6. 3D Scanning and Printing

Assignment: Test the design rules for your 3D printer. Design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively. 3D scan an object (and optionally print it)

Steps

Test the design rules for your printers using a bench model. Explain what are the limits of your printers and the Design and 3D print an object (small, few cm3, limited by printer time) that could not be easily made subtractively. 3D scan an object, try to prepare it for printing (and optionally print it). Linked to the group assignment page. Explained what you learned from testing the 3D printers. Documented how you designed and made your object and explained why it could not be easily made subtractively. Documented how you scanned and prepared an object (for 3D printing). Included your original design files for 3D printing (both CAD and common format for 3D printing). Included your hero shots.

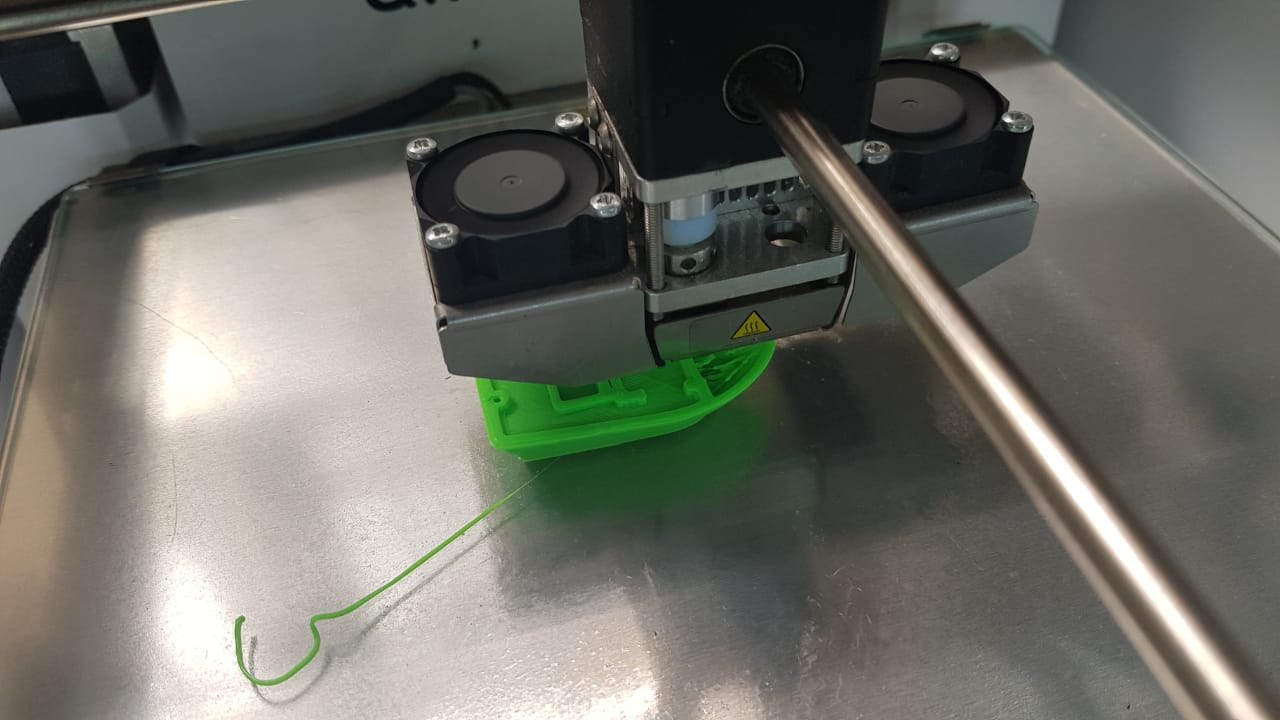

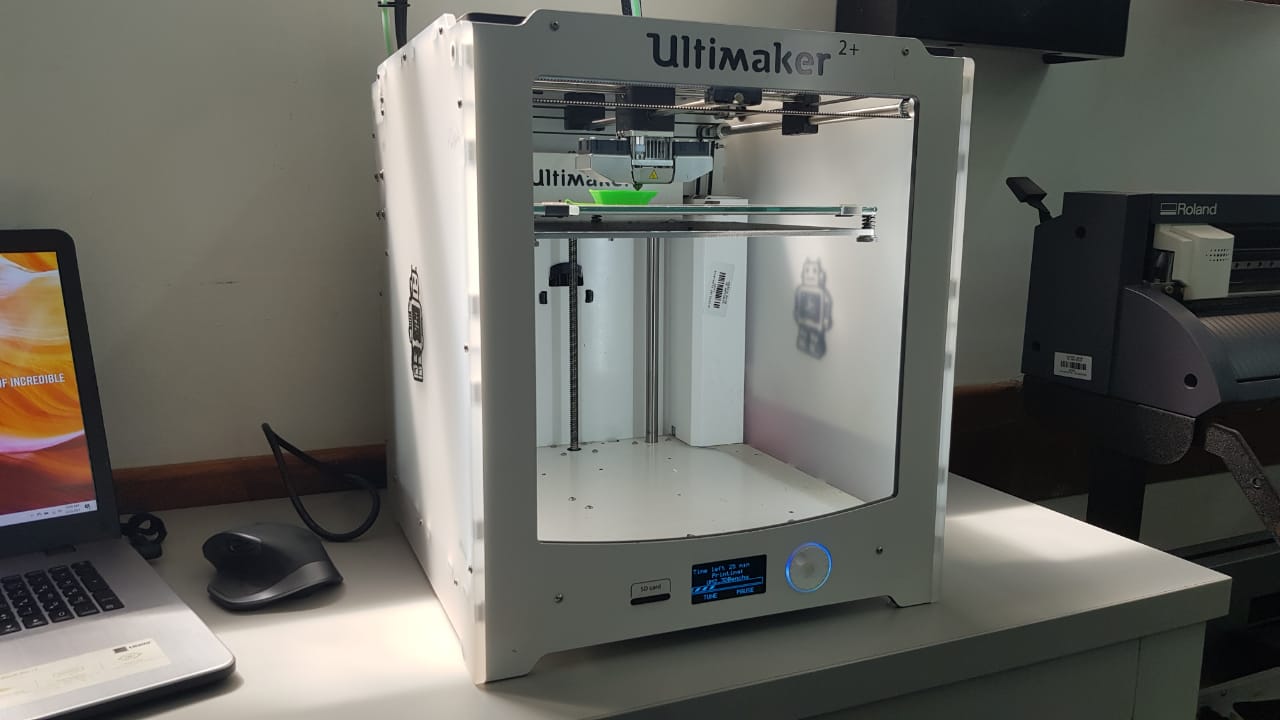

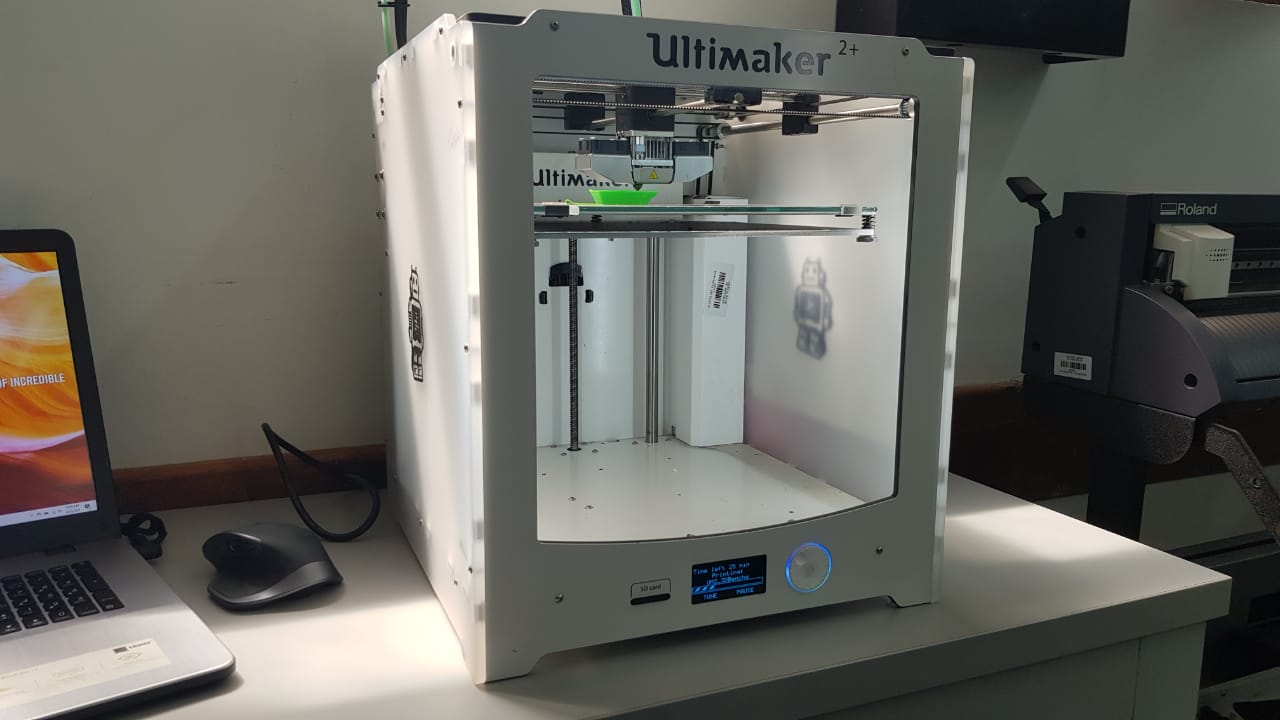

The 3D printer: Ultimaker 2+

Print Technology: Fused Filament Fabrication (FFF)

Build Volume: 223x223x205 mm

Print Surface: Heated Bed (50-100*C)

Filaments: PLA, ABS, CPE, Nylon, PC, PP, CPE+, TPU

Filament Diameter: 2,85mm

Nozzle Diameter: 0,4mm

Layer Resolution: Up to 20 micron

Print Speed: 30-300mm/s

Precision: 12.5/12.5/5 micron

Operational Noise: 49dBA (average)

Desktop size: 357x342x388mm

Supplied Software: Cura File Types: STL/OBJ/DAE/AMF OS: Windows/Mac/Linux Connectivity: standalone SD card

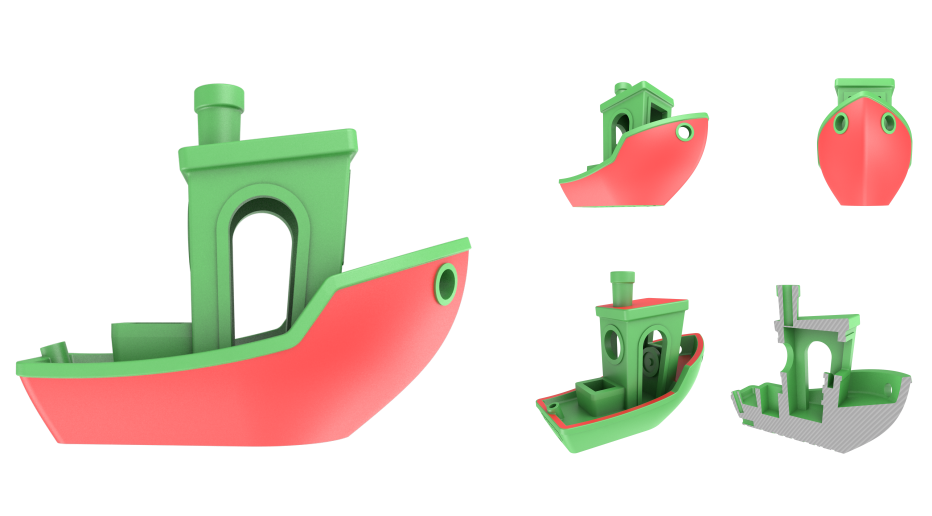

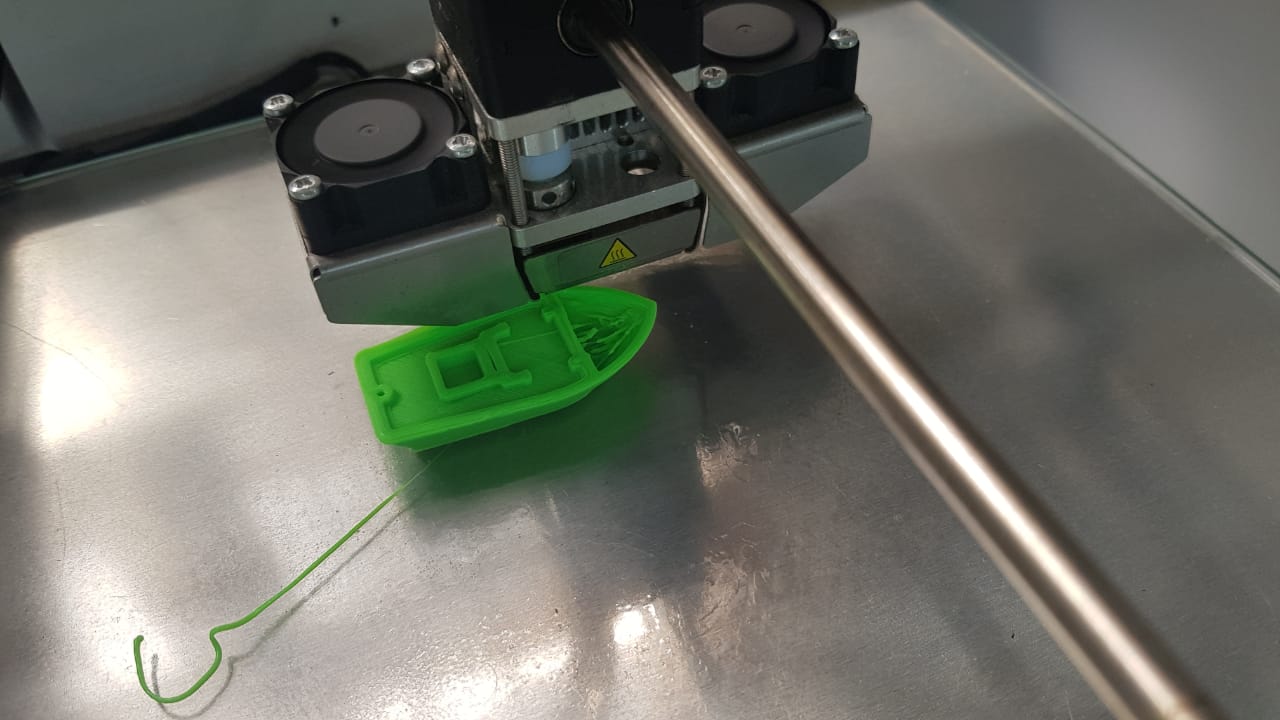

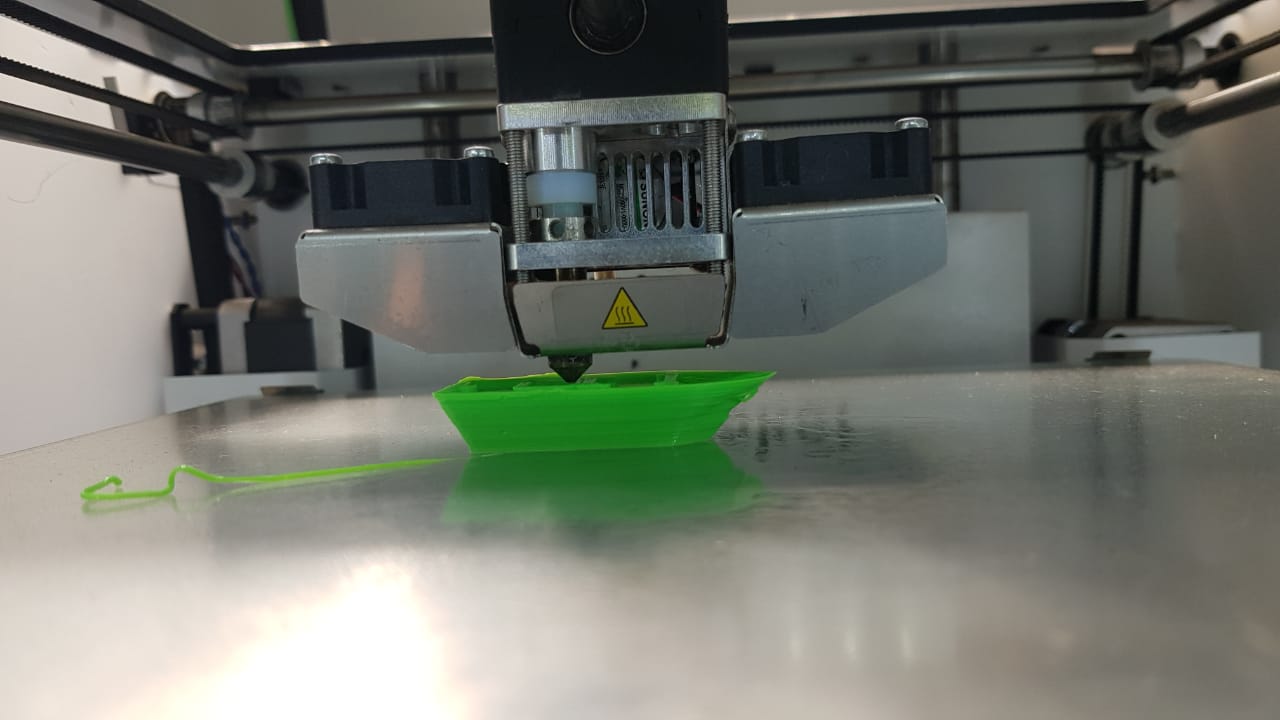

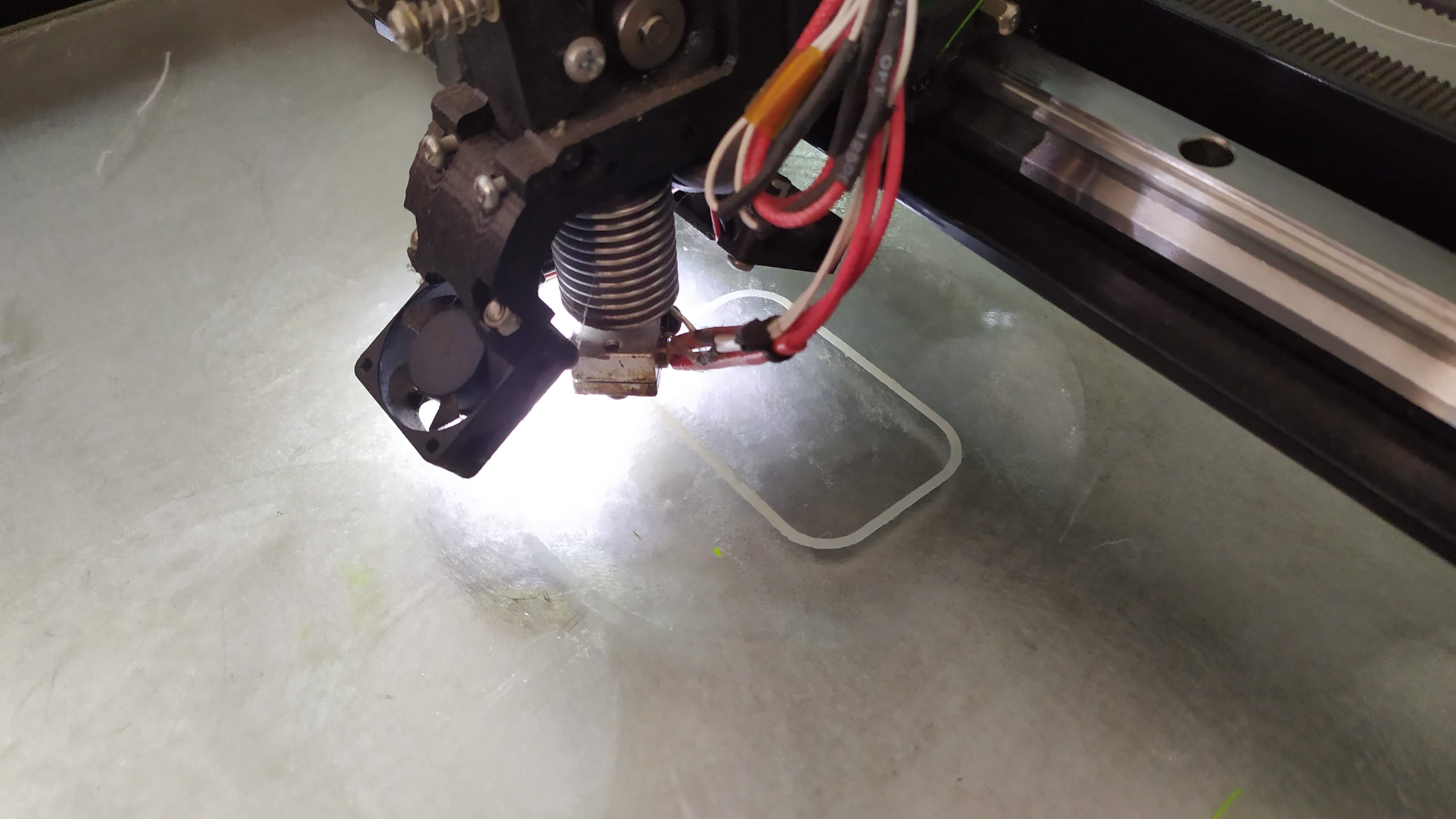

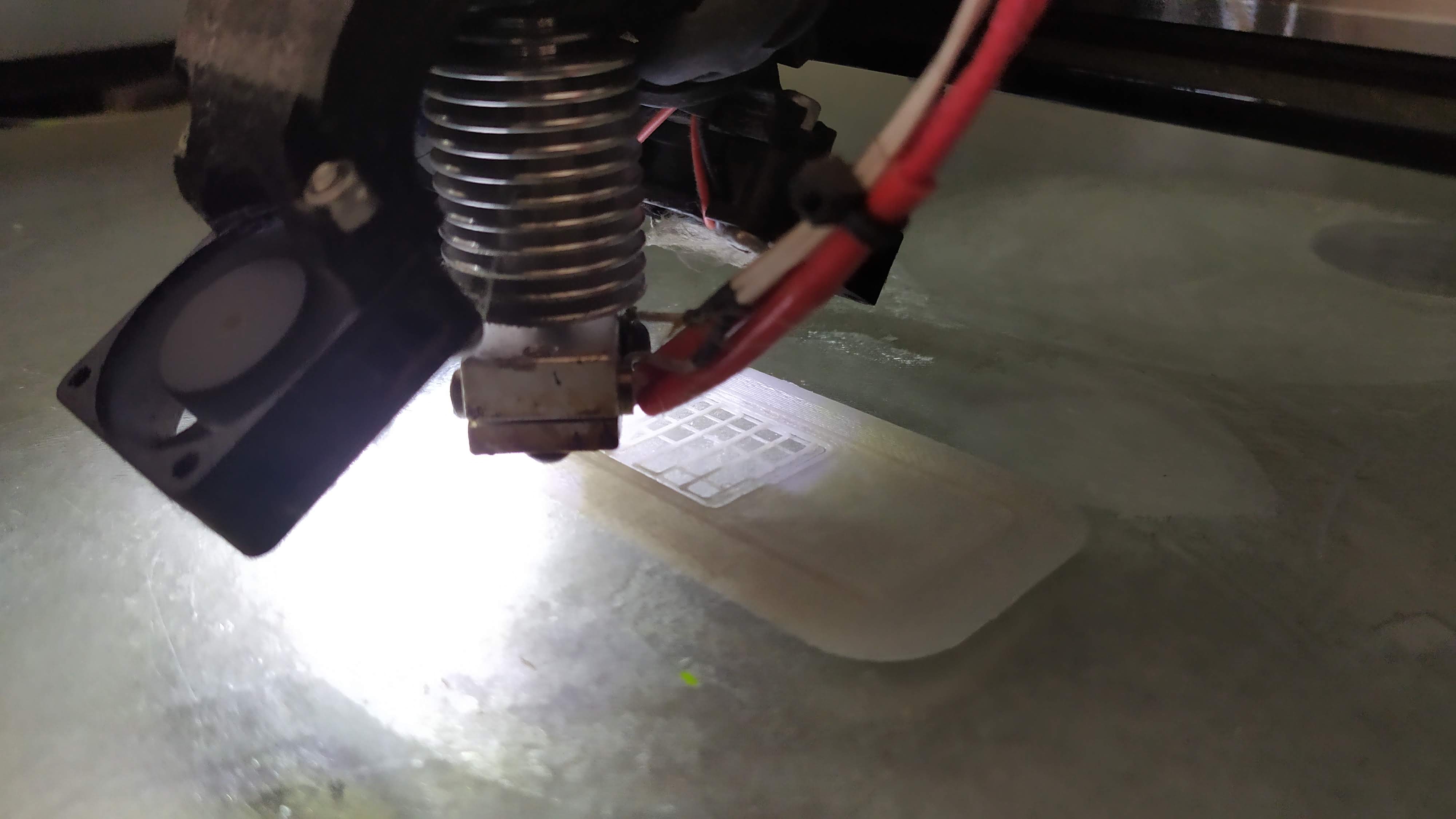

3D printer test: #3DBenchy

About #3DBenchy

#3DBenchy is a 3D model specifically designed for testing and benchmarking 3D printers. It is a small recognizable object that you can download for free, make and share.

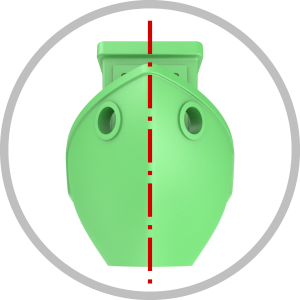

#3DBenchy is designed to offer a large array of challenging geometrical features for 3D printers, and touch on different issues related to additive manufacturing.

The 3D model is designed to print at 1:1 scale without support materials. It is challenging for most 3D printers but the small volume (15.55 cm3) typically prints in well under two hours and does not require much material.

The different surfaces of the #3DBenchy model reveal typical issues regarding surface finish, model accuracy, warping, etc.

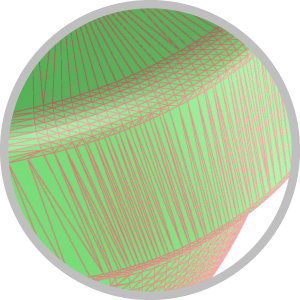

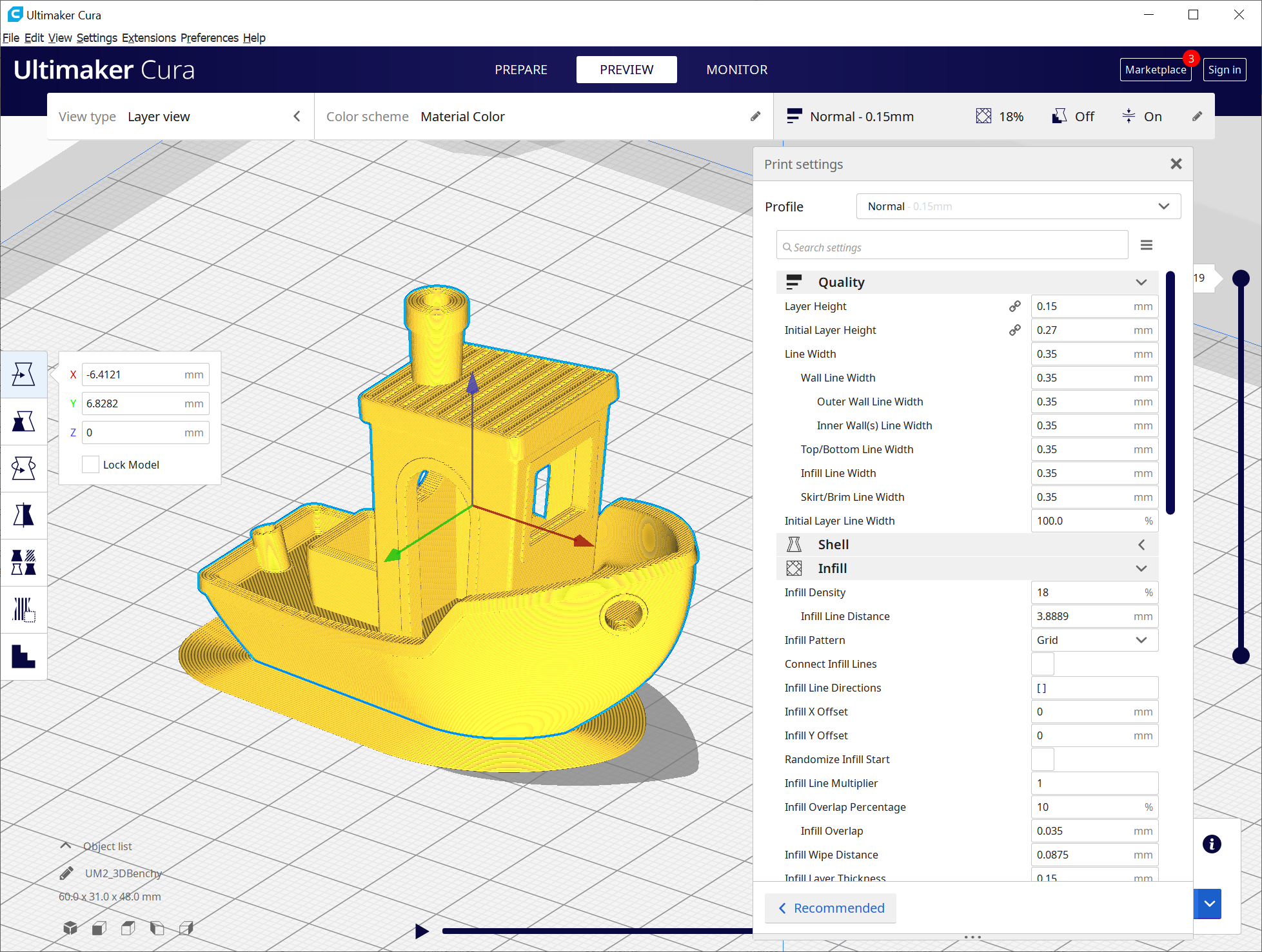

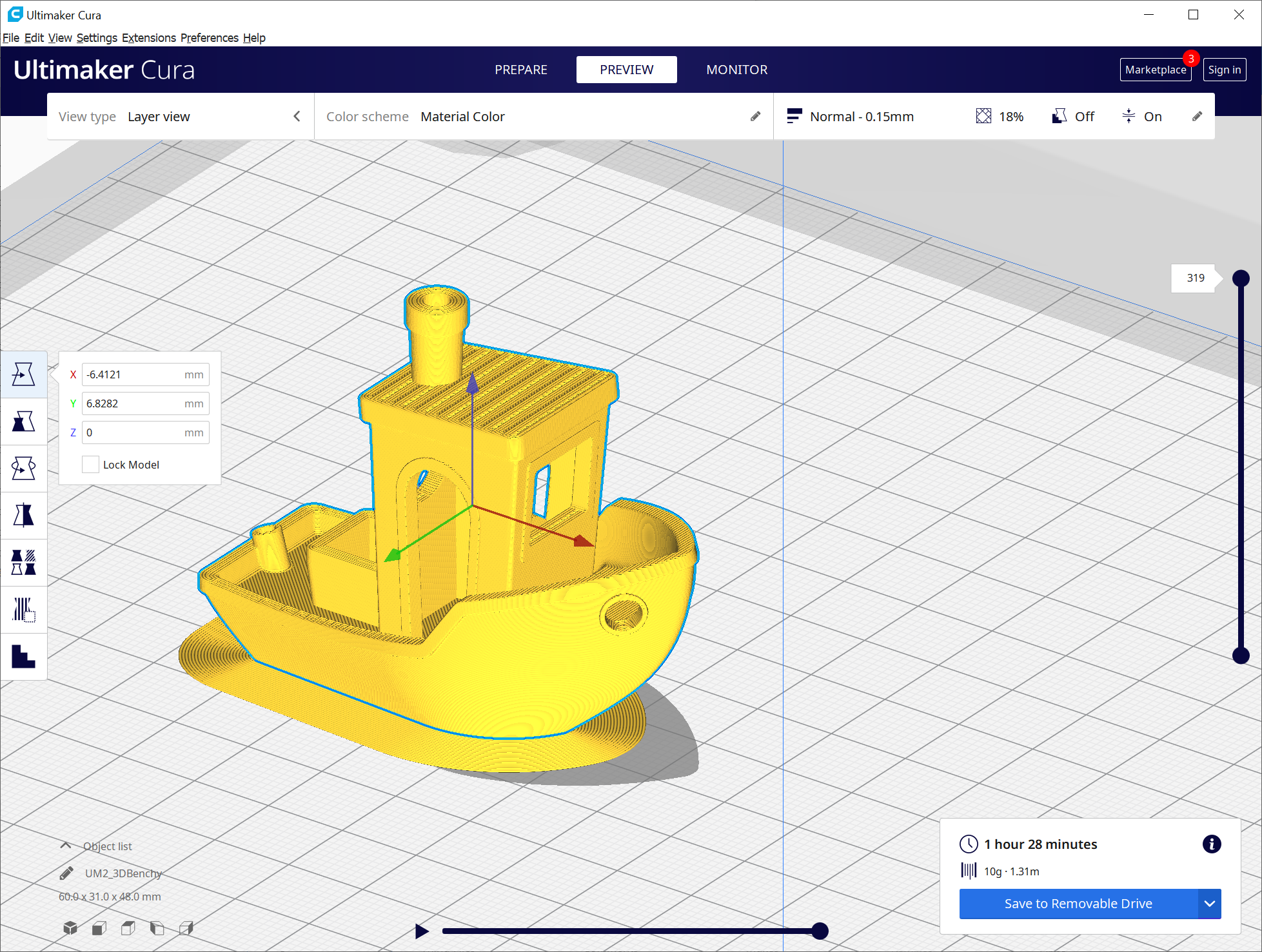

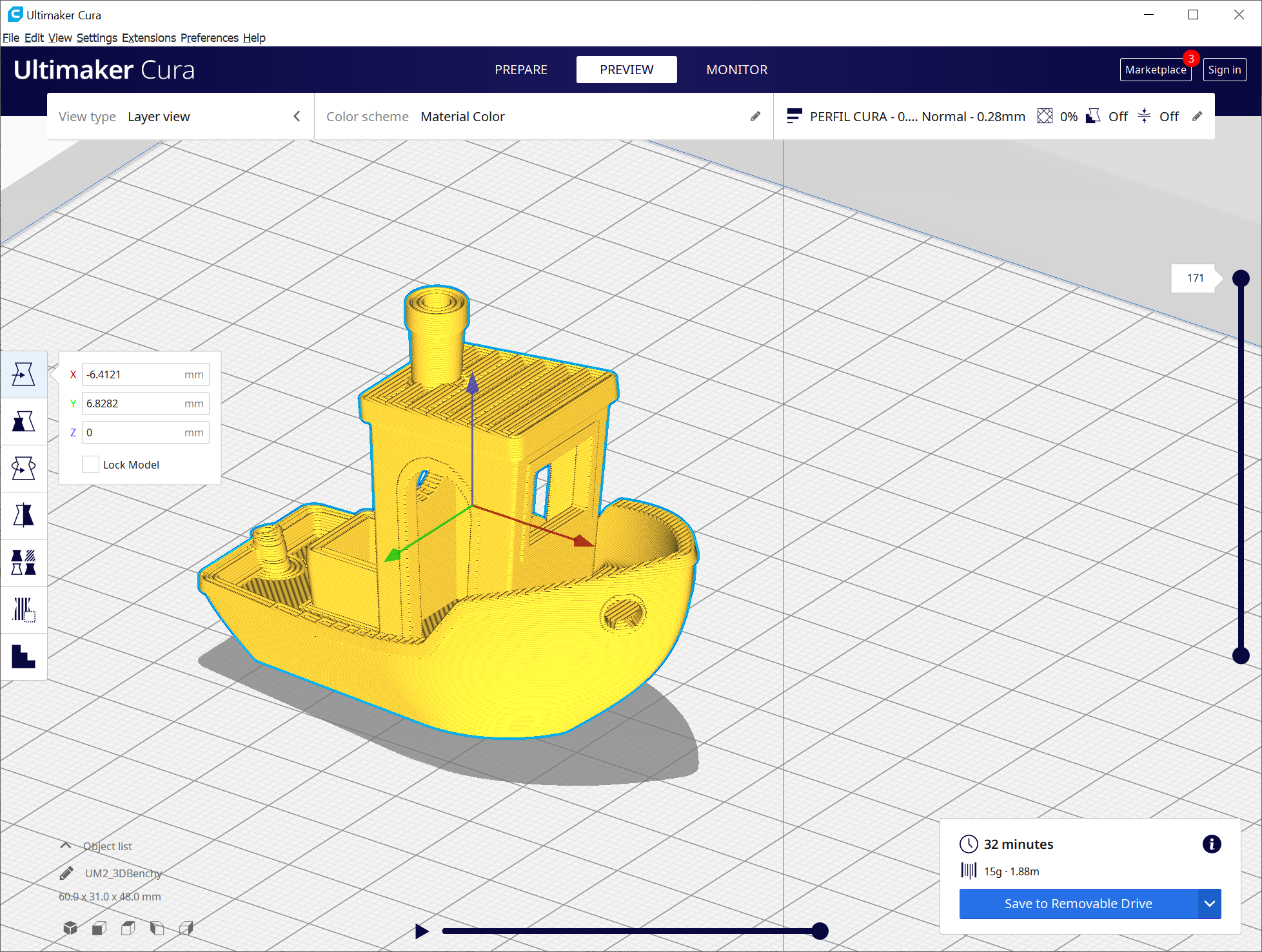

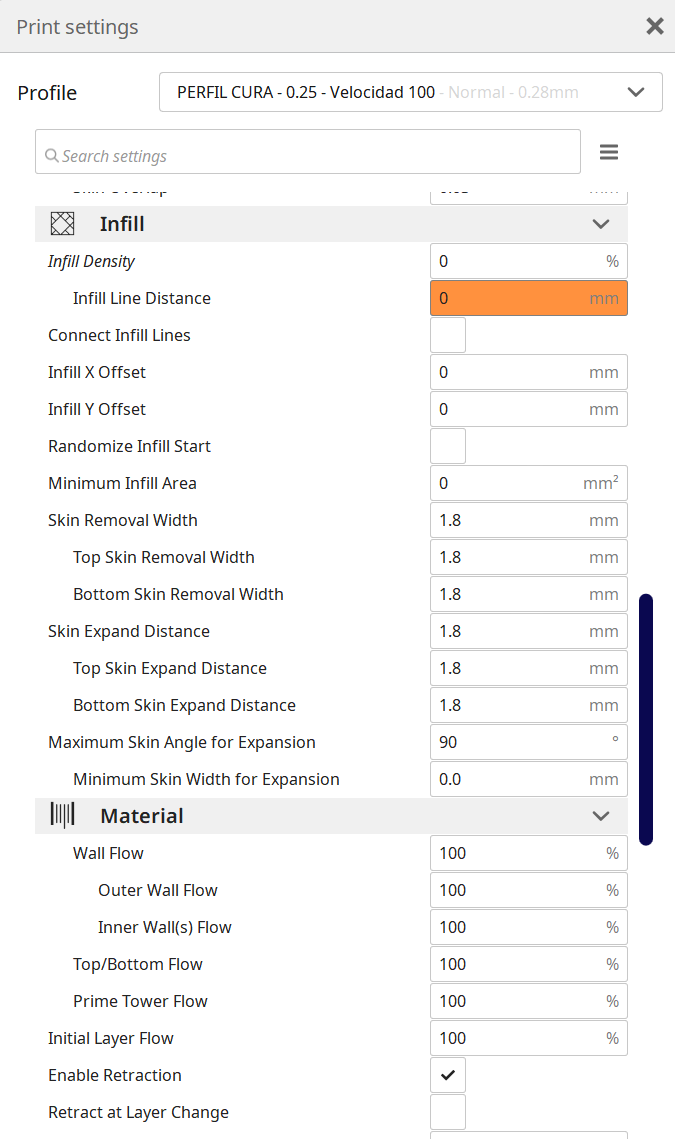

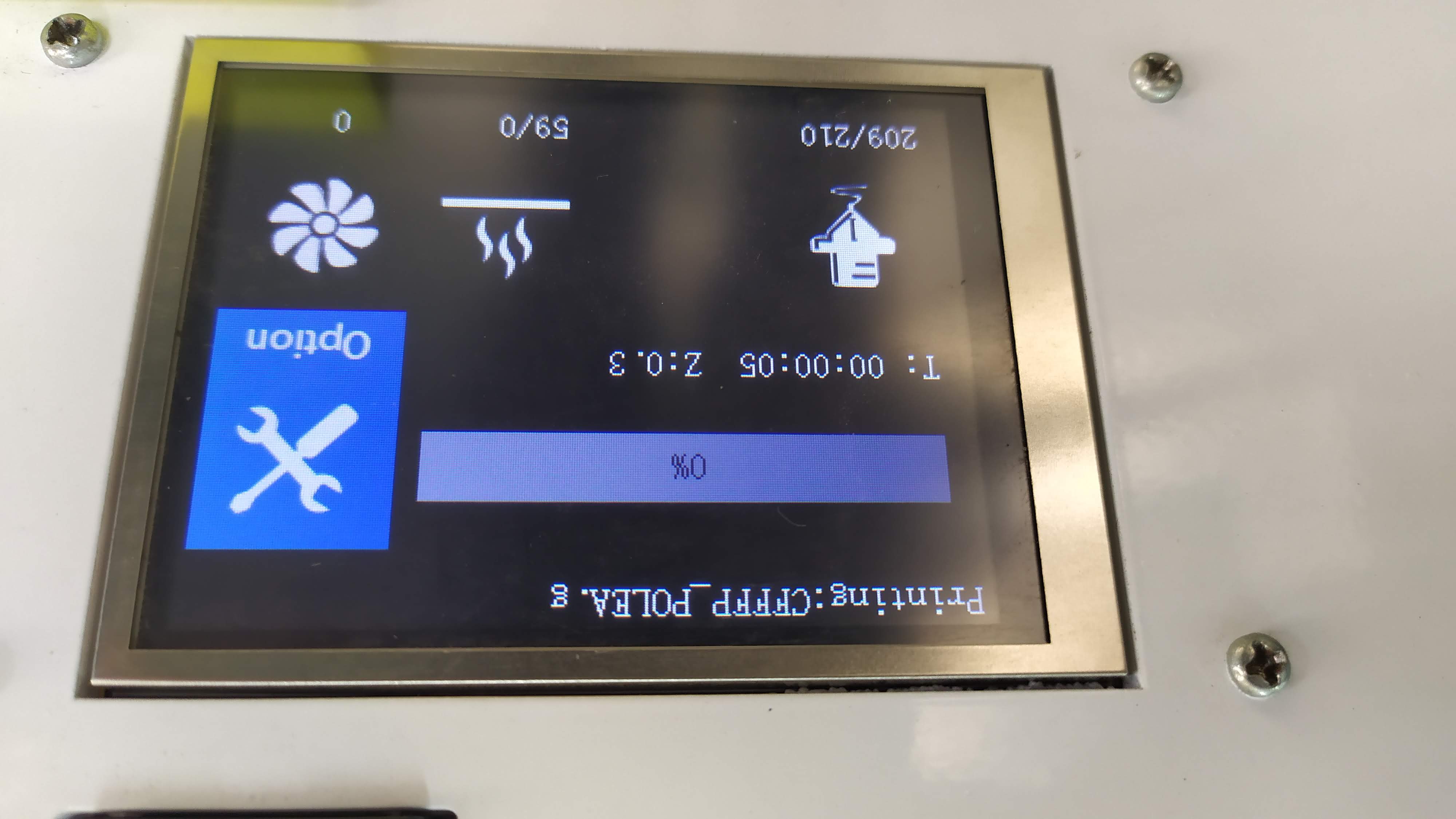

GCode for the printer using CURA

Cura is an open source slicing application for 3D printers. It was created by David Braam who was later employed by Ultimaker, a 3D printer manufacturing company, to maintain the software. Cura is available under LGPLv3 license. Cura was initially released under the open source Affero General Public License version 3, but on 28 September 2017 the license was changed to LGPLv3. This change allowed for more integration with third-party CAD applications. Development is hosted on GitHub. Ultimaker Cura is used by over one million users worldwide and handles 1.4 million print jobs per week. It is the preferred 3D printing software for Ultimaker 3D printers, but it can be used with other printers as well. https://en.wikipedia.org/wiki/Cura_(software) We start by testing the default CURA settings that are assigned to the Ultimaker 2+ printer. By testing the initial settings, we can review the print quality and then experiment by making some modifications to the values.

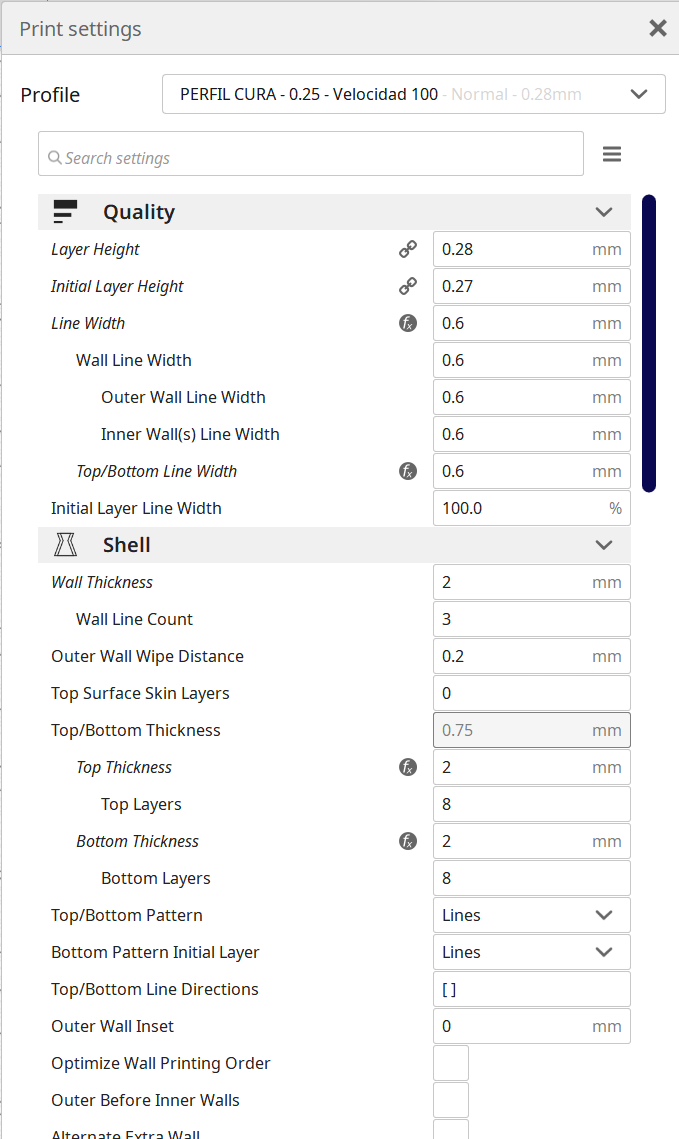

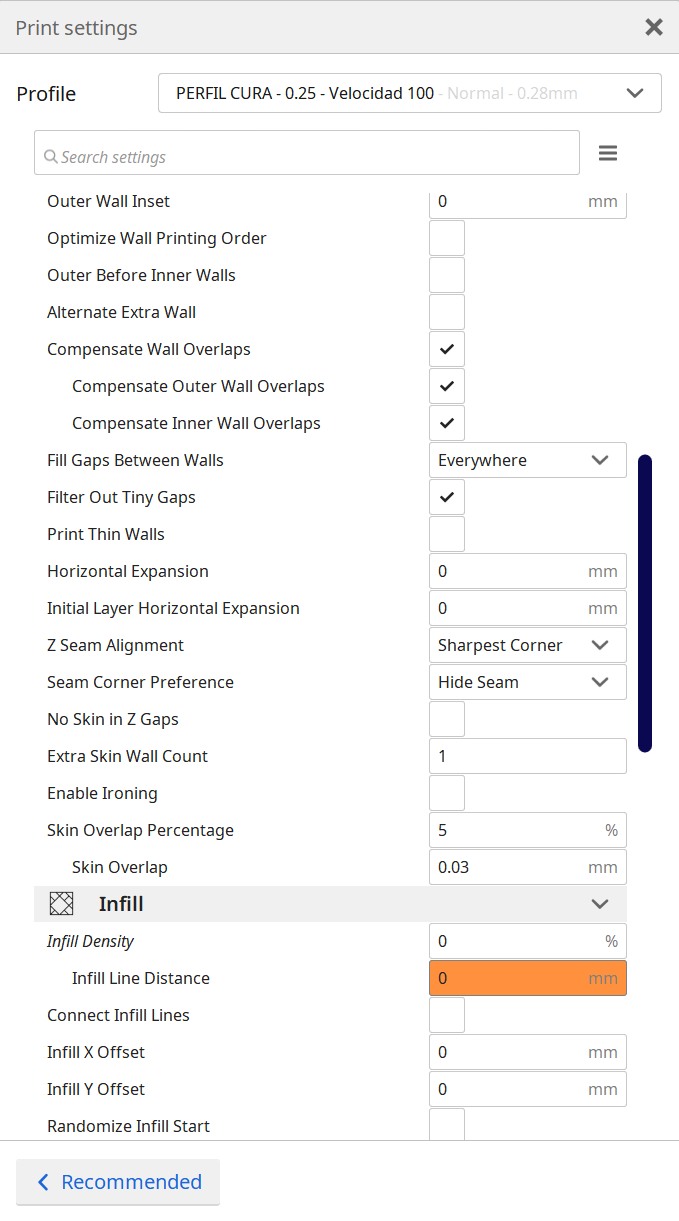

We start by testing the default CURA settings that are assigned to the Ultimaker 2+ printer. By testing the initial settings, we can review the print quality and then experiment by making some modifications to the values.

Changing thes values of the print settings: Changing speed and layers height

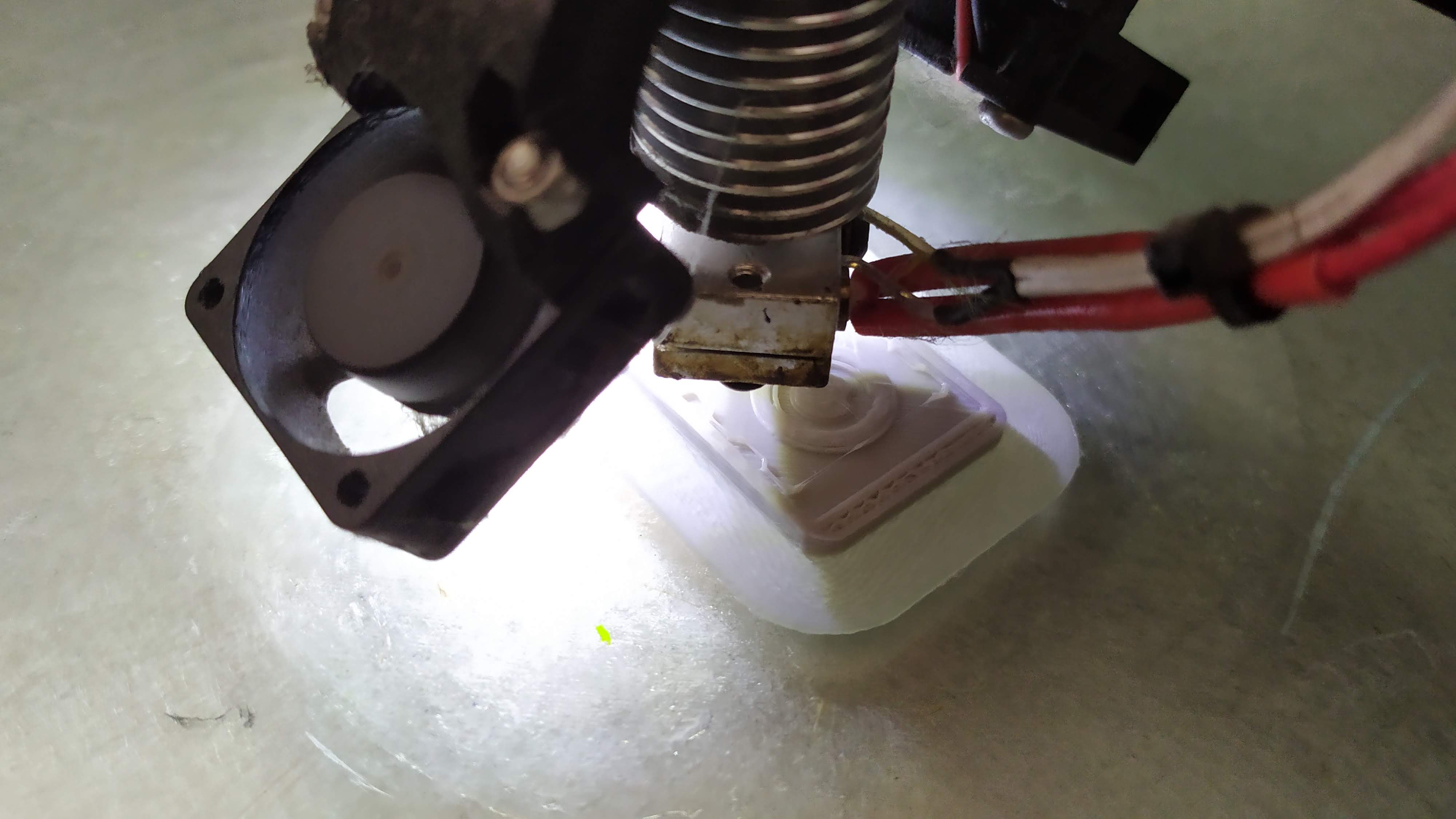

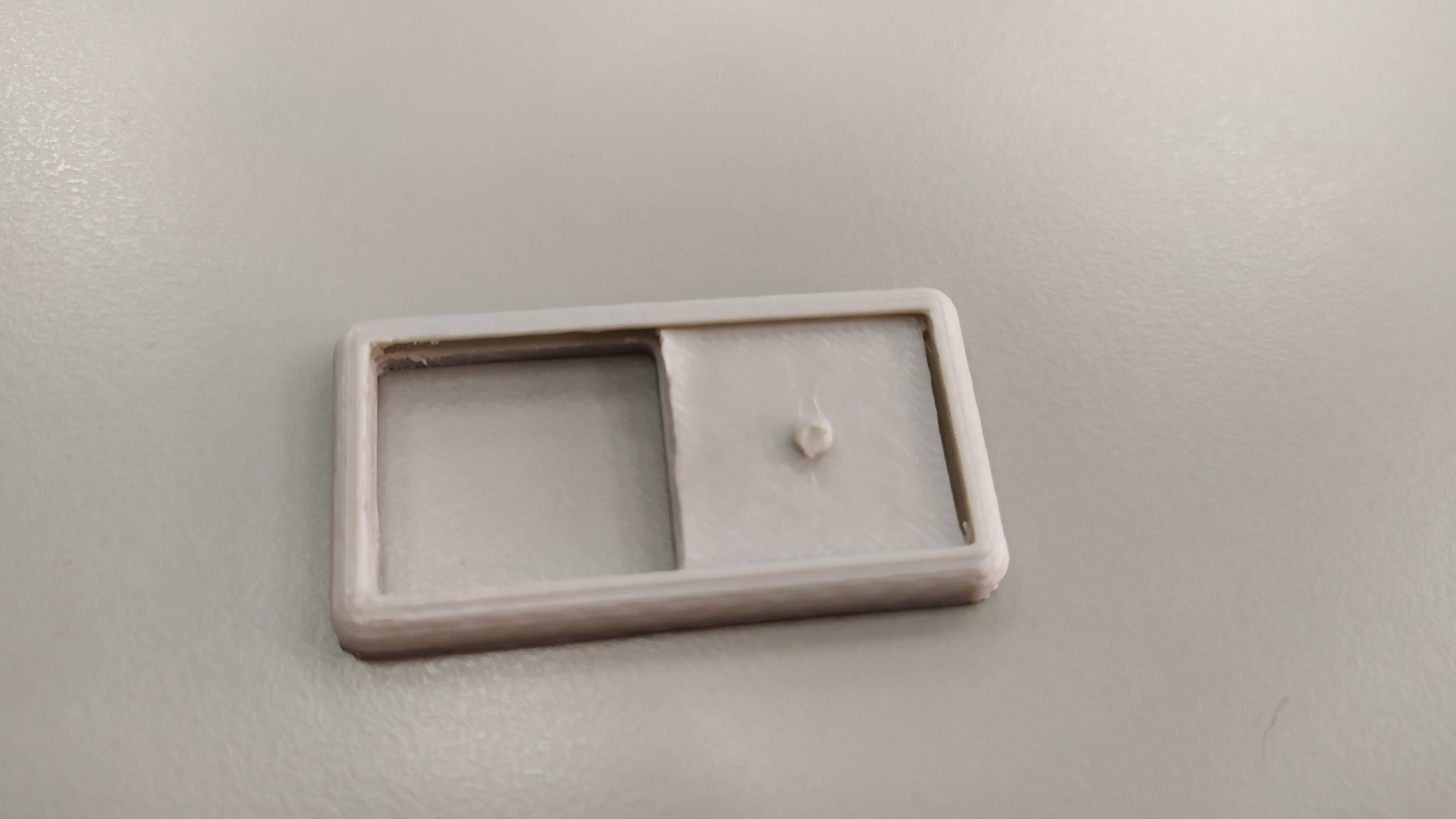

Camera security

Camera security

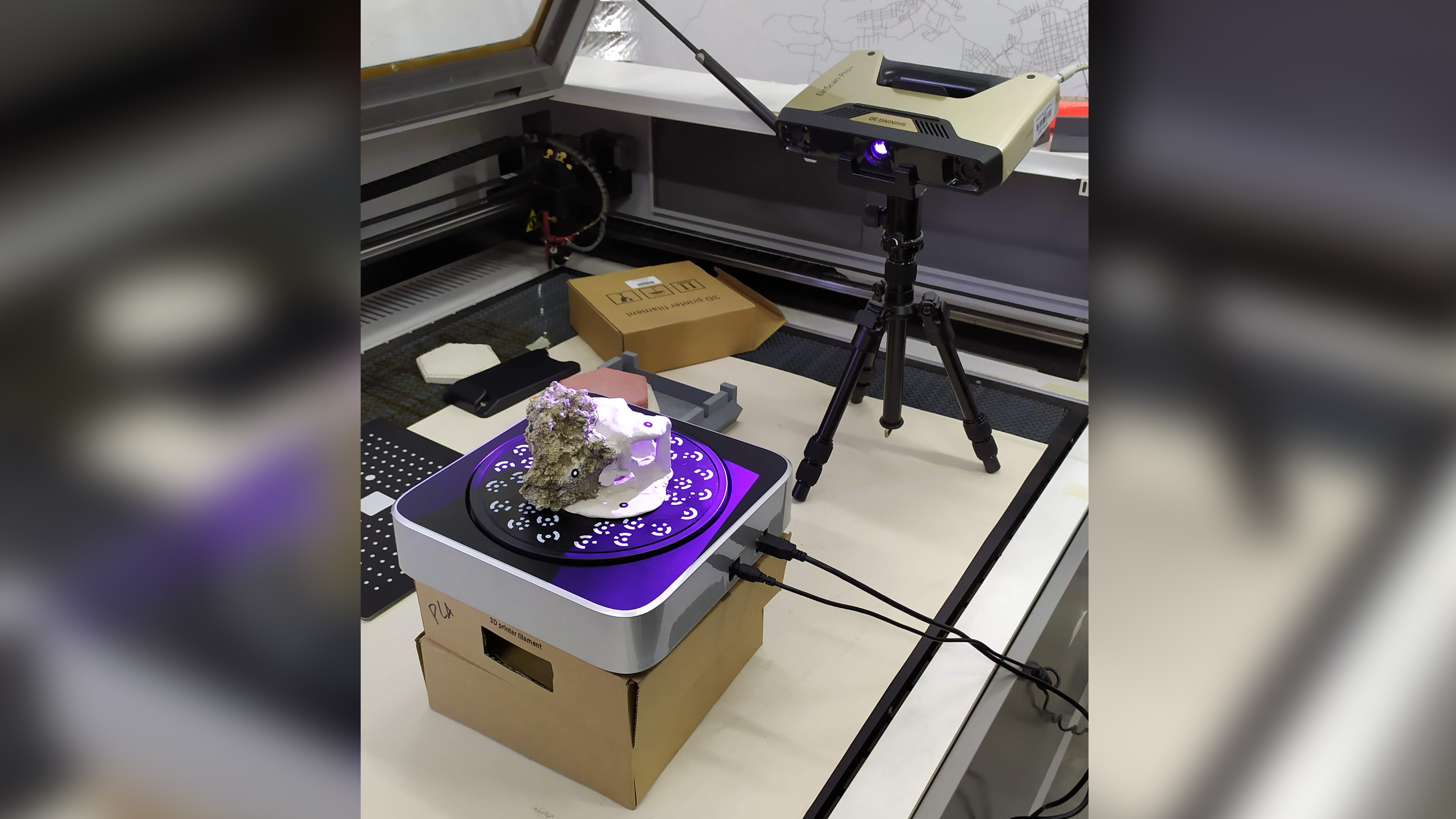

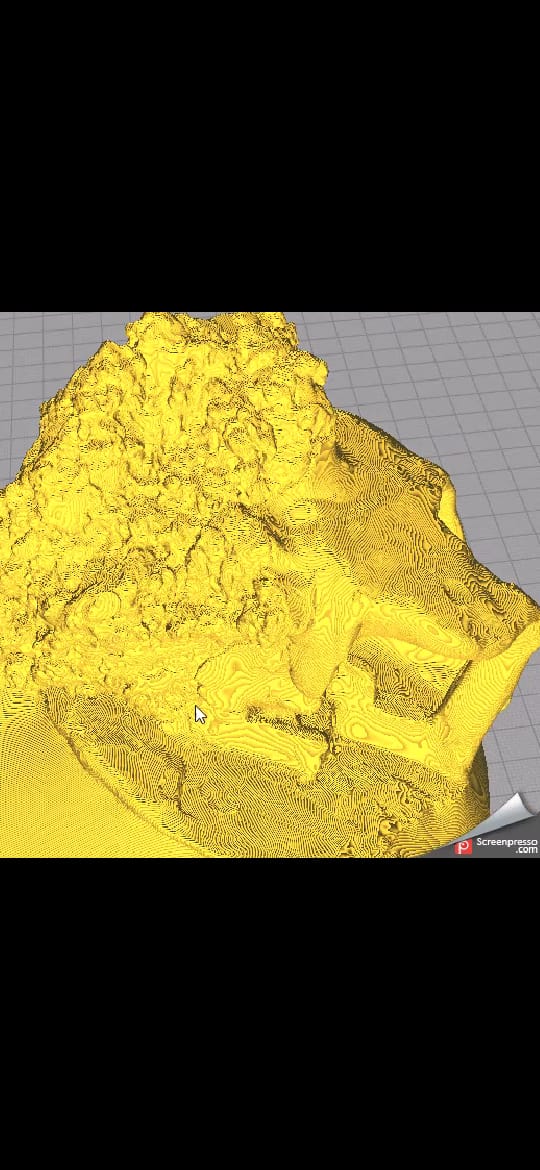

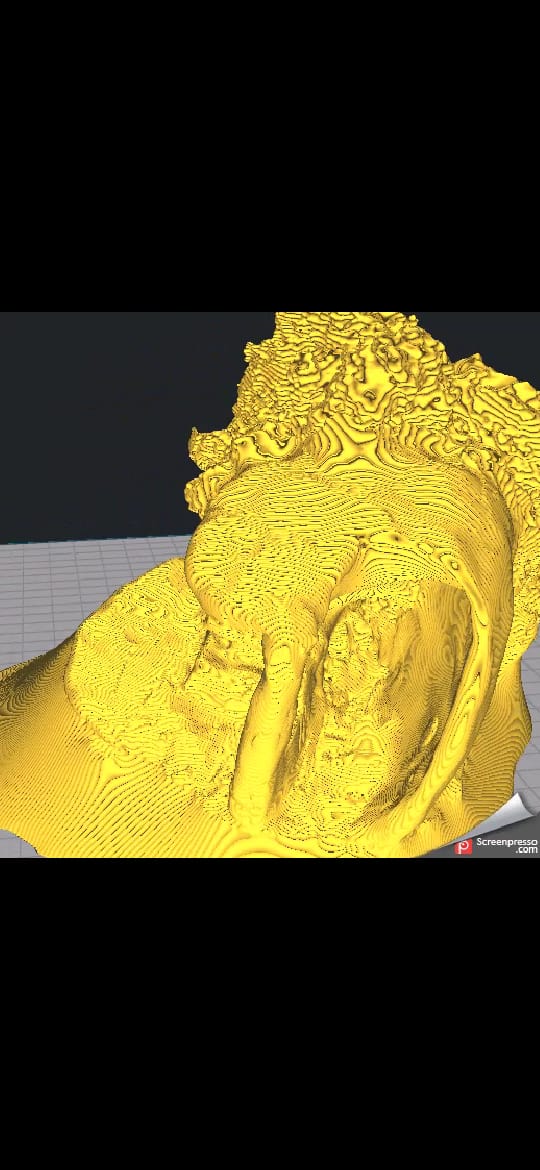

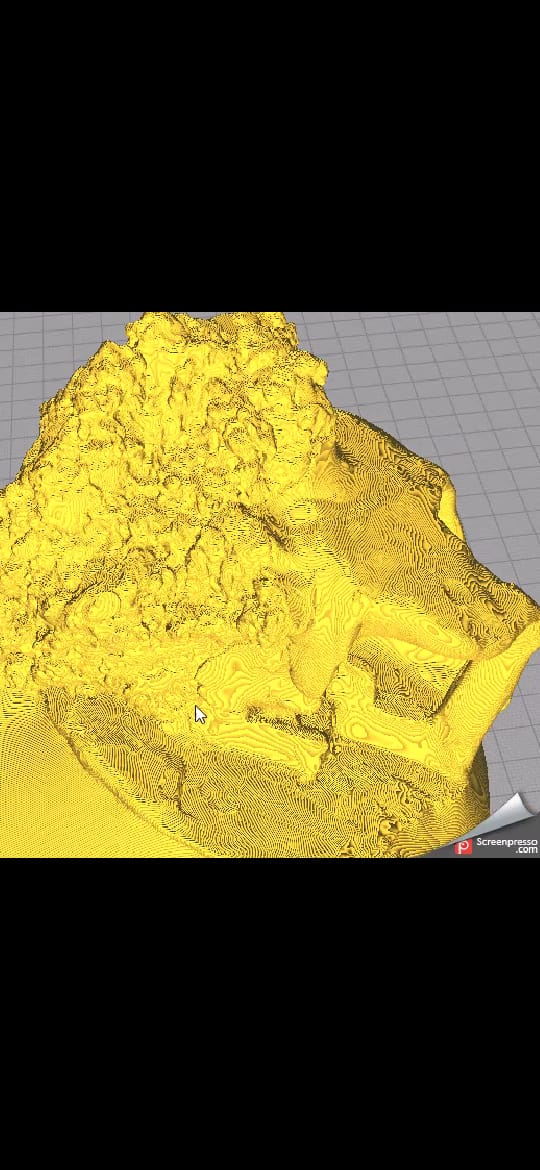

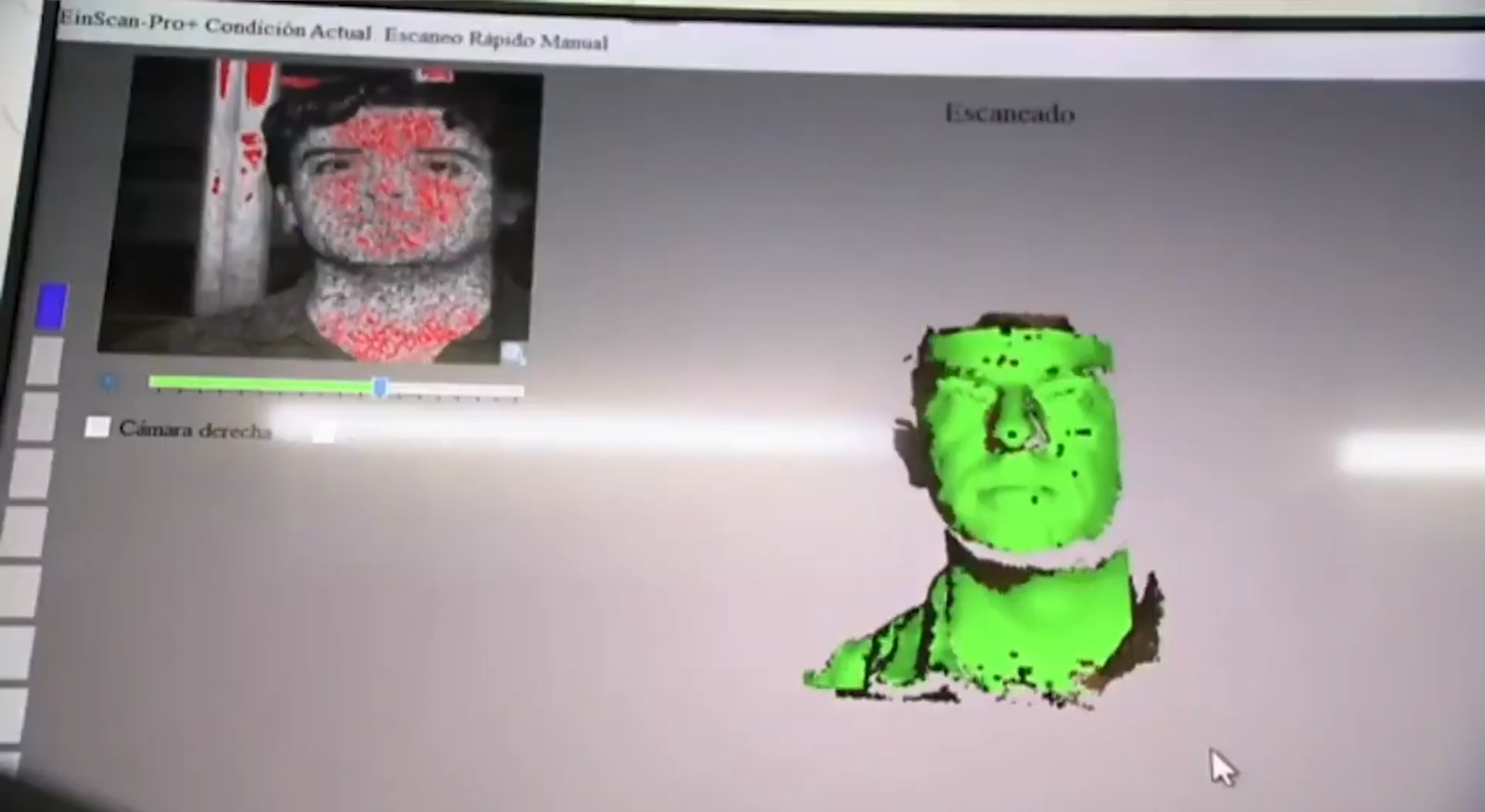

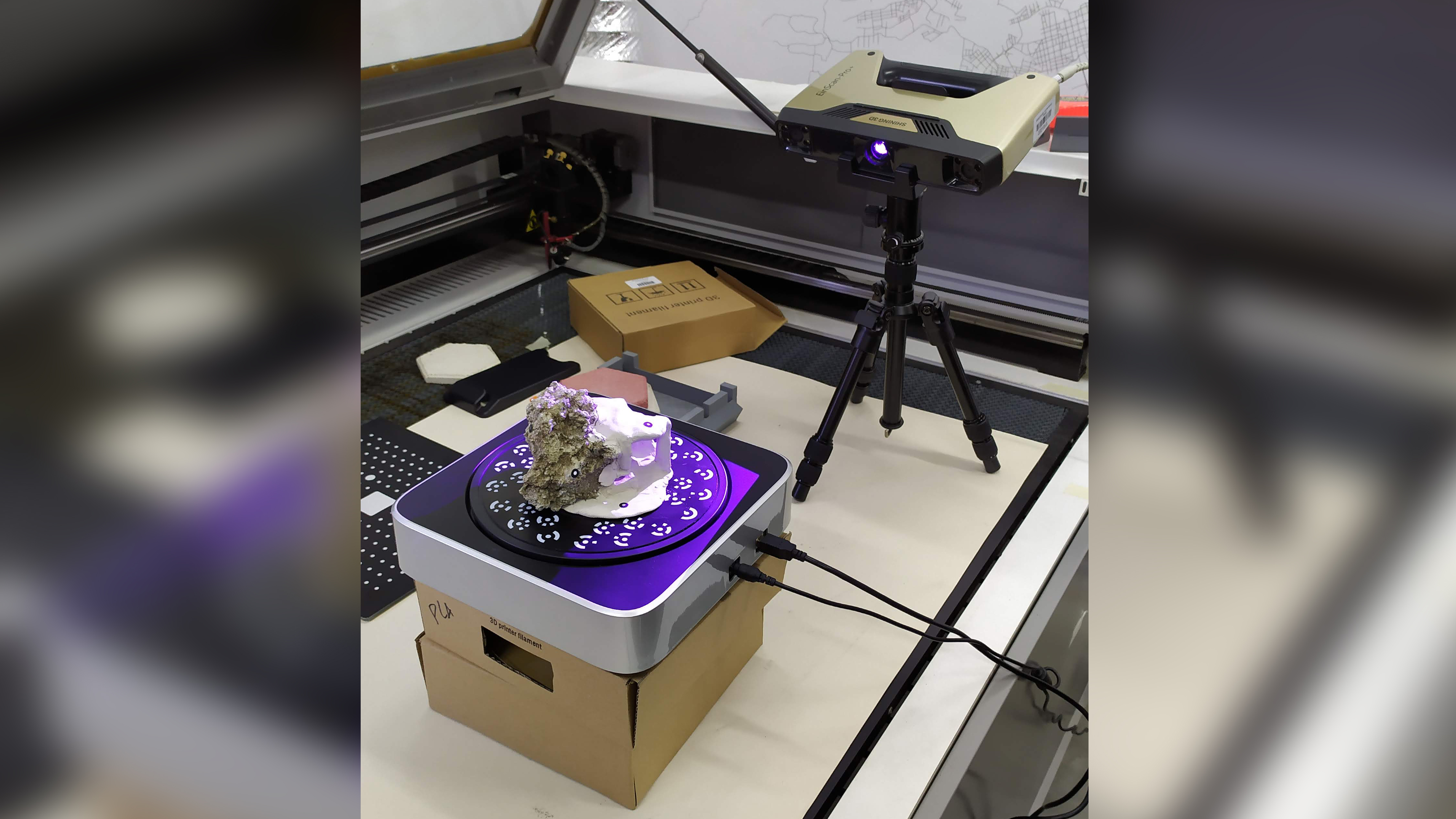

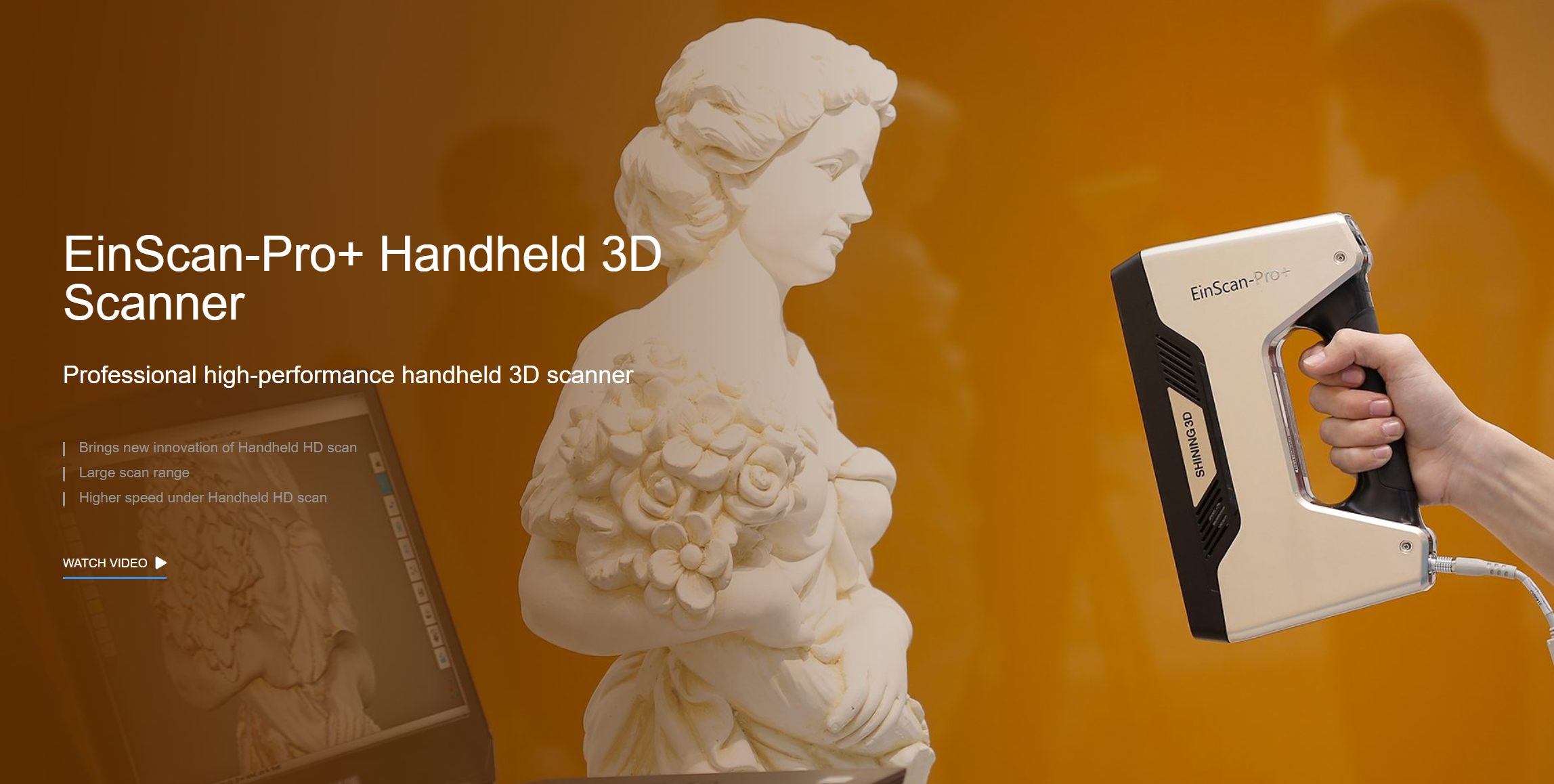

3D scanning: 3D Einscan Pro+

he EinScan-Pro+ is a portable 3D scanner designed by Shining 3D, a manufacturer based in China. The EinScan-Pro+ is the latest version of the EinScan-Pro and was introduced during the CES 2017. This professional handheld 3D scanner uses a white structured light 3D scanning technology, based on LED lighting. We do not recommended outdoor use as the sun affects the structured light, even under cloudy weather. In addition, the EinScan-Pro+ is delivered with the latest version of the EinScan software. This software includes an improved user experience, enhanced user-friendliness of the software interface, one-click data upload to the “Sketchfab” platform, and streamlined process to share scanned 3D data directly over the Internet. EinScan v2.5 also includes multiple new and upgraded functions for a more efficient 3D scanning process.

Specs

Single Shot Accuracy: 0.1mm

Scan Speed: 550,000 points/sec

Point Distance: 0.2 – 3 mm

Texture Scan: No

Align Mode: Markers Alignment

3D scanning test