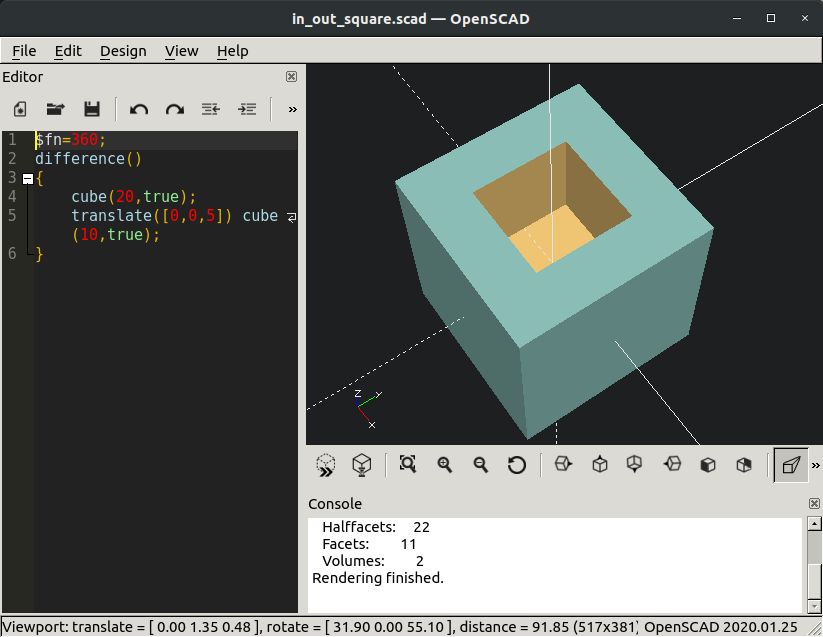

We designed a 20 mm cube and subtracted a 10 mm cube from the inside of the first cube.

Designed dimensions are:

20 mm cube

10 mm cube

5 mm wall

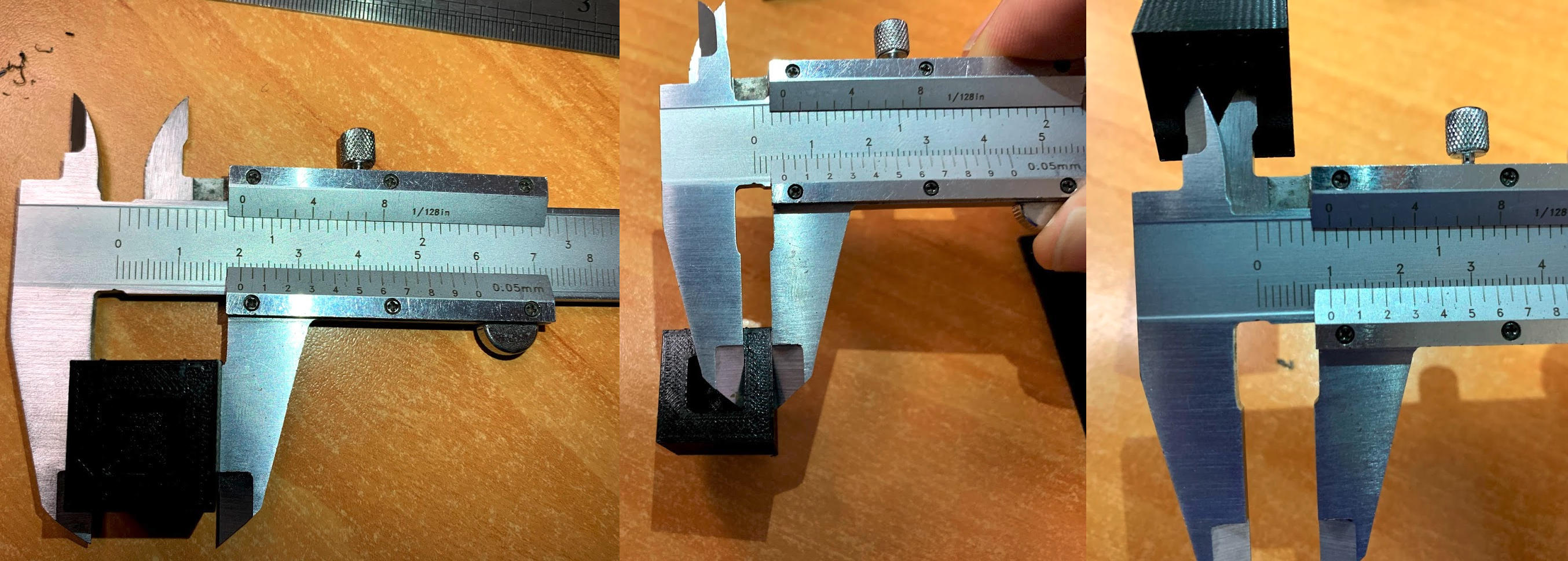

Difference between designed dimensions and printed dimensions:

| Designed dimensions | Measured dimensions |

|---|---|

| Cube: 20 mm in X, Y, Z | 20 mm in Z | 20,02 mm in X | 20,07 mm in Y |

| Cube: 10 mm in X, Y, Z | 10 mm in Z | 10,01 mm in X | 10,01 mm in Y |

| Wall: 5 mm in X, Y | 5,01 mm in X | 5,01 mm in Y |

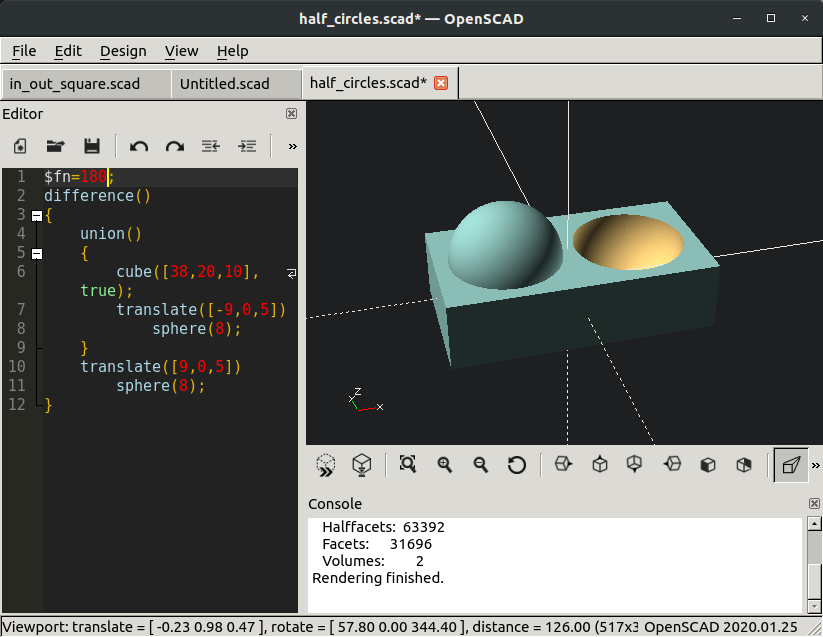

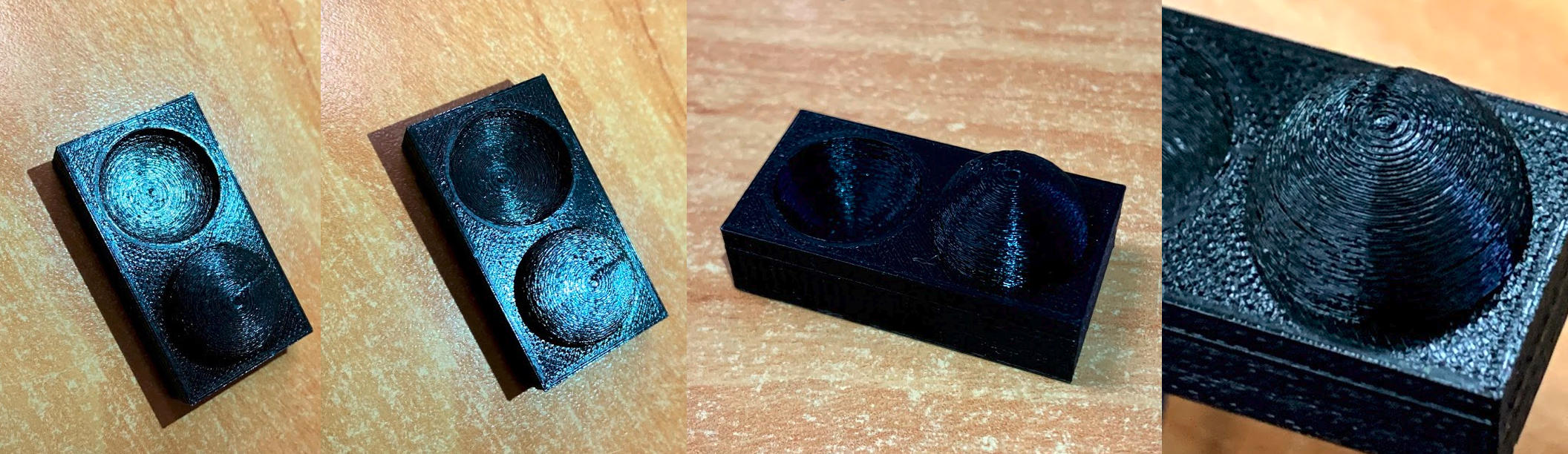

We made Neil's apparent surface finish test to visualize the angle of the print.

The model has two 8 mm radius spheres, one positive and one negative on a cuboid.

The steps are actually more visible towards the top and bottom of the spheres.

We used 3 mm mdf for the test and cut several squares and rectangles of different sizes.

Settings for the test are:

Cut power: 70-60%

Cut speed: 22 mm/s

Engrave power: 23%

Engrave speed: 50 mm/s

In all the shapes, the measured dimension was slightly smaller than the designed dimension. The difference is approximately 0,1 mm for all cases.

We used 3 mm mdf for the test and cut several circles of the same size.

The software provided by the manufacturer has no control over the rate of the laser.

Settings range for the test are:

Power: 20% to 70%

Speed: 5 mm/s to 30 mm/s

We found different speed/power combinations for cutting the material.

At 20%, 30% and 40% power and any speed, the machine only engraves this material.

20% power has the best visual results for engraving (no over-burning along the path).

The lowest power for cutting is 50% at 5 mm/s and 10 mm/s.

The fastest speed for cutting is between 15 mm/s and 20 mm/s at a power between 60% and 70% power (maybe faster with more power).

At 60% power and 15 mm/s the material looks less burnt.

At higher speeds and power the rate can be noted.

Presumably, if the rate option was available, we could cut at higher speeds and 50% power.

We used 3 mm mdf for the test and cut several rectangles of different sizes.

Settings for the test are:

Cut power: 45-50%

Cut speed: 12 mm/s

Engrave power: 15-20%

Engrave speed: 200 mm/s

For all the shapes, the measured dimension was slightly smaller than the designed dimension. The difference is approximately 0,2 mm for all cases.

The material for the test was mdf, thickness is 3 mm.

Settings for the test are:

Cut power: 45-50%

Cut speed: 12 mm/s

Engrave power: 15-20%

Engrave speed: 200 mm/s

The tested range for joints was from 2,8 mm to 3,5 mm in increments of 0,1 mm.

The best results were for 2,8 mm.