Group Assignment 3D Scanning and Printing.

This weeks assignment

- test the design rules for your 3D printer(s)

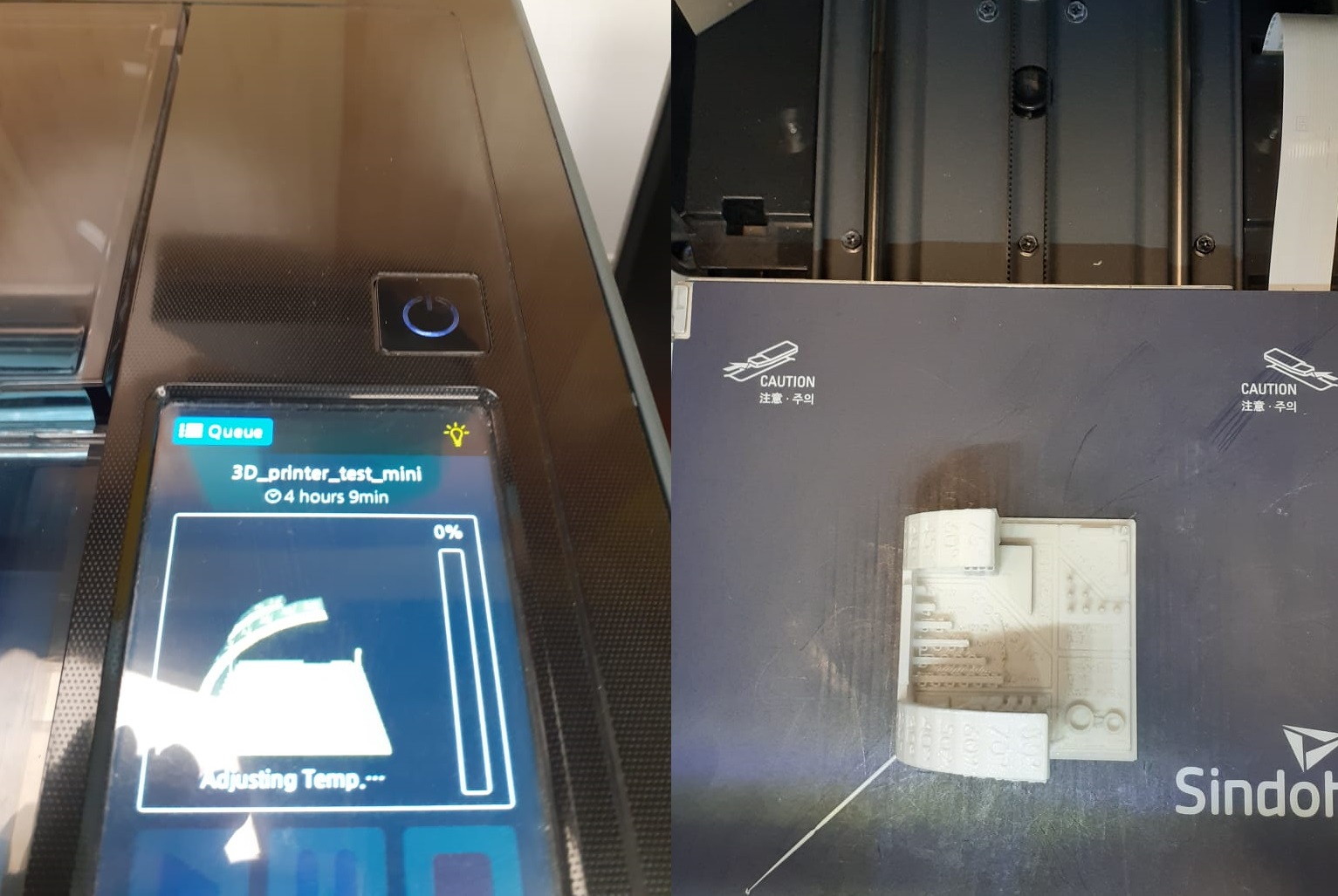

In my fablab sindoh

3dwox DP200

1.Technology: Fused filament fabrication (FFF)

2.Type: Material extrusion

3.Year: 2017

4.Manufacturer: Sindoh

5.Manufacturer country: South Korea

As a group we worked on testing the 3D printer to define some design rules by printing several of these test files:

- clearance

- angle

- overhang

- bridging

- thickness

- dimensions

- surface finish

Angle

The printer can print angles up to 20° without problems.

Surface finish

The surface finish looks good even with a 0.2mm layer thickness print.

Clearance

The test shows that a 0.4mm clearance between parts need to be respected.

Bridging

Bridging is perfect even at 20mm distance.

Thickness

This test shows that a minimum of 0.2mm wall thickness must be respected. A 0.1mm wall could be printed but is unusable in practice.

Dimensions

This test shows an internal dimension of 9.66mm and an external dimension of 20.14mm. That means the printer has to be calibrated.

Overhang

An overhang longer than 3mm must be supported for good results.

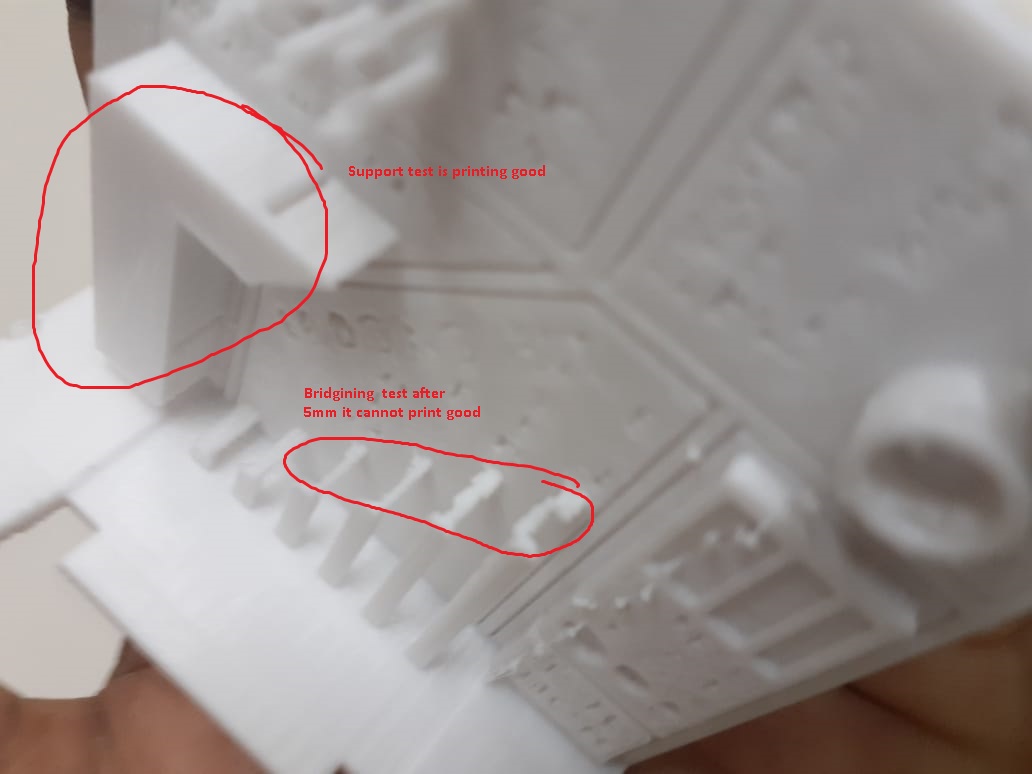

We have printed object one is with out support and with support. some test is not coming good some of them are found good following are the details

Finding and observation for the test print.

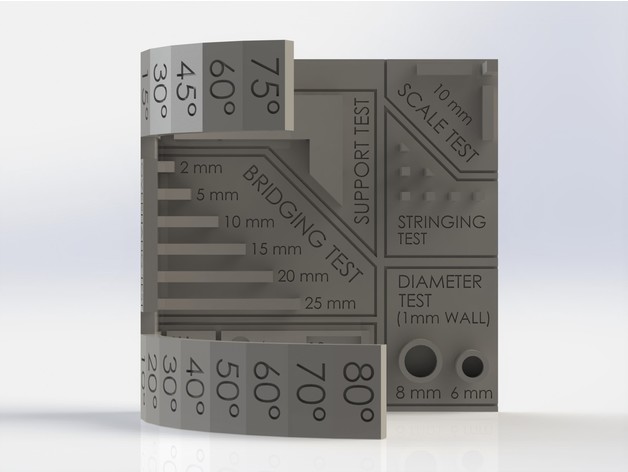

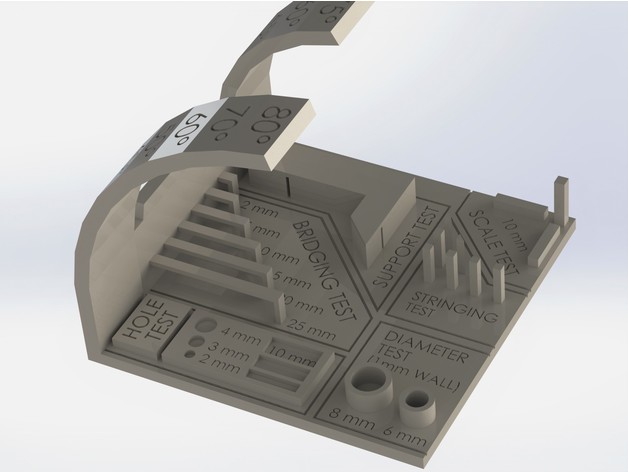

1.bridging test 2mm,5mm,10mm,15mm,20mm,25mm

2.Diameter 8mm,6mm test 1mm wall is printed fine

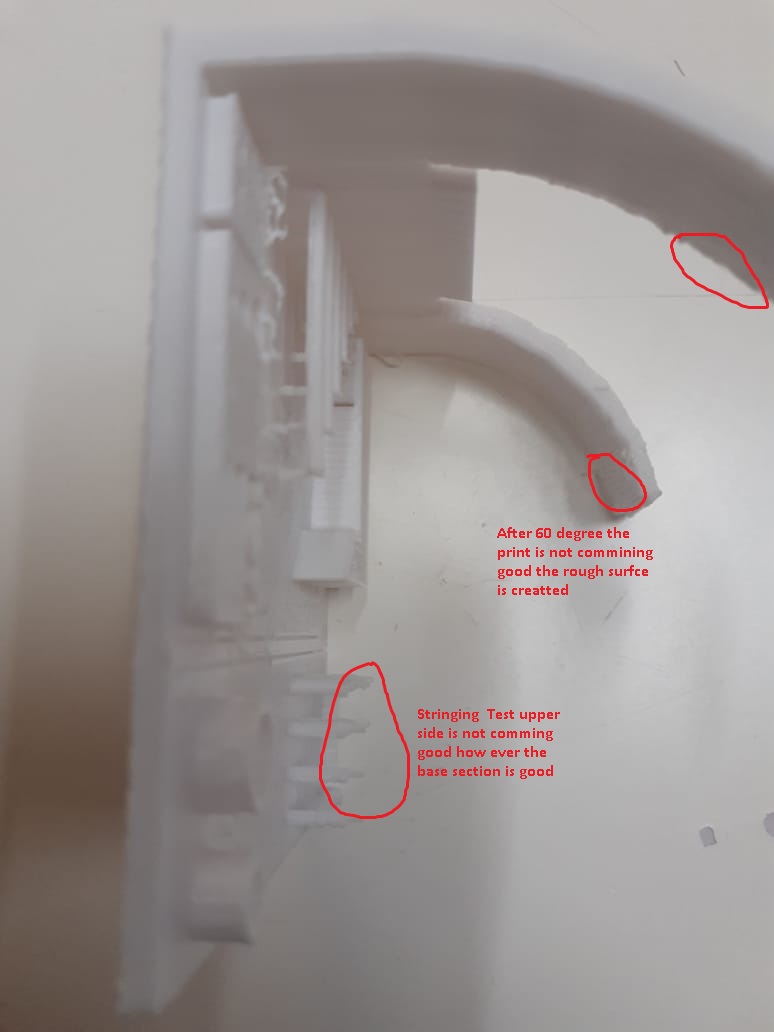

3.stringing test-top tips is not good printed

4.scale test- Fine printed

5.support test- fine printed

6.hole test- Fine printed except 2mm

7. Degree test :-after 60 degree printing but not good one

After printing with support in normal speed the object degree band is printed good

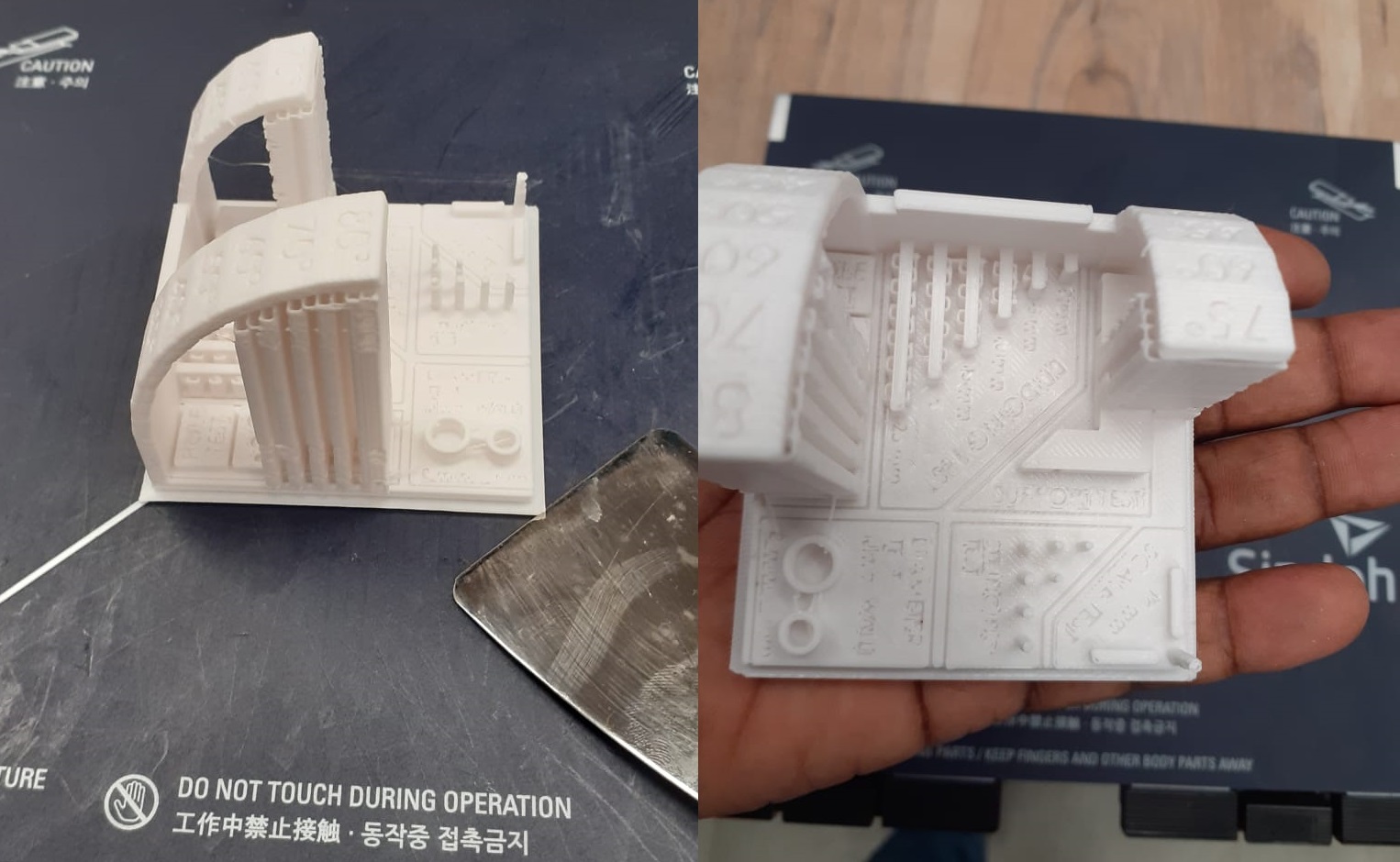

We printed this object without support and in fill 100 % .Here are the outcomes

.jpeg)

Bridging is not printed properly after 25 mm.Till 20 mm it is printed fine.Also the circle aftere 8mm diameter ar not printed perfetly.till 5 mm printed fine.

.jpeg)

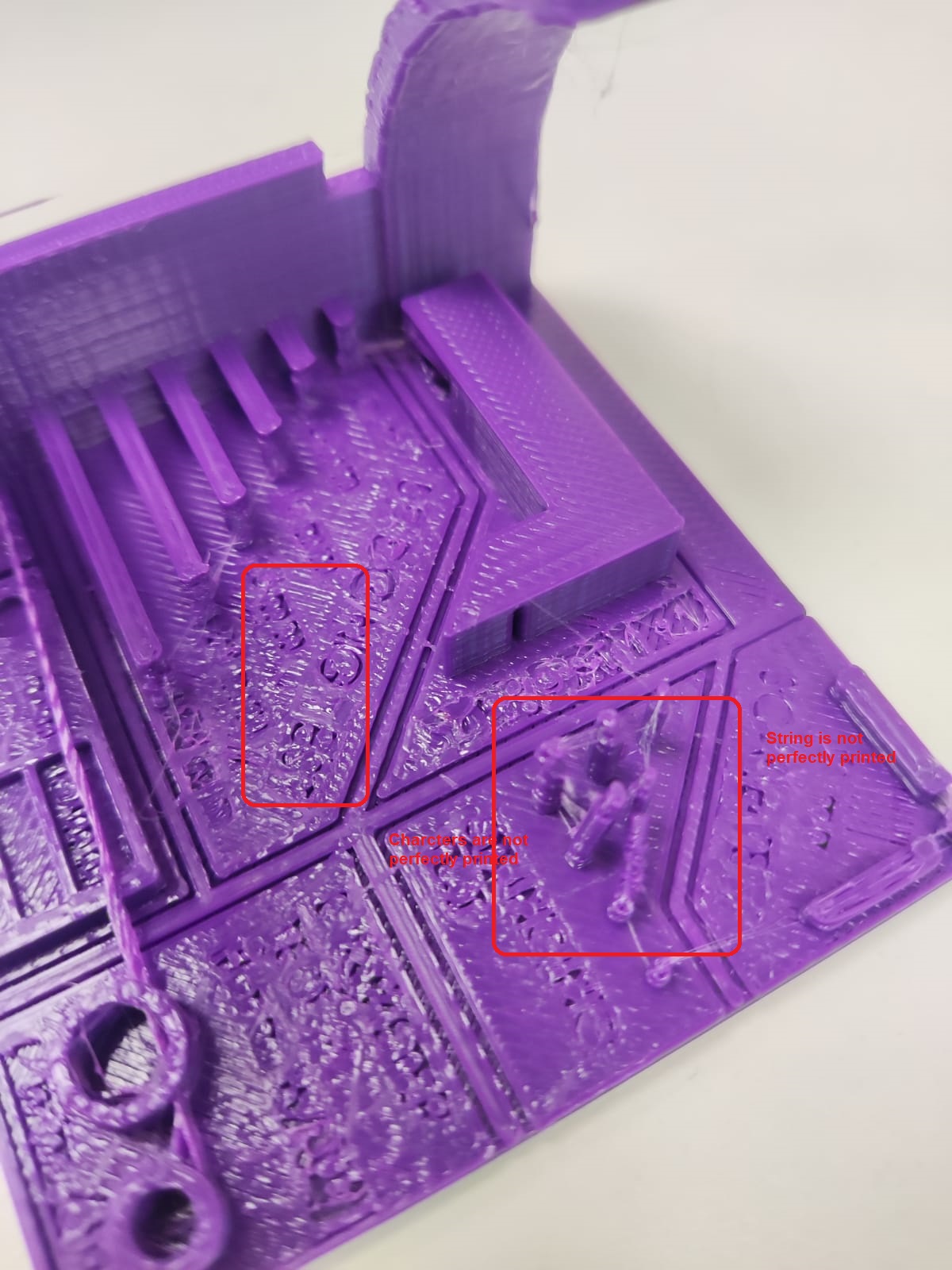

String is not printed perfectly and charcaters also not printed perfectly.