♦ Computer Controlled Cutting♦

|

|

Third week started with computer controlled cutting.In previous week we have made some designs using CAD software.Now in this week we are going to design parametric design using one of CAD software.And also we will cut that design using laser cutter.I was very excited to use laser cutter and vinyl cutter.I have used these machine before,but this time I am going to make something different .From this week group assignment started.

Please refer group assignment here:

Group Assignment:Characterize your laser cutter's speed,power,rate,focus,kerf.

Individual Assignment:Cut something on the vinyl cutter design,laser cut and document a parametric construction kit,accounting for the laser cutter kerf.

After wednesday lecture,on next day our local instructor gave lecture on laser cutter,how it works,how to operate it,also she told about safety rules.Then we are started our group assignment.We have to calculate speed,power and kerf for different material like cardboard,MDF,acrylic.We cut cardboard with different speed and power because we have to test which speed and power is suitable for cardboard.

Laser Cutter

At Vigyan Ashram we have "SIL" laser cutter

Laser Cutter

This is CO2 laser cutter.We can cut or engrave with different speed and power.

This SIL laser is 2.5D machine ,which means it can move in X ,Y direction and up down .

Machine Specifications:

Model Number:131025-131018

Laser Type:Co2 DC glass laser

Power Supply: AC230V,50Hz

Power Rating:80W

Working Area:900x600cm

Format Supported:.DXF,.OBJ

Parts of Laser Cutter:

1.Isolation Transformer:It gives constant 230V supply and avoid surge and remove noise.

2.UPS:At Pabal we have voltage fluctuation and load shading ,so to avoid sudden shut down of machine ,UPS is used as backup.

3.Compressor:During operation continous air flow is maintained which prevents material from burning.

4.Exhaust:It collect gases evolved during operation and throws them outside.

5.Software:RDworks is the software used to send files to the machine.

Safety rules for Laser Cutter :

Keep a continuous eye on the machine during operations.It becomes easy to take action in case of any flare-ups.

We shouldn’t use toxic,flammable materials for cutting in laser cutter.

Clean laser cutter after using it.

Group Assignment :

Power,speed and kerf calculation:

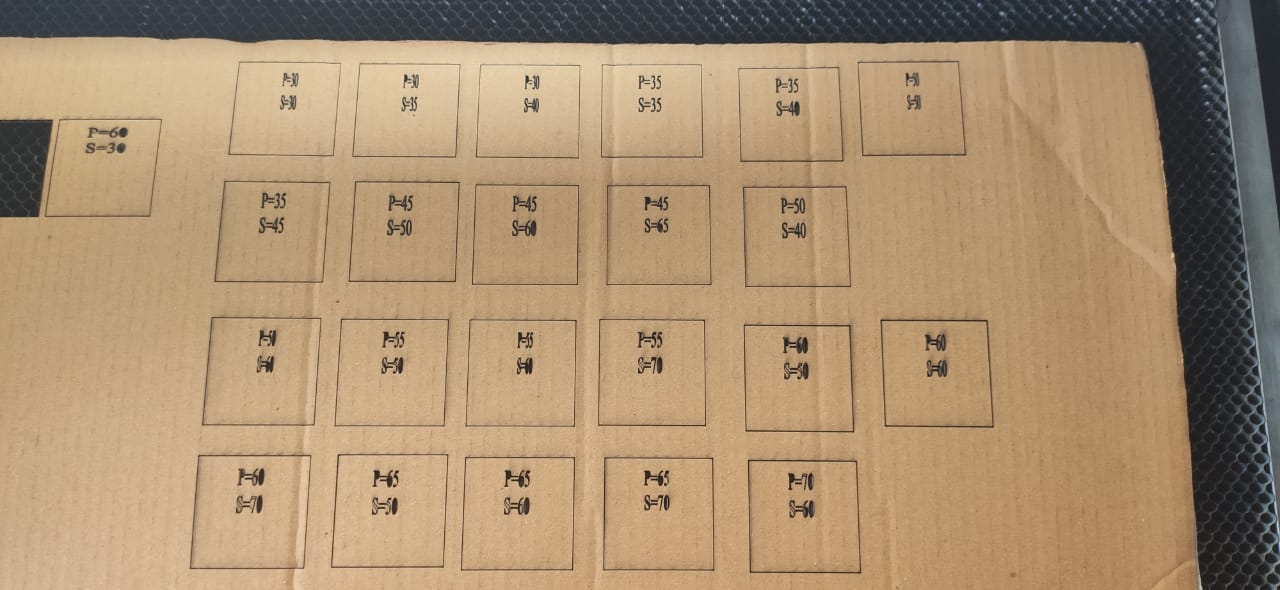

In this group assignment we have made design in RDworks.We have made 50x50mm rectangle.To check the correct speed and power for different material we have cut different rectangle for different values.We have checked for cardboard, MDF,acrylic material.

Testing

After designing that file is given to machine ,file is displayed on machine display.

Bed level is set using bed leveler for that you have to move X,Y and Z axis.

By setting bed level,origin is set,from where you want to start your design to print.

♦kerf calculation:♦

After cutting all the designs for cardboard ,mdf ,acrylic.We have measured kerf for cardboard using vernier.

Kerf Calculation

Measuring value using vernier we got as 49.6mm and our rectangle is of 50mm, andit cut from both side so value of kerf is 0.4/2=0.2mm.

For exact press fit design we have to add kerf values in our design.

Individual Assignment :

♦ Parametric Design:♦

Parametric design is a paradigm in design where the relationship between elements is used to manipulate and inform the design of complex geometries and structures.In parametric design ,if we change one parameter all parameter get changed.This is the advantage of parametric design.We need not to change whole design.

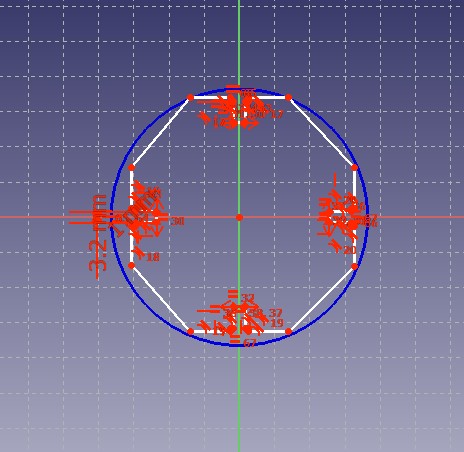

In I have used freecad software for parametric and press fit construction kit.I have drawn simple object like traingle,octagon,square,circle that can be fit in different combination by adding kerf value.

These are some images of parametrics design.It is simple to draw design and give constraints to it.

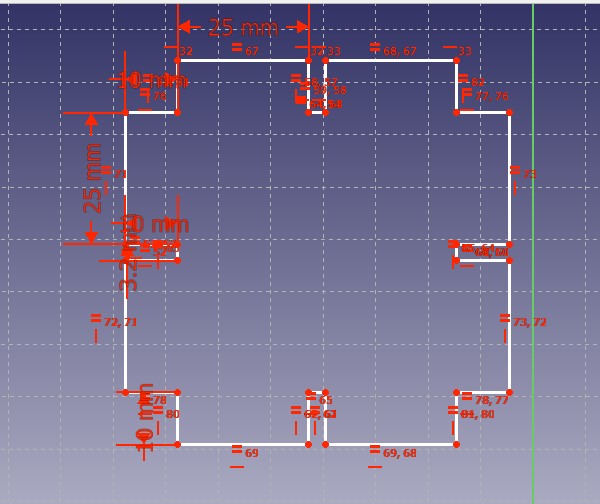

Design1

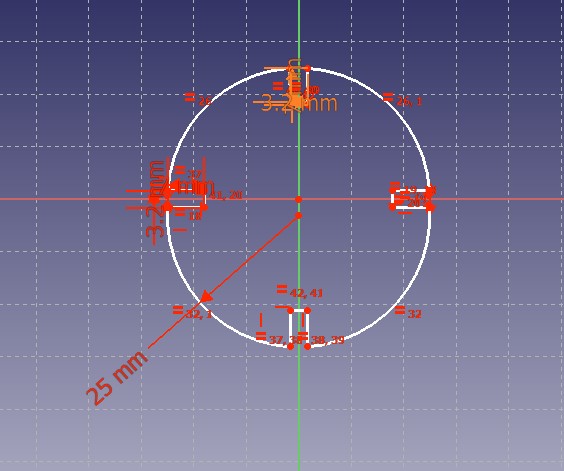

I made another design of circle with 25mm radius and kerf is added in notches.

Design2

Design3

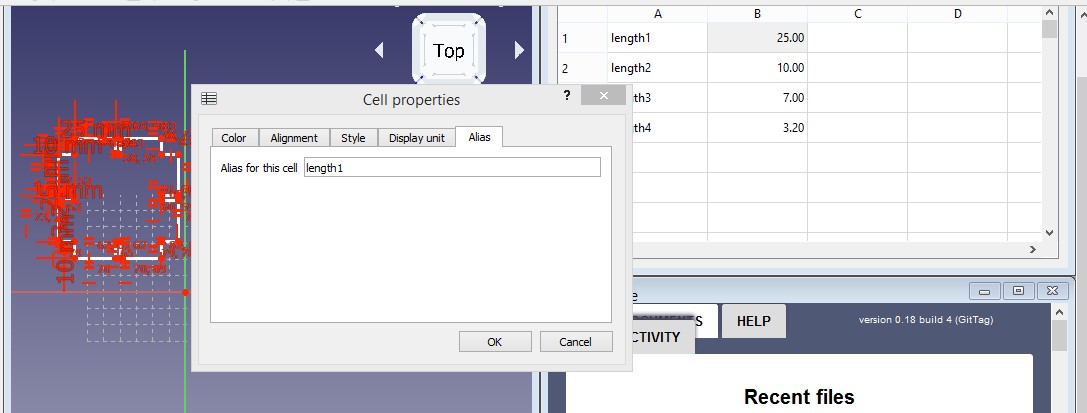

As we have to make it parametric ,we need spreadsheet to add values of lengths.So select spreadsheet, make new spreadsheet.

Assign values as per your requirement.Right click on value ,go to properties,select alias option and give name to it.

Design4

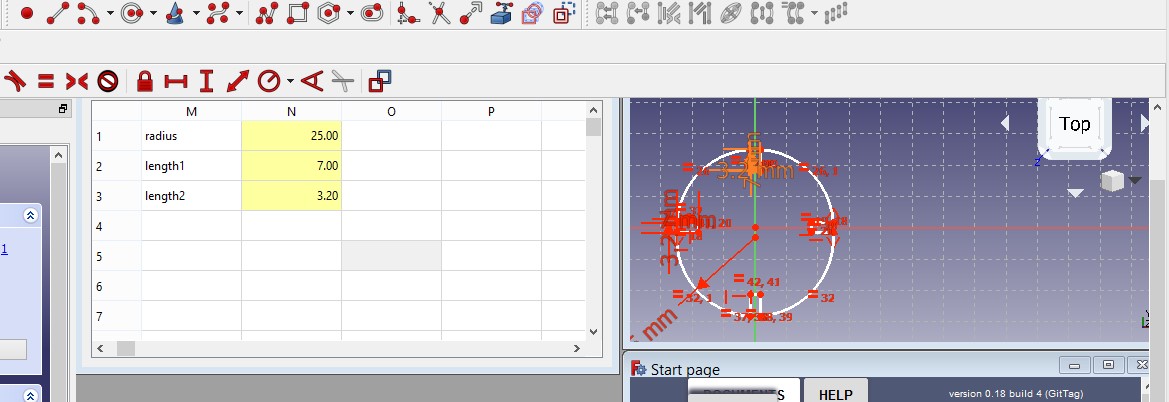

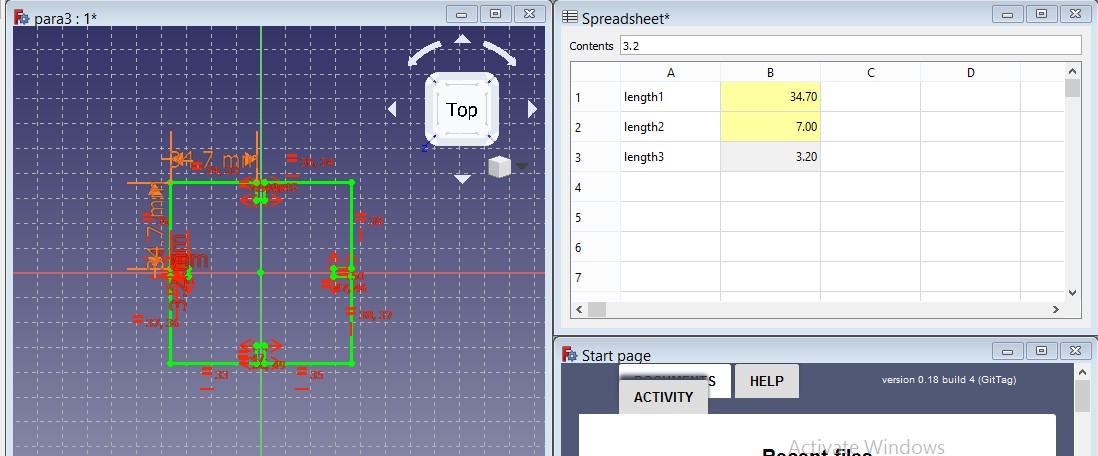

Here I have shown spreadsheet with design.If I change value in spreadsheet, design also get changed.

Design5

This is another design with spreadsheet.Save file in DXF format

Design6

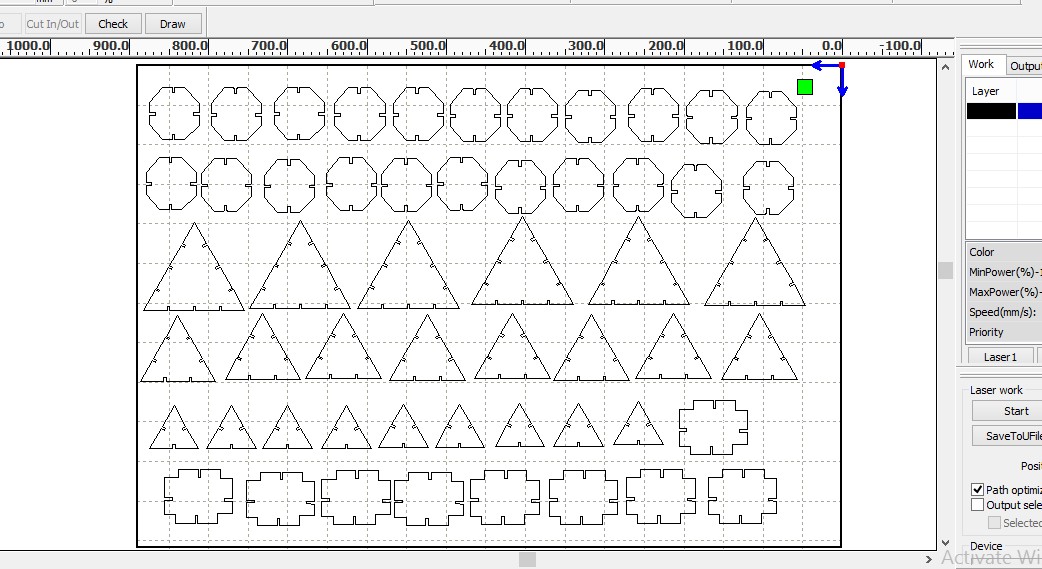

Import design file in Rdworks software.Rdworks is software which send files to machine.

For this .DXF or .OBJ files are required. Fix the speed and power in RDworks.

Design7

In group assignment we have checked power and speed.We have given different speed and power to cardboard and cut different pieces.From that I got exact values of speed and power.In individual assignment I have used speed=70 and power=40.

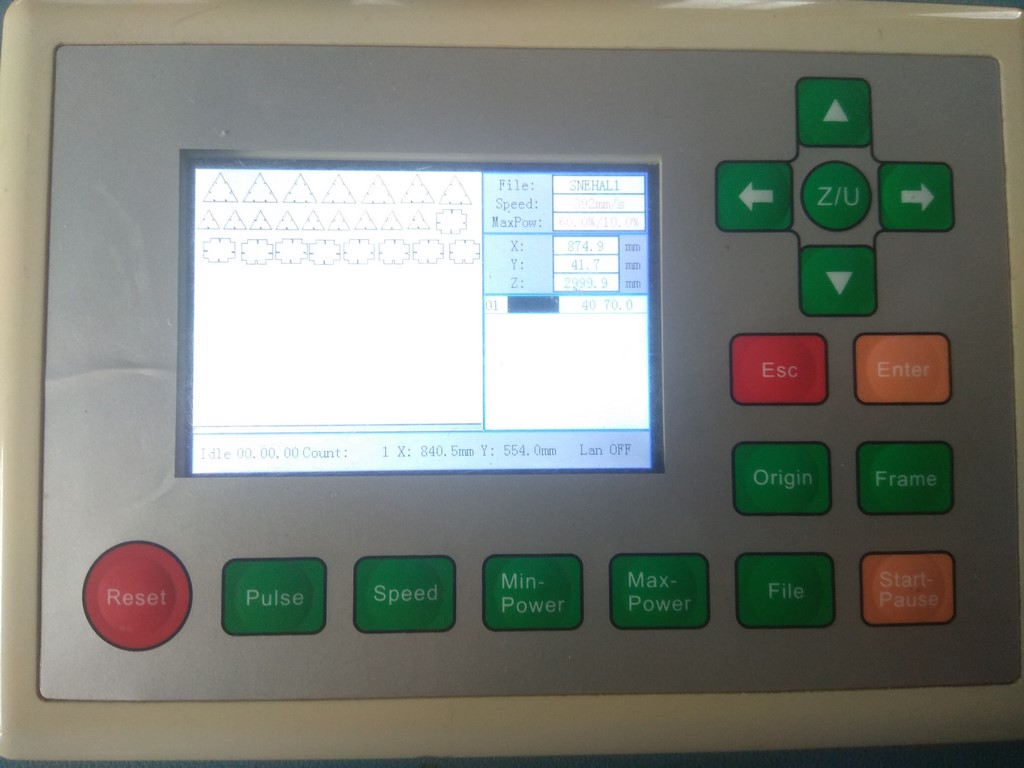

This is the dashboard of laser cutter which showing file which I have given to laser cutter.

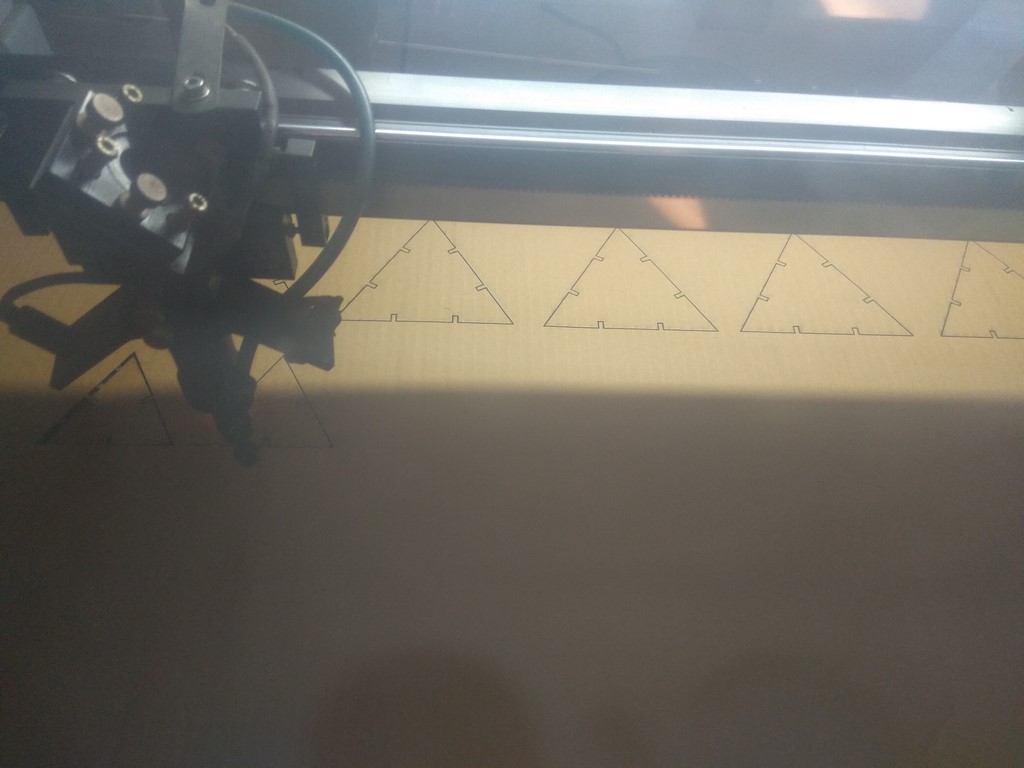

This is the laser cutting process.

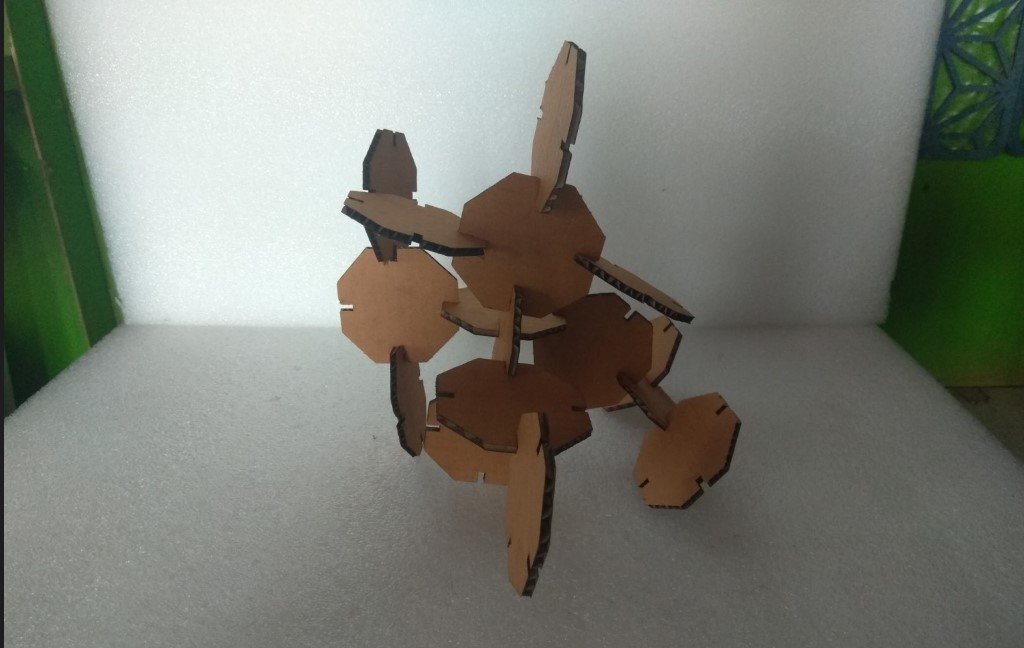

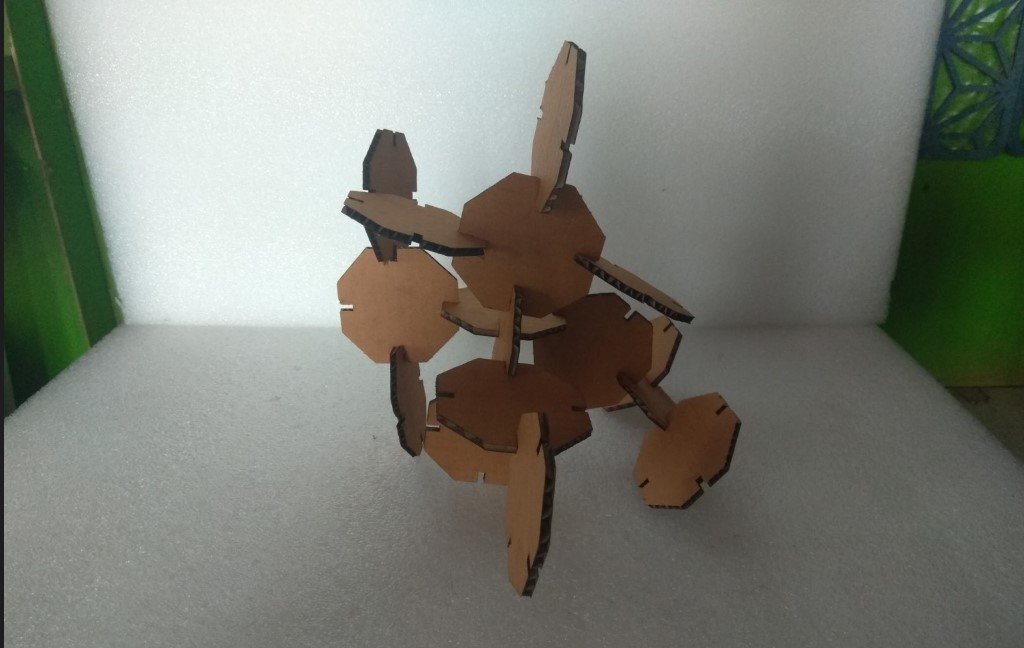

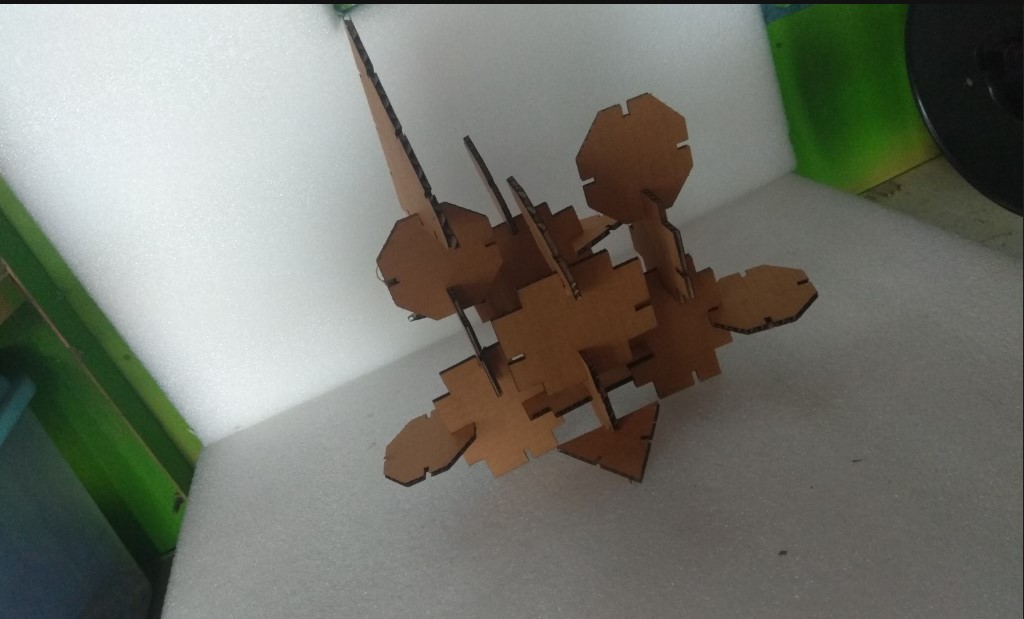

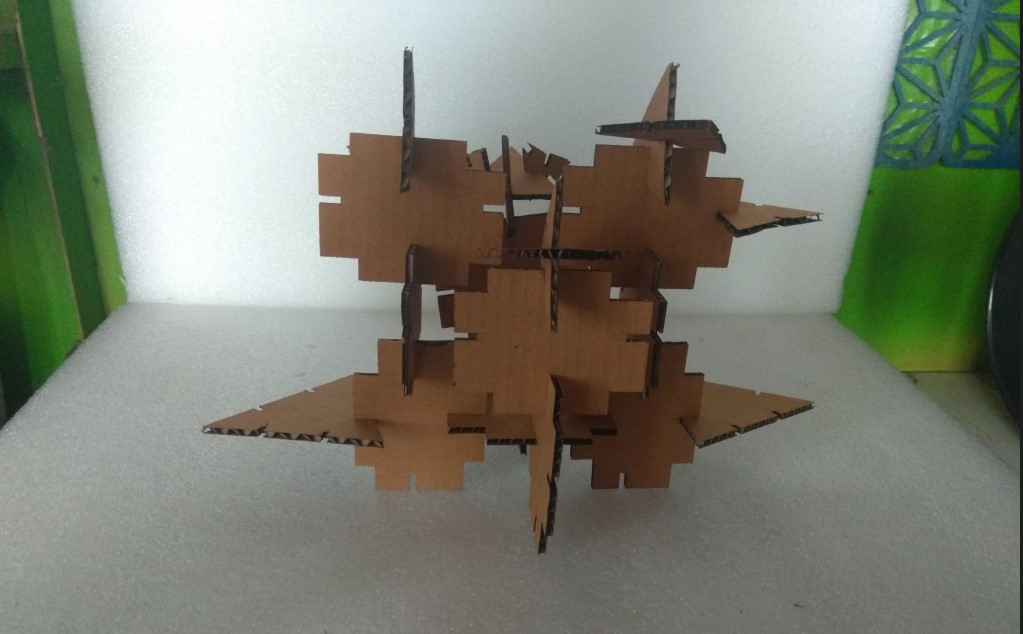

These are some images of my final prametric construction kit.

Design8

Using same geometry I have made different shapes.

Design9

Design10

Vinyl Cutter

In Vigyan Ashram ,we have "Roland Camm-1" vinyl cutter.

Roland

Some parts of the machine are explained here:

a.Cutting Blade: The small,pin-point,sharp blade cuts the vinyl sheet.

b.Roller:Adjust the roller between the frame we want our design to cut on Vinyl sheet.

c.operation lever: To adjust the vinyl sheet we can tighten and lossen the lever.

d.Software:Fab module is the software used to instruct command to vinyl cutter.

e.Display panel:Menu,Test,Enter,Origin and the operation being conducted is shown on the screen.

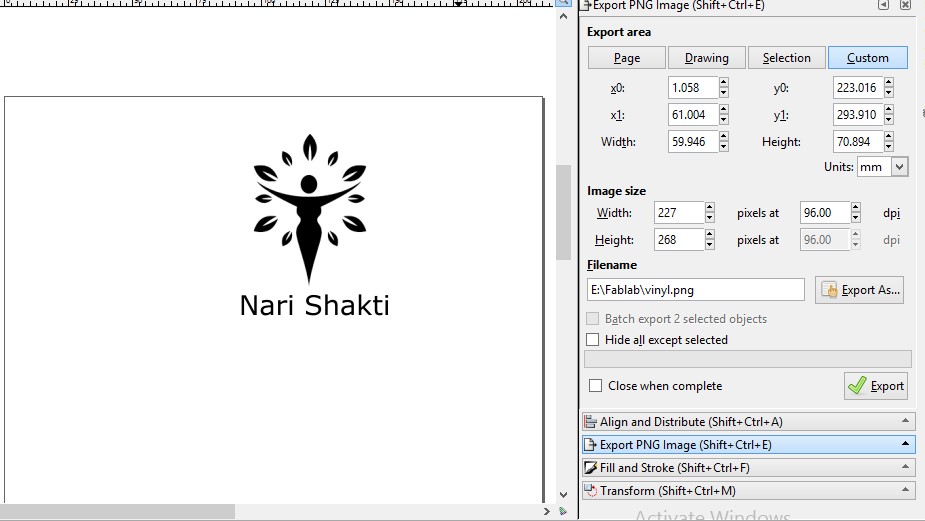

I have made logo using coreldraw in last assignment.But I want to cut something different thats why I downloaded image from internet.I edited that image in inkscape.I have added text and grouped the image and text using Ctrl+G command.

Inkscape design

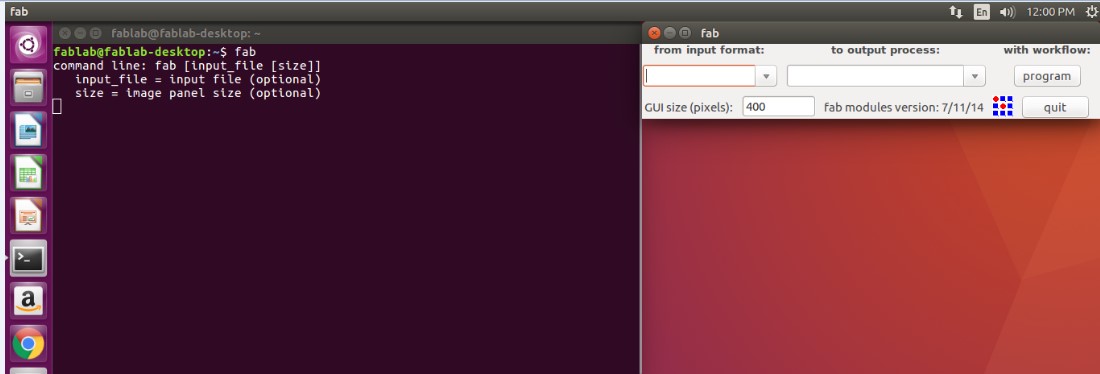

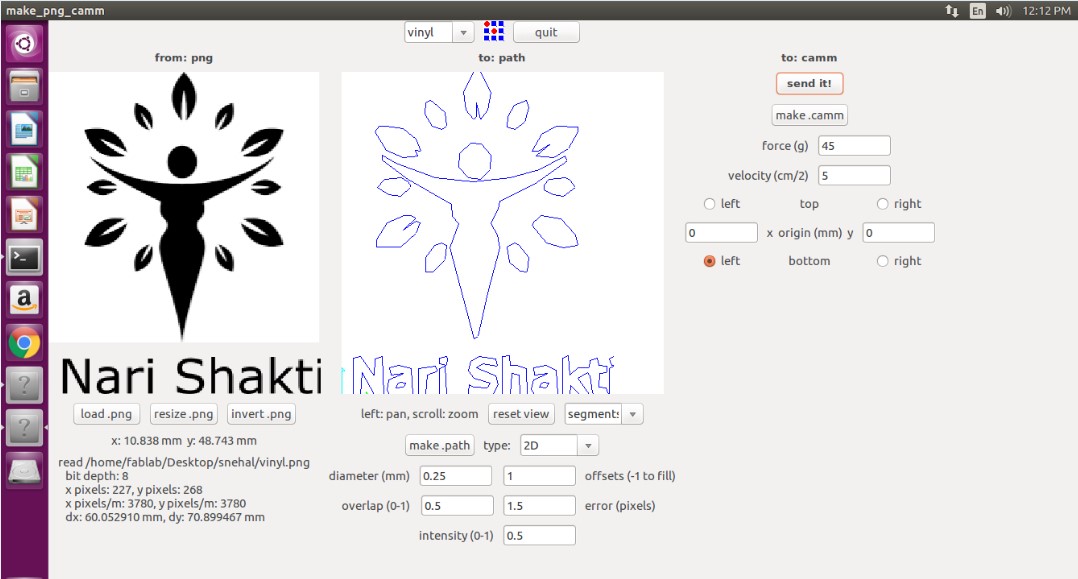

Open terminal in Ubuntu.Run "fab" command.Another window will open.Select your input and output files.

For vinyl cutter .PNG file required.When we design in inkscape or coreldraw ,export file as png image.

Terminal window

Load image and select segment option.Click on make camm .

Load Image

After making this switch on vinyl cutter,set the paper roll.Set the origin from where you want to start print.

You can download software which is "fabmodule".From desktop send the file.

It has basically 4 commands and 4 direction keys to move the sheet.

Under “Menu”, selecting piece measures the length and breadth of the vinyl sheet.

“Enter” key commands roller to move between the sensors.

Set the “Origin” and checked the functinoning of blade with “Test” key.

working

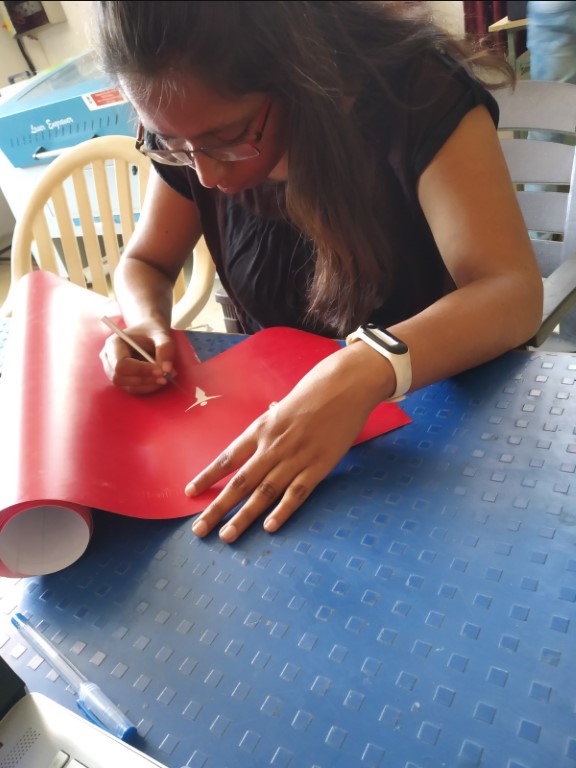

By using X-acto tool,I am pilling out the sticker.

Pilling Out

Final Logo

Learning Outcomes:

This week was very interesting.I have learned lot of things.In group assignment we calculated different parameters like speed,power and kerf for cardboard.Before starting of this week I dont even know about parametric design.So I have seen tutorial and started working using freecad.So I learnt how to make parametric design .To talk about vinyl cutter ,we can set the origin. Fab module software is used to send files to machine.Both machine handling experience was very nice.I like construction kit assignment.