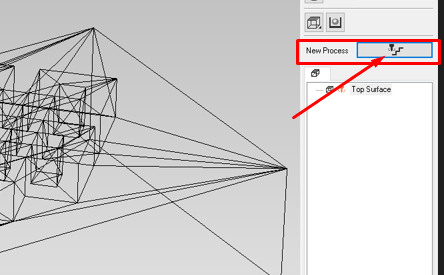

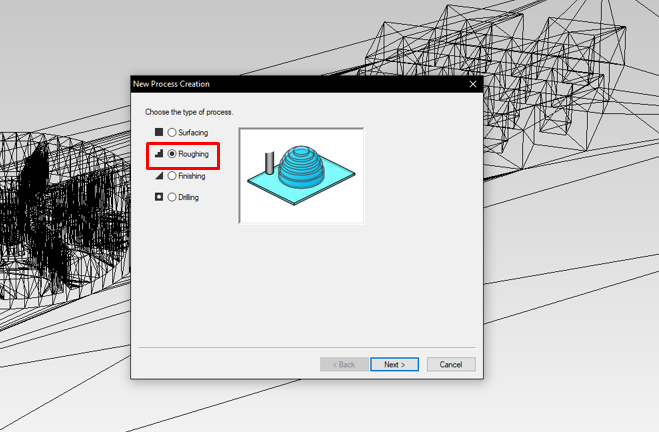

Click on the new process

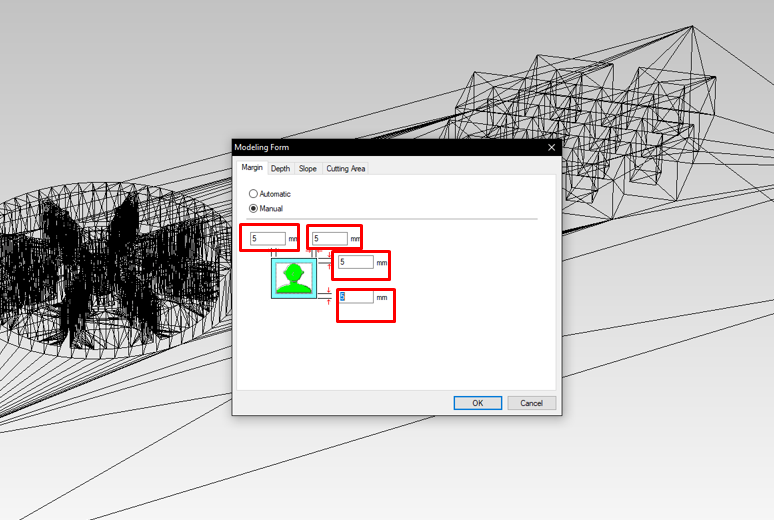

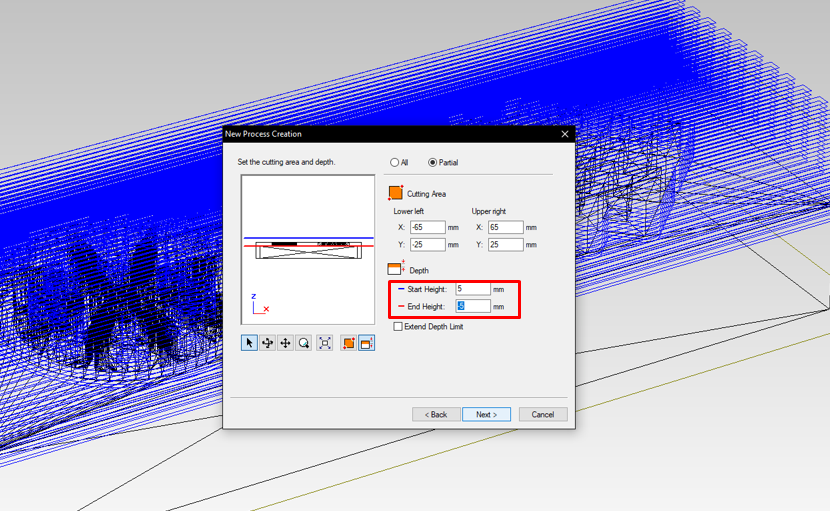

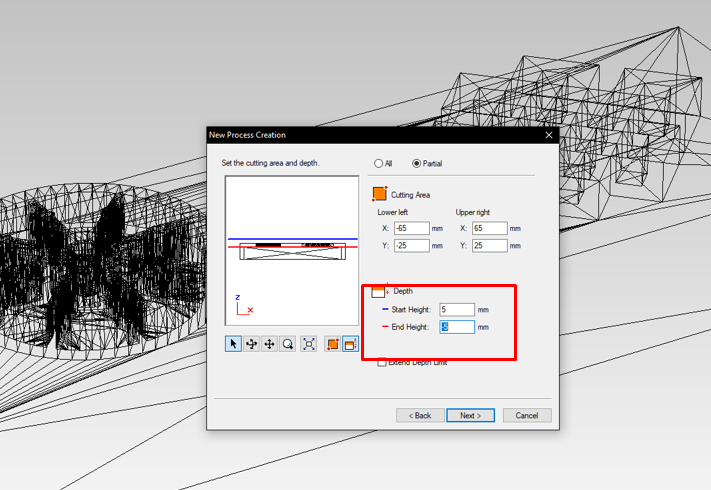

I kept 5mm space between 4 sides of the block and 4 outerline of the design.

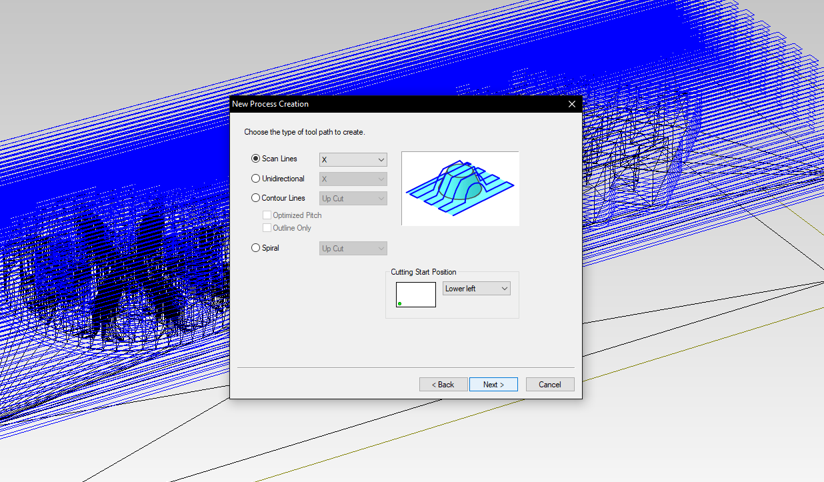

I need to do roughing and finishing process

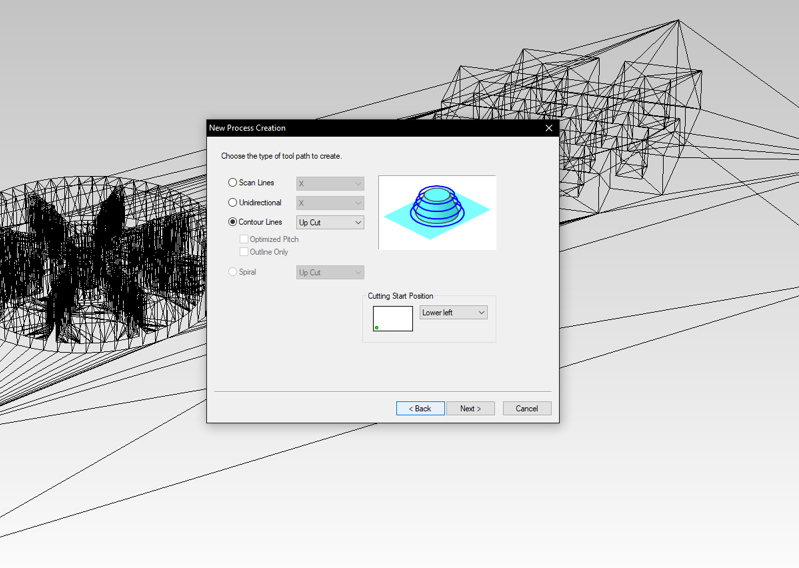

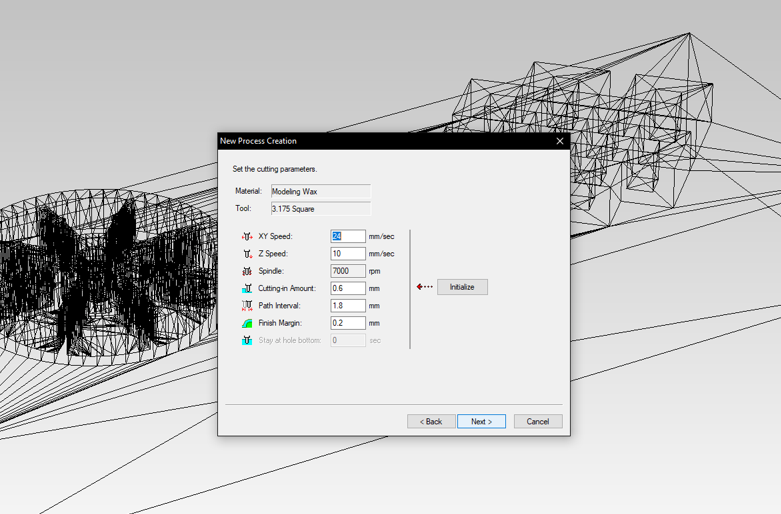

For roughing

Gave process name roughing1

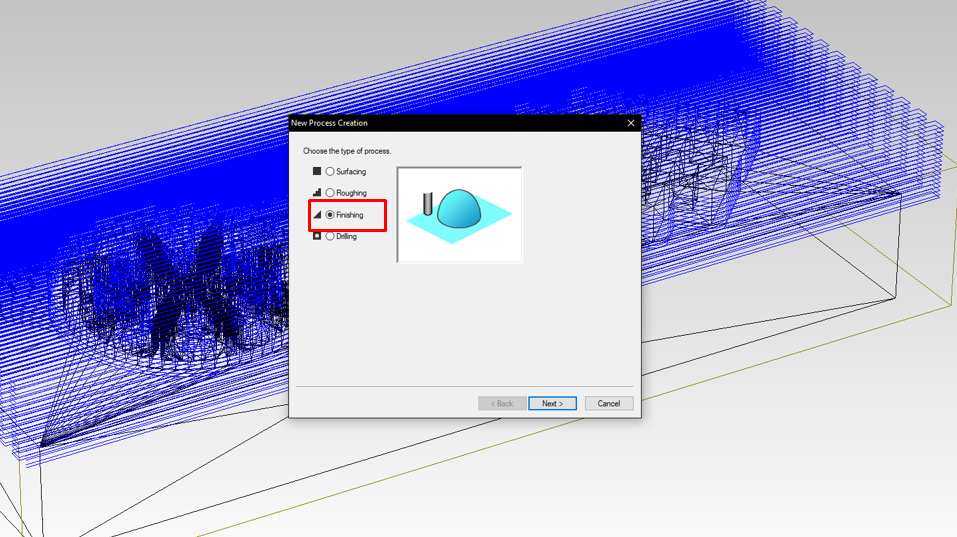

For Finishing

Gave process name as finishing1

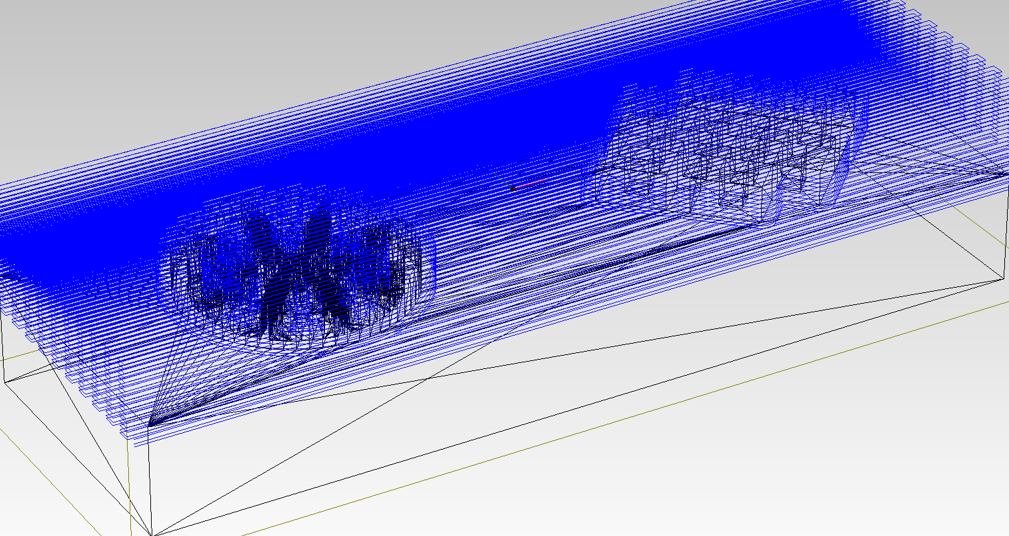

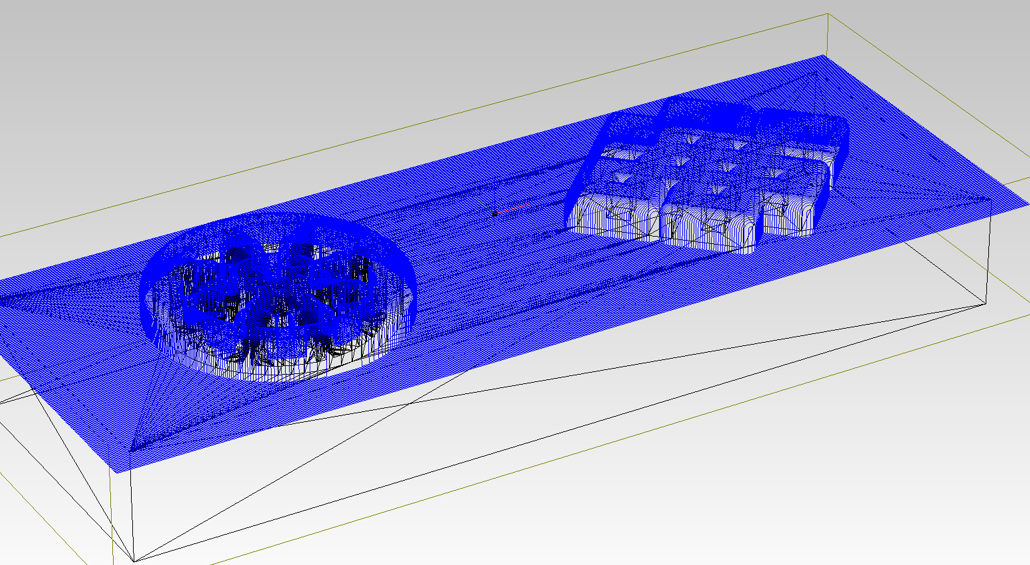

Click on the cut to preview toolpath

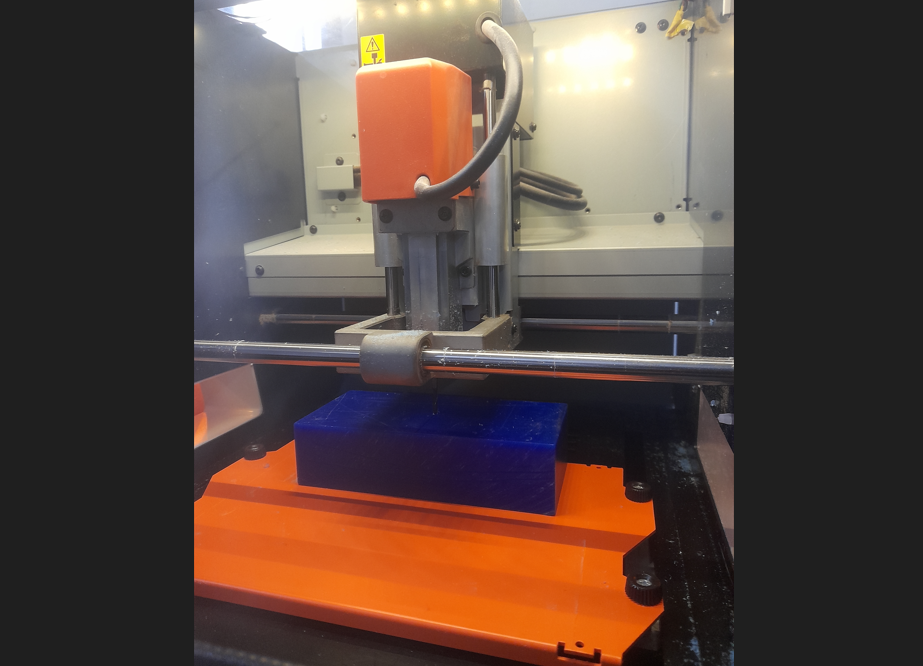

Milling the molding block

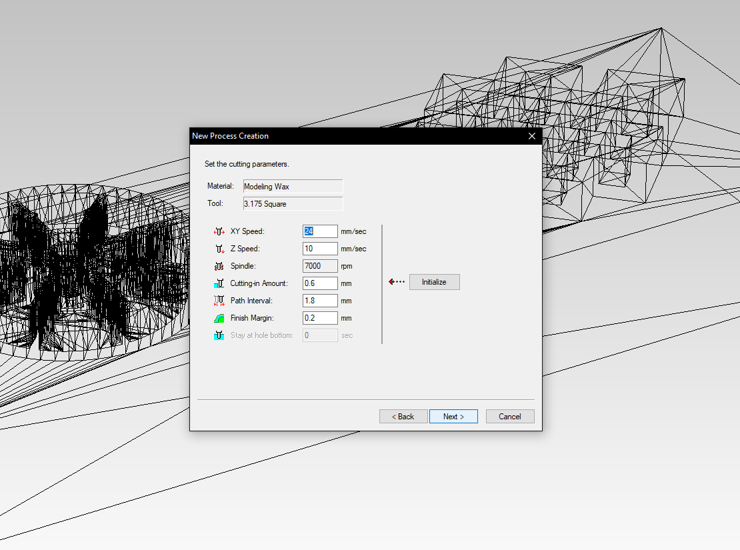

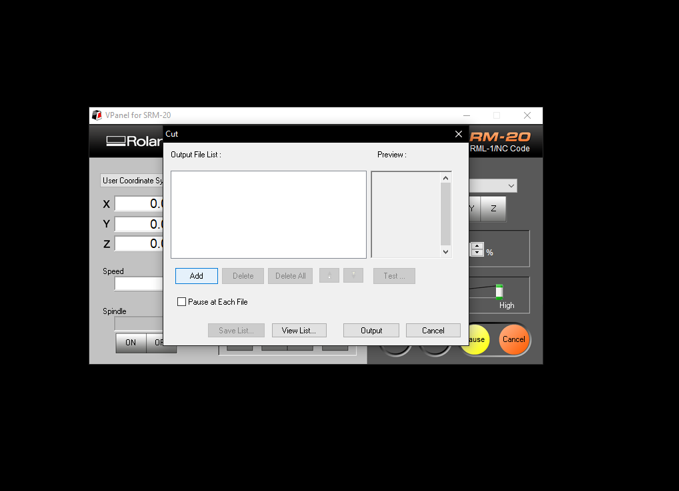

I have made 2 files from modela player-4 for roughing and finishing the mill. The .stl file format is converted into prn format to fed to Vpanel

Z-axis should be 5mm above the surface

i used 2 kind of end-mill

1. 3.175sq for roughing

2. R1.5825 ball for finishing

I opened Vpanel Apps to mill the molding block

Molding

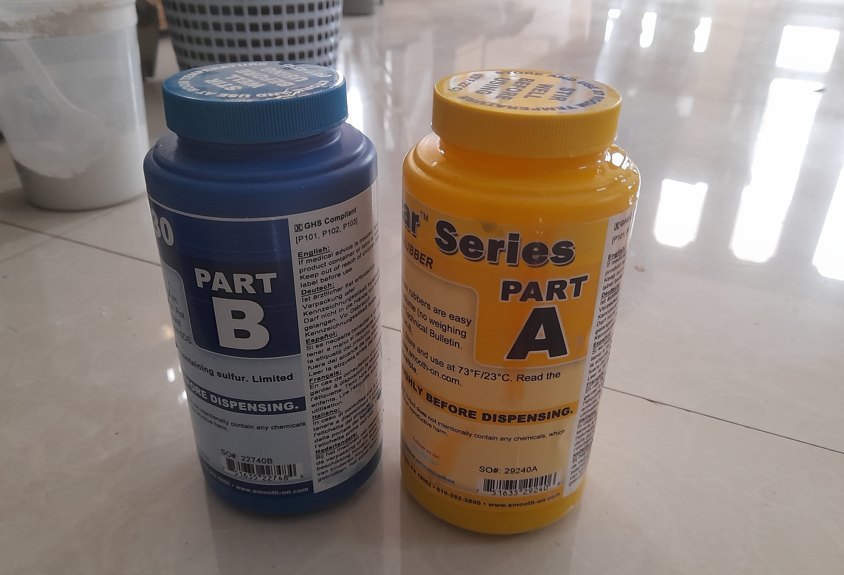

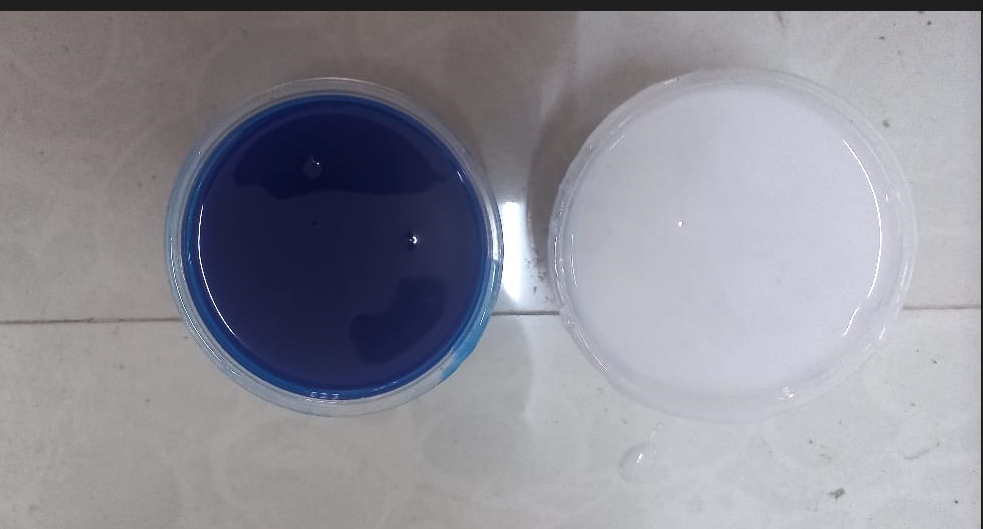

1. For molding i used silicon mold. Mixed partA and partB on equal ratio.

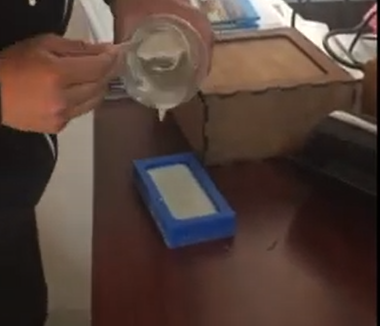

Pour Silicon partA and partB in a containter to mix. Pour slowly for not creating air bubbles inside

Mix partA and partB. Than pour it in wax mold that have been milled

Give vibration to remove the air bubbles by hitting slowing on wax

Silicon mold

Casting

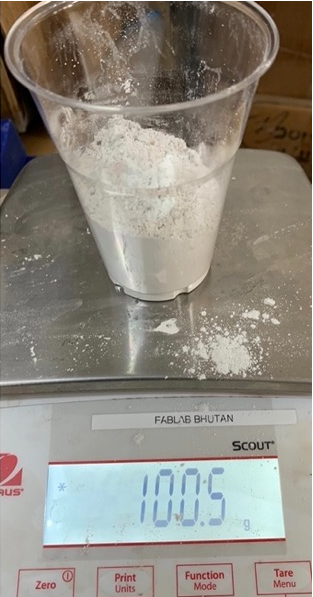

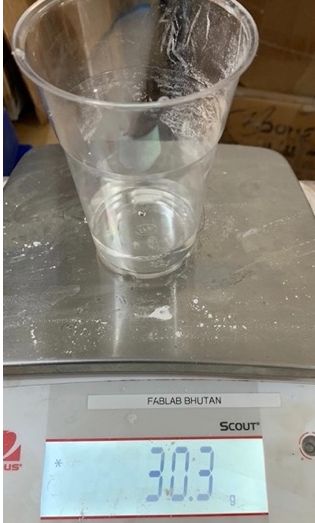

I used hydro-stone and water for casting. The ratio is (hydro-stone)100 and (water)30.

Mix hydro-stone with water and pour it in silicon mold for casting