Group Assignment

On this week we learned about safety protocols while using machine. The machine that we have in lab is shopbot.

link for our group assignment

Individual Assignment

Computer Numerial Control

CNC is an automated controlled machine which follows the programmed instruction.

The machine that i used for my assignment is shpbot.

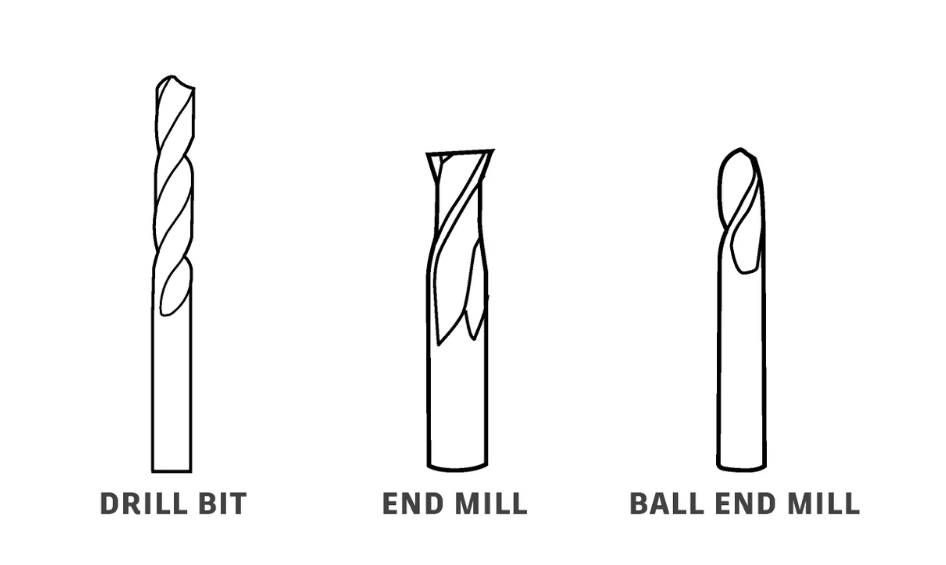

Types of cutting tools

Image source google

There are two types of cutting tools in ShopBot.

Drill bits and end mills(or router bits)

Drill bitd

It is the drill bit that we use in hand drill. It is used only for drilling holes and for moving straight

End mills

These bits are designed to cut while moving sideways through the material. There are two common type of end mills. Regular and ball end

A. 1"60 degree V Flute

B. 60 degree engraving bit

C. 1/8" Upcut ball nose

D. 1/4" Solid carbide 2-Flute ball nose

E. 1/4" Upcut super "0" Flute

F. 1-1/2" 90 degree V flute

Designing softwawre

Fusion360- I am more comfortable with fusion so i am using only fusion to design. I have designed a bookshelf.

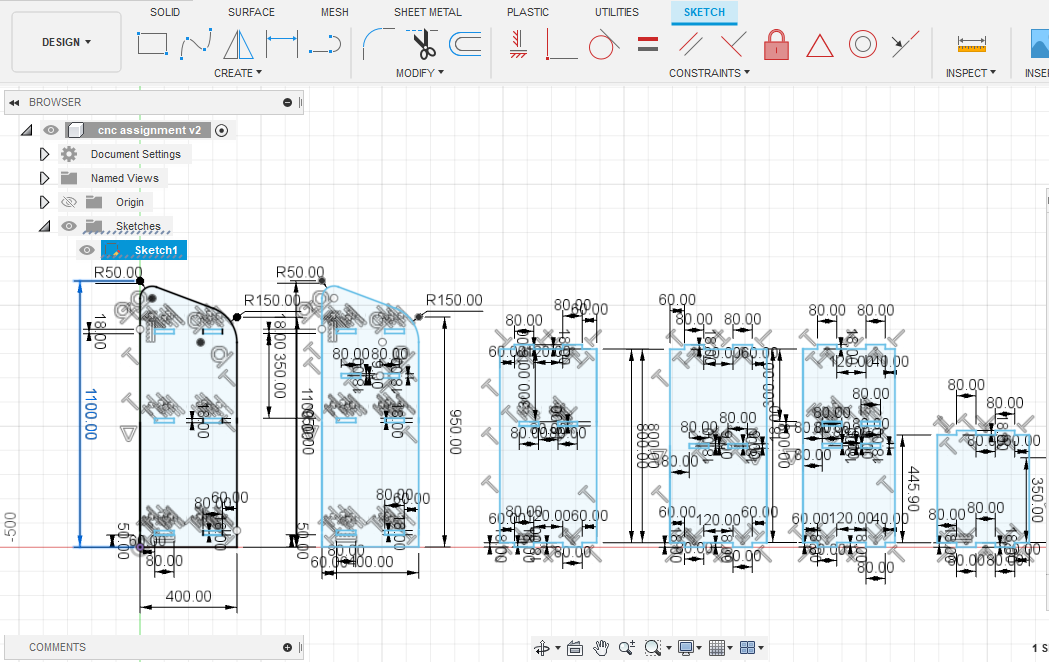

Steps for designing in fusion

I opened the fusion360 to design a bookshelf for my asignment. I sketch a 2D design of bookshelf.

I gave a height of 1100mm and width of 800mm.

After giving all the measurement i made curve on some edges by using fillet

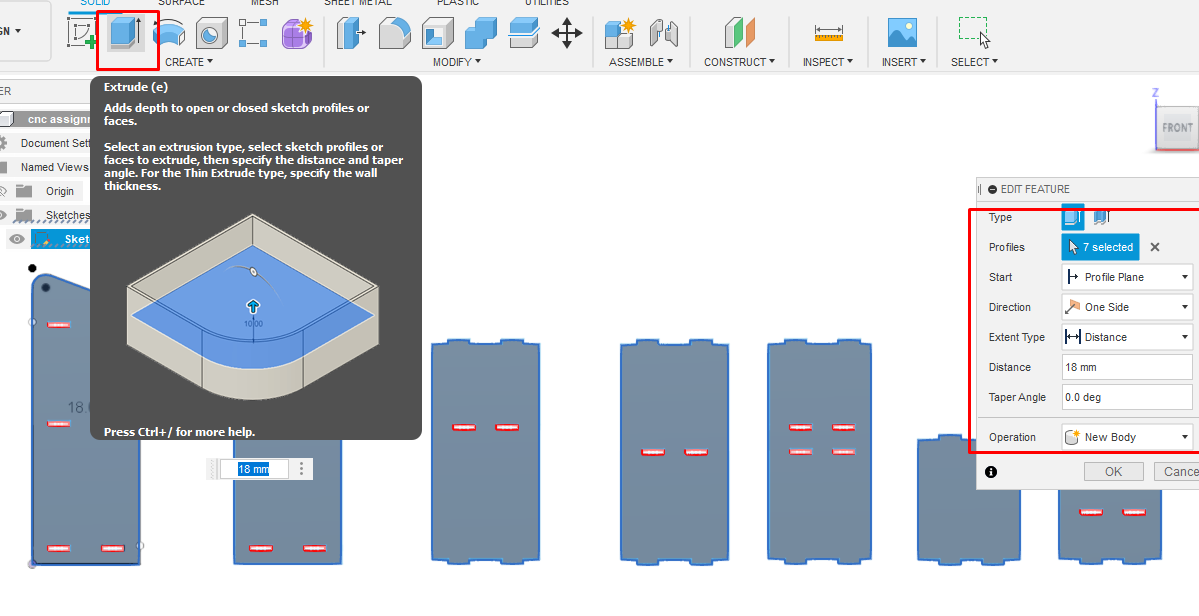

AFter i am done with sketch, i extruded the design. I gave the 18mm thickness because the plyboard i m using is 18mm thick

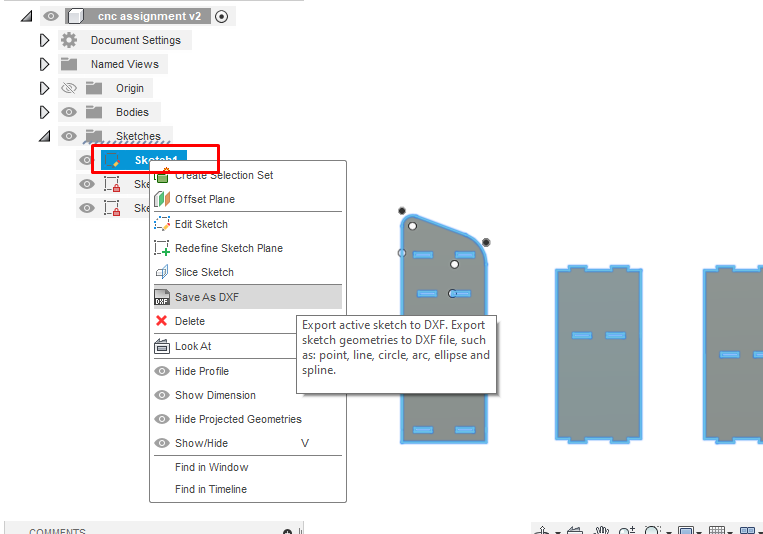

I export the file in .dxf format. For that i right click on sketch of any design and saved in .dxf.

Aspire and shopbot

Aspire

Aspire provides a powerful but intuitive software solution for creating and cutting parts on a CNC router. There are tools for 2D design and calculation of 2D toolpaths such as Profiling, Pocketing, and Drilling as well as 2.5D toolpaths including; V-Carving, Prism carving, Moulding Toolpaths, Fluting, The Chamfer Toolpath and even a decorative texturing strategy. What makes Aspire our premium package is the added 3D design tools which enable you to create your own 3D relief models and machine them with 3D machining strategies. Aspire’s unique 3D modeling tools coupled with the comprehensive set of 2D design and editing tools make it easy to create your own 2D and 3D parts from scratch as well as the ability to import and edit external 2D and 3D data.

Link to download Aspire

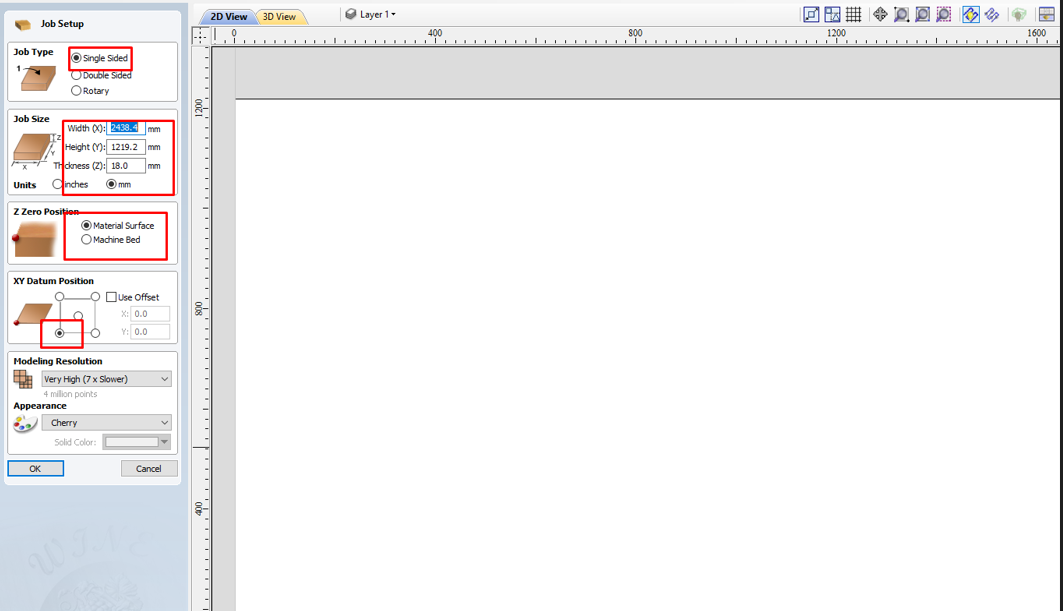

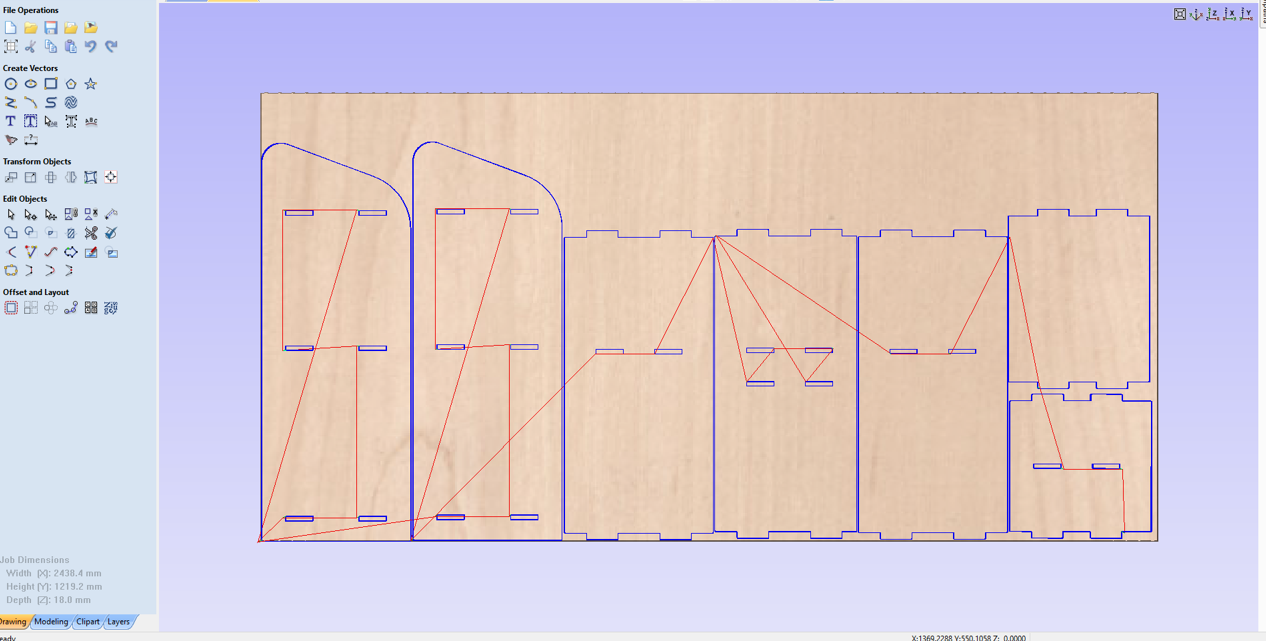

Open aspire and click on create a new file

On new file we have to give width, height and thickness of the material in job size

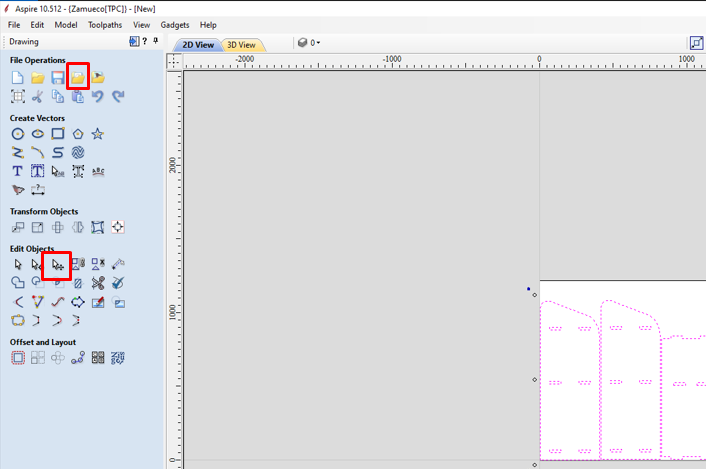

I import dxf files and allign all the design

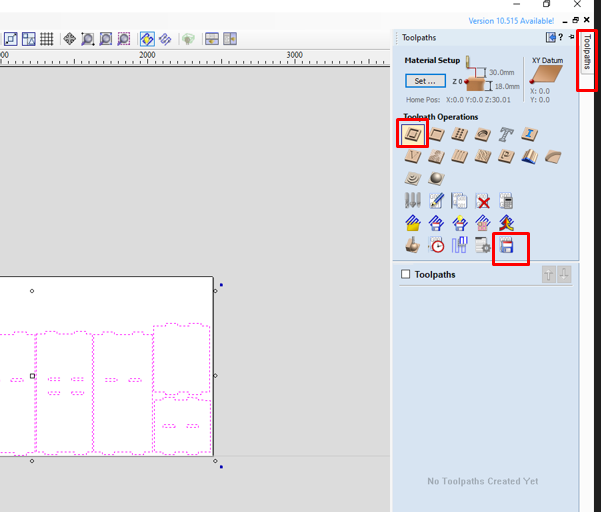

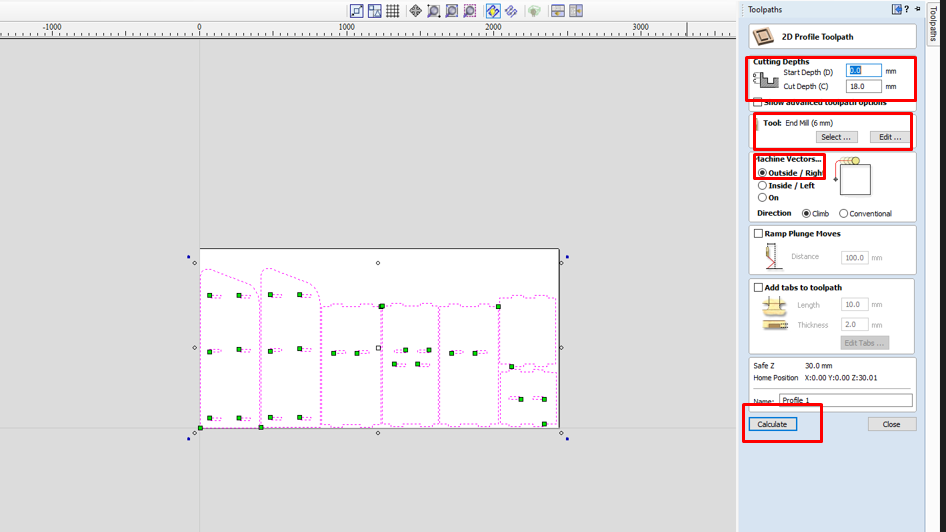

After alligning all the design i click on toolpaths on top right corner and select profile toolpaths to generate path for cutting

I gace cut depth as 18mm since i want to cut through the material and click on calculate.

Toolpath will be generated. Than click on save toolpaths

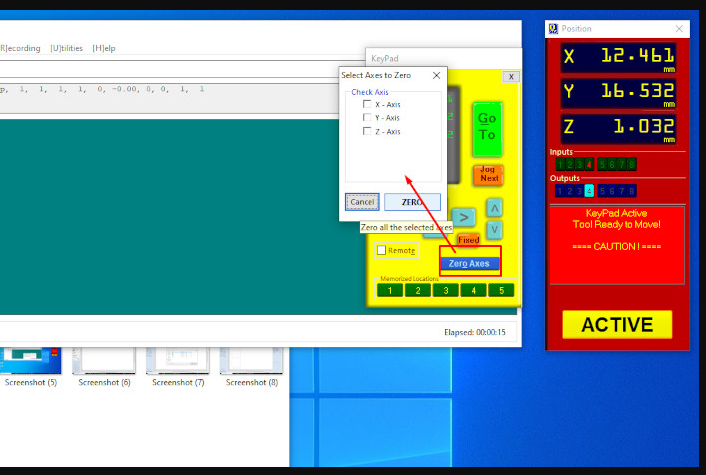

This is the software that runs ShopBot CNC Tools. With the ShopBot Control Software, you can enter individual commands to move the tool or run a ShopBot Part File, a cutting file created in a CAD/CAM program such as the ShopBot Design Software Suite, to cut out a part.

After setting toolpaths we can cut in a machine. ShopBot 3 is a machine software to control and make machine work.

Open th ShopBot 3 software. An application to control machine will pop up. Click on KeyPad Controller. On keyPad controller set X and Y on orgin and gravity on Z-axis.

Than we can cut the design

Assembly

After cutting on shopbot I assembled the bookshelf.

Final result of my assignment