This Week I worked on the laser cutter Epilog Laser Fusion M2

This is the laser machine that we are using in our fablab.

|

To characterize the various materials for laser cutting

We have characterize the following materials for the laser cutter:-

1)MDF Board

2)Plywood

3)Veneer Wood

4)Acrylic board

Proceudure undertaken:-

3mm Acrylic Sheet :-

For Cut:-

A simple design of 19 mm circle was made in Corel Draw and the same was sent for the print in the Laser Cutter using different paramenters.

The parameters used for cutting the 3.5 mm Acrylic Sheet with different parameters was as under:-

| 3.0 mm Acrylic Sheet | First | Second | Third | Fourth |

|---|---|---|---|---|

| Speed (%) | 50 | 50 | 10 | 10 |

| Power (%) | 50 | 70 | 80 | 90 |

| Freq (%) | 50 | 50 | 50 | 50 |

| Result (%) | A simple cut was observed but the design was intact in the Acrylic. | Cut was a little bit deeper but the design did not extract from the wooden ply. Some dark spots were visible on the Acrylic | The cut was extracted from the Acrylic with ease | Through this dimension also the cut was easily removed from the Acrylic |

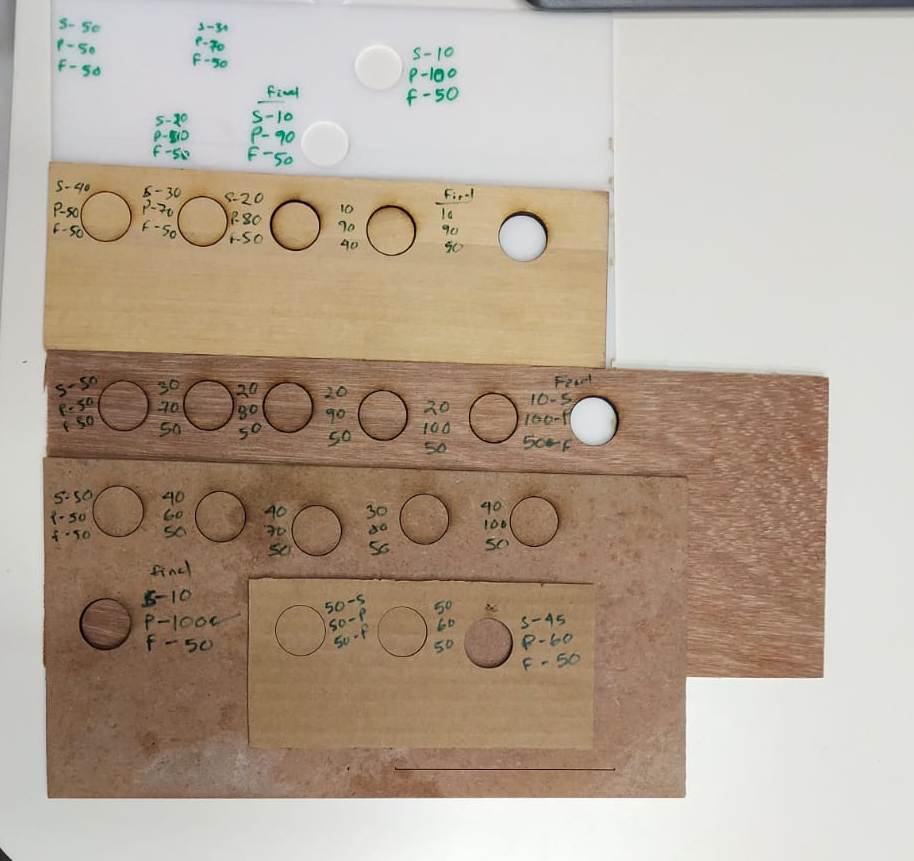

3.55 mm MDF Board :-

For Cut:-

A simple design of 19 mm circle was made in Corel Draw and the same was sent for the print in the Laser Cutter using different paramenters.

The parameters used for cutting the 3.55 mm MDF Board with different parameters was as under:-

| 3.55 mm MDF Board | First | Second | Third | Fourth |

|---|---|---|---|---|

| Speed (%) | 50 | 40 | 30 | 10 |

| Power (%) | 50 | 70 | 80 | 100 |

| Freq (%) | 50 | 50 | 50 | 50 |

| Result (%) | A simple cut was observed but the design was intact in the MDF. | Cut was a little bit deeper but the design did not extract from the MDF. | The cut was extracted from the MDF with ease | Through this dimension also the cut was easily removed from the MDF Board |

3.54 mm Plywood Sheet :-

For Cut:-

A simple design of 19 mm circle was made in Corel Draw and the same was sent for the print in the Laser Cutter using different paramenters.

The parameters used for cutting the 3.54 mm Plywood Sheet with different parameters was as under:-

| 3.54 mm Plywood | First | Second | Third | Fourth |

|---|---|---|---|---|

| Speed (%) | 50 | 30 | 20 | 10 |

| Power (%) | 50 | 70 | 80 | 100 |

| Freq (%) | 50 | 50 | 50 | 50 |

| Result (%) | A simple cut was observed but the design was intact in the MDF. | Cut was a little bit deeper but the design did not extract from the MDF. | The cut was extracted from the MDF with ease | Through this dimension also the cut was easily removed from the MDF Board |

3.61 mm Veneer Board :-

For Cut:-

A simple design of 19 mm circle was made in Corel Draw and the same was sent for the print in the Laser Cutter using different paramenters.

The parameters used for cutting the 3.61 mm Veneer Board with different parameters was as under:-

| 3.61 mm Veneer Board | First | Second | Third | Fourth |

|---|---|---|---|---|

| Speed (%) | 40 | 30 | 20 | 10 |

| Power (%) | 50 | 70 | 80 | 90 |

| Freq (%) | 50 | 50 | 40 | 50 |

| Result (%) | A simple cut was observed but the design was intact in the Veneer Board. | Cut was a little bit deeper but the design did not extract from the Veneer Board. | The cut was extracted from the Veneer Bioard with ease | Through this dimension also the cut was easily removed from the Veneer Board |

Following are the images of the characterisation:-

To characterize the various materials for laser Engraving

We have Engarved the following materials for the laser cutter:-

1) MDF Board

2) Plywood

3) Card Board

4) Veneer Wood

5) Acrylic board

For Engrave:-

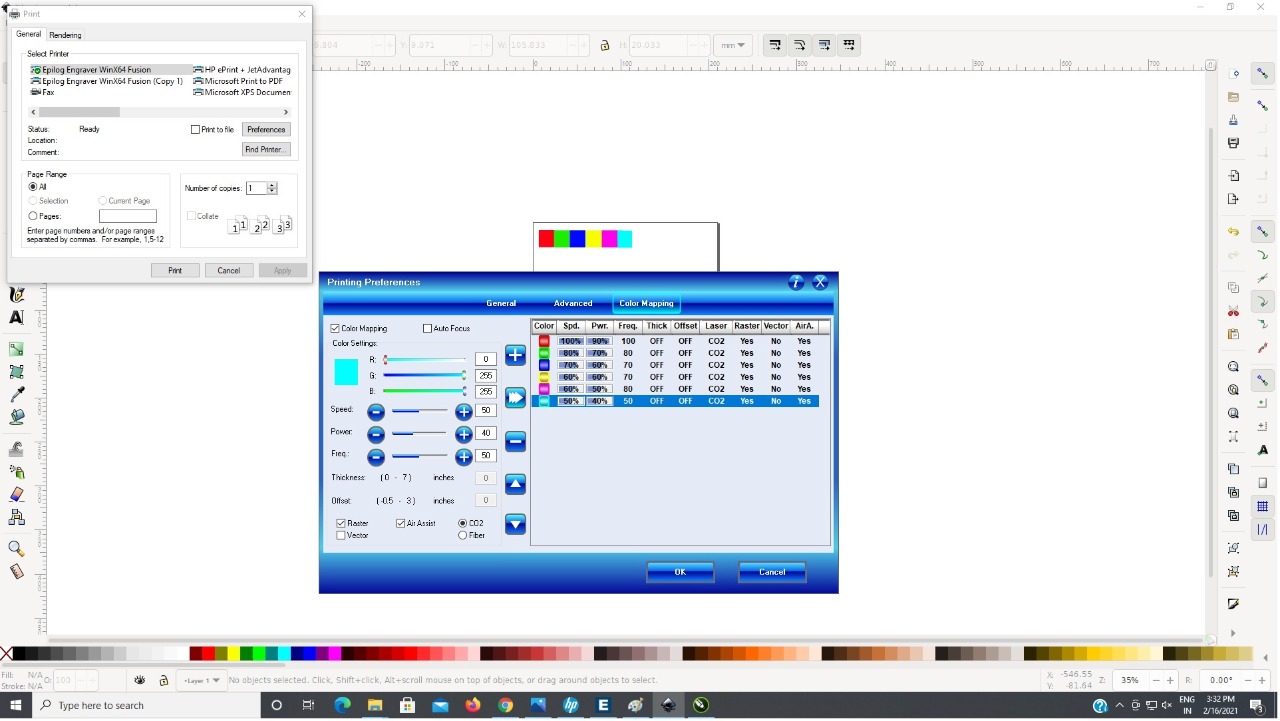

A simple square was filled with diff colors was made in Corel Draw and the same was sent for the print in the Laser Cutter using different paramenters.

The parameters used for engraving the above materials are as under:-

| Parametrers | Speed (%) | Power (%) | Frequency (%) |

|---|---|---|---|

| Red | 100 | 90 | 100 |

| Green | 80 | 70 | 80 |

| Blue | 70 | 60 | 70 |

| Yellow | 60 | 60 | 70 |

| Pink | 60 | 50 | 80 |

| Cyan | 50 | 40 | 50 |