Catagory - Computer Controlled Cutting

Session date -

Describing speend, power, focus, kerf and clearance on lasercutter.

A link for our group assignment

click me

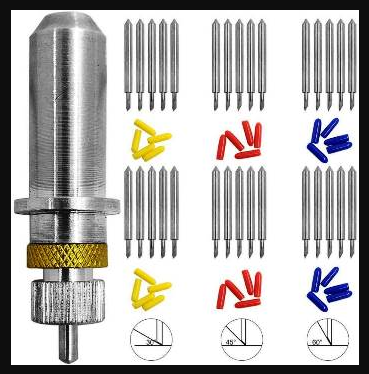

The vinyl cutter that we have in our lab is Roland CAMM GS-24. Vinyl cutter comes with three types of blade.

Image source google

30 degree cutting blade- These blades are excellent in cutting small fonts and complex lines. Its for cutting materials which are within 0.5mm.

45 degree cutting blade- These blades are mostly used for general purpose for a normal size fonts and normal materials which is within 1mm.

60 degree cutting blade- These blades are mostly used for large fonts and tough materials which are within 1mm.

We have used plastic Sicker vinyl sheet. Settings required for it are

Speed 20cm/sec

Cuting Force 30 gf

Blade- 45 degree

It is a print and cut software for windows and macOS, which allows to cut designs and letters in vinylcutter. This software reads .svg format.

For my assignment I have downloadeed a black and white image from google. I have converted the image to .svg using online converter. Here is a link to .svg online converter click me

Push the lever to insert the vinyl sheet on machine.

The vinyl sheet has to be on the white dashed line or else it will appear sheet unloaded and lock the lever.

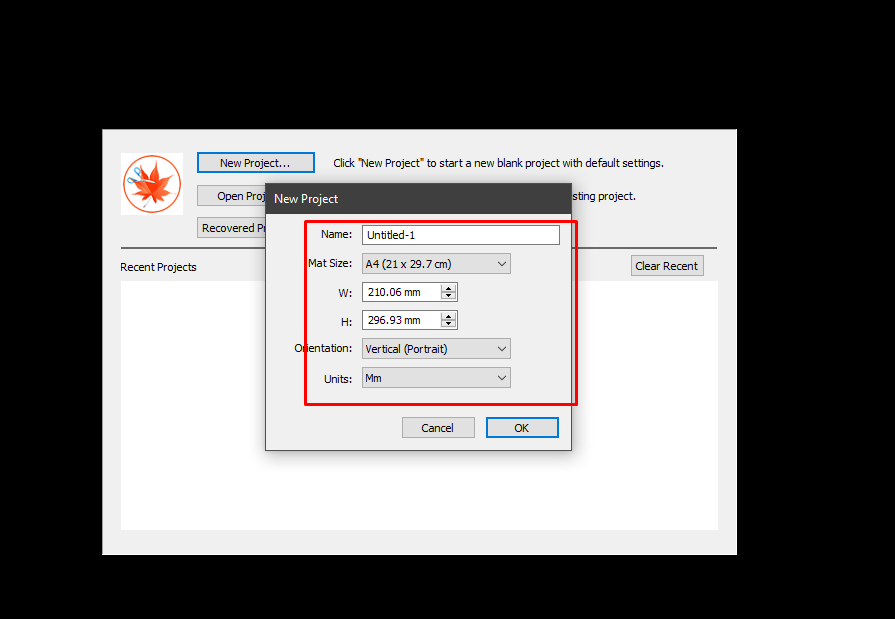

Open easy cut studio software to cut the design

As given in the image below a dialog box will appear wen we open the software. On that dialog box we need to change the material size depending on the size of material. We can even set the orientaion of the design.

Click on the file which is on the top left corner and click on import to import the design for cutting. once the design is imported we can adjust the size of the design by dragging on the image.

When it is all set i clicked on cutter and a dialog box have popped up as shown in below image. click on the cut to start cutting on vinyl cutter

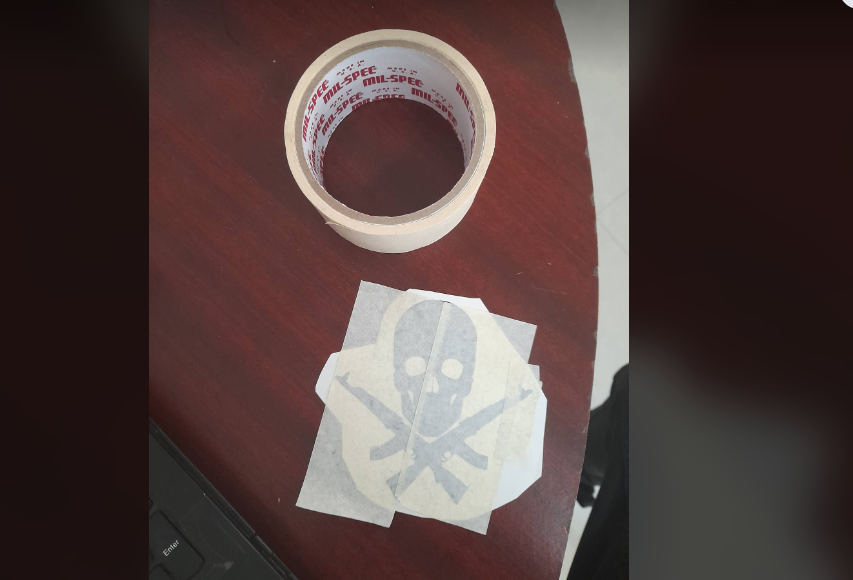

I have used masking tape to paste the design on an object. The masking tape is having more glue so to remove glue i paseted the tape on my pant and than pasted it on the design.

Orginal file

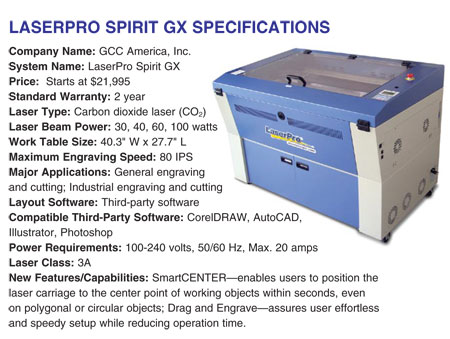

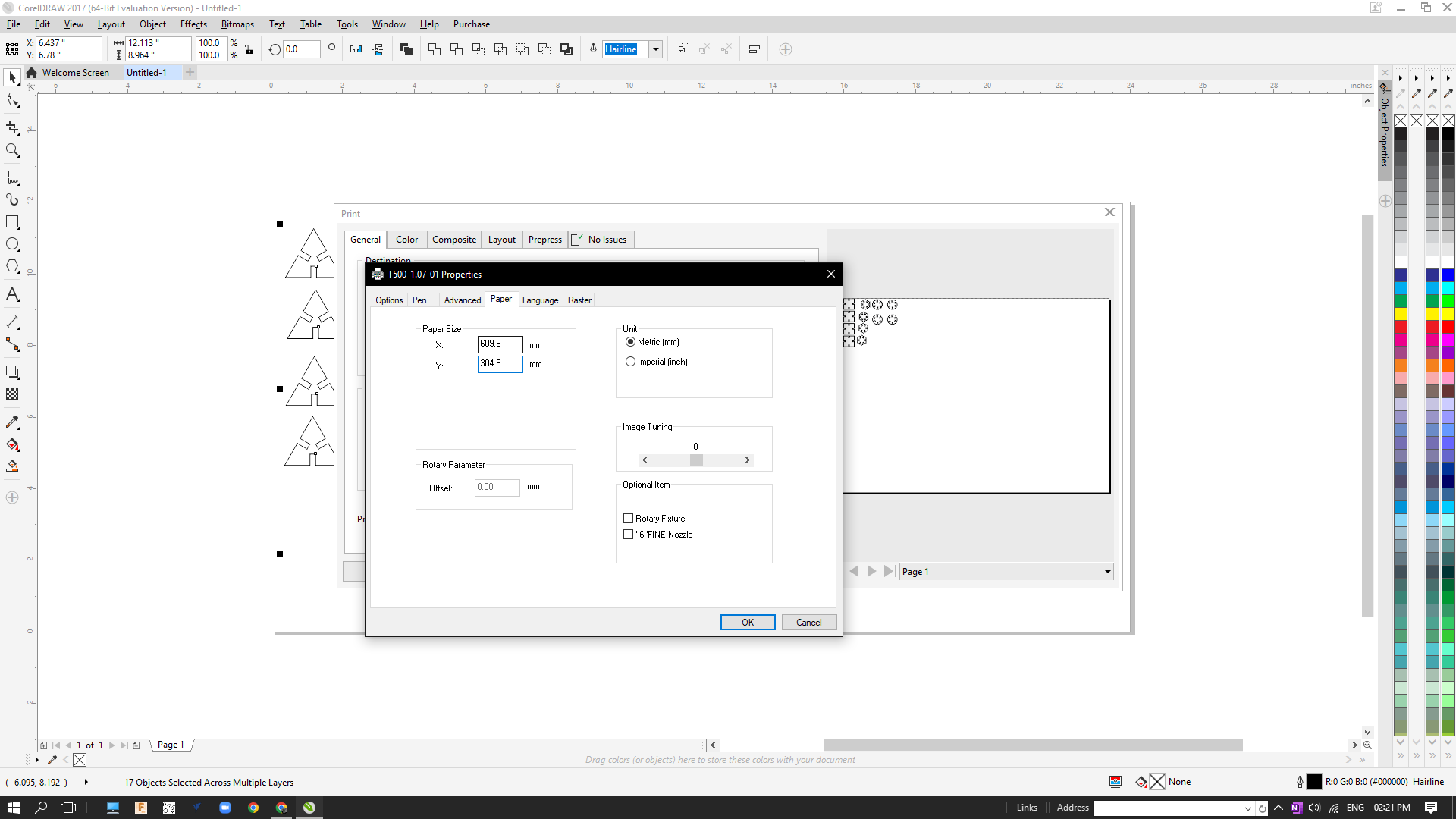

skull.svgThe next machine that we learned about on this week is laser cutter. laser Cutter is a subtractive manufacturing machine. The laser cutter that we have in our lab is GCC laser pro. The image format that laser cutter accepts is windows bitmap format(BMP) and its used for engraving. DXF file format is a vector graphi and it is used for cutting. The engraving space of laser cutter is 609.6mm and 304.8mm.

Image source google

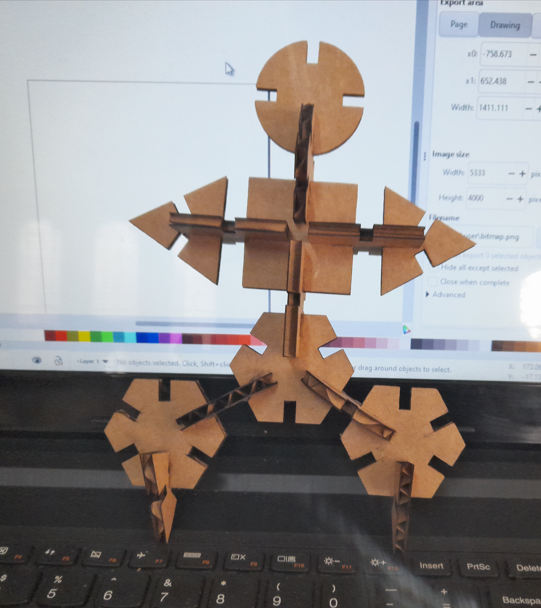

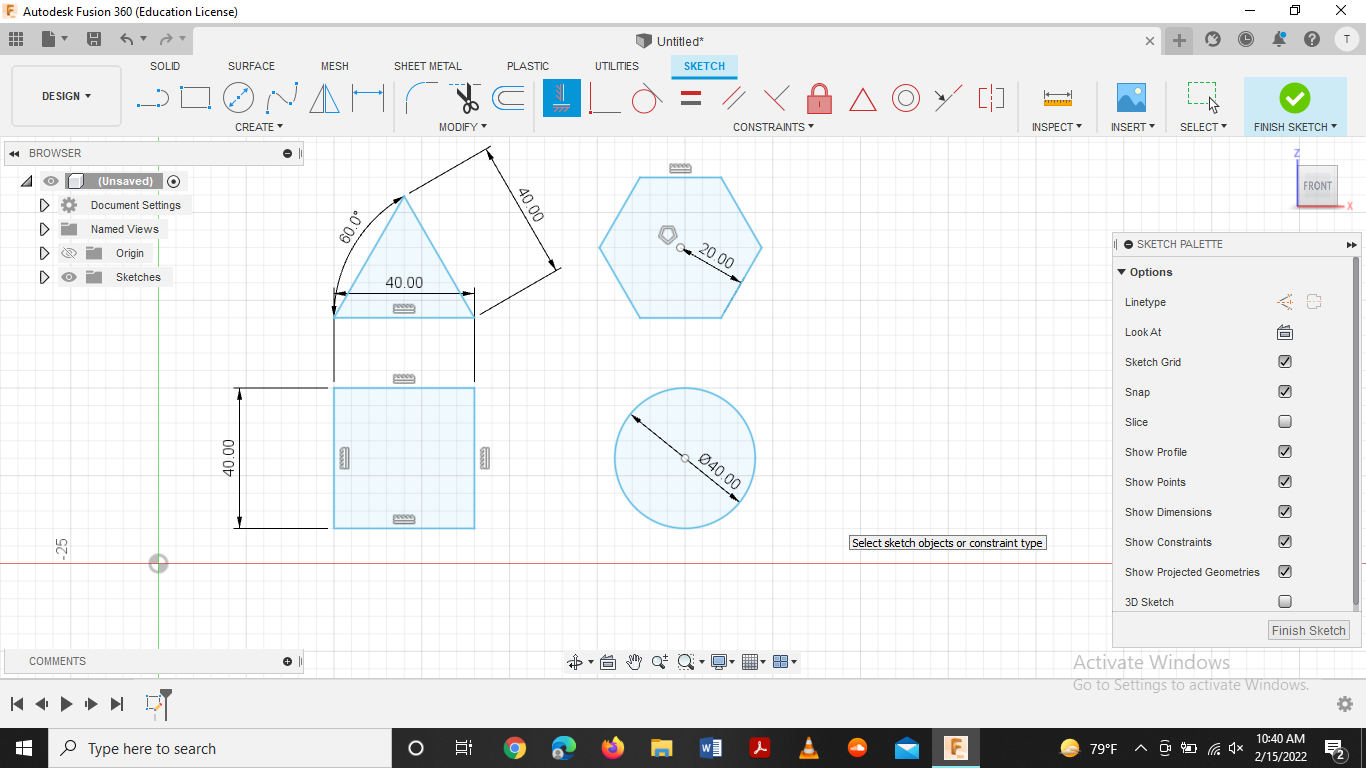

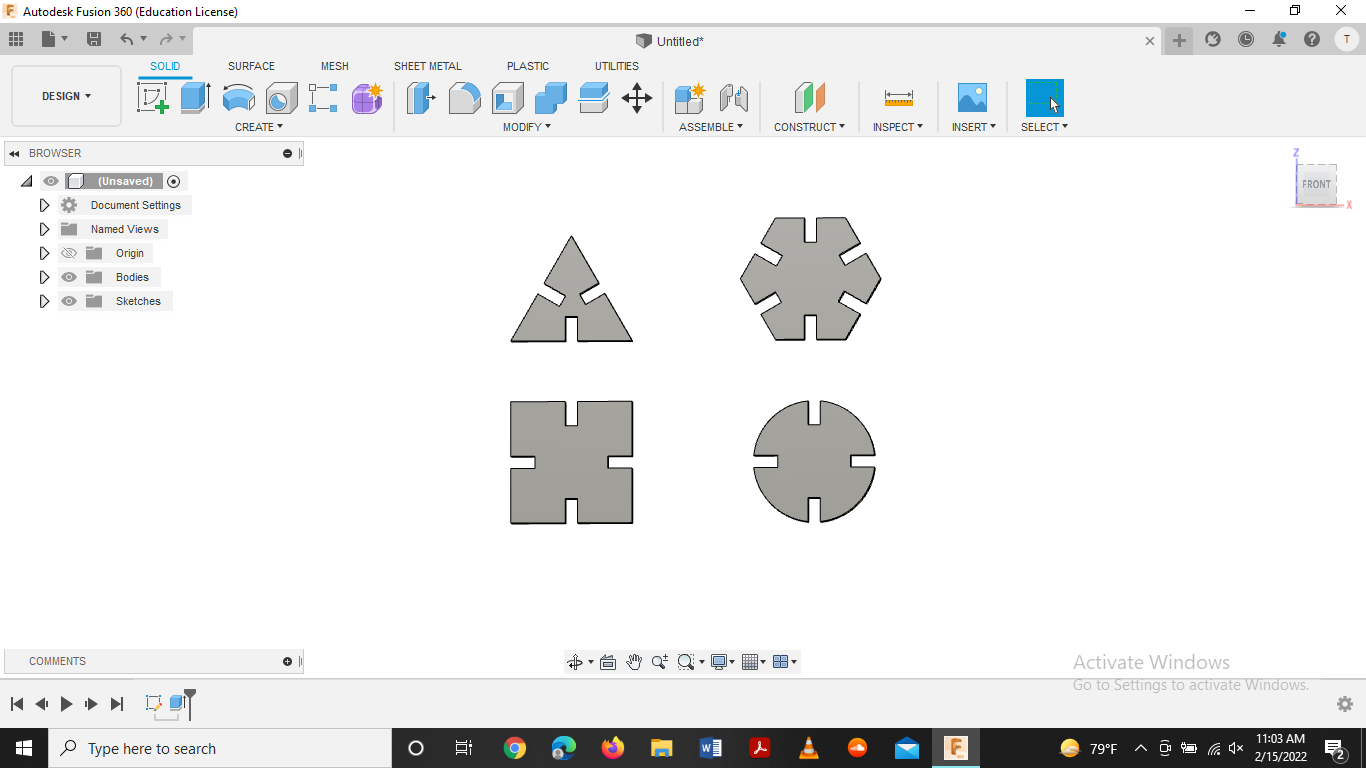

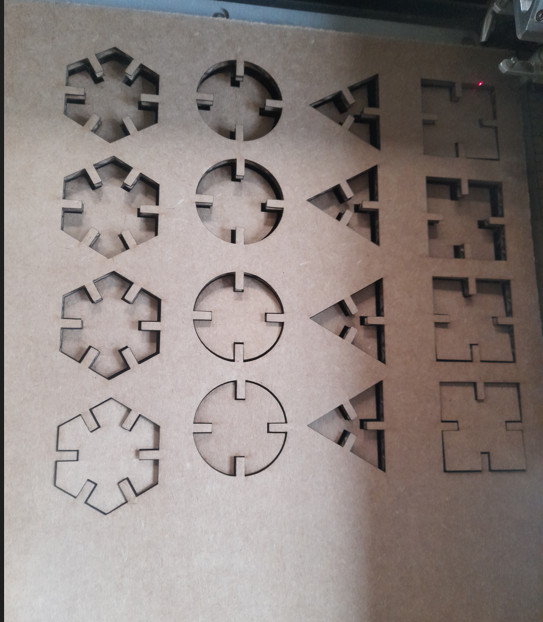

The assignment for the week was to design a parametric design and cut it using laser cutter. I have designed a triangle, square, circle and hexagon with a hinges to join.

I have used fusion360 to design.

For circle and hexagon i gave 40mm diameter and for triangle and square i gave 40mm length on all sides

For hinges i kept 4mm width as the thickness of material is 4mm , and length is 8mm.

After designing on sketch i extruded 4mm for all design.

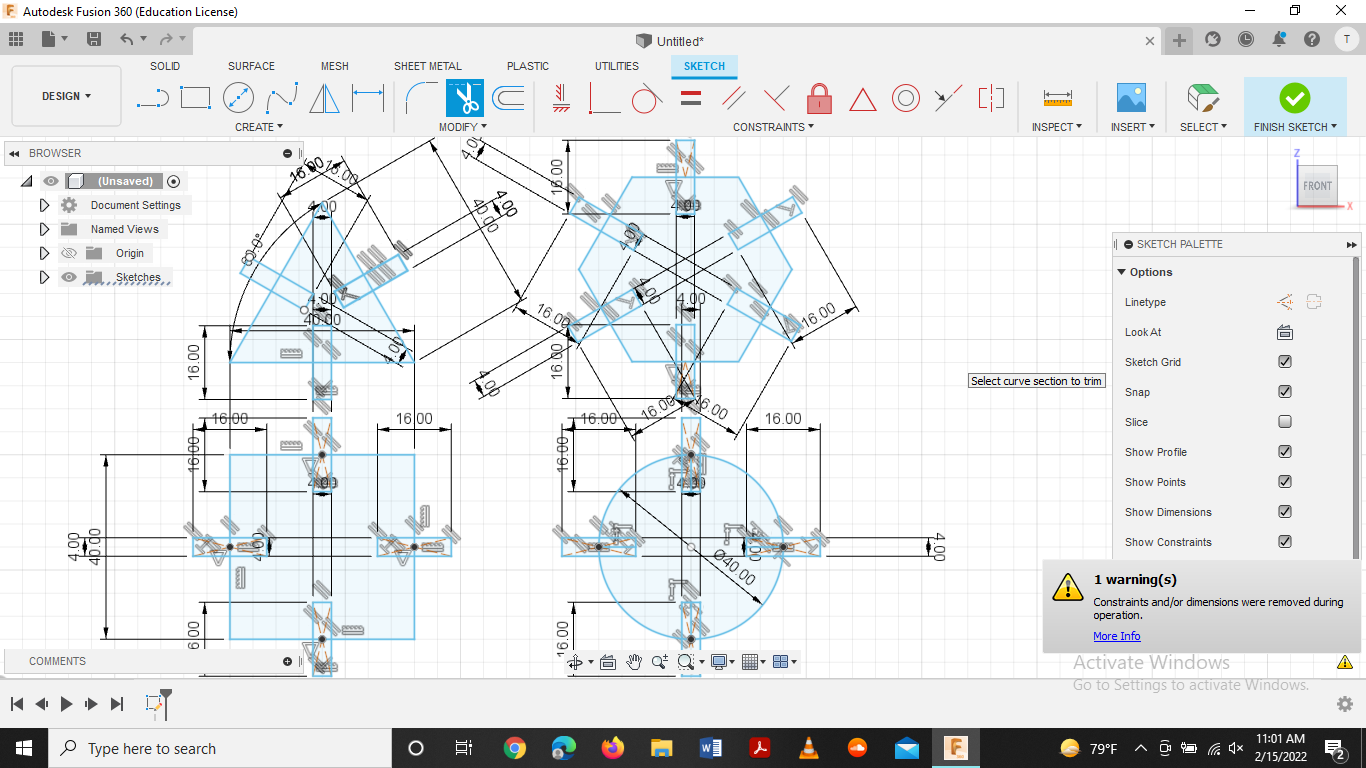

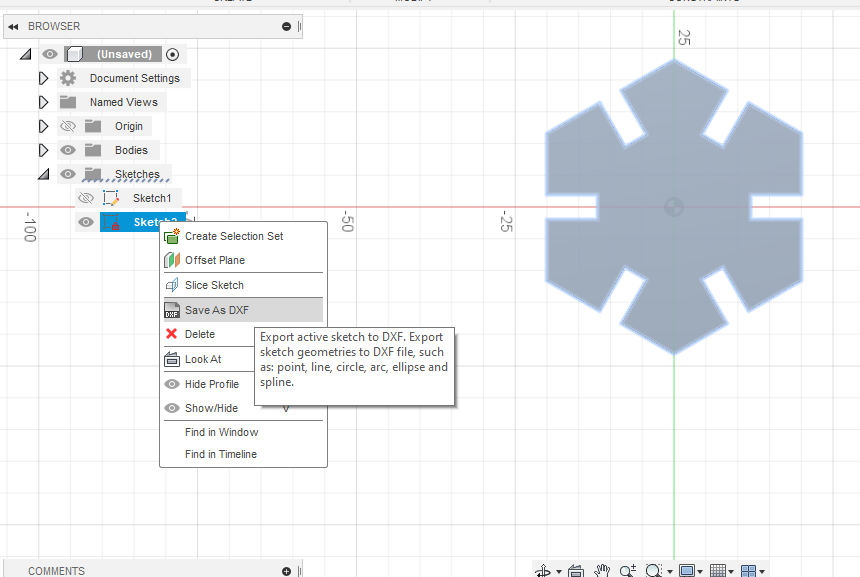

Than i export the design in .dxf format because to cut on laser cutter we need to cut through corelDRAW software. For corelDRAW we need the file in >DXF format.

After designing the design i have to cut the design on laser cutter. To cut on laser cutter it has to be done from CorelDRAW software. CorelDRAW reads in .dxf format.

Open corelDRAW and open a new page

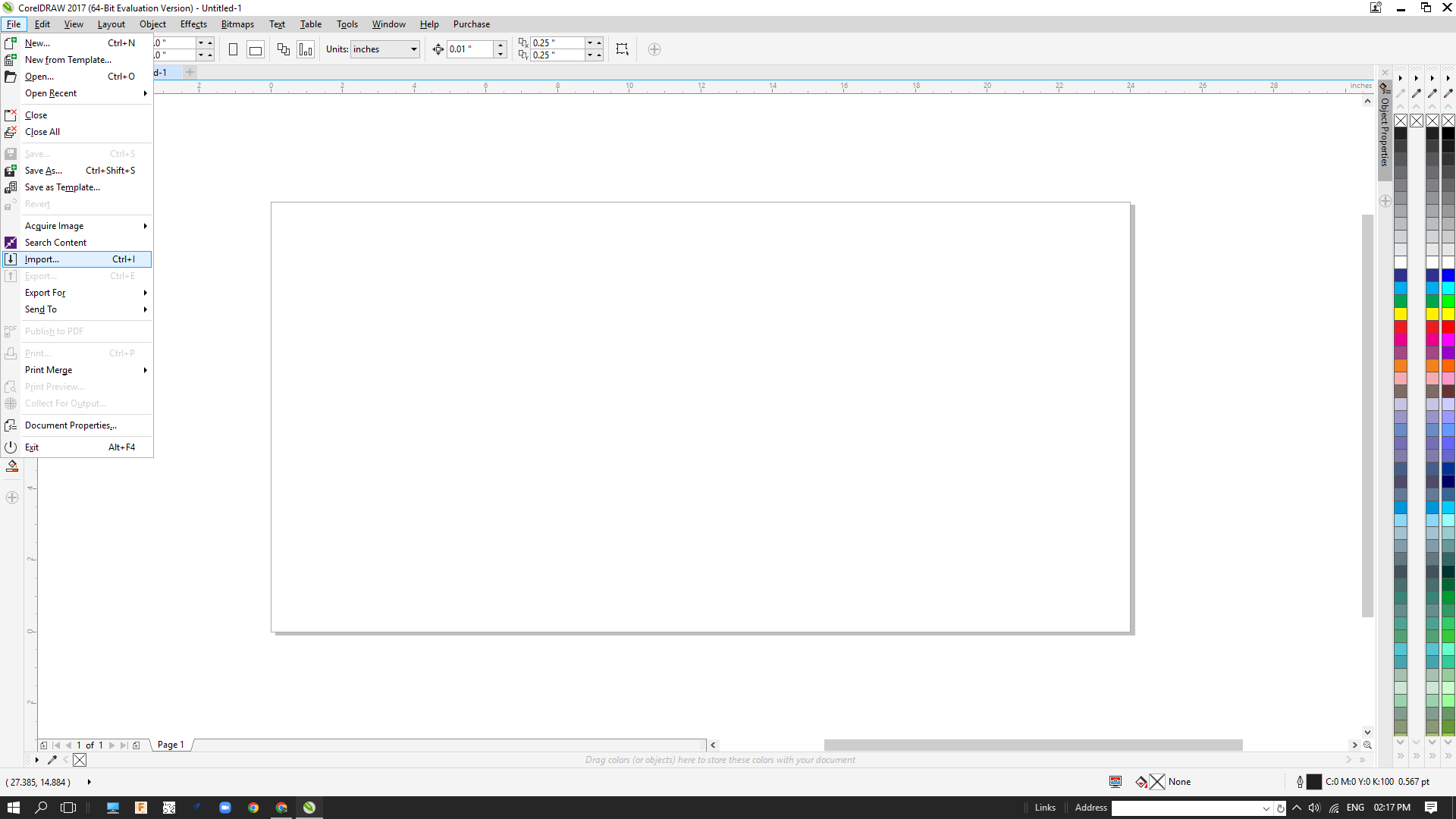

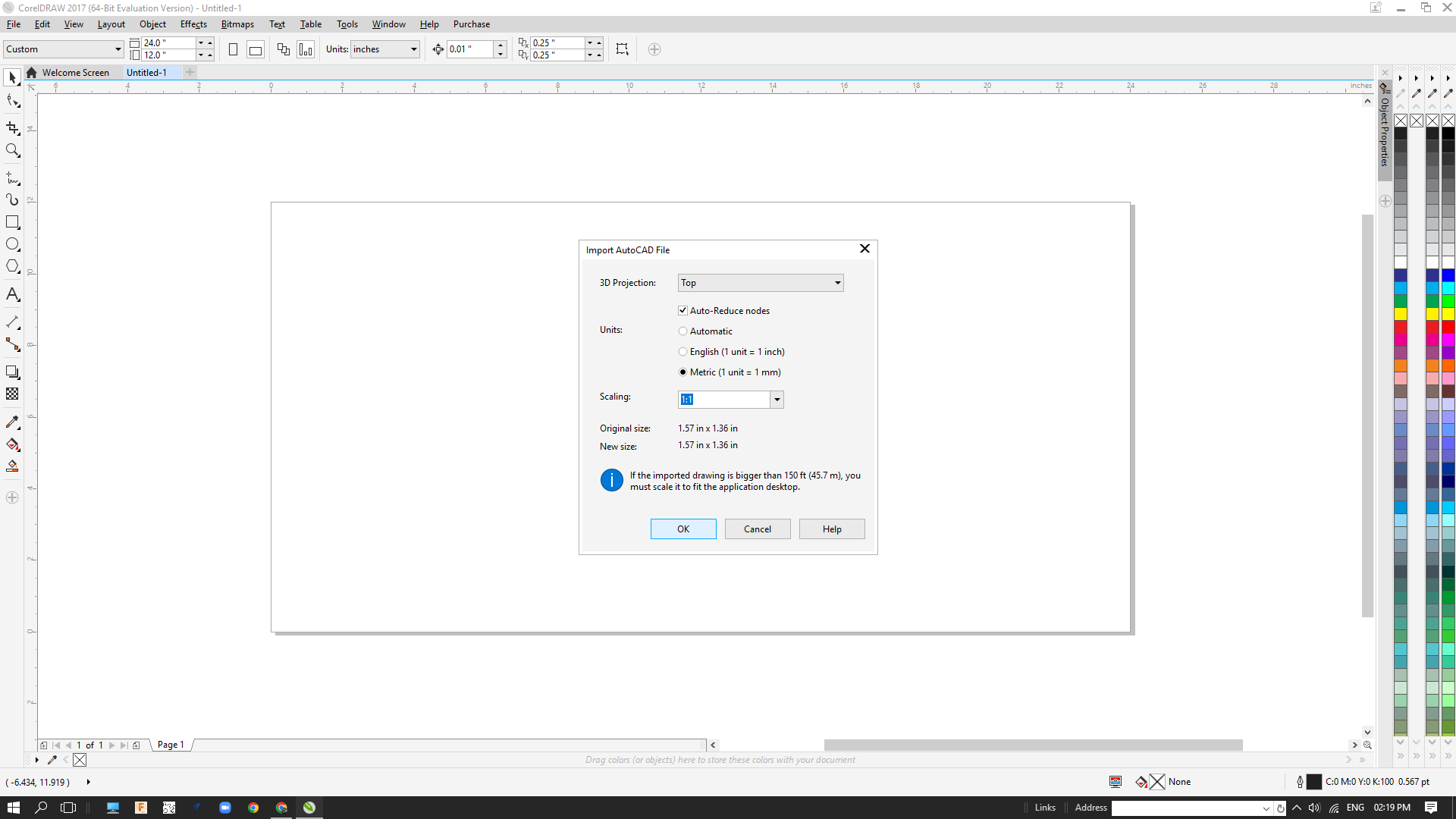

Import the dxf files

Scale the file. I kept it 1:1 as i wanted to cut on given length

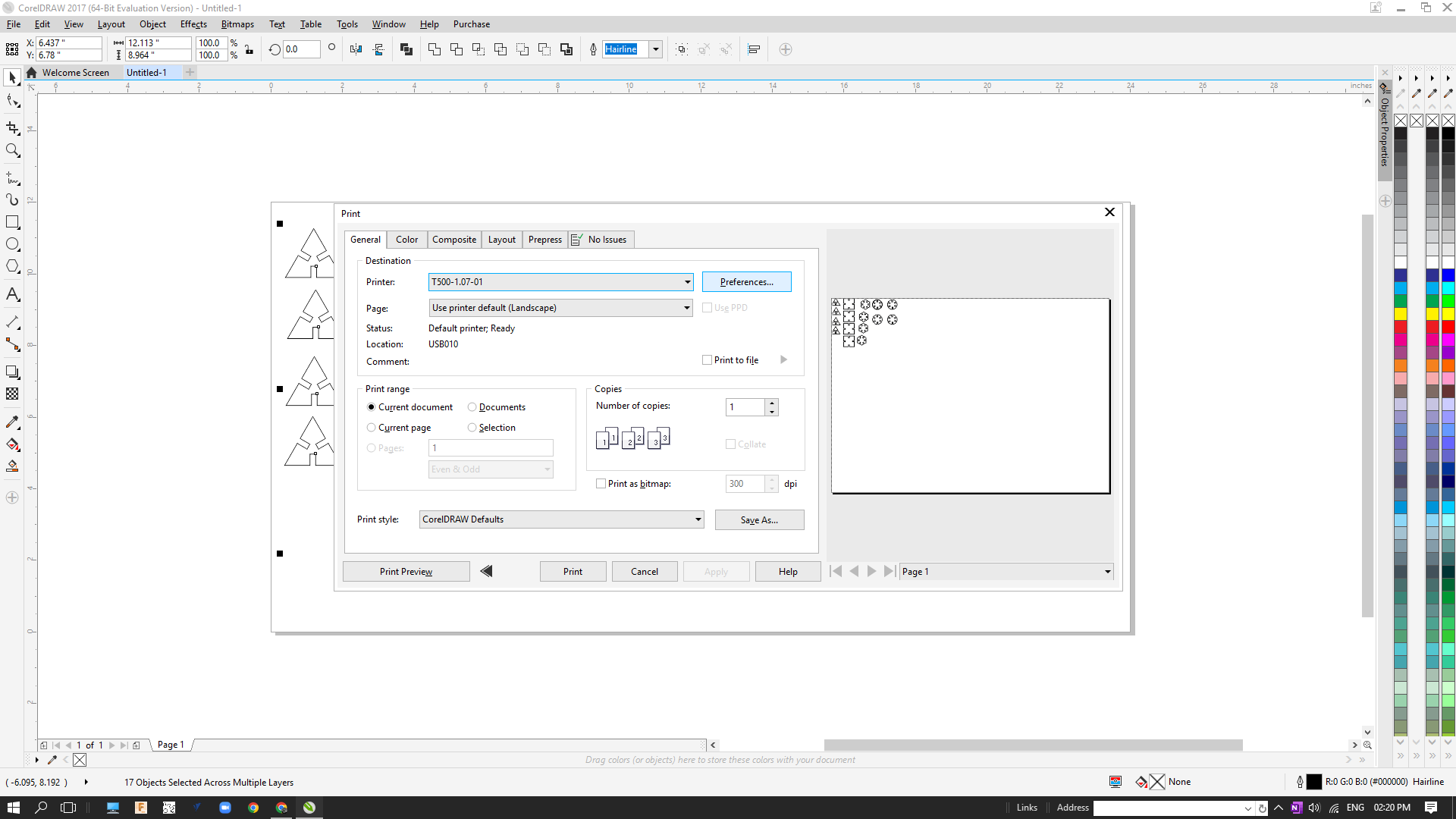

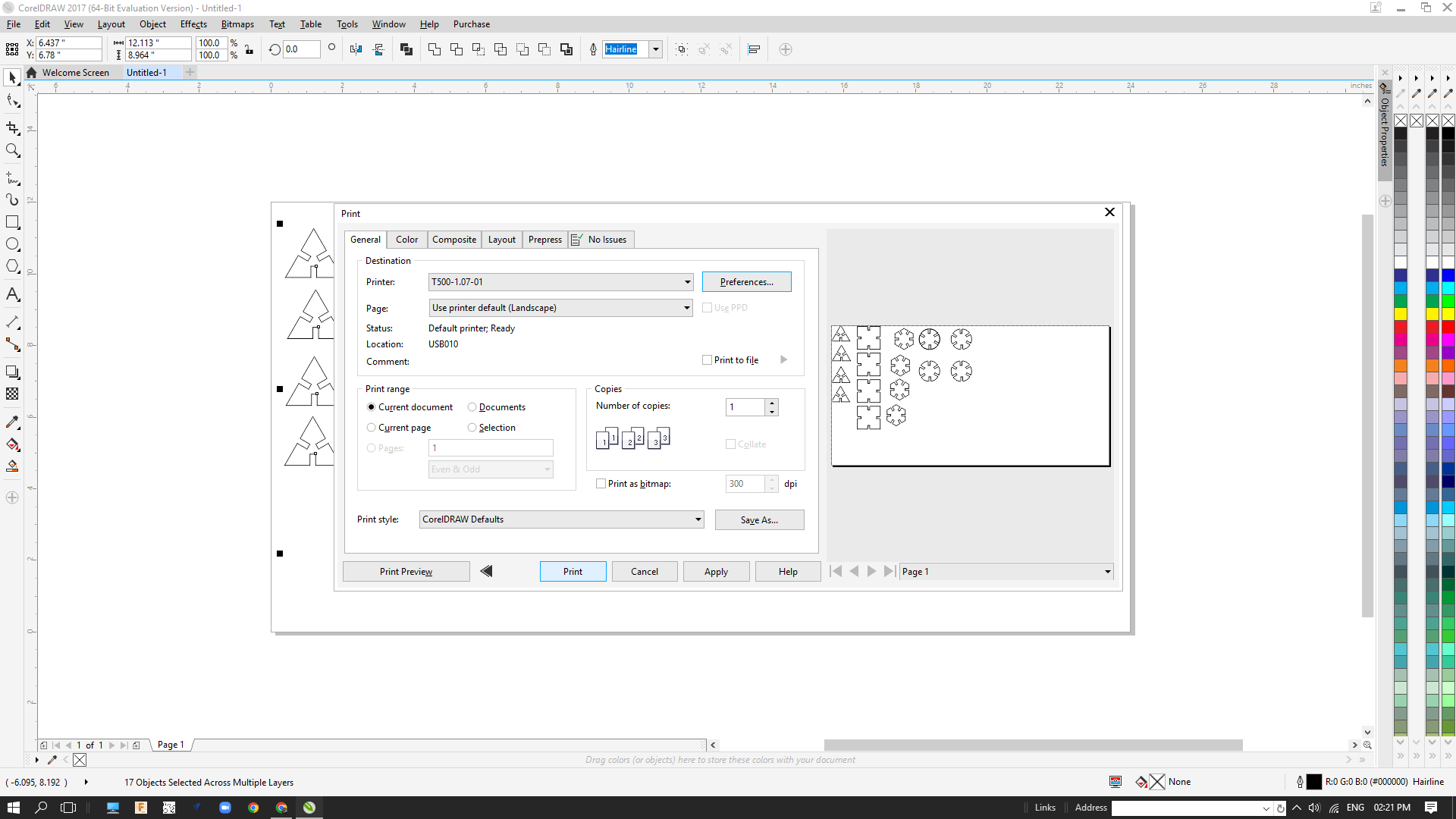

press on ctrl & P to print. A dialog box will appear as shown in picture below. than click on preferences

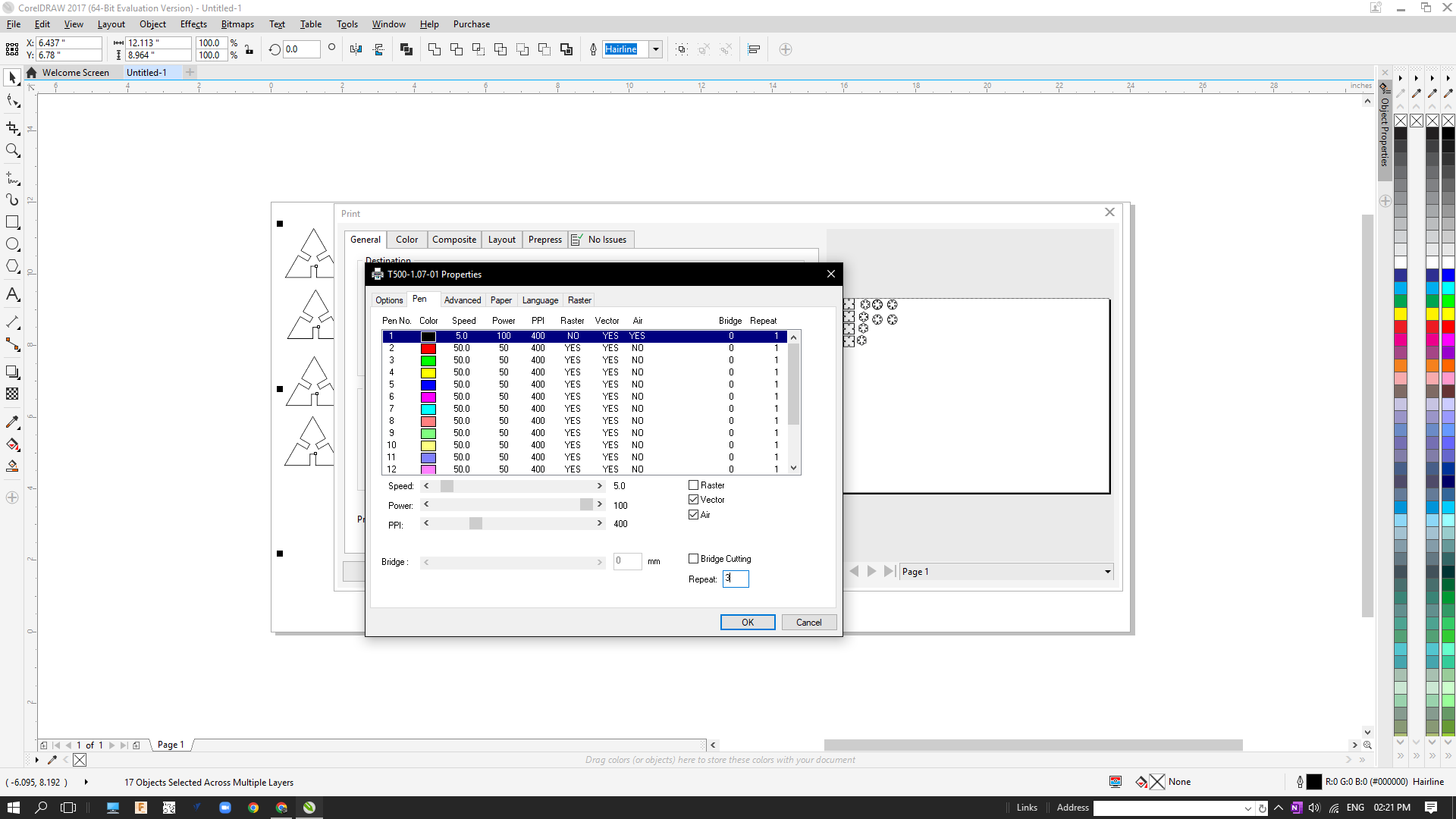

Set the speed to 5 and power to 100 and tick on vector.

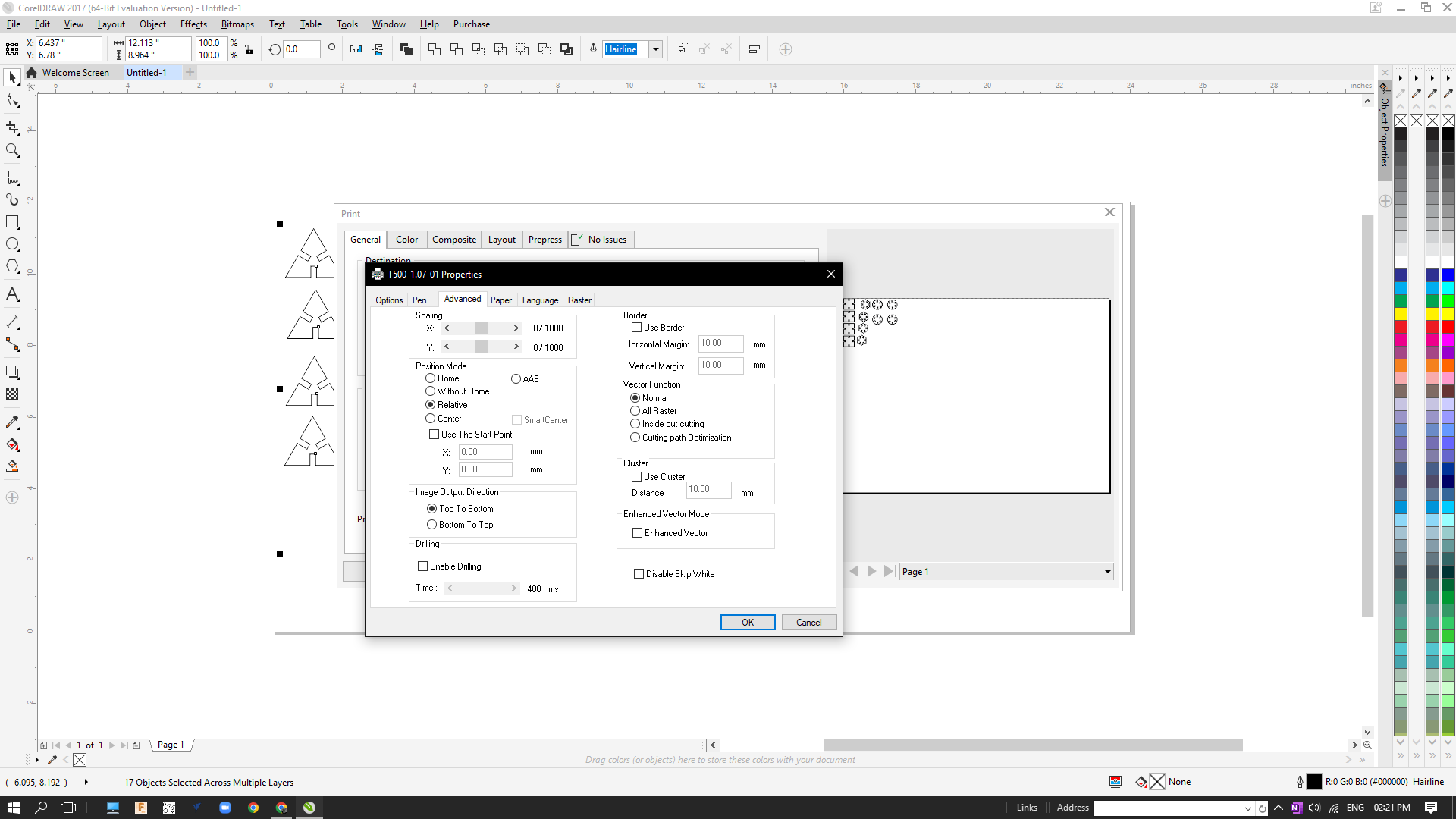

go to pen and select on relatives. it will allow the machine to start from the home we set.

Give the size of the material in mm.

After all the setting click on apply and start to print

Turn on the laser cutter and set zero. Auto focus on it and start to cut

I have constructed a transformer and a bike