The function of air quality management is checking emissions. The control - technology or control measurements describe the apparatus, processes which reduce air pollution. The emission reduction depends on the technology or process. In general the technologies or processes which reduce the pollution the best are placed in areas with the largest pollution. The choice of the control technology depends on the environment, technique, economic factors and the type of pollutant. There are 2 types of emissions, i.e. particulate emissions and gaseous emissions. For these 2 types of emissions there are also 2 types of emission-reduction techniques, i.e. particulate-purification techniques and gas purification techniques.

Particulate purification techniques concentrate on catching the particles which are transmitted by a pollution source. There are several factors that play a role at selecting a purification technique. The characteristics of the particles in the exhaust flow influence the choice of purification technique. These characteristics are the particle size, flow of the exhaust flow, the temperature, the humidity, and several chemical properties such as explosion limits, acidity, alkalinity, and combustibility.

Following techniques are applied at purifying particles from a polluted air flow:

● Sedimentation chamber (Gravity separator)

● Cyclone separator

● Rotating scrubber

● Venturi scrubber

● Spray chamber

● Dry electro filte

r

● Wet electro filter

● Cloth filter

● Ceramic filter

● Absolute filter

● Demister

The methods for controlling gaseous pollutants is the use of techniques to recover or destroy polluting substances. There are 4 commonly used technologies for gaseous pollutants: absorption, adsorption, condensation, and combustion (flare). The choice of technology depends on the pollutants that must be removed, purification efficiency, the characteristics of the polluted gas flow, and specific characteristics of the place. Absorption, adsorption, and condensation are recovery techniques whereas combustion implies the destruction of the pollutant.

Following techniques apply at purifying pollutants from the air flow:

● Condensation

● Cryocondensation

● Regenerative adsorption (active carbon, zeolite, polymer adsorption)

● Dry and semi-dry lime absorption

● Gas scrubbing (acid, alkaline scrubber, wet lime scrubbing, basic oxidizing scrubbing, biofilter, biotrickling filter and water scrubber)

● Thermic combustion (Recuperative, regenerative thermal oxidation)

● Catalytic combustion (Recuperative, regenerative catalytic oxidation)

● Flaring

● Foto-oxidation

● Ionization

● Selective non catalytic reduction (SNCR)

● Selective catalytic reduction (SCR)

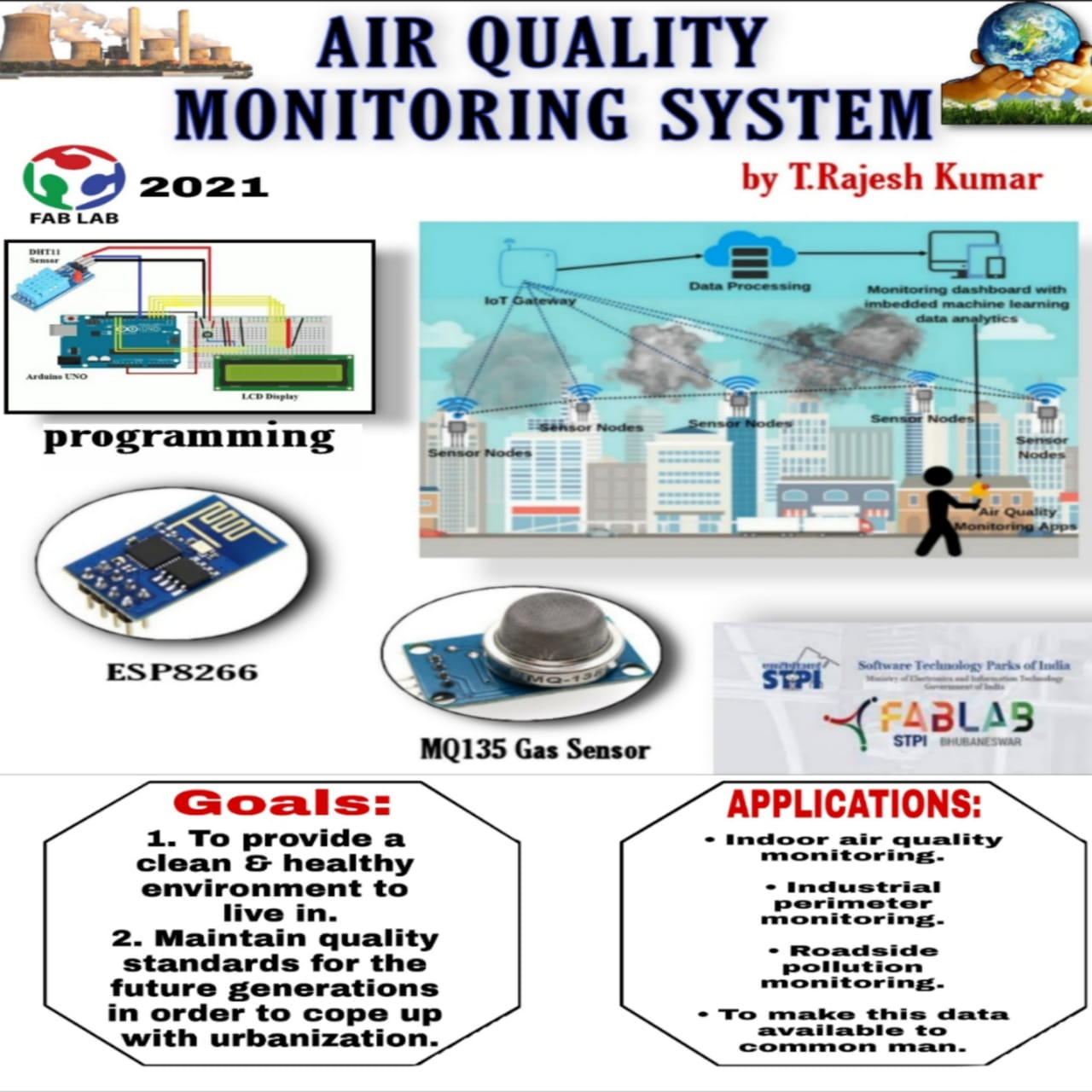

1. To Provide a clean & healthy environment to live in. 2. Maintain quality Standards for the future generations in order to cope up with urbanization.

Activated carbon has special properties that allow it to remove volatile organic compounds (VOCs), odors, and other gaseous pollutants from the air. It accomplishes this in a way that is different from other air purifiers like HEPA that only filter particle pollution from the air. Carbon air filters trap gas molecules on a bed of charcoal, a process that has a surprisingly colorful history. Here you will dive deep into how they work. Then you can consider if using a carbon air filter will meet your needs by examining its advantages and drawbacks.

Carbon air filters are the filters most commonly used to remove gases. They are designed to filter gases through a bed of activated carbon (also called activated charcoal) and are usually used to combat volatile organic compounds (VOCs) released from common household products. They are also often used to remove odors from the air, such as the smell of tobacco smoke. They cannot remove fine particles like mold, dust, or pollen from the air.

Humans have been using charcoal to purify water–sometimes accidentally–for thousands of years. First, what is charcoal or carbon? These interchangeable terms refer to the remnants of incomplete combustion. Picture the charred piece of wood that is left over after a campfire. Only the readily combustible material in the wood has burned away, either because of insufficient heat or poor supply of oxygen. The black char that remains is mostly carbon. The industrial process of making charcoal accomplishes it by heating a substance in a vacuum chamber, which releases all the volatile compounds and leaves behind all the carbon. Wood is commonly used to make charcoal, but coconut shells and coal are also used. Each substance creates a slightly different kind of charcoal. How is carbon activated? Activated carbon is carbon that has undergone some additional processing to make it better at trapping gas molecules. First, it is injected with hot air, carbon dioxide, or steam, which creates a lattice of tiny pores in the carbon, vastly increasing its surface area. This creates many more places for molecules to become trapped and makes the carbon far more effective as a filter medium. A paper by the Ohio Environmental Protection Agency notes that a single gram of activated carbon can have hundreds of square meters of internal surface area. Most activated carbon is also treated with a chemical that enhances its ability to filter specific pollutants. The colorful history of using carbon filtration. How did humans figure out that carbon can be effective at filtering contaminants? It is likely the earliest use was to remove impurities in smelted metal for the manufacture of bronze. The Egyptians appear to have been the first to use it in a medical way, to remove odors associated with infections. We know that sailors in the 16th through 18th centuries often stored their drinking water in barrels that had either been charred or smeared with charcoal on the inside to keep the water fresh on long voyages. In World War I, gas masks utilized charcoal to filter out some of the deadly gases used against the troops, but it was only effective against some of the toxins. The production and use of activated carbon grew dramatically only after World War II, eventually leading to the development of modern activated carbon air and water filters.

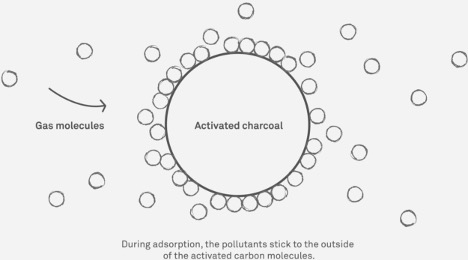

Carbon air filters remove pollutants from the air with a process known as adsorption. Note that this is different from absorption. In absorption, the substance you want to remove (let’s say water) is absorbed into the structure of the absorbent (like a sponge), but it doesn’t become a part of the absorbent on a molecular level. Therefore, when you absorb water with a sponge, the water does not become chemically bonded to the sponge. It just fills in the spaces inside it. Carbon filters on the other hand use ad-sorption, not ab-sorption. The key difference here is that during adsorption the pollutants stick to the outside of the carbon. Whereas with absorption, the pollutants are absorbed inside the structure itself–as with the sponge. Carbon is a lattice of carbon atoms connected to each other. The activation process is so important because the increase in surface area gives gases a greater area to stick to. When a molecule of some gaseous substance comes through the carbon, it can stick to the surface of the bed, provided there is an open adsorption site. The process of adsorption allows carbon air filters to filter organic chemicals (gases) from the air. The problem with the activated carbon bed is that over time, the gaseous pollutants increasingly fill up the adsorption sites of the activated carbon. Once the bed is saturated, the filter can no longer trap pollutants. In fact, chemicals with a greater affinity for an adsorption site can displace those with lesser affinity, and the affinity of a given chemical for the sorbent is highly dependent on ambient conditions such as temperature and relative humidity. So, as conditions change, different chemicals may be released from the filter. When a carbon air filter is saturated, you might notice it giving off a strange odor. This is a strong indicator that it’s time to change your carbon filter.

Carbon air filters can be an important part of your home air purification system, but they have to be used correctly. ● Make sure it uses enough carbon. Some filters claim to be activated carbon filters, but they use only a trace of carbon. These will not be effective because they become saturated almost immediately. A rough guideline is that a good activated carbon air filter uses at least five pounds of carbon–of course, not all carbon is created equal, and some may have more binding sites (and saturation capacity) than others. But, generally speaking, the more carbon used, the more effective it can be because there will be more sorption sites to stick to. ● Air flow is vital. To remove the most pollutants possible from the air, the air needs to spend the maximum possible amount of time passing through the carbon. In the air filter industry, this is known as “dwell time.” A filter with a good amount of carbon of sufficient thickness and high dwell time is going to be far more effective than a filter with a thin layer of carbon. ● Change your carbon filter. Once the carbon becomes saturated, it loses all effectiveness as an air filter. It is imperative that you change it out for a fresh carbon filter when this happens. The problem is that there is not a perfect method of knowing when carbon is saturated. Sometimes you will notice the smell; sometimes you will not. You can follow the manufacturer’s guidelines and change it on a regular basis, although this is just a rough estimate. The carbon becomes saturated depending on how heavily it is used and the amount of pollutants it is exposed to. Replacing carbon filters is a costly investment, but a monthly replacement schedule is a good starting point. Please note that according to the EPA, gas-phase filters, like activated carbon, cannot readily remove carbon monoxide, and employing other important steps, like having a carbon monoxide detector, must be used to prevent exposure. Now that you know how to use a carbon filter well, the next step is to learn which situations it can be effectively used for.

Activated carbon air filters can be helpful in a few areas. ● Volatile Organic Compounds (VOCs). Carbon air filters can be effective at filtering VOCs from the air. These are gaseous substances that most other mechanical filters like HEPA filters, cannot touch. Some of the gases in cigarette smoke or those given off by drying paint or cleaning products can be removed from the air by a carbon filter. Benzene, toluene, xylene, and some chlorinated compounds are among those that may be removed by carbon filters. ● Odors. Mechanical air purifiers that can only filter particles cannot remove unpleasant odors at all. People therefore often use carbon filters to remove smells, though of course, they cannot remove all of them.

● Filter replacement. Replacing saturated carbon filters may become inconvenient and expensive. It can also be hard to determine when your carbon filter needs replacing as there are no visible signs when it is fully saturated. You just have to guess or rely on the manufacturer’s replacement recommendations. ● Cannot remove particle pollution. Carbon air filters remove many organic compounds from the air, but as mentioned above, they cannot address particulate pollutants. These particles may include allergens like dust and pollen, or even those from secondhand or wildfire smoke–the latter of which can be especially dangerous in the near term.

Perhaps you would like to use a carbon filter to remove odors for the short term, such as during a wildfire or home renovation. Or maybe you are concerned about the VOCs being released in your home from household products or building materials (like formaldehyde). In these cases, using a carbon filter is an acceptable option. However, for the long term, a carbon filter may not be the best investment from a cost standpoint. You would need to purchase one with a large amount of carbon within the filter, constantly monitor the saturation of the filter and replace it whenever needed. In addition, because it does not remove particles which are a major type of indoor air pollutant, you would only be addressing part of the problem of indoor air pollution. For these reasons, it may be wise to invest instead in a more robust solution. There are hybrid air purifiers that contain a carbon filter as well as a mechanical filter like HEPA.

Another option is a new technology called Photo Electrochemical Oxidation (PECO). The device is able to remove gases like volatile organic compounds, but unlike a carbon filter, it destroys them. Thus, there is no risk of these gases being released back into the air because of filter saturation. An activated carbon air filter can be a good short-term option, but in the long run, the air purifier could be a better solution for your needs. Laboratory tests were performed by the University of Minnesota Particle Calibration Laboratory of the air purifier. In one experiment, PECO was tested against a carbon filter. The carbon air filter was able to remove VOCs from the air through adsorption on the filter surface; however, once fresh air was introduced into the chamber, the gases were released back into the air (this is called outgassing). In contrast, the air purification technology was able to eliminate the VOCs from the air with no danger of outgassing. Carbon’s ability to purify water and air has a remarkable history. After you have considered how carbon air filters work and when they are effective, you can decide which type of air purifier is appropriate for your situation and budget.