3D Milling in Fusion 360

If you have not yet read the first attempt at molding and casting, you should read that first.

TL;DR: I did not chamfer enough the walls and sides of my pieces during the design phase.

Lessons Learned

Unable to Extrude Tapered walls in Fusion360

I did try to chamfer those curves, but there are various things in Fusion360 that I still don’t fully understand:

Treat this as a living document that I will expand as I learn more over time:

- Sometimes extruding with a chamfer angle does not work

- It seems to work a 1 degree

- But fails at 2 degrees

- It seems to be caused by crazy curves in the sketch. These can be seen using the Curve Comb tool

Users who had similar problems.

https://forums.autodesk.com/t5/fusion-360-design-validate/taper-angle-draft-error/td-p/10055851

It all boiled down at me trying to chamfer the curves until Fusion decided it was “too much” and it rejected higher angles, and me deciding “that was probably good enough” instead of checking whether this would collision with the end-mill’s shoulder.

Future learning

💡 Future steps: learn how to design curves that have smooth continuity and that can be chamfered more aggressively.

Curve and Continuity cheatsheet

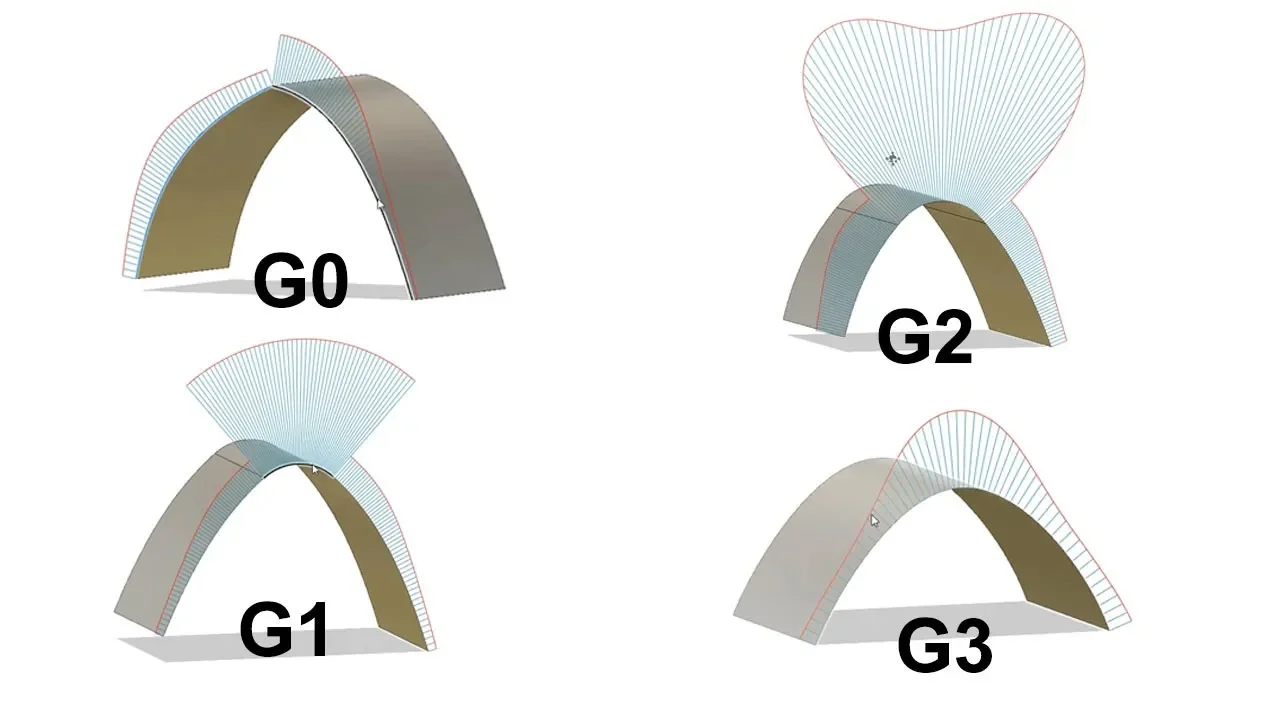

I made myself a cheatsheet to better understand the meaning of continuity during curve design.

This is just a short summary of Understanding G0, G1, G2 and G3 surface continuity using curvature comb

- G0 = No G Continuity.

- The 2 curves have a position in space in common, but there is no smoothness in their curvature. The edge has a sharp angle.

- G1 = Tangential continuity.

- 2 planes joined by a raw fillet, which is tangential to both planes. ensures that the fillet is tangent to both surfaces.

- The combs from the fillet and the planes touch because of the tangential transition.

- G2 = Curvature continuity.

- The surfaces, at the contact points, are still tangential, but now they have a similar curvature flow close between themselves.

- The change between the two surfaces (the fillet) has a less abrupt curvature as it adapts to the adjacent planes. It begins with a smooth transition from the previous surface (origin surface), then it starts bending more aggressively, and then it returns to a smooth curvature, just before connecting with the second surface (target surface).

- Can be enabled by using a Fillet with “G2” checkbox.

- G3 = Constant Rate of change of curvature

- Which I nicknamed “Meta-Tangential” for reasons that will be apparent below.

- The easiest way to distinguish between G2 and G3 is to look at the curvature combs of the surfaces or lines we are working with.

- The curvature comb for a given line or plane indicates their curve radius and their tangentiality (the spines of the curvature comb are always perpendicular to the line/plane it represents)

- G2 and G3 are similar (the lines/surfaces are still tangential) but in G3, the curve comb that encompasses the 2 lines under analysis will also, itself, be tangential, smooth and continuous.