Wildcard week

Assignment

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to):

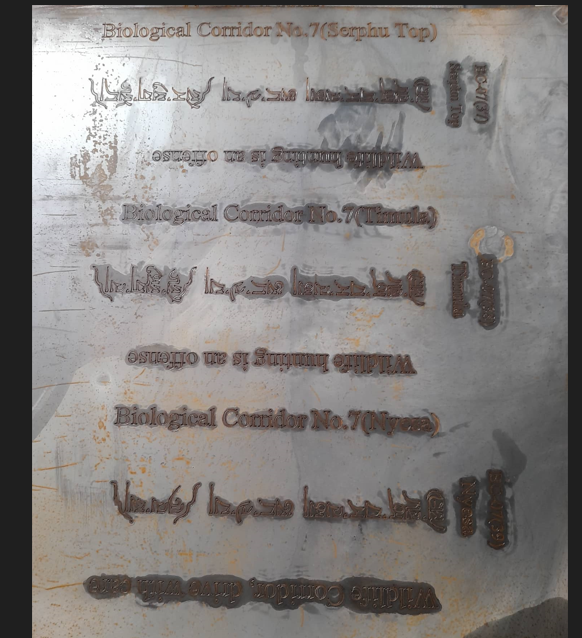

Water jet OMAX 5555

For this week I went to Super Fablab to explore on machine which is not present in our lab. The machine i learned about is Waterjet cutter OMAX 5555

Image source google

OMAX 5555 waterjet is a perfect machine witha smaller footprint but capable of cutting medium size materials

The machine is fast, efficient and precise. The machine provides top performance in waterjet machining of complex parts from many materials

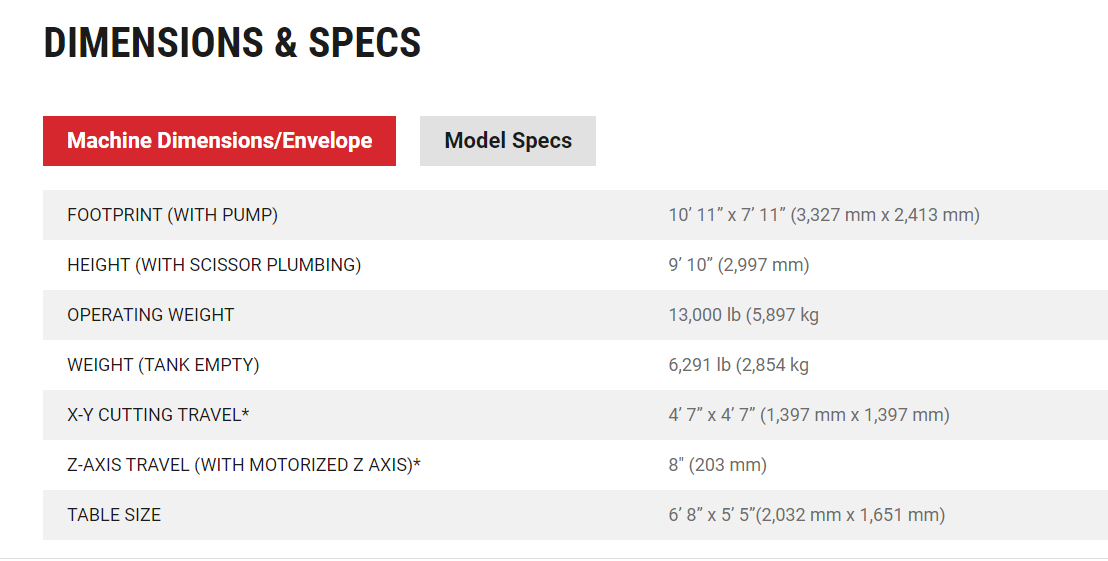

Dimensions And Specification

Image source google

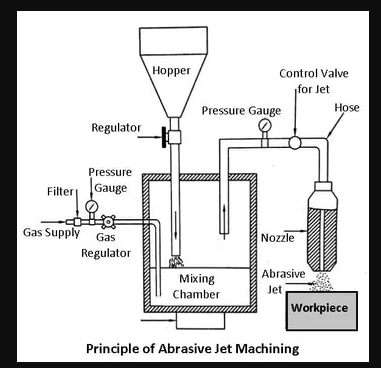

Abrasive

Abrasive jet machining is a process that uses abrasive propelled by a high velocity gas to erode materials from the work piece. Common uses includes cutting heat-sensitive, thin or hard materials. It can cut all materials except diamond.

Image source google

I wanted to cut a board for our community forest which will be placed in the border of my village and community forest. So i asked for a DXF file from our community to cut in OMAX 5555 waterjet.

So to cut in OMAX 5555 we need to use two softwares

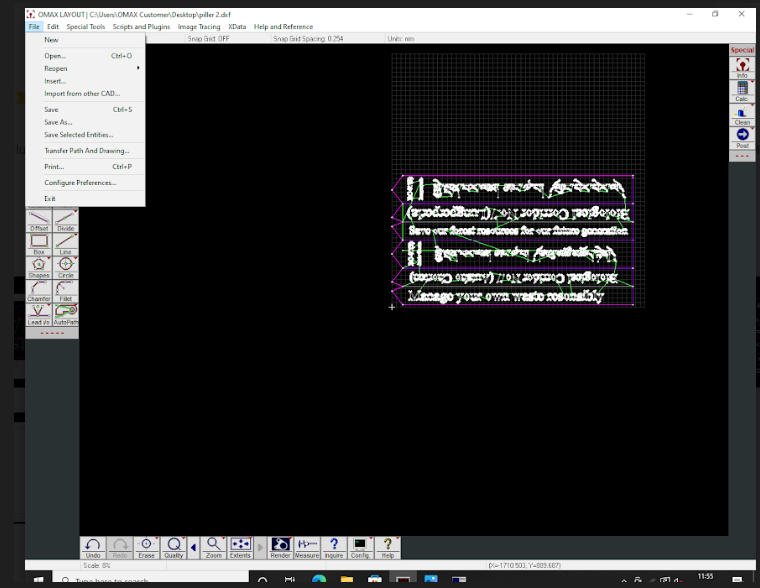

1. OMAX layout

Omax layout is a 2D CAD software that creates a toolpaths for OMAX waterjets. Layout provides the tools necessary to import 2D CAD files such as dxf and process them for use with the Omax Maxiem 1515 and protomax waterjet. OMAX layout will generate file in ORD format.

2. ORD MAKE PREMIUM

It is a software to make the machine cut the material

Steps to cut in OMAX 5555 waterjet

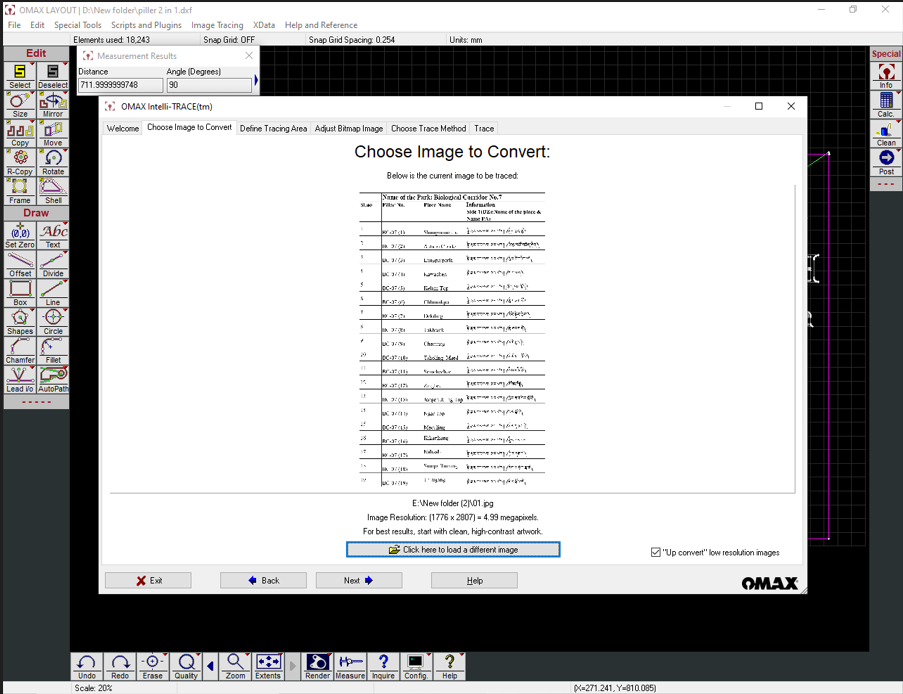

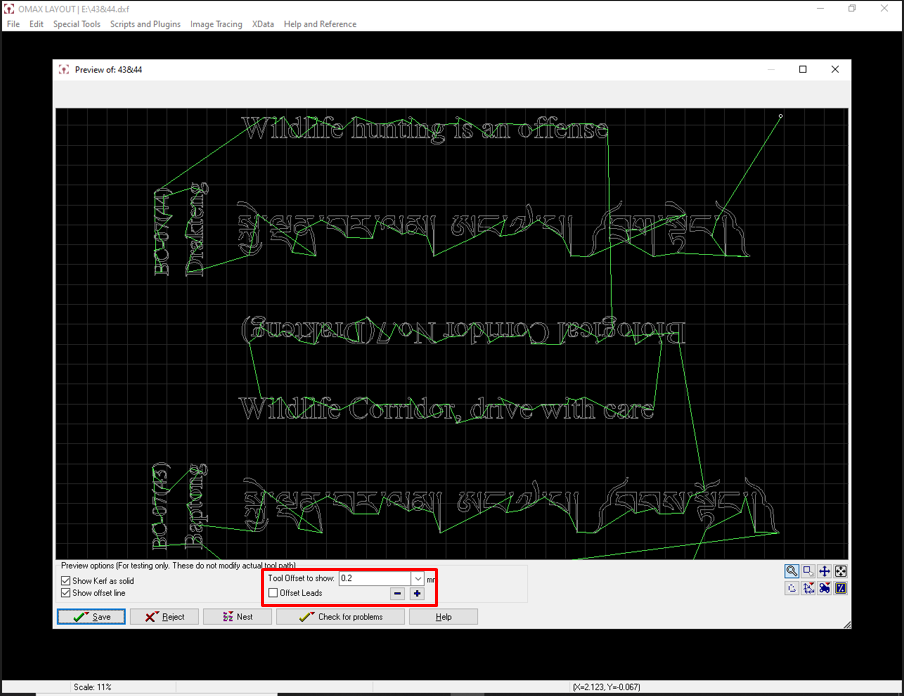

I opened the OMAX layout software and add DXF file by clicking on file and insert the file

If our file is in different format we can convert it into dxf

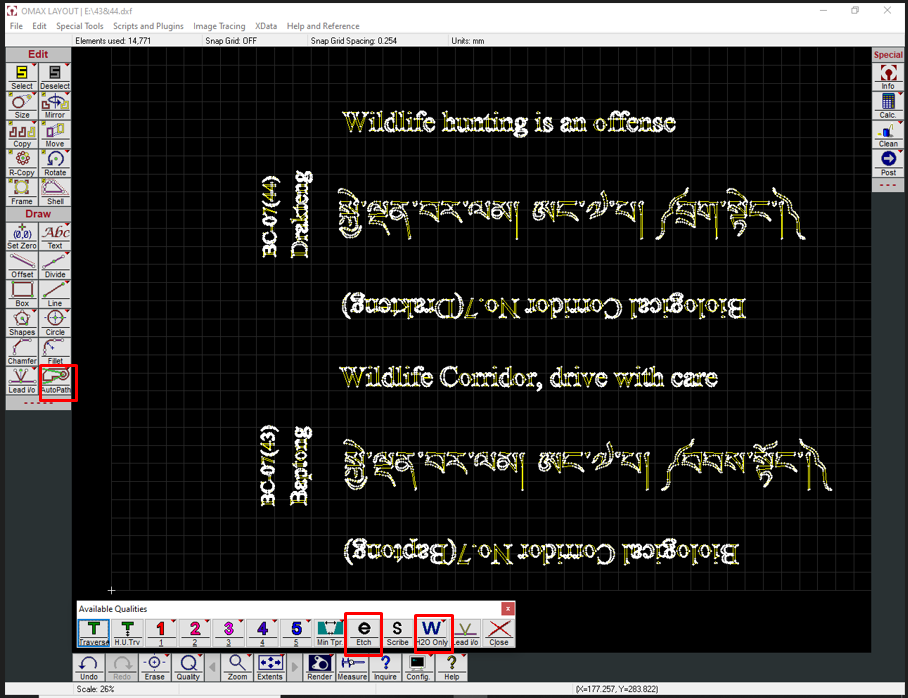

Than Select all and right click on quality and select "Etch" for etching and click on h20 for writing with water.

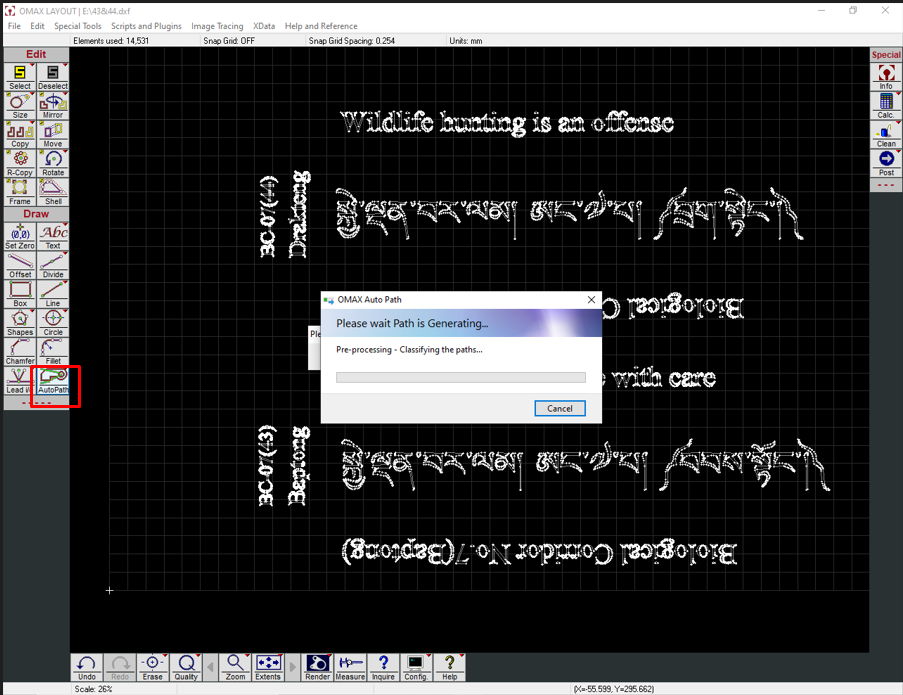

Than left click on autopath to generate the toolpath

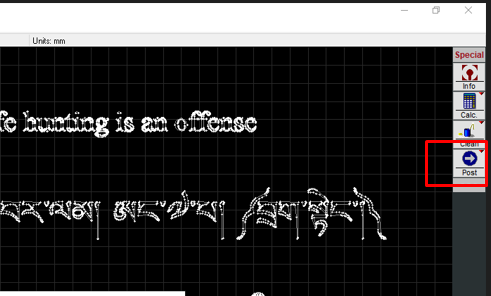

Now we need to do zeroing and set starting point for the machine. So click on post and select a starting point on the design.

We have to set the width of the line by clicking on tool Offset or we can set manually from offset lead.

Than export the file in ORD

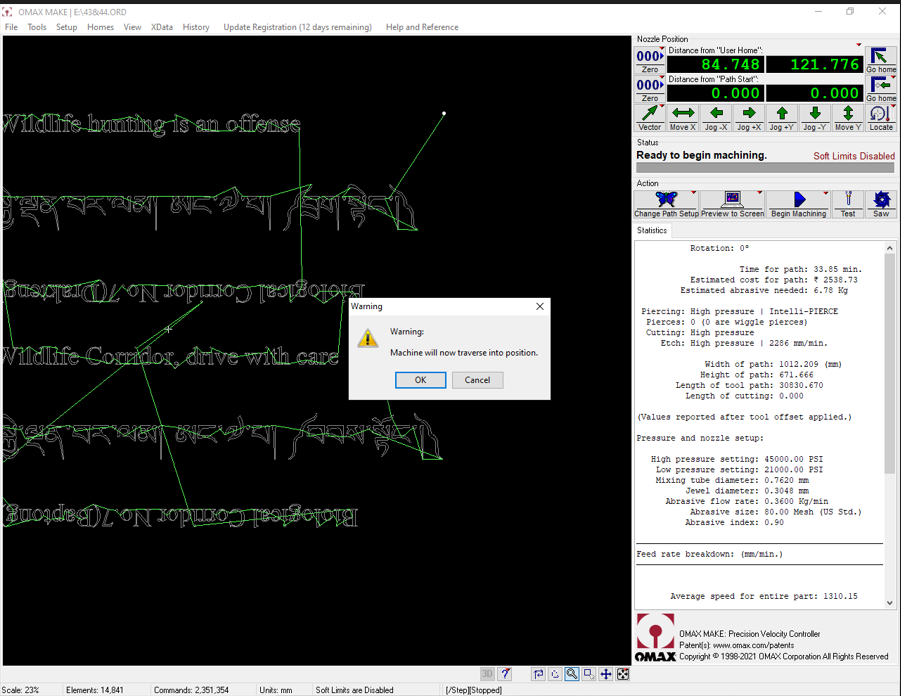

ORD make premium

This software is for cutting the material

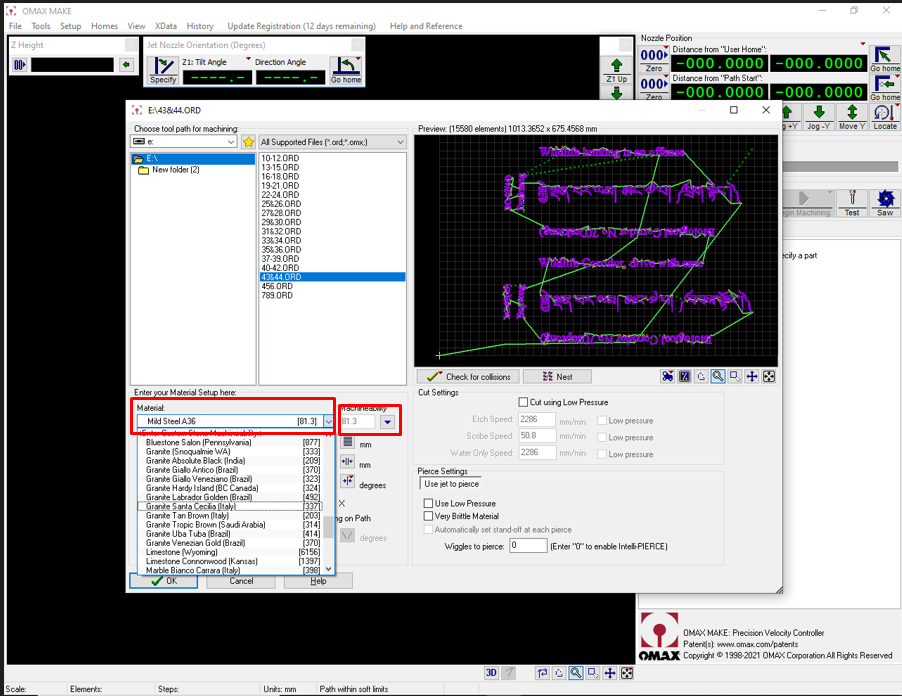

So firstly we have to open the MAKE software and select the DXF file. Than select the material and the thickness of material. the material I used is Mild steel

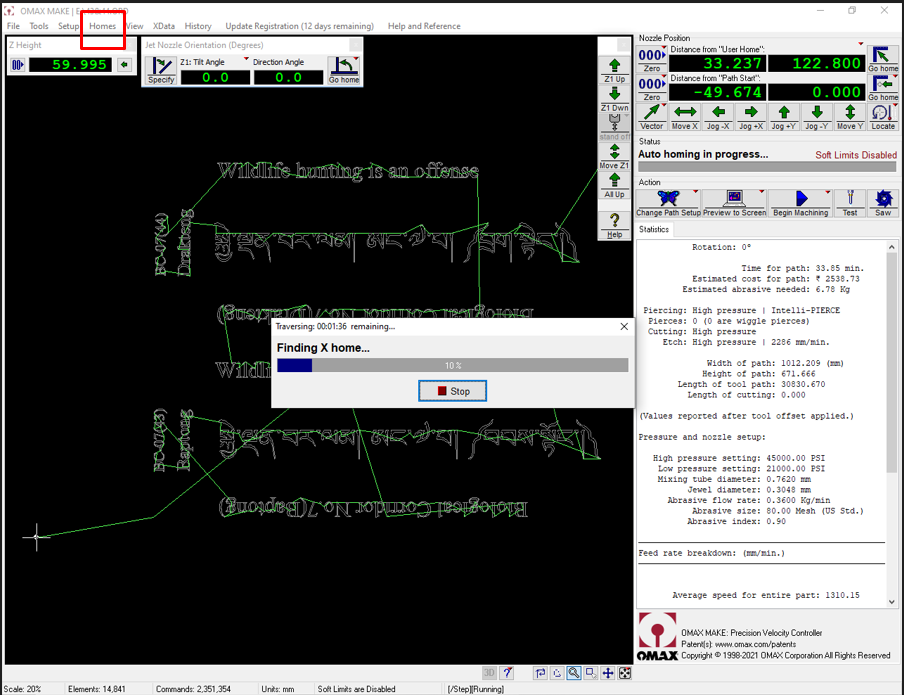

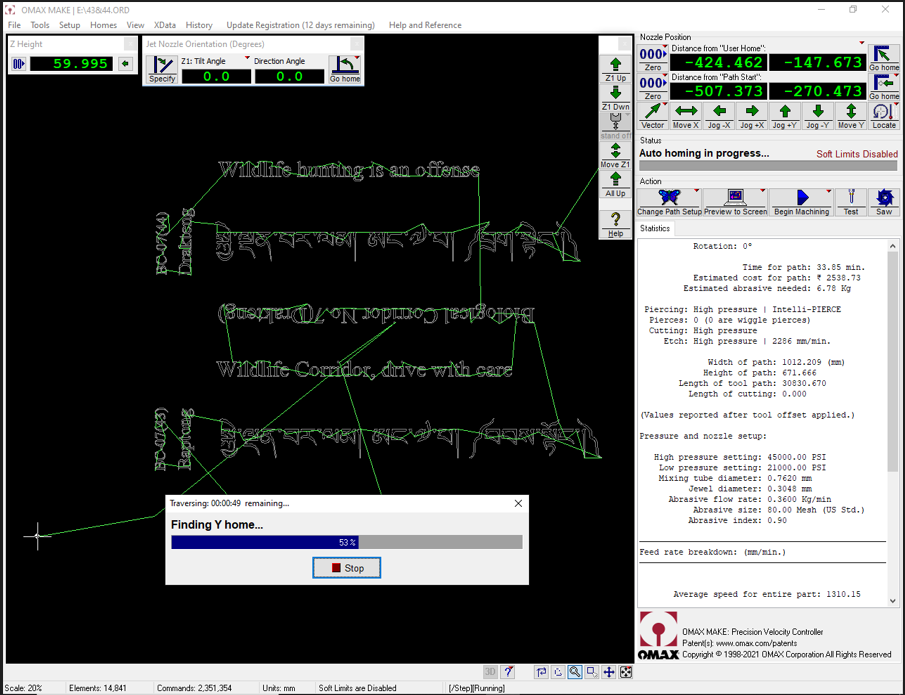

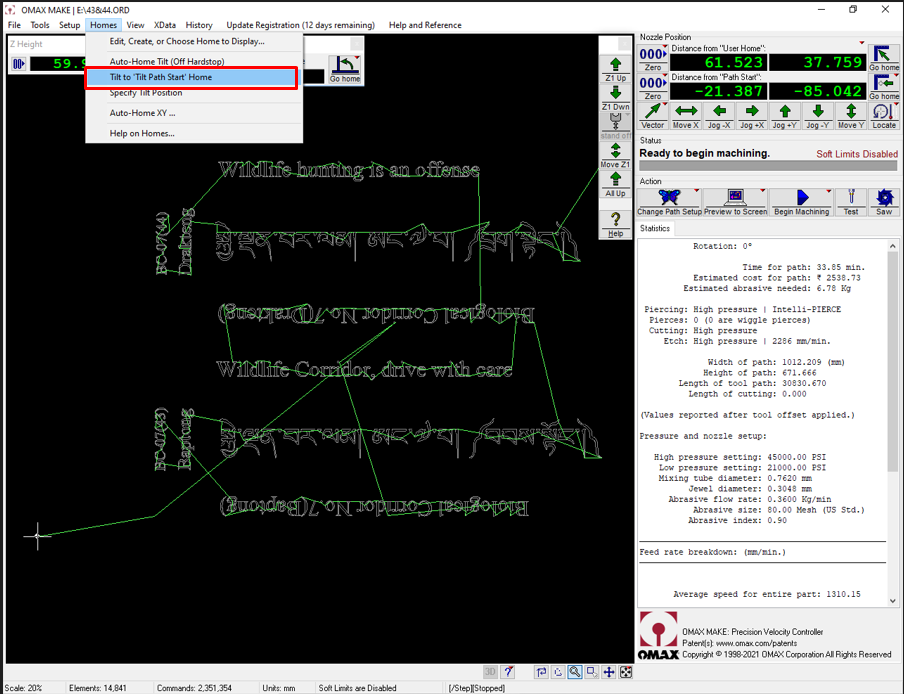

Than click on home and set Auto homing X and Y

next we need to auto home the tilt axis. This machine is having 5 axis and it is X, Y, Z, TX(tilt x) and TY(tilt y)

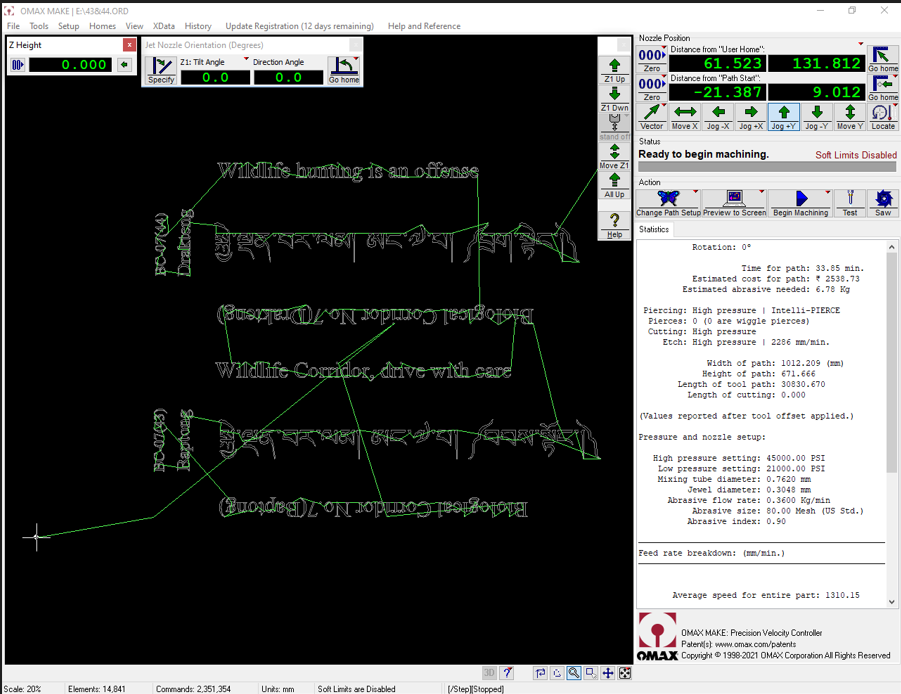

than click on Z height for homing job place

Than click on Zero for homing X, Y and Z

Than clamp on the materials for making materials stable

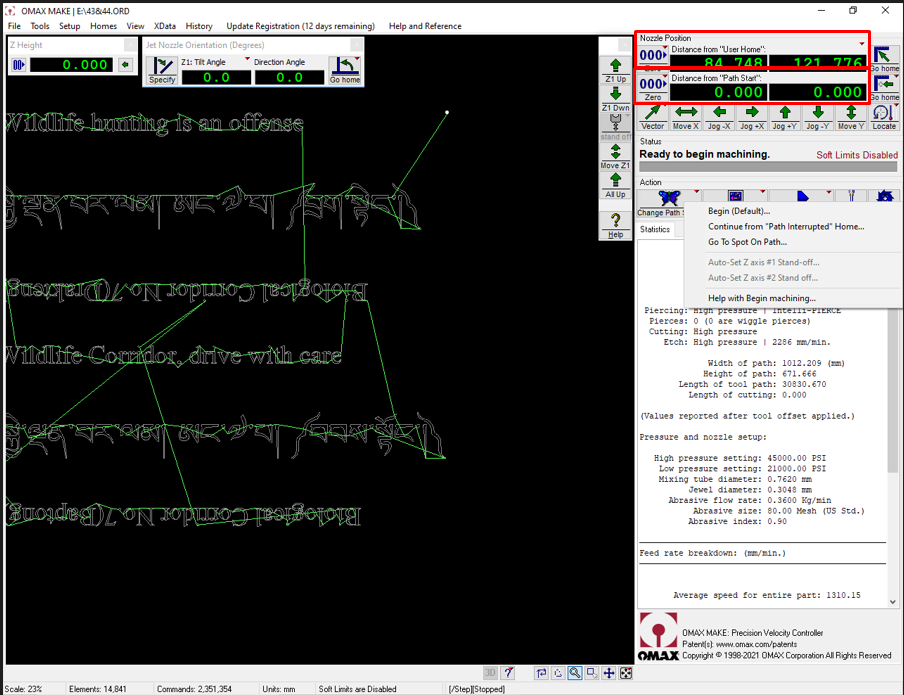

User home is a home for the machine

Path start is the home that we set

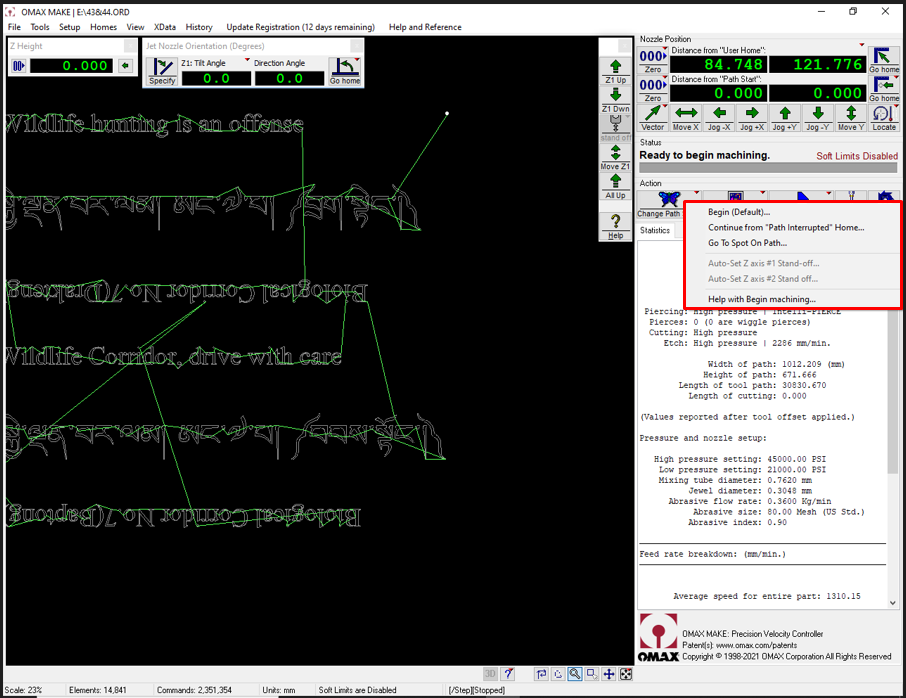

Than chick on begin machining and begin to path

Now the machine will traverse into position and click on start to cut

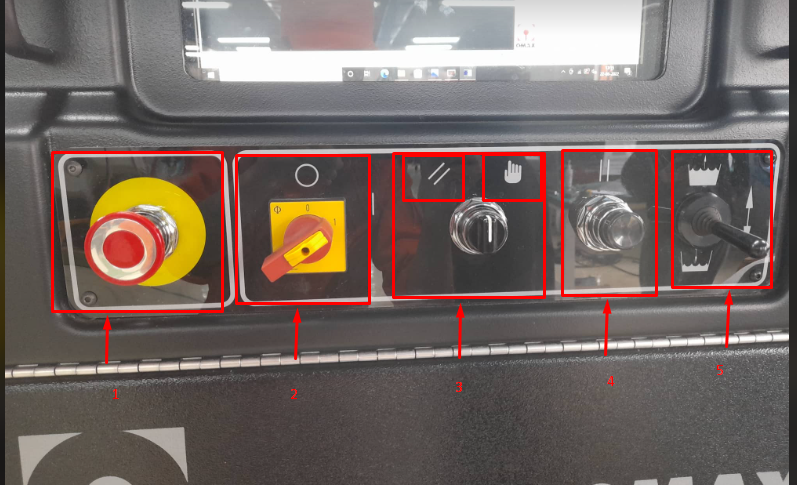

Operator Control Panel

The operator control panel provides function switches for system operation.

1. Emergency Stop:- Immediately shuts down the high pressure pump and all abrasive waterjet operations. Use this button for only for emergencies. When it is presed it not only stops machine operation but also loses machine positioning data

2. Power ON/OFF:- Starts the PC after the pump is powered ON and shuts down the PC and pump when powered OFF

3. // is Reset:- Disables all axis motor drives and resets any faulted drive

Motor override:- Overrides motors and is used for machine diagostic purposes only

4. Pause:- Stops all machine operation temporarily without the loss of machine positioning information.

5. Water level control:- Raise the water level when lever is pushd upward and lowers water level wen lever is pulled down.

Final result