For the molding and casting week Alex experimented with making machinable wax at home. He made all the wax for both our students.

So we had the idea of building a machine that would take care of stirring the ingredients and monitoring the temperature. Initial idea was to develop a system which assists in the process for preparing the machinable wax for molding and casting processes. The composition of machining wax prepared at Fab lab St Jude and Fab lab Veritas is based on a solution of Paraffin wax, its modification is usually done with forms of polyethylene.

Paraffin wax (or petroleum wax) is a soft colorless solid derived from petroleum, coal or shale oil that consists of a mixture of hydrocarbon molecules containing between twenty and forty carbon atoms. It is solid at room temperature and begins to melt above approximately 37 °C (99 °F), its typical melting point is between about 46 and 68 °C (115 and 154 °F), and a density of around 900 kg/m3. It is insoluble in water, but soluble in ether, benzene, and certain esters. Paraffin is unaffected by most common chemical reagents but burns readily. Its heat of combustion is 42 MJ/kg.

High molecular weight polyethylene is a translucent white solid. In thin sections it is almost entirely transparent. At ordinary temperatures it is tough and flexible and has a relatively soft surface that can be scratched by the nail. As the temperature increases, the solid becomes softer and finally melts at around 110 ºC, transforming into a transparent liquid.

At temperatures below 60 ºC., Except for very low molecular weight samples, polyethylene is very poorly soluble in solvents, but at higher temperatures it is easily soluble in hydrocarbons and halogenated hydrocarbons, although it is still very poorly soluble in more polar liquids, such as alcohols, acids, esters, amines, phenols, and nitro compounds.

The speed with which the solubility varies as a function of temperature is often so great that it gives the appearance of almost a critical temperature below which the polymer is insoluble and above which it is easily soluble.

The solubility of polyethylene depends to some extent on the molecular weight; the most soluble varieties are the ones with the lowest molecular weight; but at temperatures below 110 ° C, the degree of branching of the chain and, consequently, the ability of the solid polymer to crystallize is also very important.

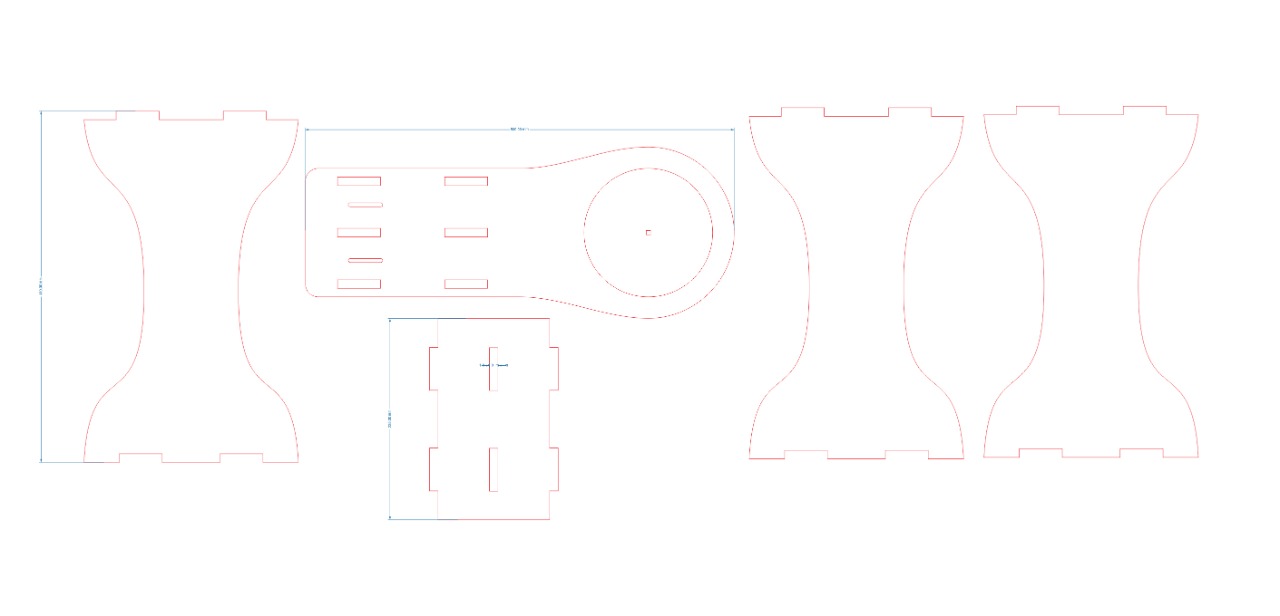

This process could be useful to follow by a Cycle process based on the PDCAmethod.

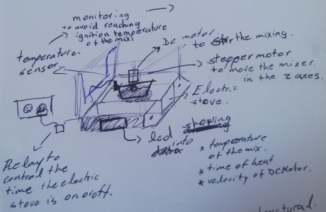

In the first phase of Plan we discuss the idea, some functions, and components the machine must include based on the expectations we have as a Team.

At this phase, my contribution (Luis) has been related to preparing a list of components and a system scheme based on basic and desirable functions that the machine must include.

So, I prepared the list considerating four main kinds of components (Heater, Movement, Monitoring & Control and Structural materials or devices)

| Device or material | Function | Description |

|---|---|---|

| MDF and acrylic | This will be used to build a box around the electric stove which brings structural support to integrate all the parts. |

This could be composed of one layer 8 to 10 mm or various glued layers (less gross). This will be useful too to build the support for the DC motor which is going to move the stirrer pallet of the mix. |

| 3D printed clamps and supports |

To Attach motors or other parts to the structures |

Must have enough diameter to attach support mechanisms for DC motor of the stirrer and other parts added to the machine. |

| Rubber timing belt |

This will be connected to a stepper motor and is going tobe used to rotate the mixer along the z axis. |

Long enough to go from the motor to the wheel that turns the stirrer. |

| Stirrer | This will be attached to the wheel, which in turn is connected to a stepper. Could be interchangeable to work with different composition mixes. |

It must be composed of a material resistant to heat to be able to stir mixes with different compositions. MDF mixer press-fit kit. |

| Electric stove | An already built electric stove that is attached to the base of the structure. |

Ideally one burner stove, 110 V. |

| Stepper motor | Stirring mechanism. Variable speed. With proper stepper driver based on Neil's design. |

Nema 17. |

| Temperature sensor |

To monitor temperature of the mixd. We could also add a sound alarm to avoid ignition temeperature. |

Submergible, and with enough range. |

| LCD | For human - machine interface. Display time, temperature, speed, and other relevant information. |

I2C 16x2 should be enough. |

| Relay | To control the power going to the burner. Controls time and temperature. |

Common 5V / 120V relay. |

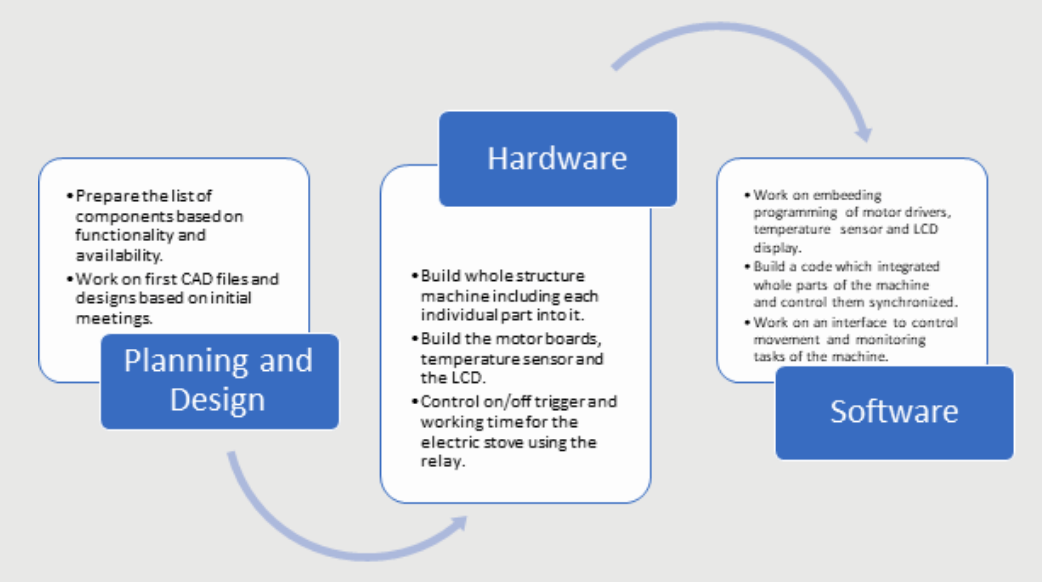

The second phase “Do” is going to follow the next Flowchart:

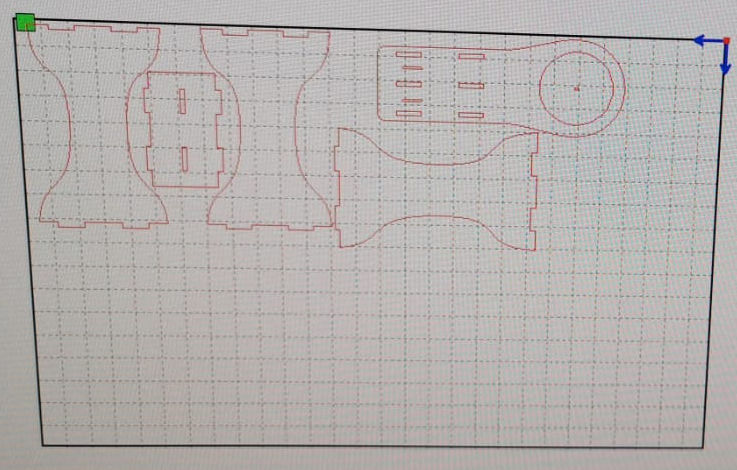

The frame of the machine was designed using CorelDRAW. Is a 2D desing for laser cutting in acrylic.

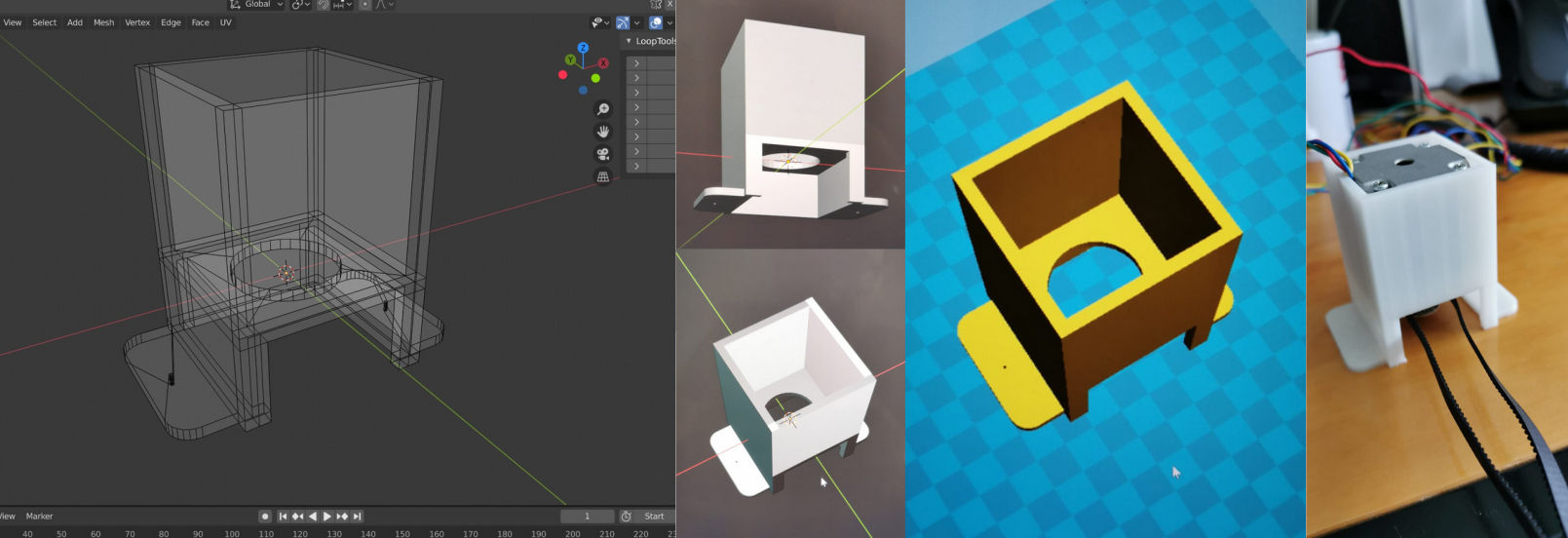

Then it was assembled and positioned over the burner to have a clear view of the proportions.

The support for the stepper motor was designed using Blender. It is a box that encases the motor and has an opening for the shaft, as well as legs for attaching to the frame

So far, we have the frame and the motor support.

We still need to fabricate the spinning wheel structure and the stirrer.

For the automation, we started testing with Arduino board.

The first steps were to make a temperature reading and display it on an LCD (16x2). We ordered the DS18B20 waterproof temperature sensor probe (link) but are still waiting for it to arrive. In the meantime, we tested a DTH11 temperature sensor and programmed the Arduino board to display the data on an LCD.

We also set the limit temperature to 26 °C for testing, so when the reading goes above 26, there is a warning:

We still need to write the code for the machine to control the stepper and the user interface.

After that, we need to design and fabricate the boards for the machine, but they will be based on what we do with the Arduino board.

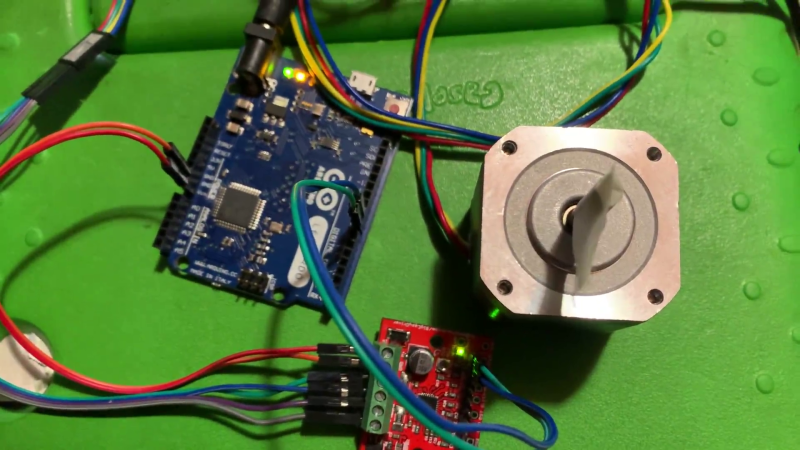

We will use a bipolar stepper motor Nema 17 to drive the stirring mechanism.

The motor driver (BigEasyDriver) was tested with the motor and an Arduino Leonardo: