CNC

To test runout, alignment, speeds, feeds, and toolpaths for our CNC machine.

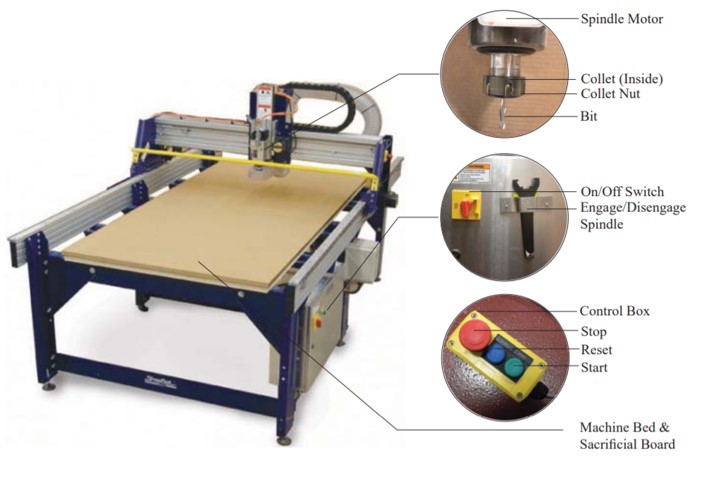

GET STARTED

- Always wear safety glasses and hearing protection when operating CNC machines.

- Always wear safety glasses when closely observing cutting tools. Always wear safety boots or other suitable footwear.

- Always keep long hair covered when operating CNC machines.

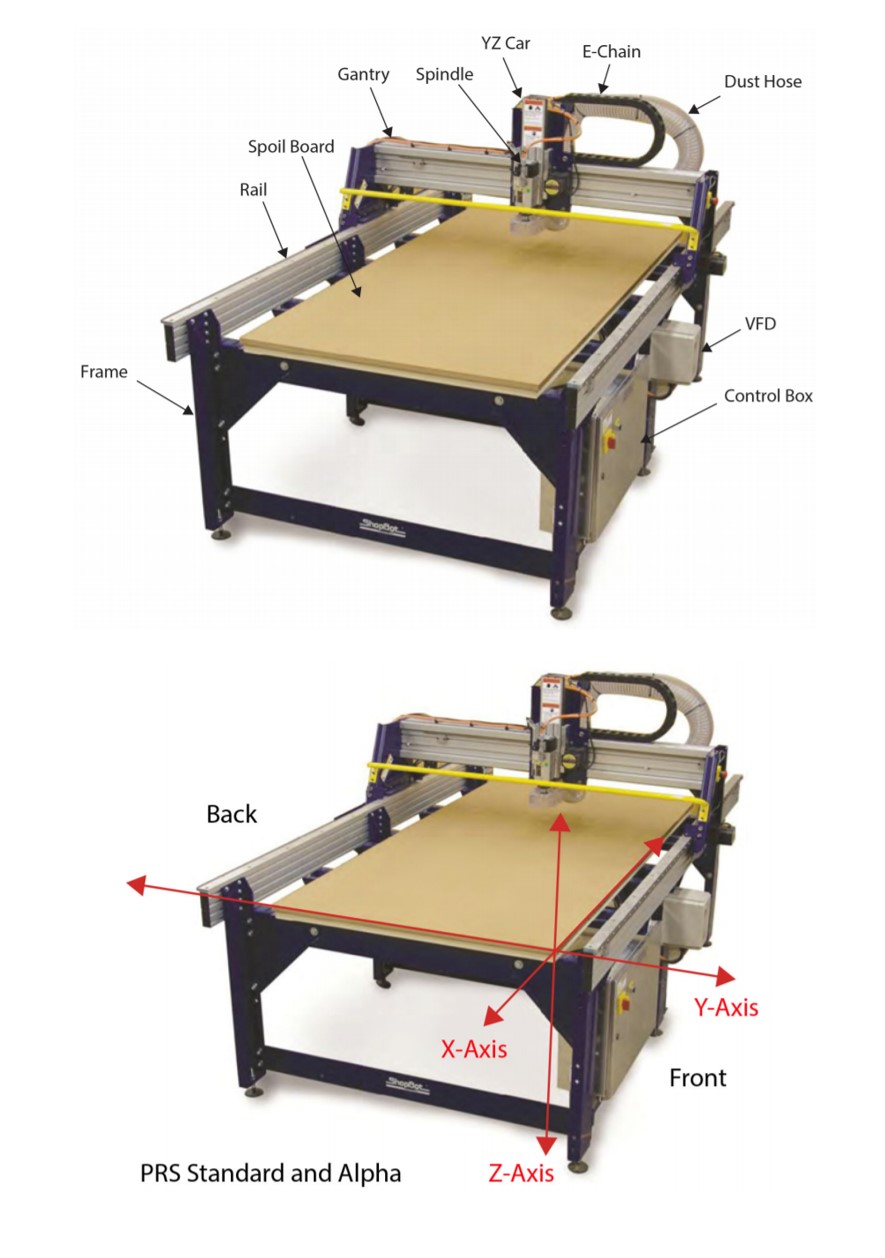

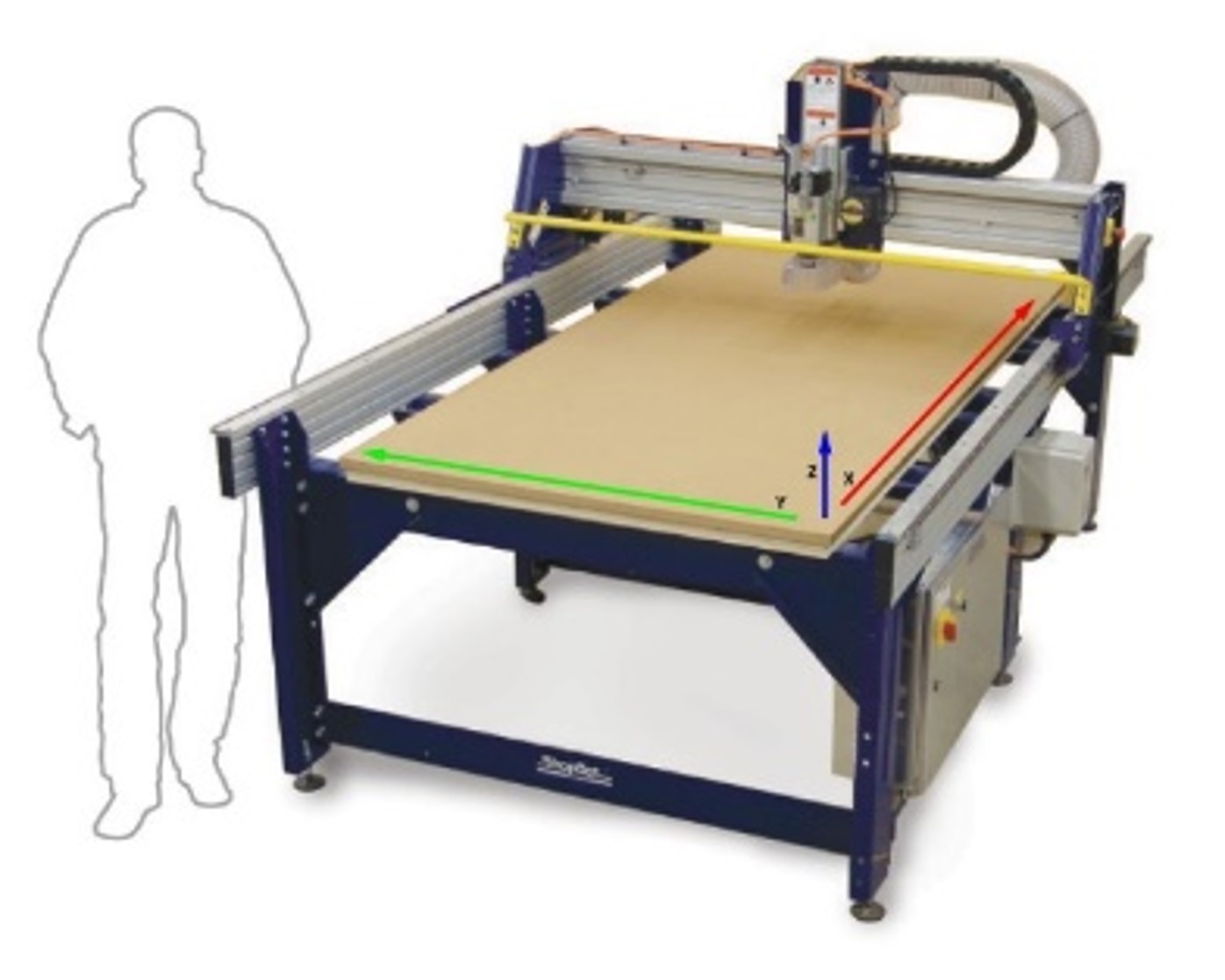

1. Insert the material to the CNC we will use MDF 15mm.

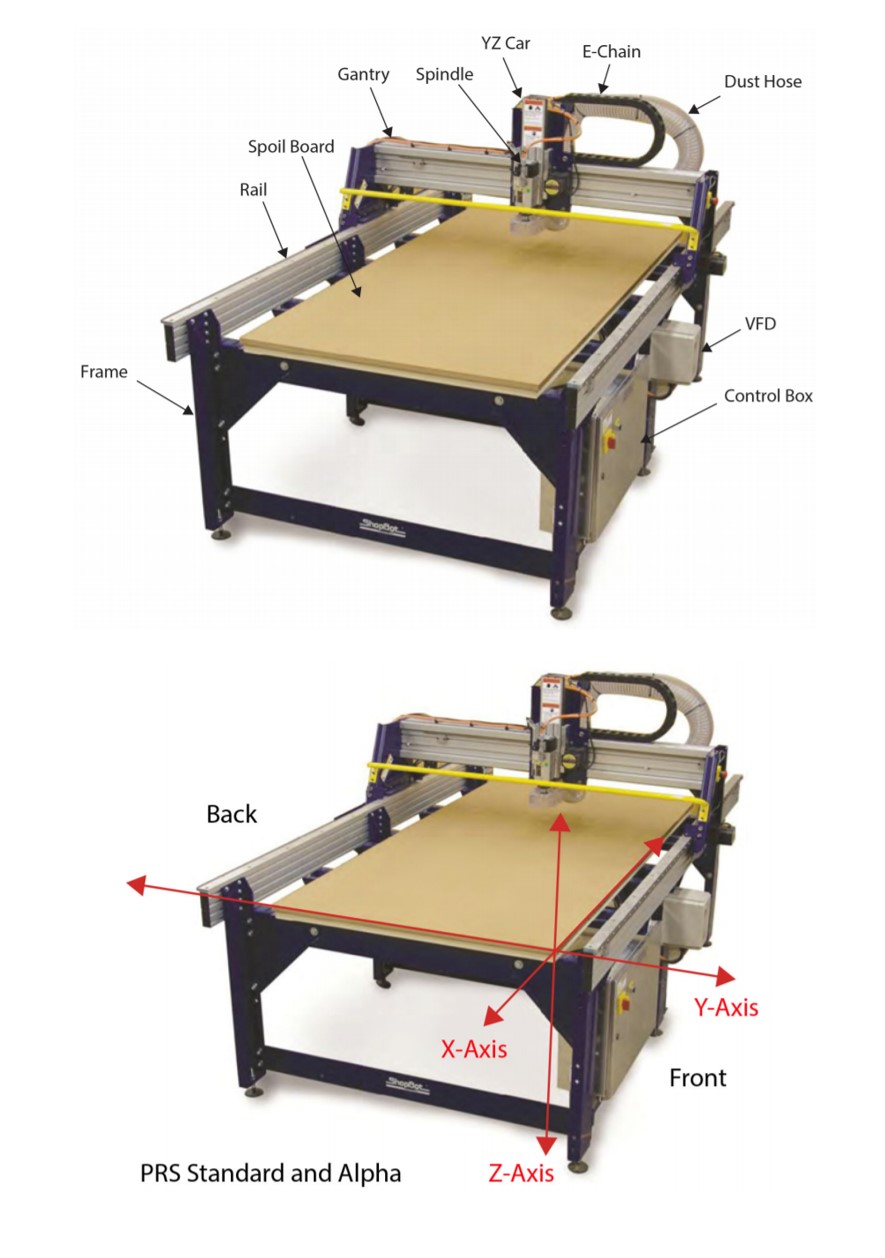

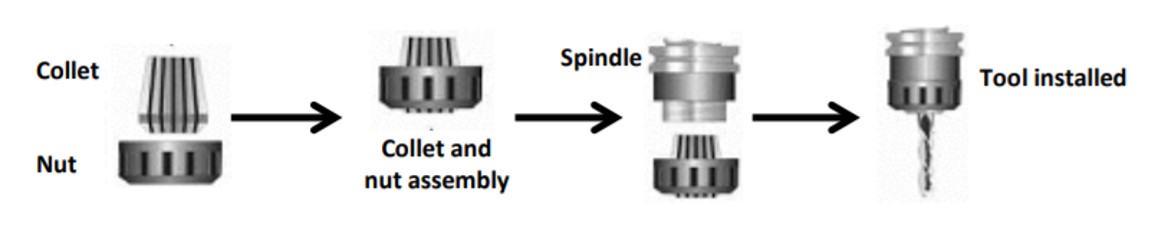

2. Changing the bit we will use 1/8 end mill bit for all the three processes.

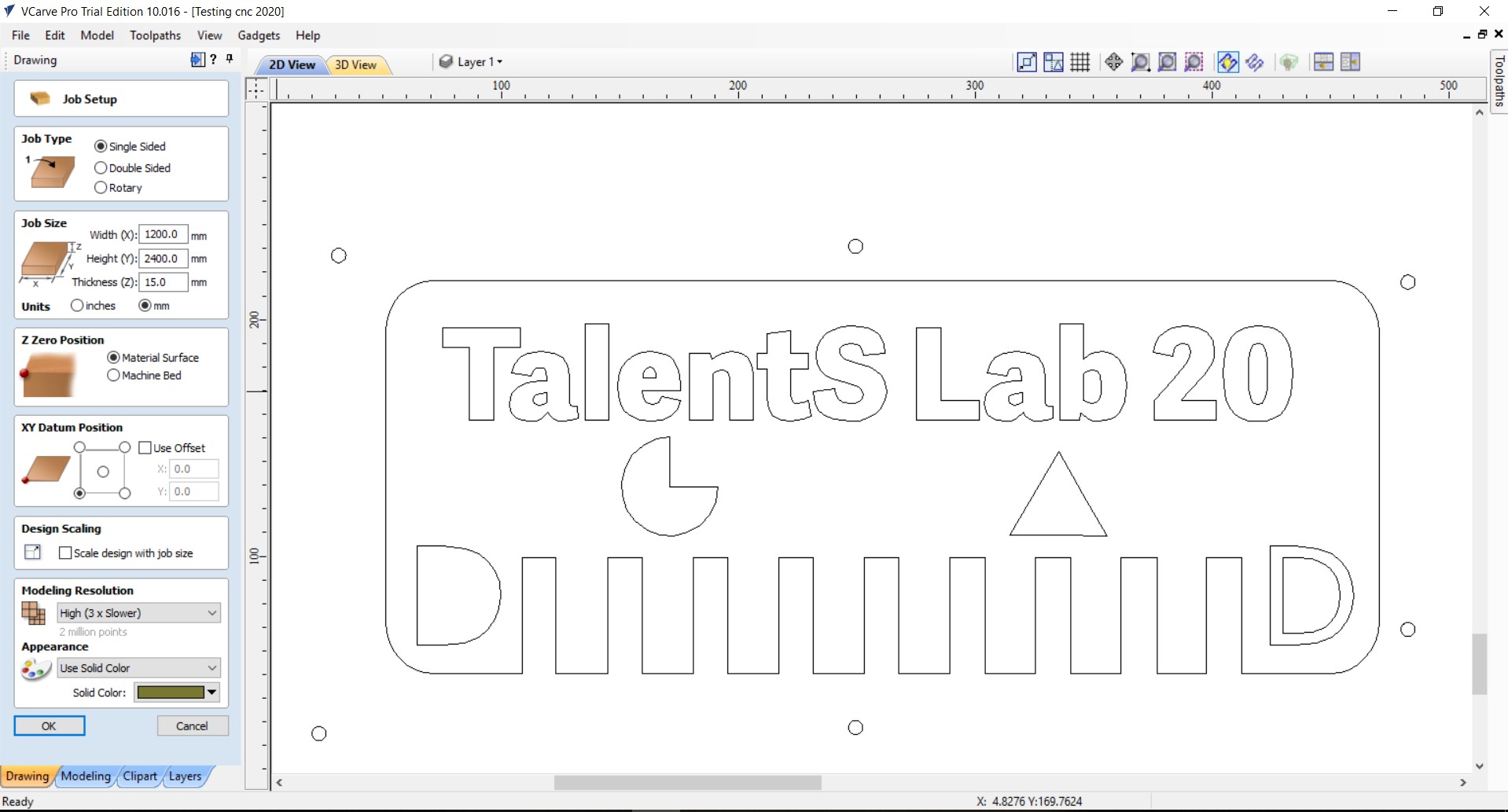

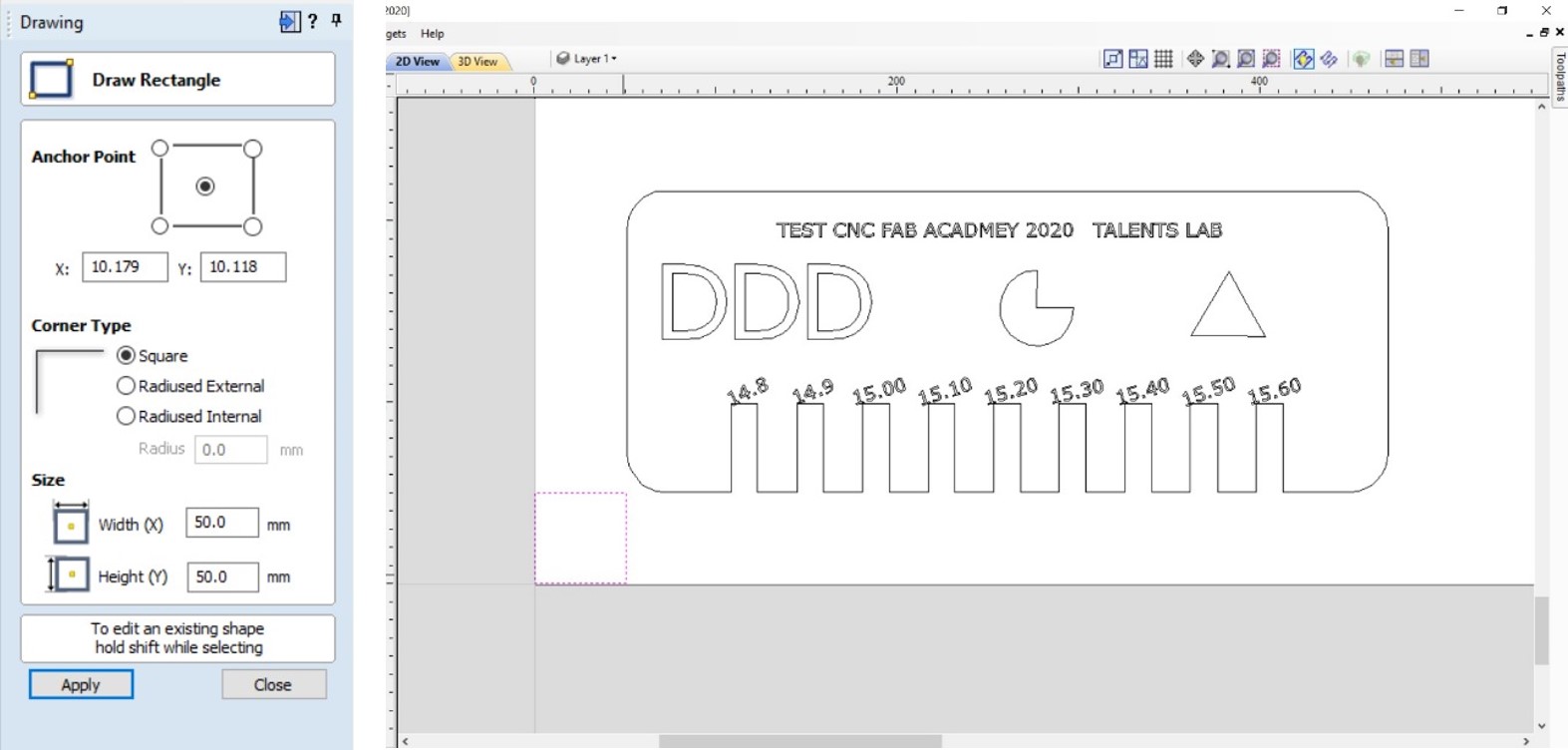

3. convert the toolpaths to Gcode file, by using VCarve pro software.

4. Demonstrate how to apply the design to the CNC machine and CNC software.

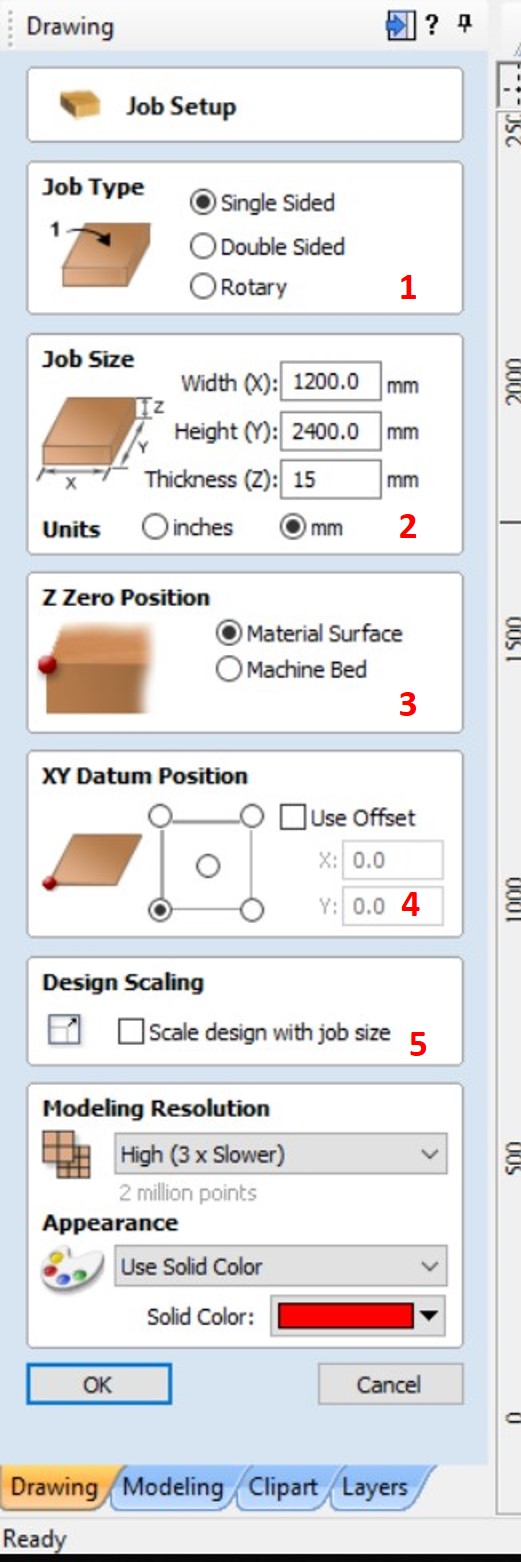

1.We chose the single sided as our job type.

2. The job size we added the workpieces size 1200x2400mm and it can be changed depending on your workpiece but always make sure the design can fit in the workpiece.

3. For Z zero position we chose the material surface.

4. We unchecked the use offset option and we prefer starting from the left corner.

5. Make sure to uncheck the design scaling.

6. Click Ok.

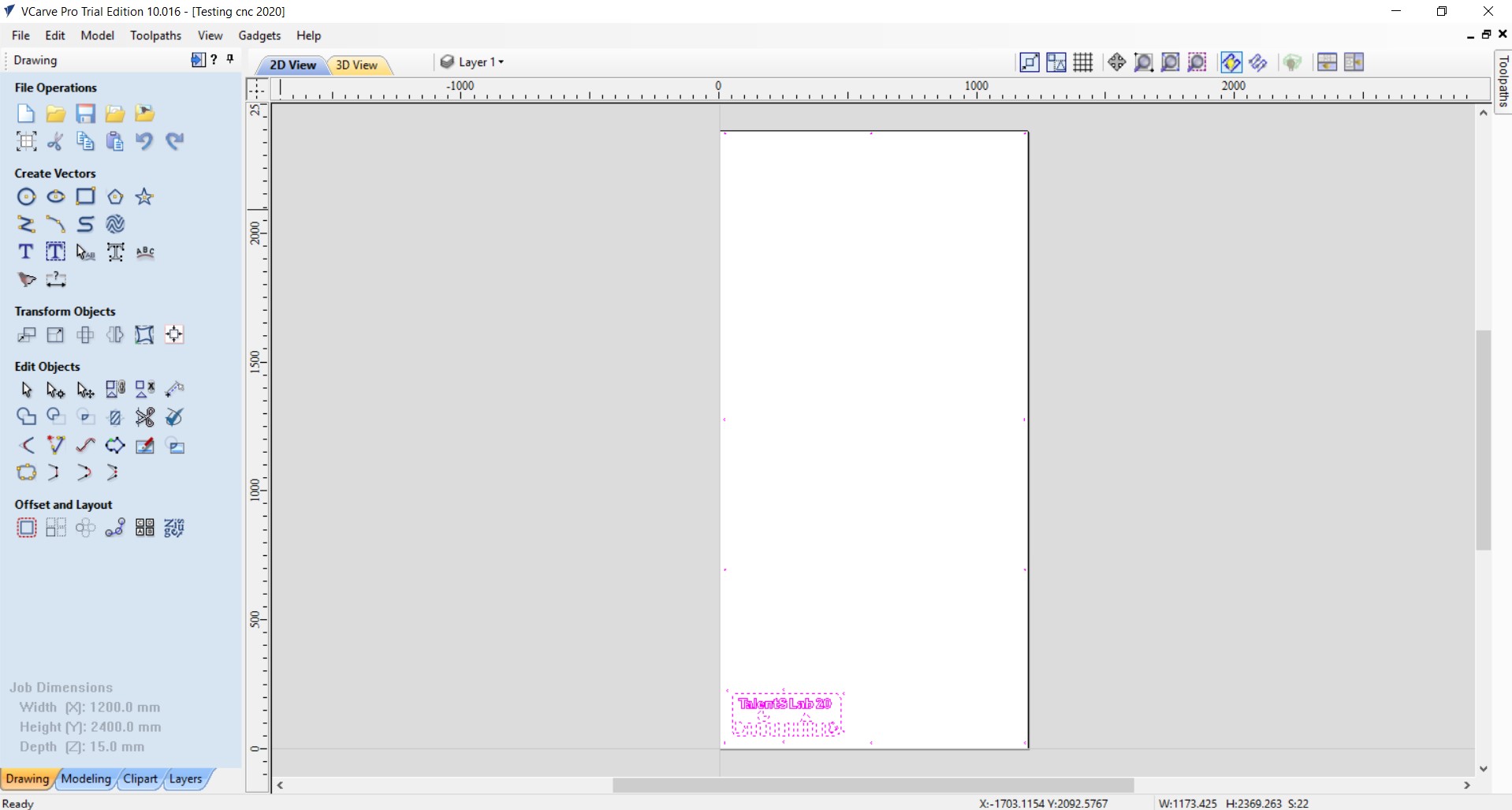

- Now after we set the job setup, we can see the design in 2D view or 3D view.

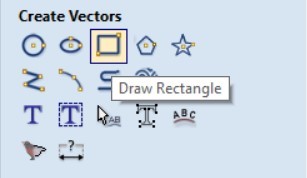

- The tools in the left side are very useful for quick design edits.

- And we used some of them to edit our design.

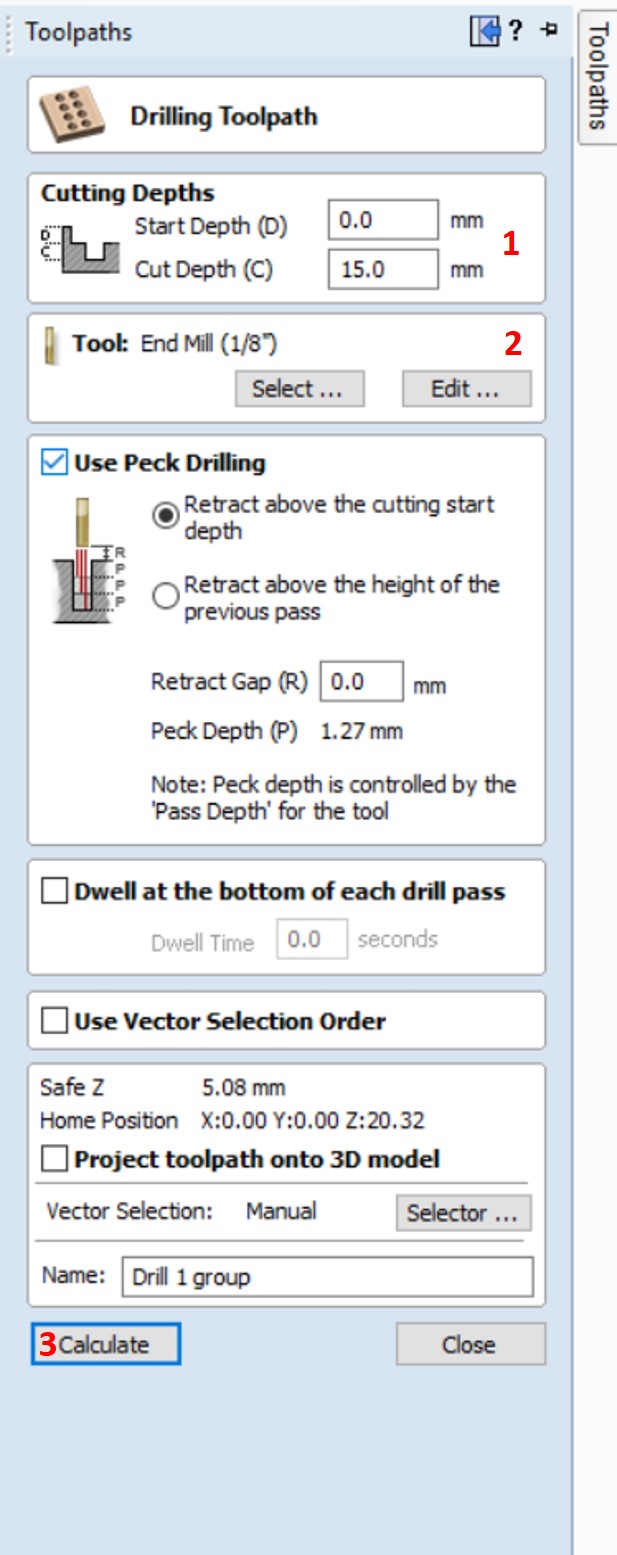

1.Add the same material thickness and you can add 5mm more to make sure it touches the spoil surface sheet.

2.Choose the bit tool, we chose 1/8 end mill.

3. Click on calculate to generate the toolpaths Gcode file.

1.Set the cut depth 5mm only out of 15mm.

2. Select the cutting bit.

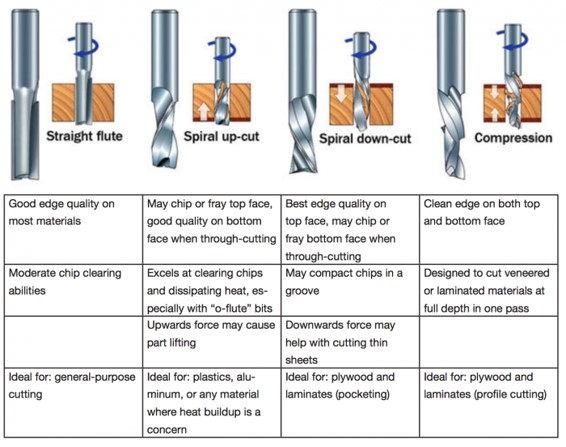

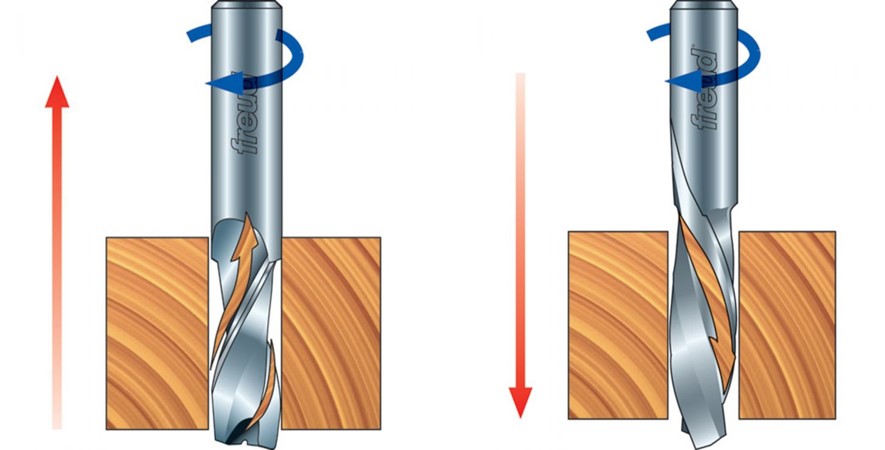

3. Set the cut direction to climb.

4.Click on calculate to generate the cutting toolpath.

1.Set the cutting depth, by adding the material thickness.

2.Choose the cut tool, we chose the end mill 1/8.

3. Machine vector for those small pats we will test to cut them inside.

4.Add ramps to toolpaths, and the type will be smooth.

5.Click calculate to generate the cutting toolpaths.

1.Set the cutting depth, by adding the material thickness.

2.Choose the cut tool, we chose the end mill 1/8.

3. Machine vector for those small pats we will test to cut them outside.

4.Add ramps to toolpaths, and the type will be smooth.

5.Click calculate to generate the cutting toolpaths.

Copyright © 2016 Minimax Digital Firm - Design: Tooplate