Test runout, alignment, speeds, feeds, and toolpaths for your machine (CNC router)

We are using this CNC Routing machine Sopbot PRSalpha.The features of this machine

are following :-

2) Tough precision linear bearings on the moving gantry and hardened steel rails for the x-axis.

3) Reliable rack-and-pinion power transmission on each axis.

4) Impressive cutting speeds of up to 600 inches per minute (depending on cutting bit and material) and rapid transit speeds of 1,800 inches per minute.

5) Step resolution of .0004”.

6) Positional accuracy of +/- .002”.

7) Sealed Industrial UL Certified Control Box.

8) Emergency Stop disconnect switch in the Control Box with integrated and cabled remote Emergency Stop Buttons.

9) Z-zero Touch-Off Plate and XY Proximity Switches.

10) ShopBot Control System software to run your CNC.

11) Dust Skirt ready to connect to your dust collector.

12) Each new ShopBot tool includes powerful design software to create to create CNC projects.

13) Shipped as four ready-to-assemble modules. On-site assembly and training available.

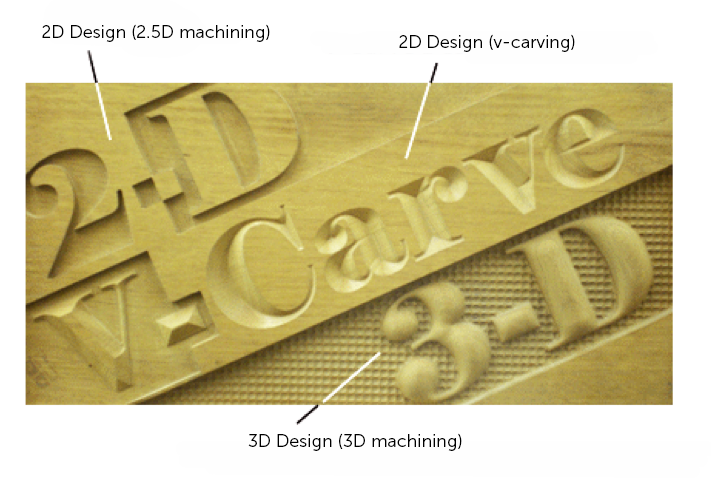

Difference between 2D , 2.5D and 3D CNC

when the Z axis of some CNCs moved only when X and Y were not moving, or only had a single up and down position. These earlier CNCs were thus not capable of 3D carving and were referred to as 2 or 2.5D tools

What is 2d CNC

If all we have is a flat outline of something we want to cut out, that would be considered 2D

What is 2.5d CNC

If we then added straight up and down movements of the cutter into and out of the material, we might now consider the project as 2.5D,cut features like grooves or flat pockets,where you are pocketing areas (e.g. around letters in a sign)All such cutting can be done in one or more different cutting planes after plunging to a cutting dept, V-carving as a 2.5D design process.

What is 3d CNC

this capability is technically described as 3-axis interpolation, which means that moves are made smoothly in 3D space using diagonals and curves. In 3D, your CNC cutter tip follows paths at 3D angles or in 3D curves in order to mill or carve complex shapes into the material

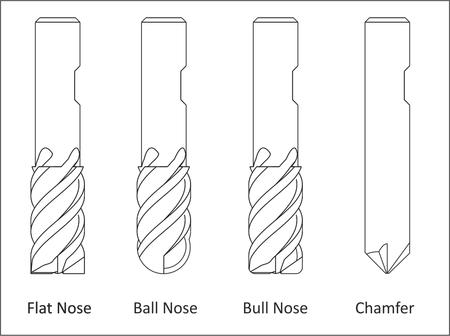

There are following types of Endmils:-

We drawn the following design to fins the kerf and the best fit for our individual assignment: