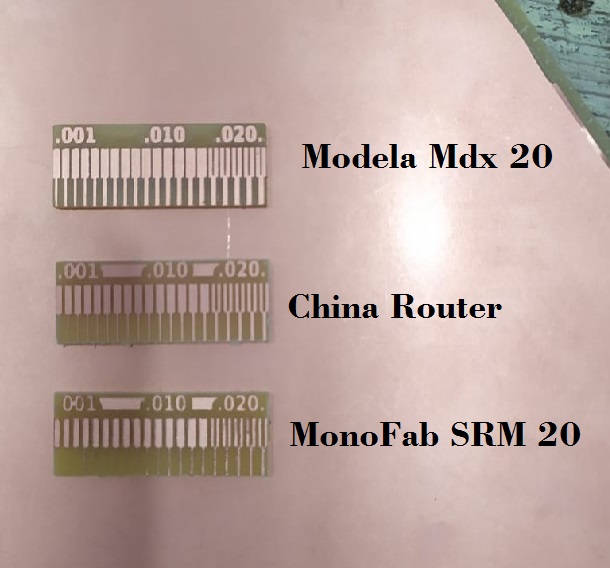

This assignment is about characterizing the milling machine's clearance and minimum trace width. This document outlines the processes we made during the group assignment on Roland MDX-20. The students contributed to the group assignment by making the same test on the other machines like SRM-20 and another chinese milling machine.

Preparation and machine setup

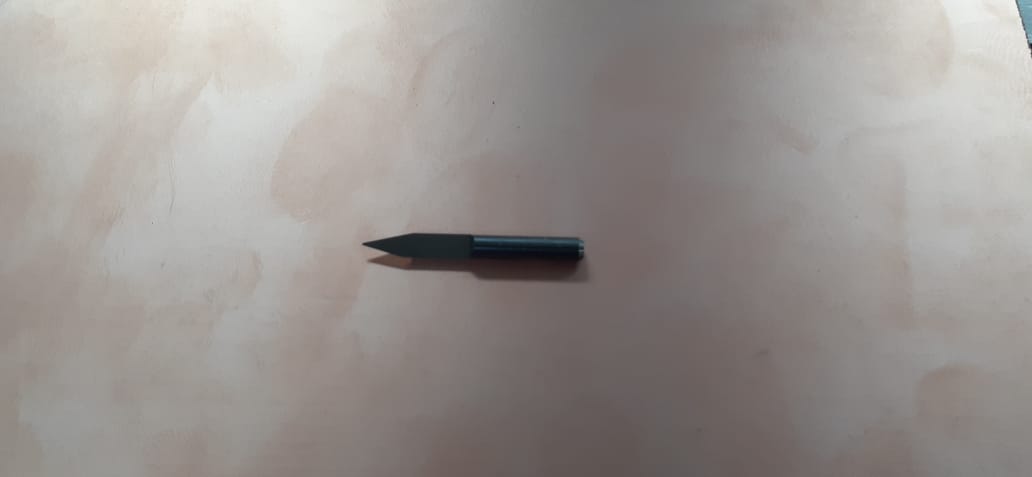

We want to characterize the machine using this V bit

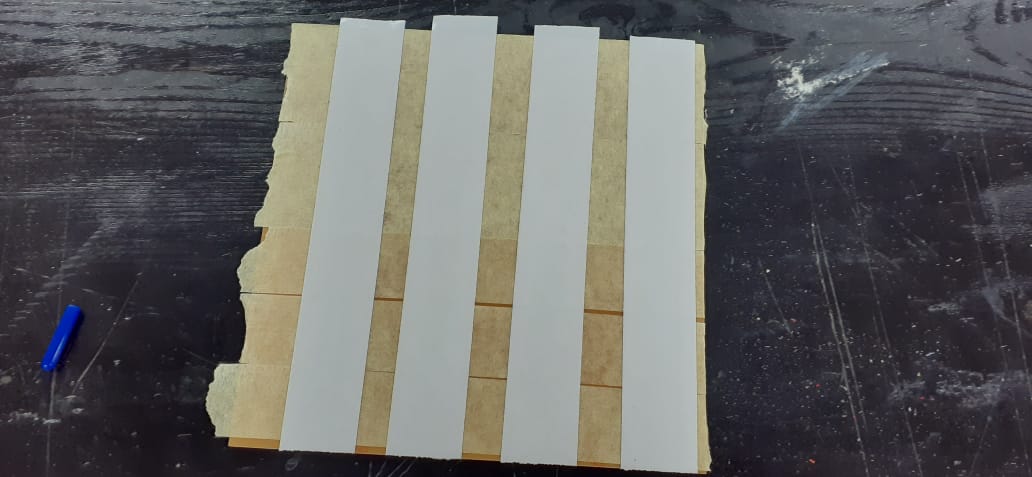

Then we prepared the copper sheet by adding two layers of tape, one layer masking tape and the the other layer is the double side tape to fix the copper to the sacrificial layer.

As shown in the image below; the back of the copper tape after appling two layers of tape

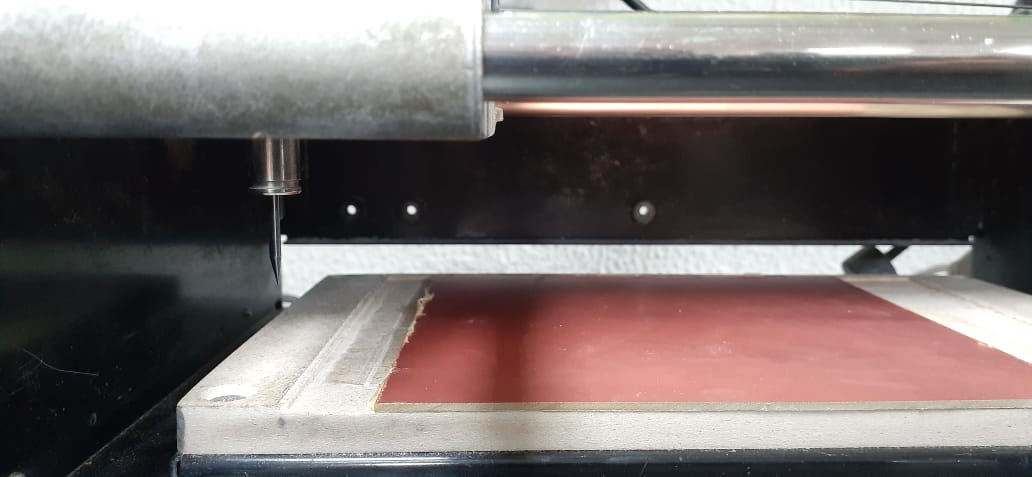

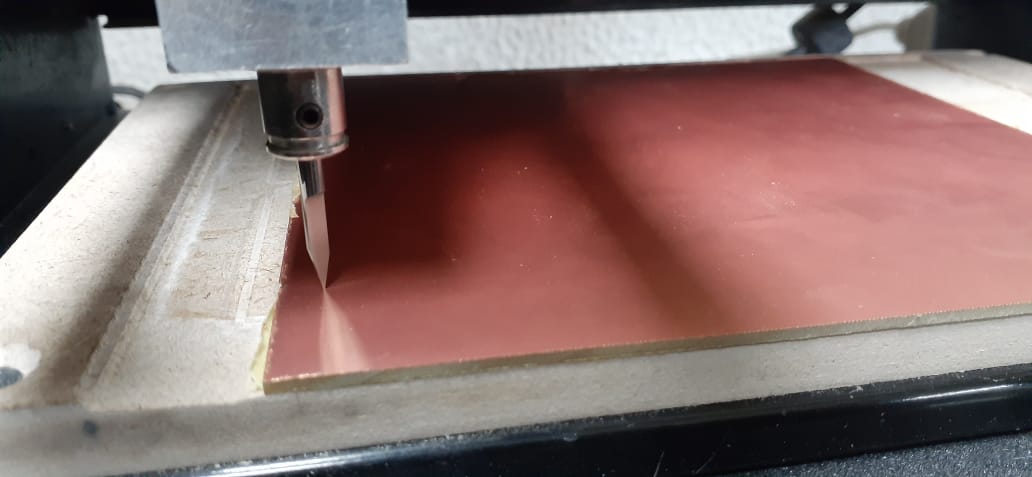

Then we fix the copper to a sacrificial layer of wood fixed on the machine. As shown in the image below.

Then we setup the xyz origin point on the surface of the copper.

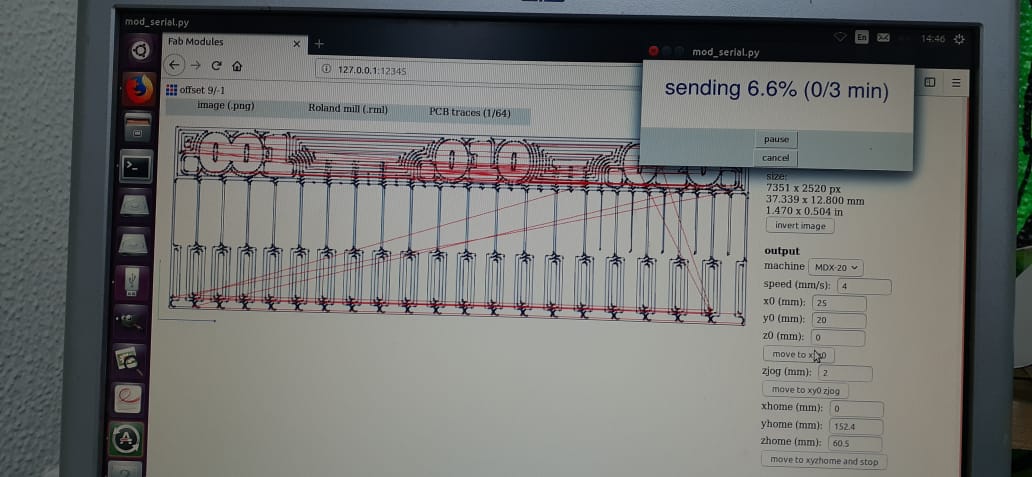

Toolpath generation and machining

We downloaded the test files from the class page and used fab modules to generate the toolpath and send it to the machine.

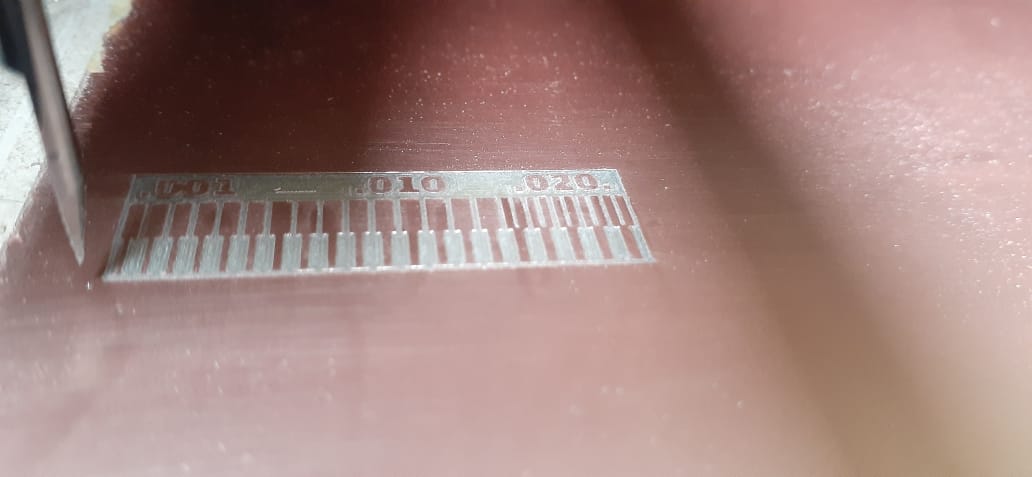

Here is the output after the milling process

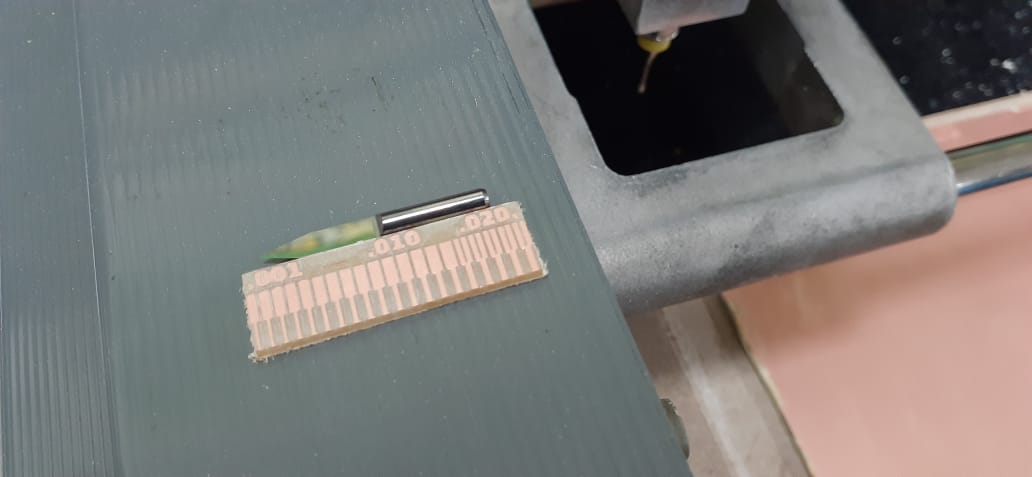

Then we cut the board using 1/32" endmil. The image below shows the final output and the v bit which was used in the test.

Students contribution

The students performed the same test on other machines in the lab like the SRM-20 and another chineese machine.