3D Scanning and Printing:-

This week Assignment was

1)design and 3D print an object (small, few cm3, limited by printer time)that could not be made subtractively

2)3D scan an object (and optionally print it)

My Idea for this was to design a whistle as a 3D Object:-

The whistle is a single unit object.

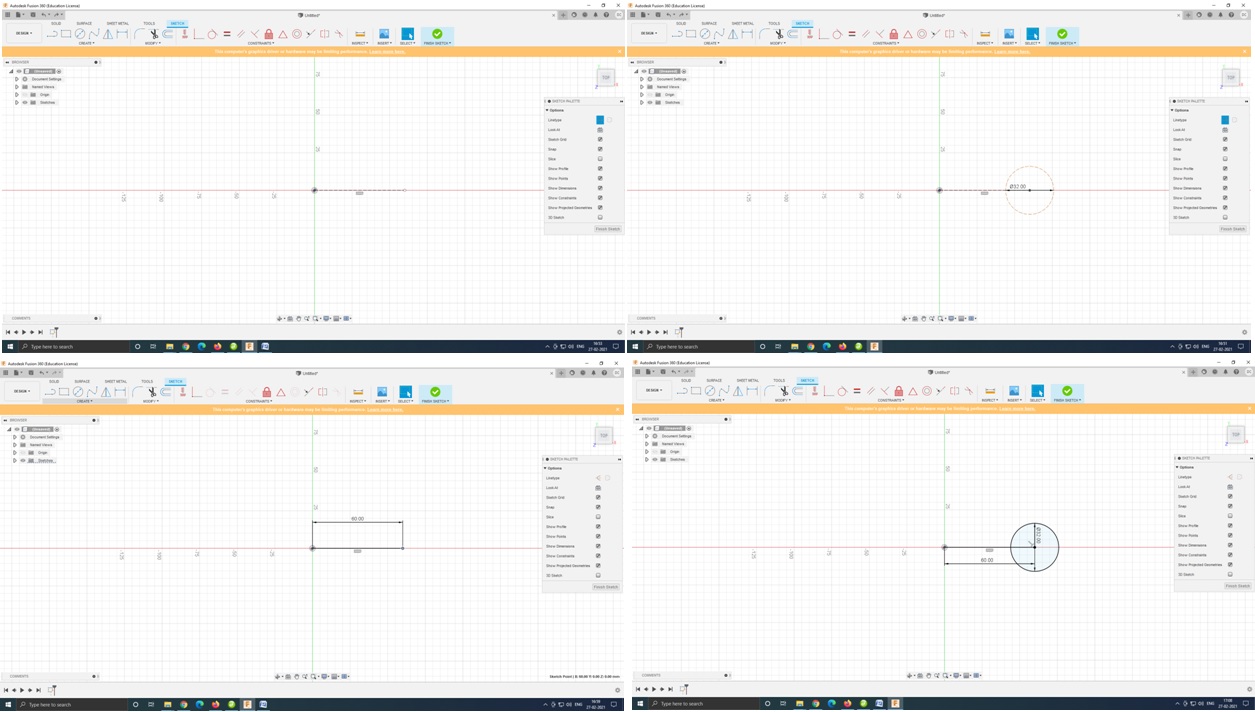

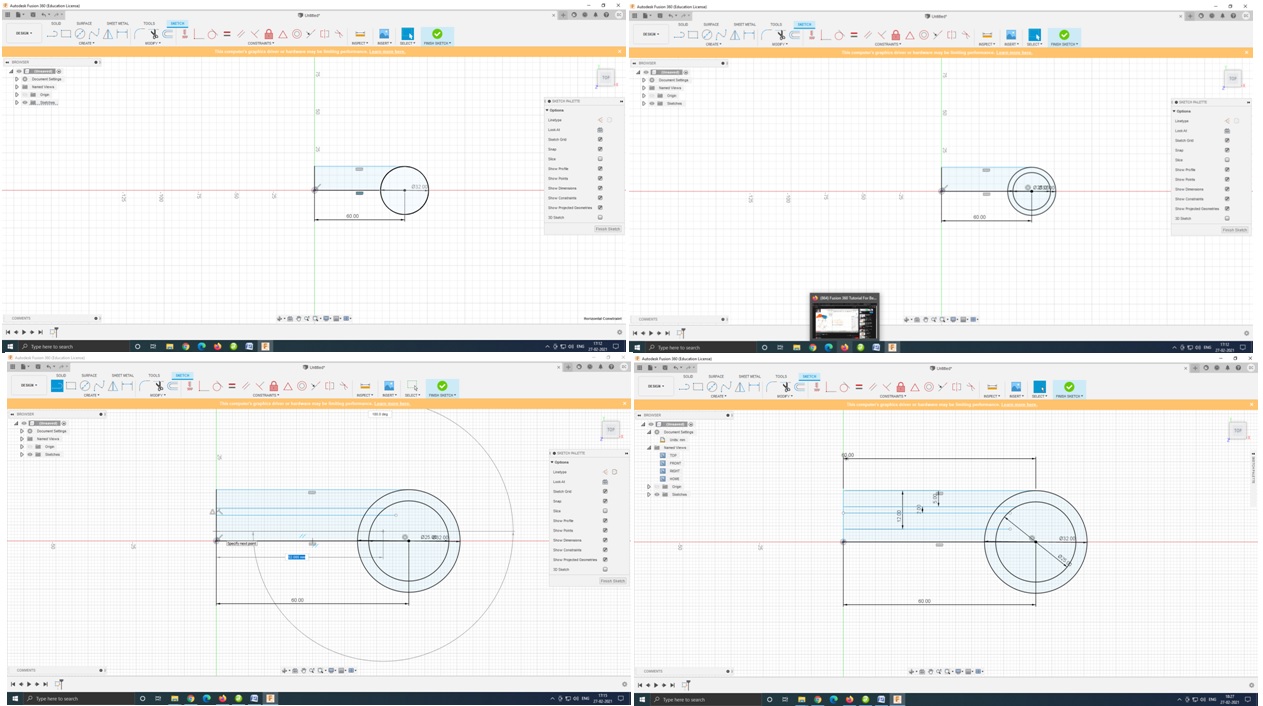

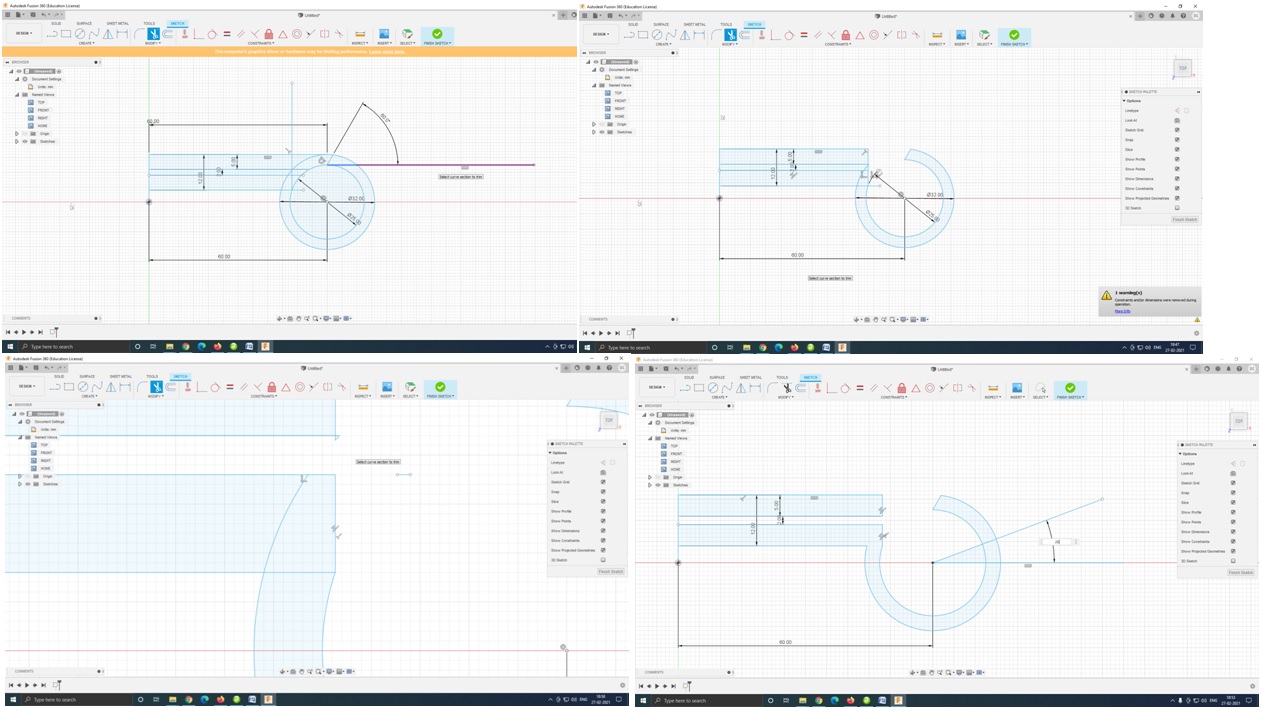

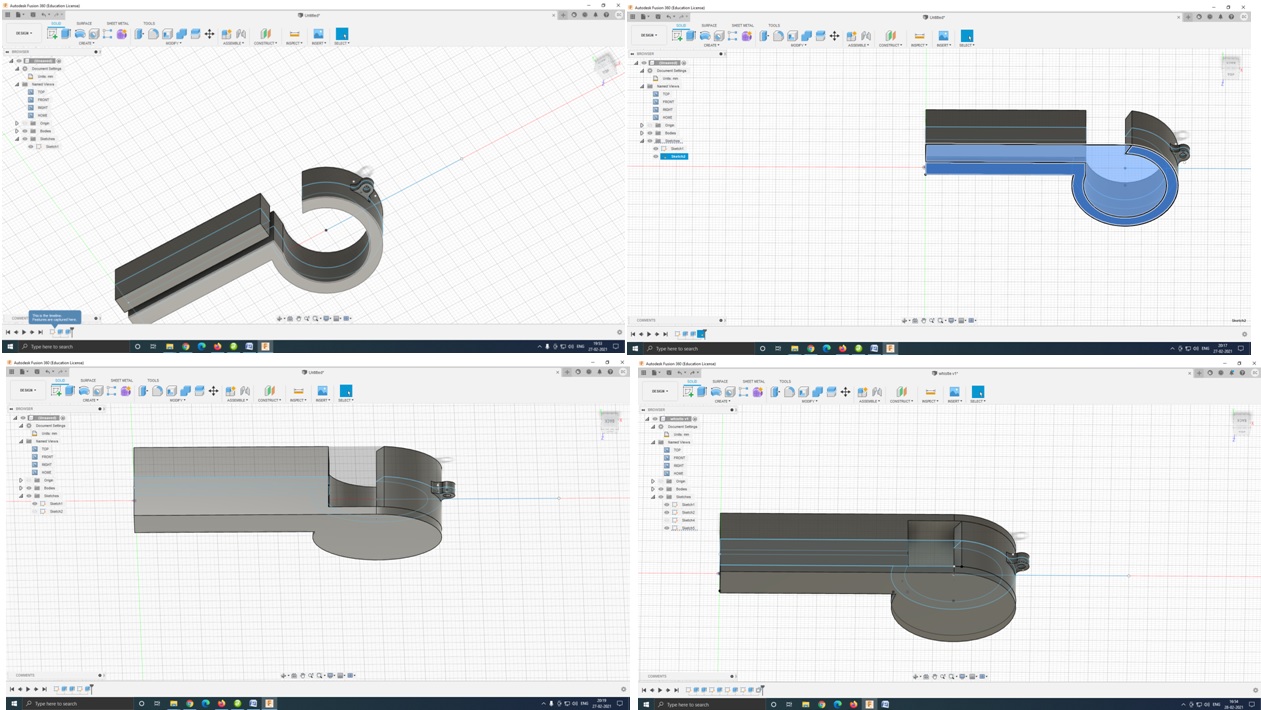

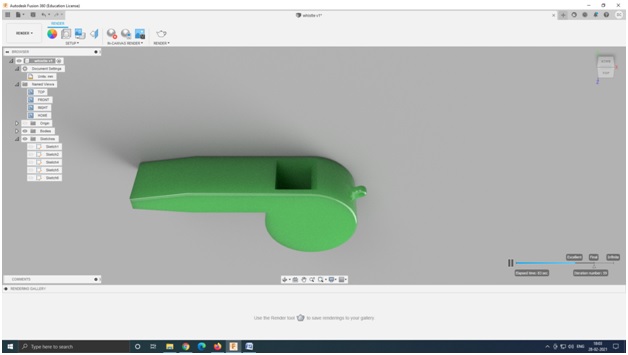

I used the Fusion 360 for designing of the whistle:-

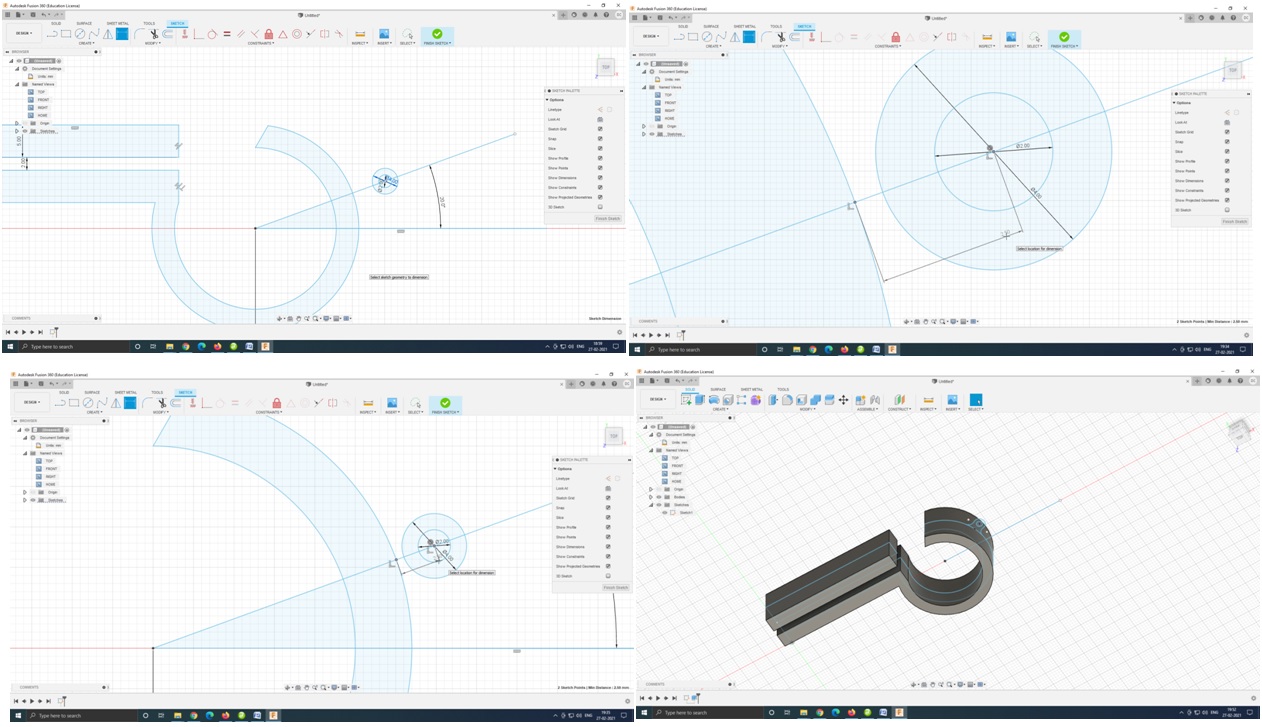

Here are the screenshots how i designed the whistle from scratch:-

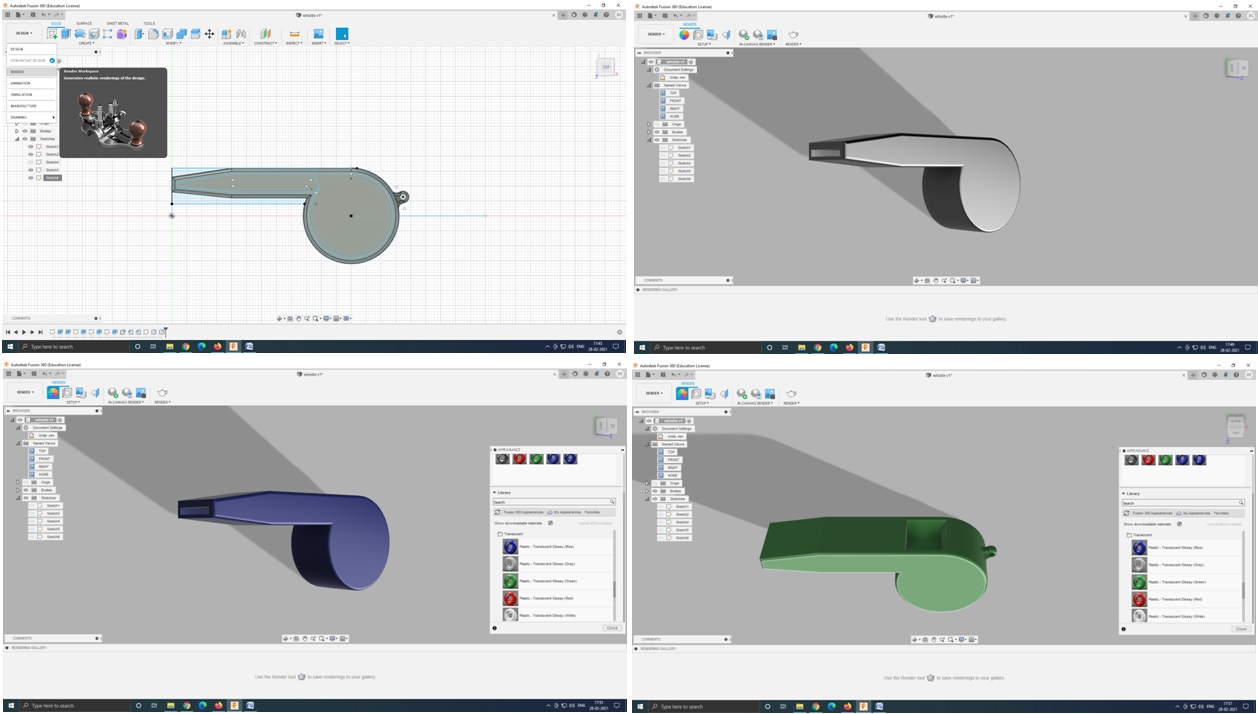

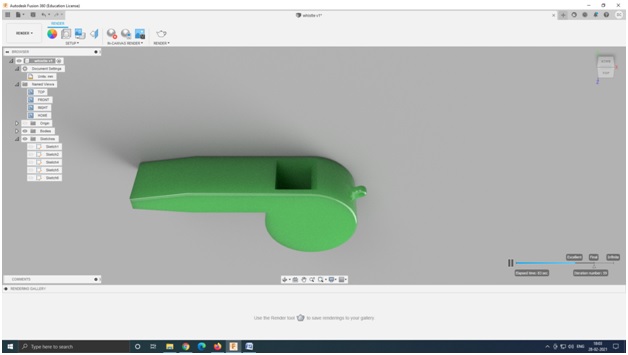

Here is the final design how it will be printed.

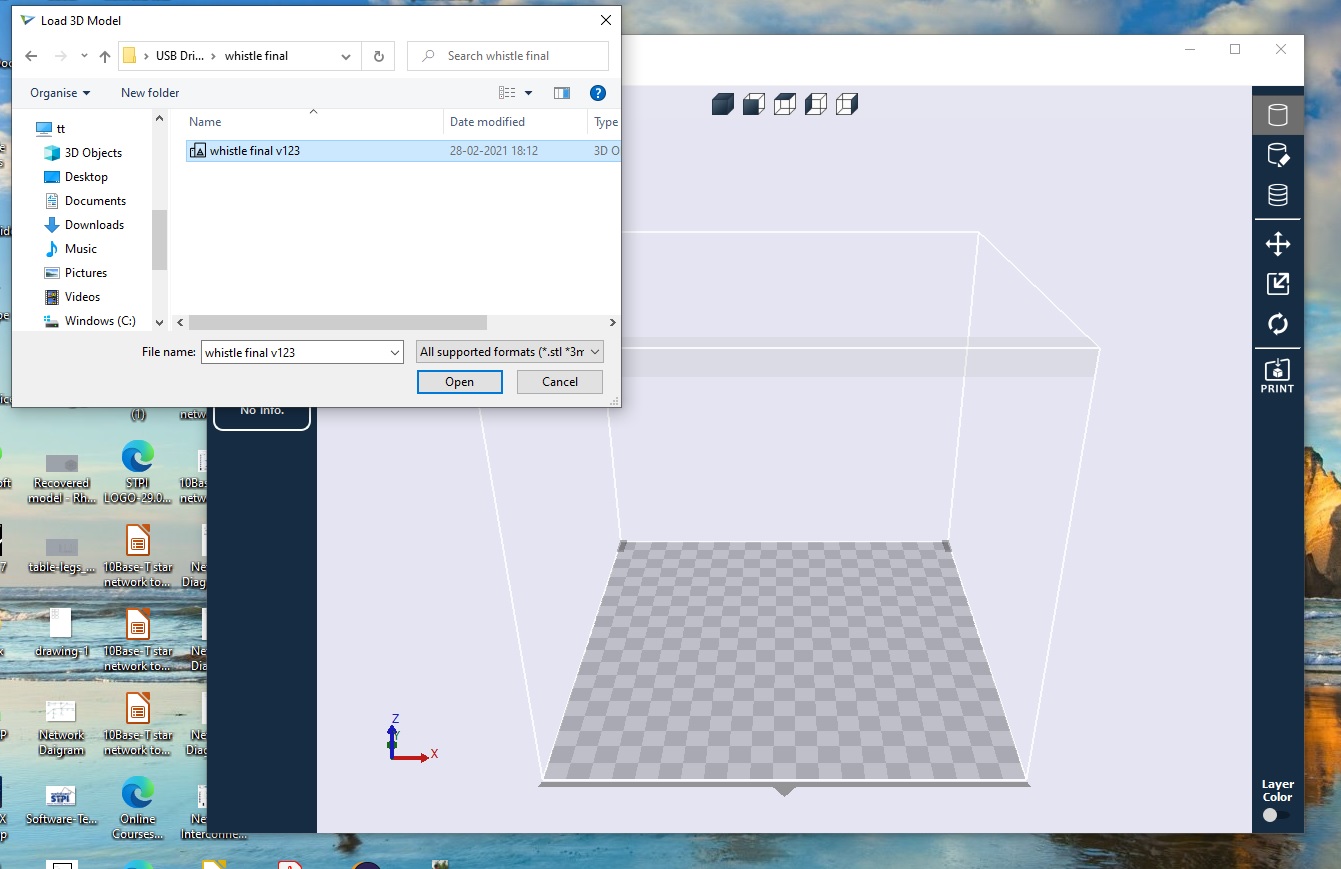

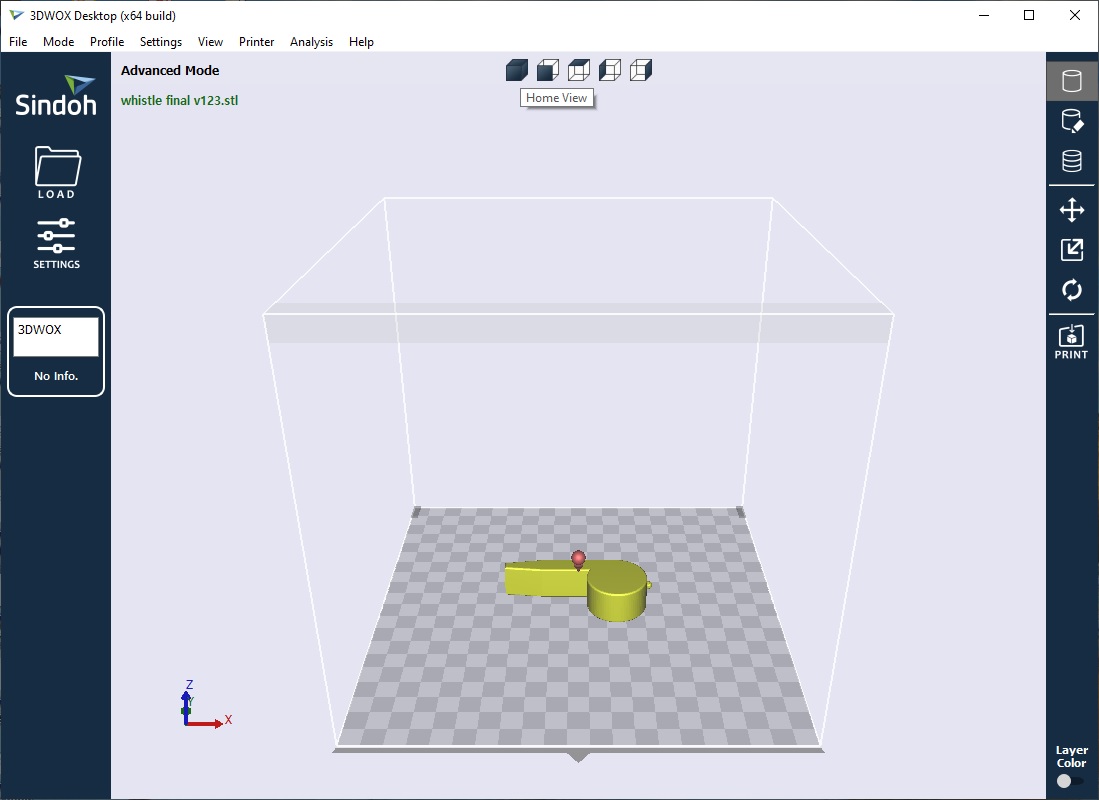

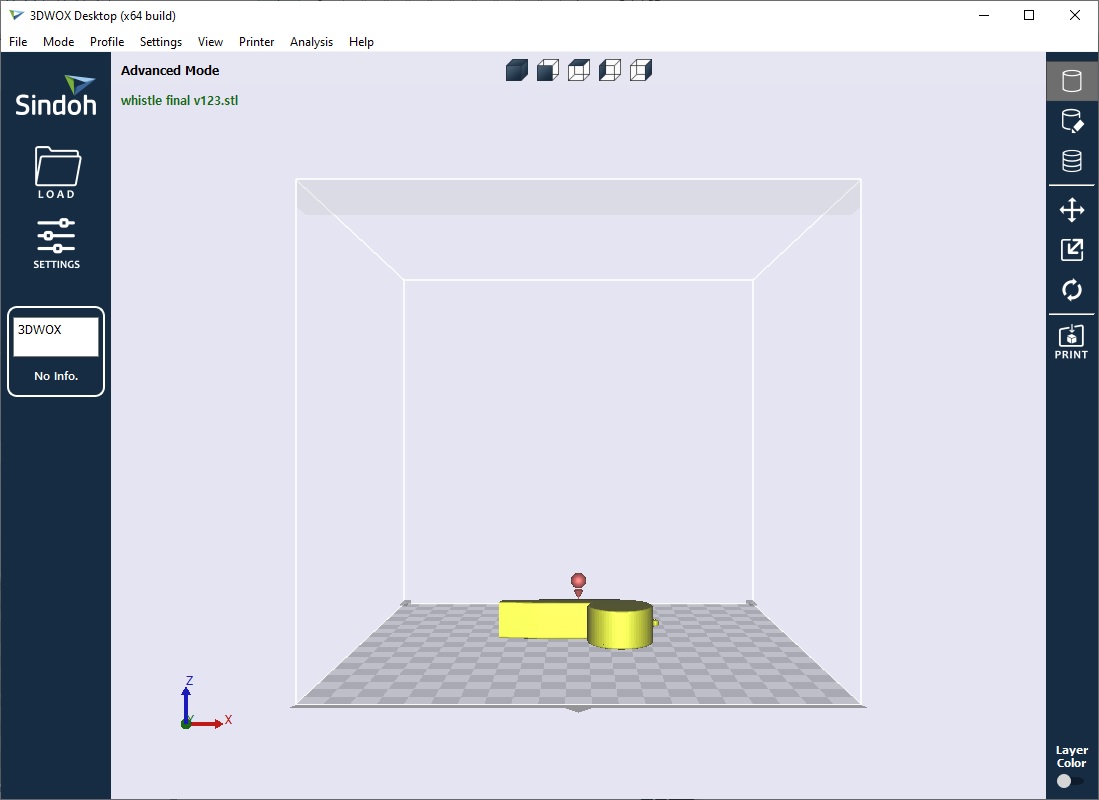

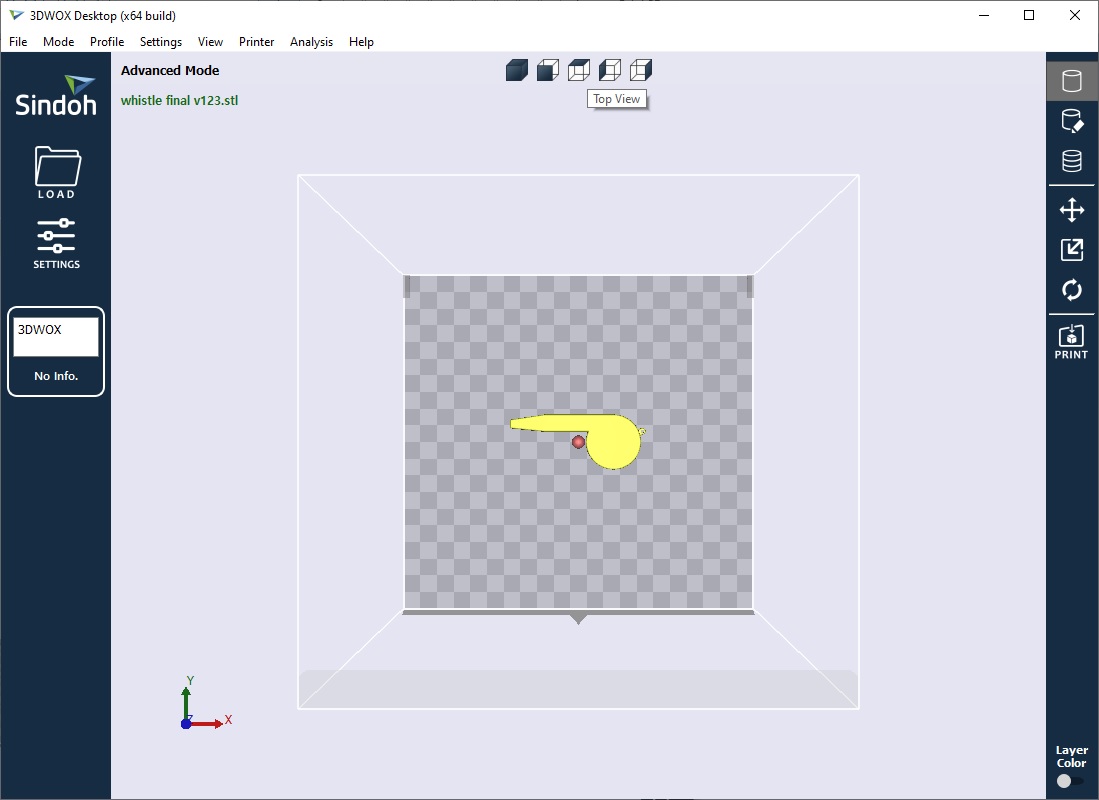

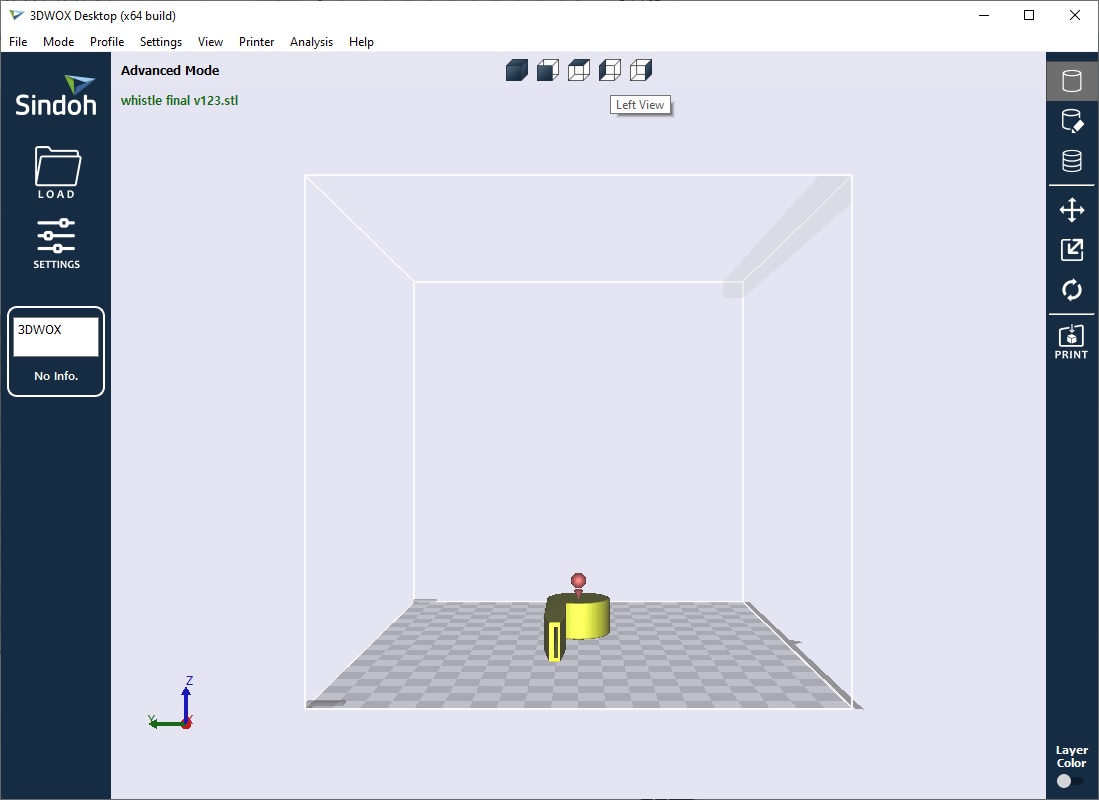

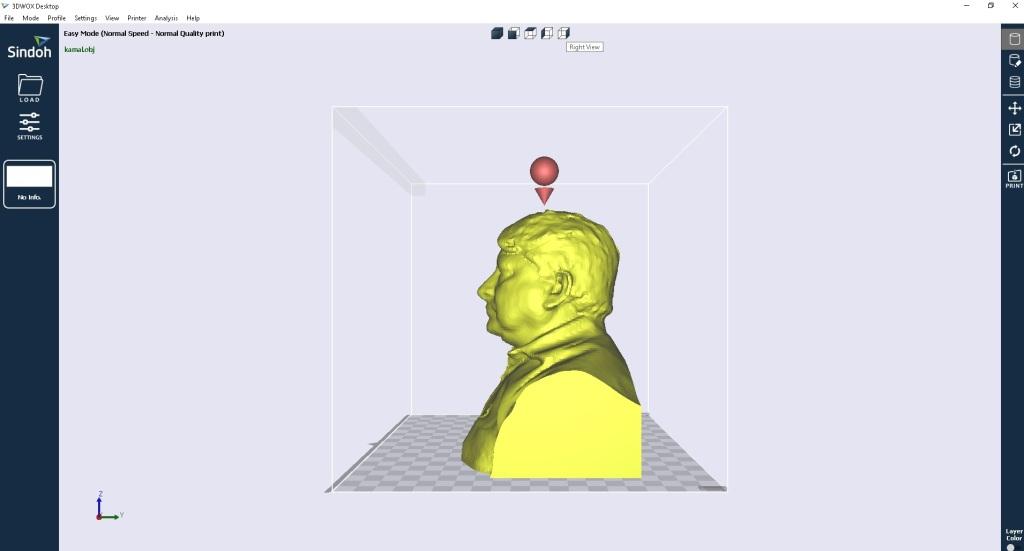

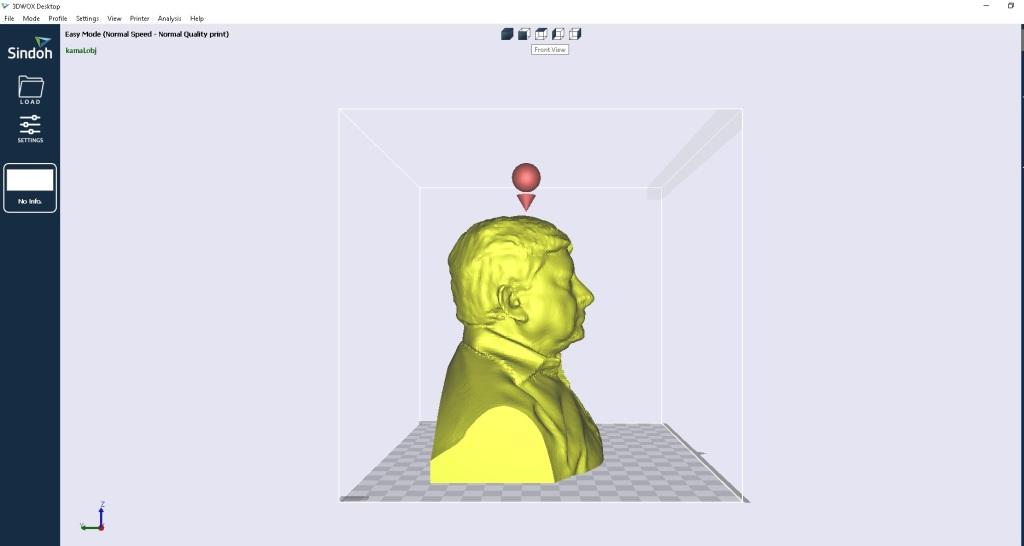

After this Exported the whistle file i the .stl format and sen it to the sindoh 3D WOX software and checked the orientation how it will be printed.

After This I I view the formation of base and the layers in my design and then calculated it for savin it in G-Code. G-Code is the language by which the printer understands the inputs and converts the inputs into a desired output.

Here is my 3D printed Whistle

Here is the video :-

This This Whictle can be made additvely only.This whstle cannot be made subtractively.Because it has the hollow part in it.

.Additive process builds parts layer by layer by depositing material according to digital 3D design data.Subtractive manufacturing is a product development process that continuously cuts away material from a solid block, such as metal. This can be done manually or using CNC (Computer Numeric Controlled) machinery.Injection molding is a manufacturing process used for producing products in large volumes. As the name suggests, parts are produced by injecting heated material into a mold.Additive manufacturing, aka 3D printing, is the process of producing 3-dimensional objects from a computer file, where the part is built by adding material layer-by-layer.3D printing process as it presents many significant advantages over the more traditional manufacturing methods of subtractive manufacturing and injection molding.

Subtractive manufacturing process involves removing sections of a material by

machining or cutting it away. Creating a Sculpture from wood is Subtractive Process.Additive manufacturing process is a process that adds successive layers of material to create an object. Creating a terracotta sculpture by adding soil part by part is Additive Process.

I Scanned the image of my SAO and printed it.....

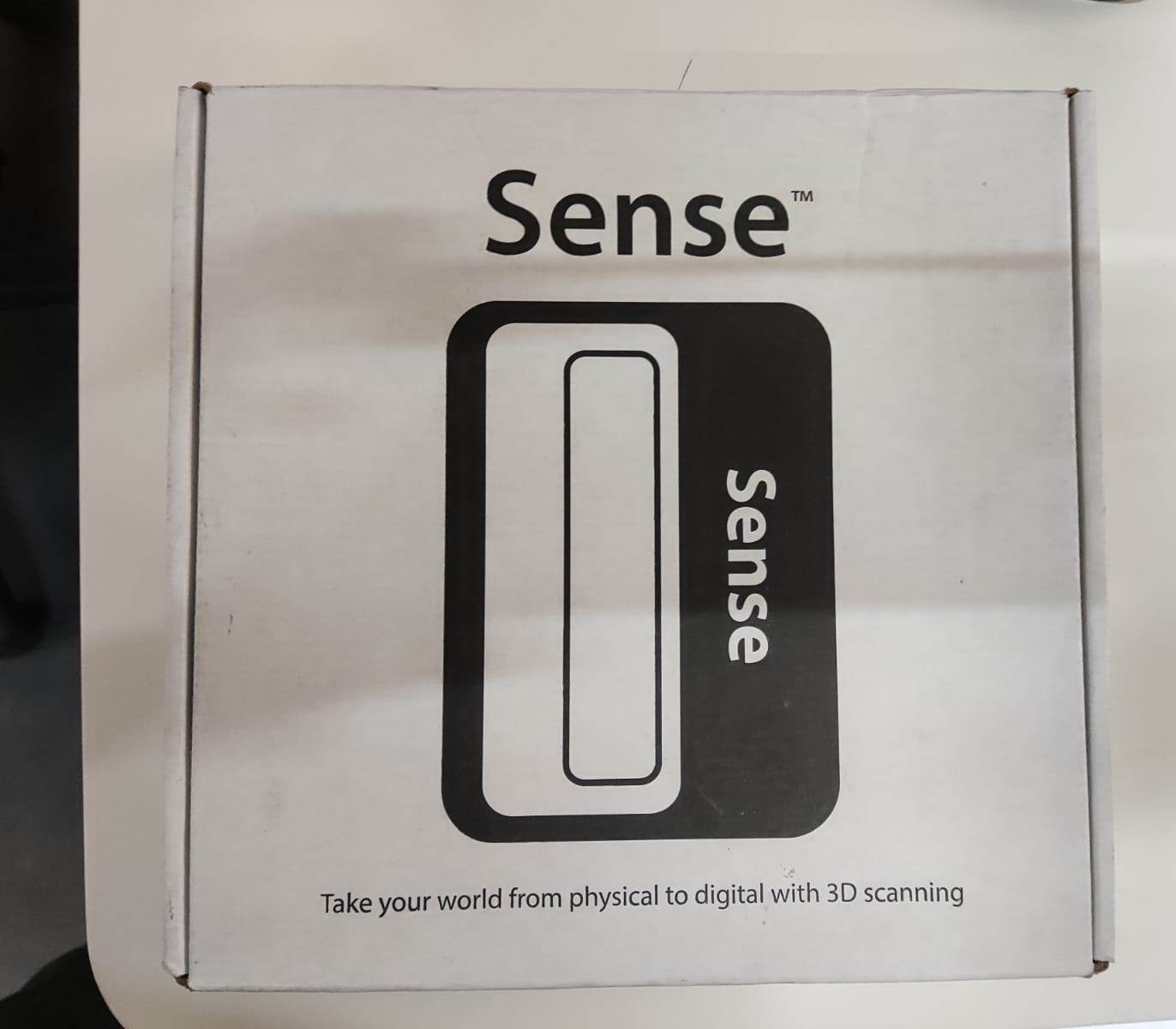

I decided to use the 3D Sense scanner for scanning the image.

Sense 3d scanner itself is pretty light, and looks like it could double as a ray gun at a sci-fi convention. You hold it in your hand and move around the object to scan it. The scanner projects a patterned infrared (IR) beam onto the object from the bottom opening that is then detected by the middle webcam.

I downloaded software from Customer Support Center page: Customer Support Center page. I chose Sense (Windows 10 64 bit). After This i connected the

Scanner to my PC as instructed in the mannual

RUN THE SENSE SOFTWARE

When you installed the Sense software, a shortcut was created on your desktop. Use the shortcut to open the application.

NOTE: If the scanner is not connected to your computer, a message will state "Device not connected." Plug the USB

connector for the scanner into the USB 3.0 port on your computer.

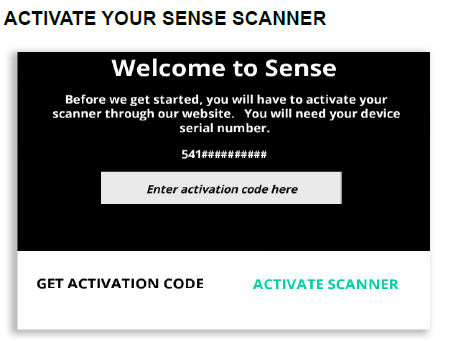

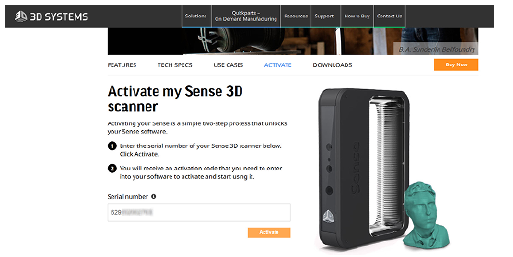

1. You will then be prompted to activate your Sense 3D scanner.

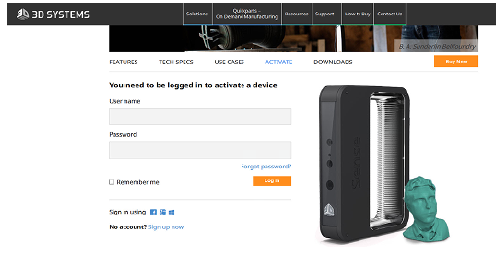

2. The 3D Systems Sense support site will display. Login to your 3D Systems account (if you do not have an account, create one).

3. The Activate Sense Scanner screen will display. Enter the serial number shown on the device in the Serial Number field.

4. Once acitvated online, you will be provided with a 4 digit activation key (which is also e-mailed to you).

5. Once you have your activation code, you can enter it into the Sense activation dialog box. Click Activate Scanner to complete the

activation.

Then software was ready to scanning.

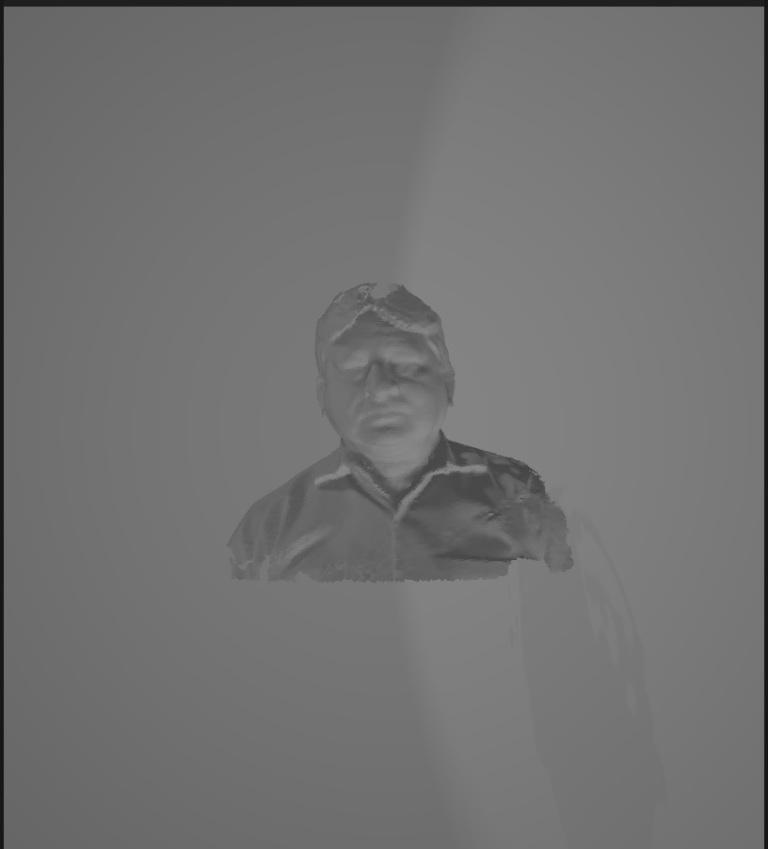

After This i scanned the image of my officer for scanning

Here is the image illustrating how the scanner is used.

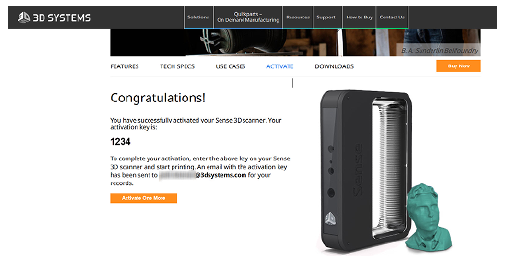

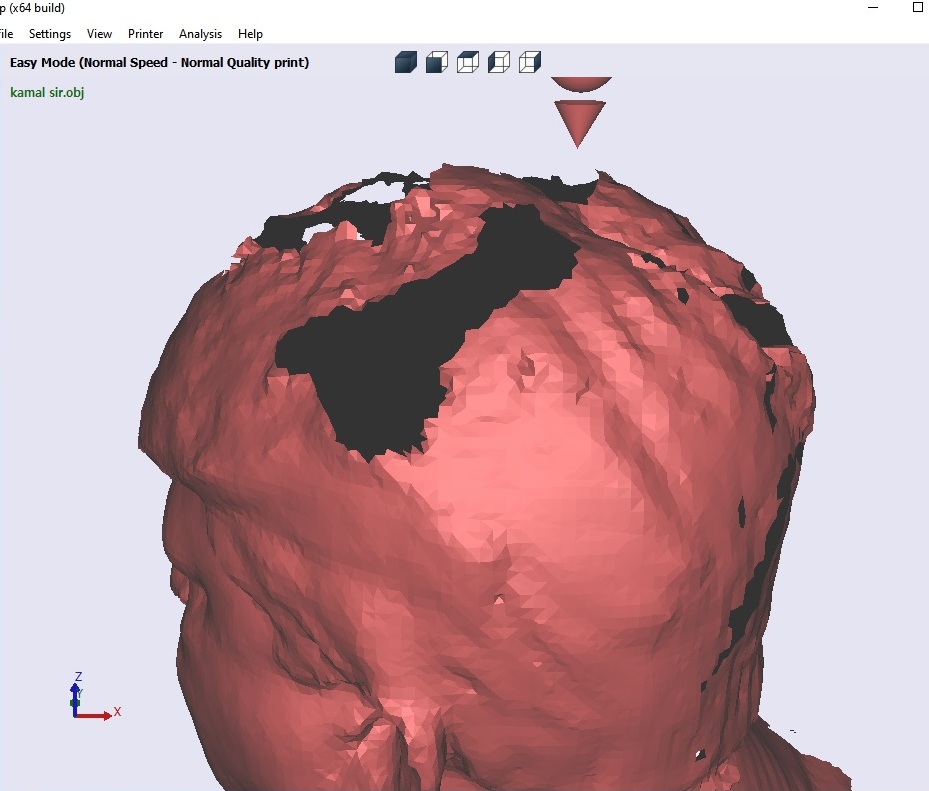

I face the problem in scanning the 3d image of M. SAO.The limitation of this scanner is that it cannot scan the shiny parts.The movement of the scanner should be very precise and it should be stable.It is very difficult.It took mei around 30 minutes to scan the 3d image.

I Made the SAO sat on the chaur and hold the 3d scanner stable in one hand and rotated the chair in full circle slowly and slowly an d did the scanning.

The scanner cannot scan the shiny part.You can check in the following image that scanner cannot scan the hairs of the person.Before scanning the face the

sweat from the face should be removed and i it should be shine free.For the post processing the trimming and the filling should be done.

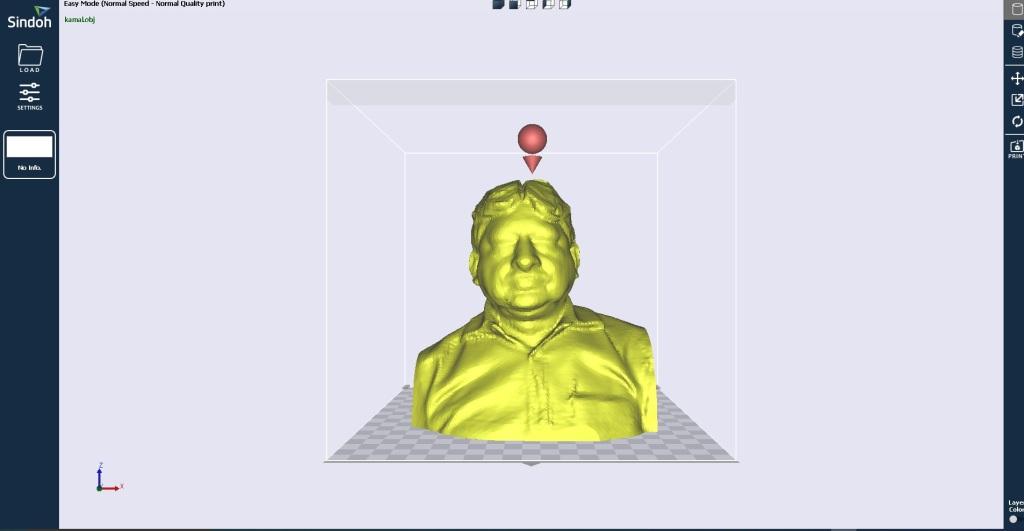

Trimming the unnecessary or crack scan and make it solidified.As the statue has to be submitted to him so i did print in sindho

I face the problem in scanning the 3d image of M. SAO.The limitation of this scanner is that it cannot scan the shiny parts.The movement of the scanner should be very precise and it should be stable.It is very difficult.It took mei around 30 minutes to scan the 3d image.

The limitation of the the 3D printer

1)Surface texture is generally too rough.

2)Materials have low heat deflection temperatures.

3)Materials generally have low strengths.

4)Manufaturing cost is high.

5)The cost to run the machine can be higher

6)There should be suffiecient light fo scanner to do he scanning.

7)You can use trimming and filling fo correcting the scanned object.

The Advanatage of 3d Printers

1) 3D prnter is good for rapid proto typing.

The Files of this week can be Downloaded here.