Welcome to Berytech Fab Lab

So the objective of the fifth week is to discover the various 3d printers available in the fab lab and the different technologies used. There are many technologies nowadays that are considered to be under the umbrella of 3d printing, by other words additive manufacturing. Among those are:

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object.

Machines Used

The main machine that was tested for this week's assignment is the following:

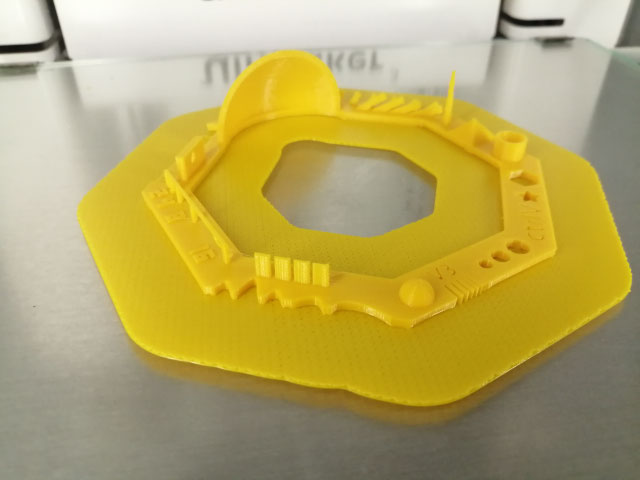

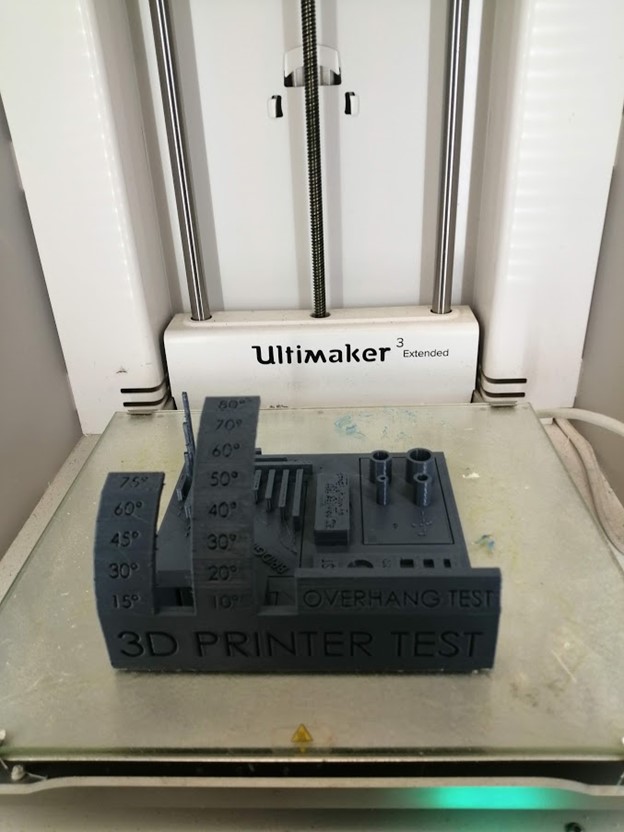

A Precision/Orverhang test was performed on a Ultimaker3 - Extended 3D printer and Cura slicer.

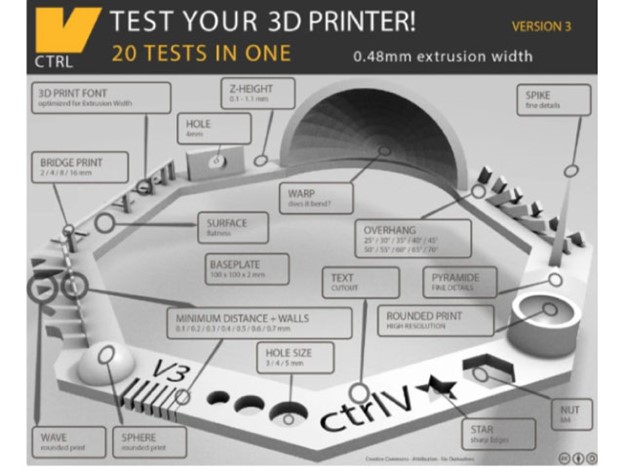

The All In One 3D Printer Test was downloaded from thingiverse.

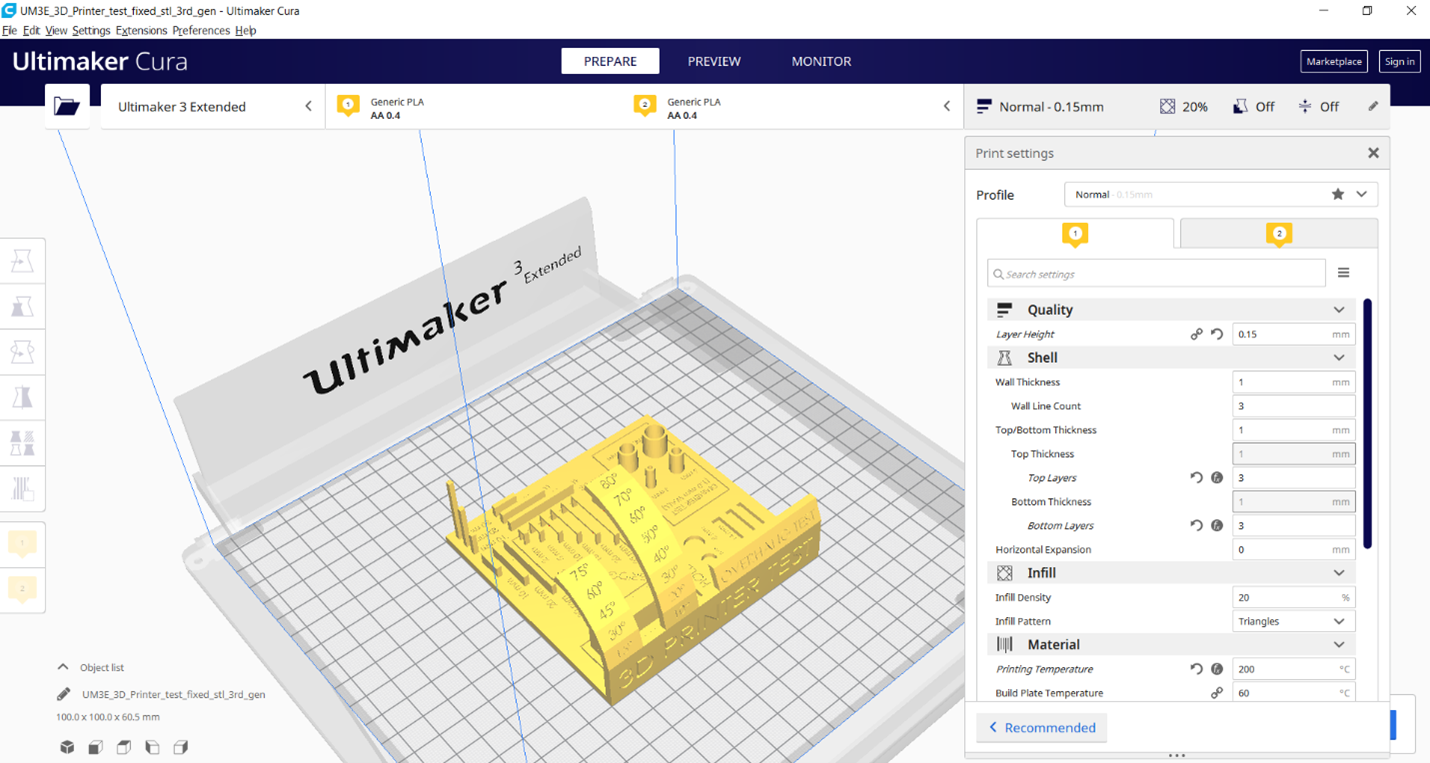

The settings used are the preset standard settings for a normal quality print with PLA filament:

A test was performed on a Ultimaker3 3D printer and Cura slicer.

The 20-in-one Test was downloaded from thingiverse.

The settings used as recommended by the design are: