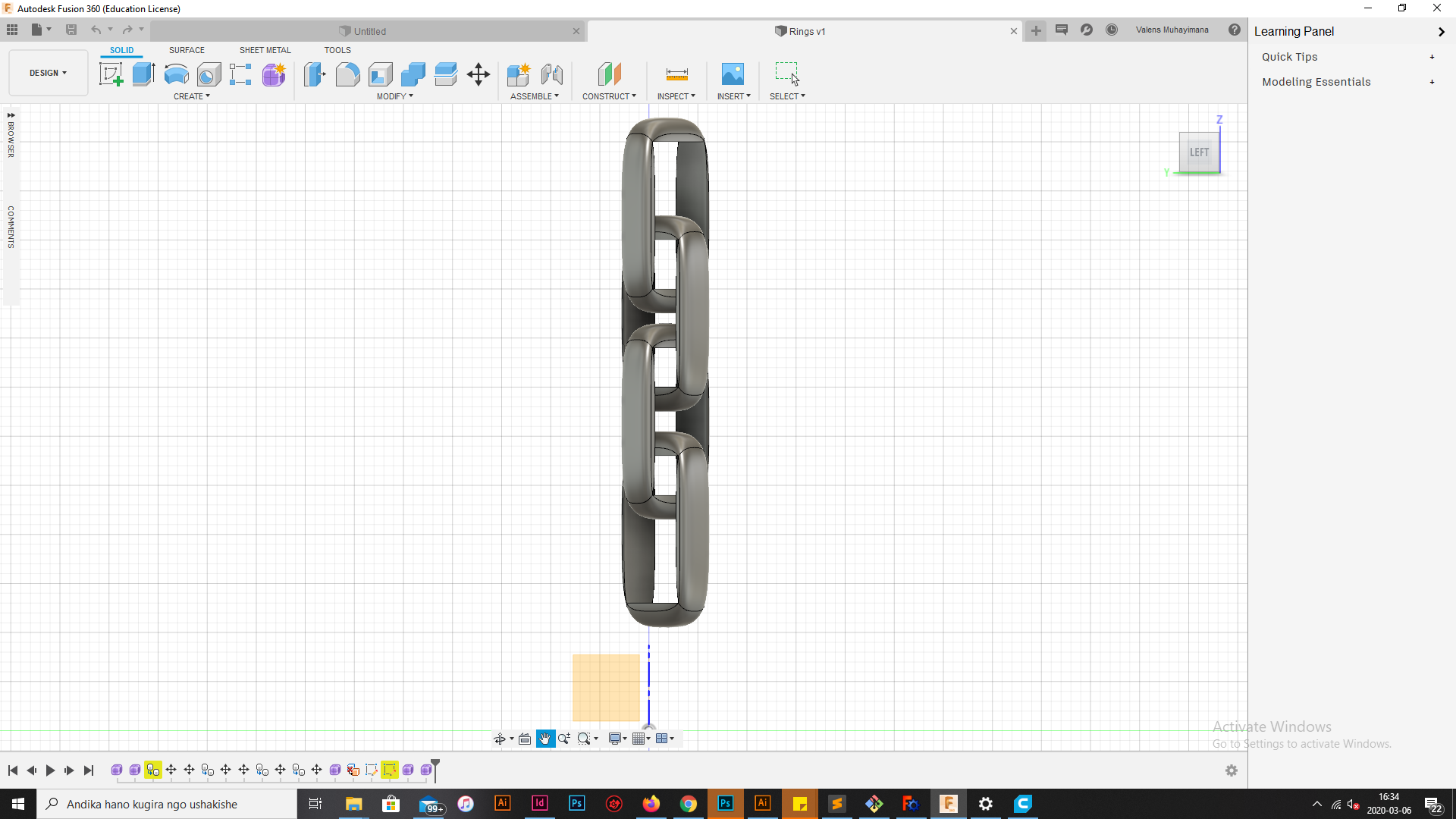

3D Printing is an additive manufacturing technique were the material is added layer by layer to form the 3D designed object. Fused Deposition Modeling (FDM) is the most common 3D Printing process were a material in a form of a spool is extruded using a stepper motor with a heated nozzle, layer by layer the 3D designed object is formed. The following designed and 3D printed object cannot be made subtractively the several rings which make up the components cannot be separated. As the additive manufacturing process begins, the rings are already printed in a way that makes it interconnected.

I been Inspired by former Fab Academy student (Salem AlMarri), the main aim of this assignement is to make an object that could not be made subtractively. The design was designed with Fusion 360 software and the is to make a platics chain.

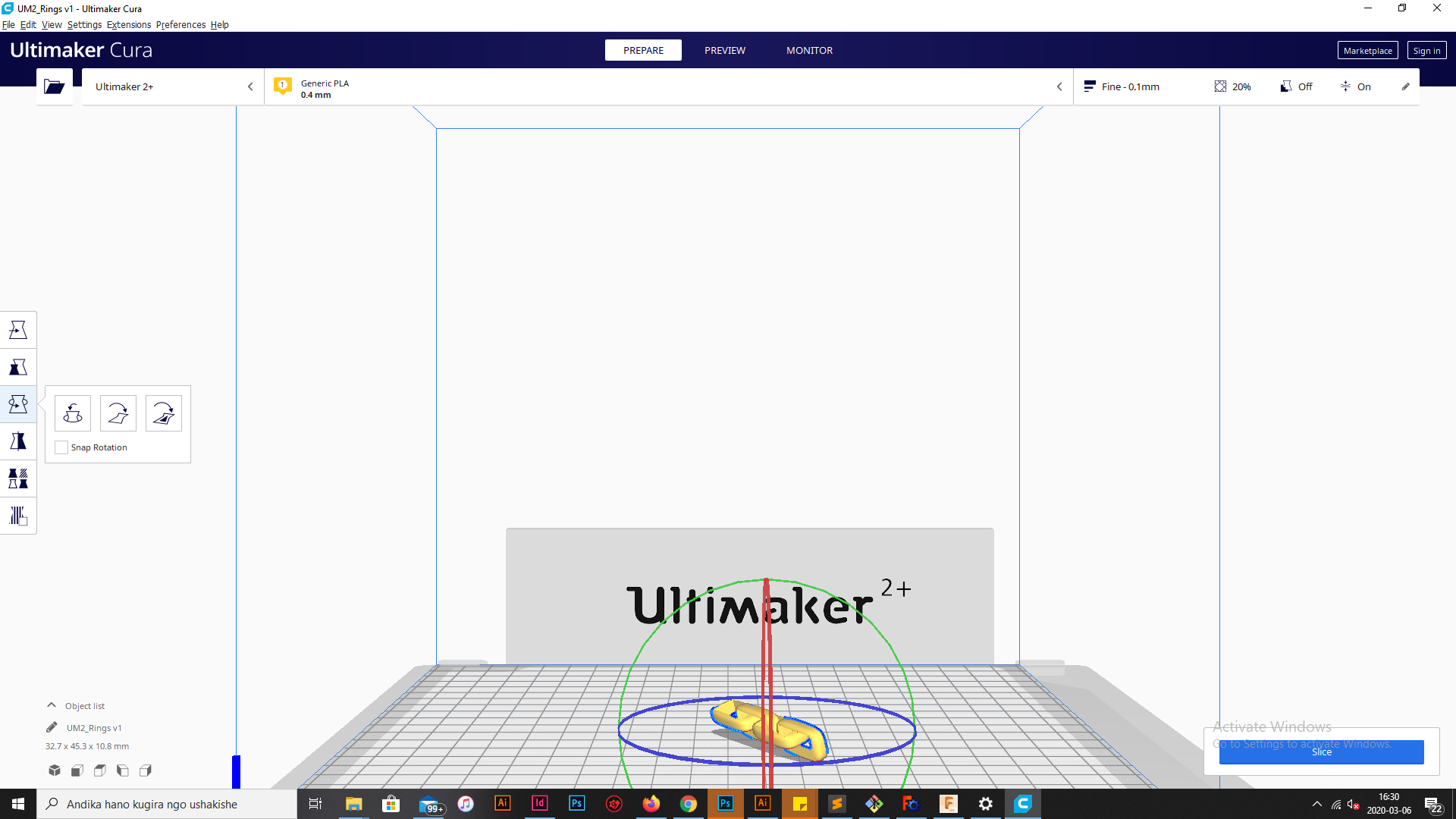

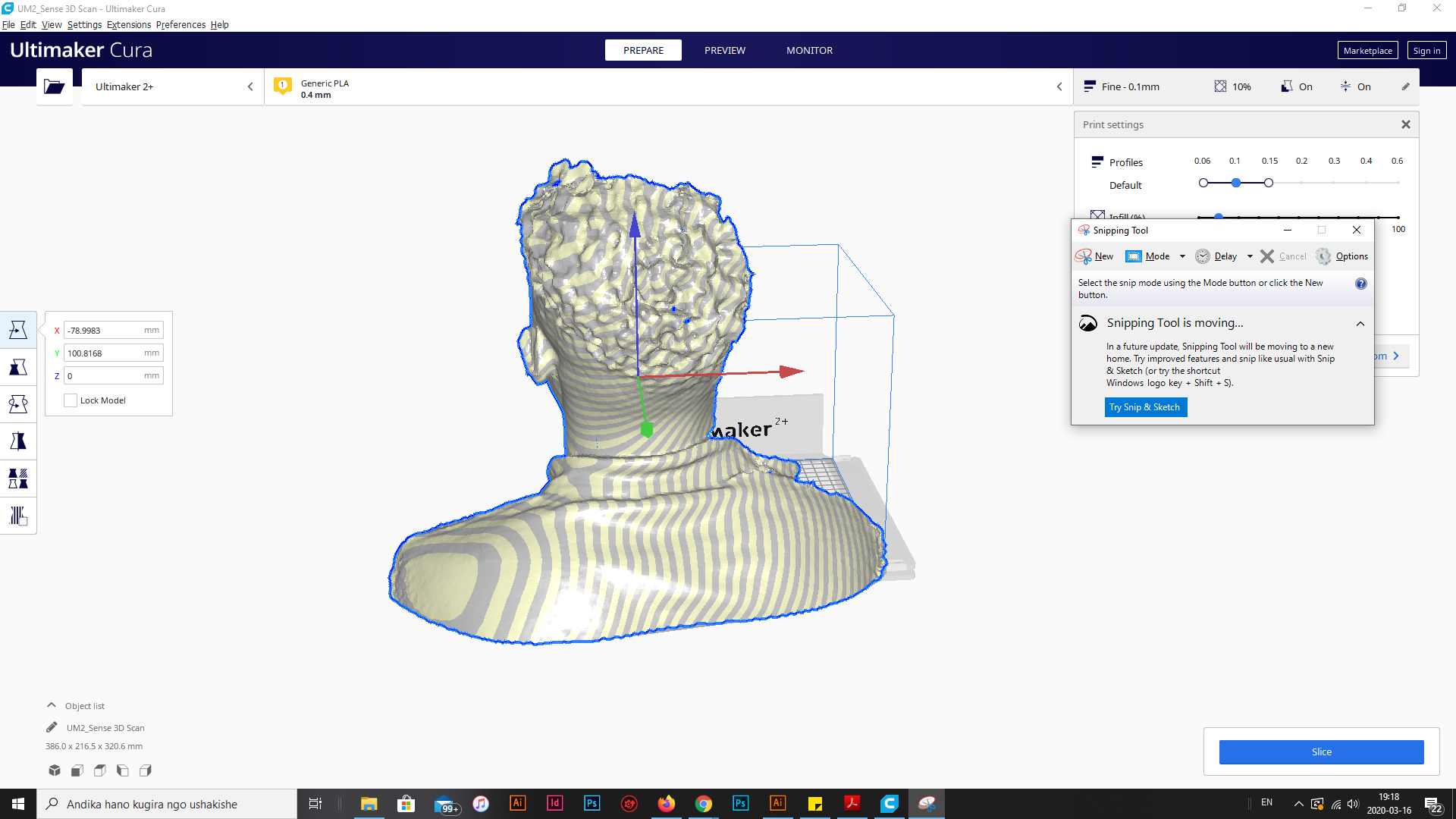

Export File Format: 3D Object (.stl), and then download an Ultimaker Software (Ultimaker Cura 4.5) for exporting a supported file for printing G* code file (*gcode)

After the board is done, we can launch the second file with the borders, remember to change the drill for the 1/32 and set again the Z origin. Do not reset the X and Y origin, if not it can move and your design will not be ok. If it is a little bit dirty, you can clean it with alcohol. This was the result:

4. Introduction to 3D Scanning

3D scanners are tri-dimensional measurement devices used to capture real-world objects or environments so that they can be remodeled or analyzed in the digital world. The latest generation of 3D scanners do not require contact with the physical object being captured.

Use 3D Systems metrology and digital inspection tools to significantly increase product and manufacturing quality, rapidly identify process issues, and build productivity.

5. Installation of Sense Device

After got 3D Systems Sense installed, it wasn't enough to enable the device working well, So I’ve made several types of research for Sense drivers and finally, I found another software and works for me. I ended up with “Sense” Let's get started for exploring more about 3D scanning and more tips!

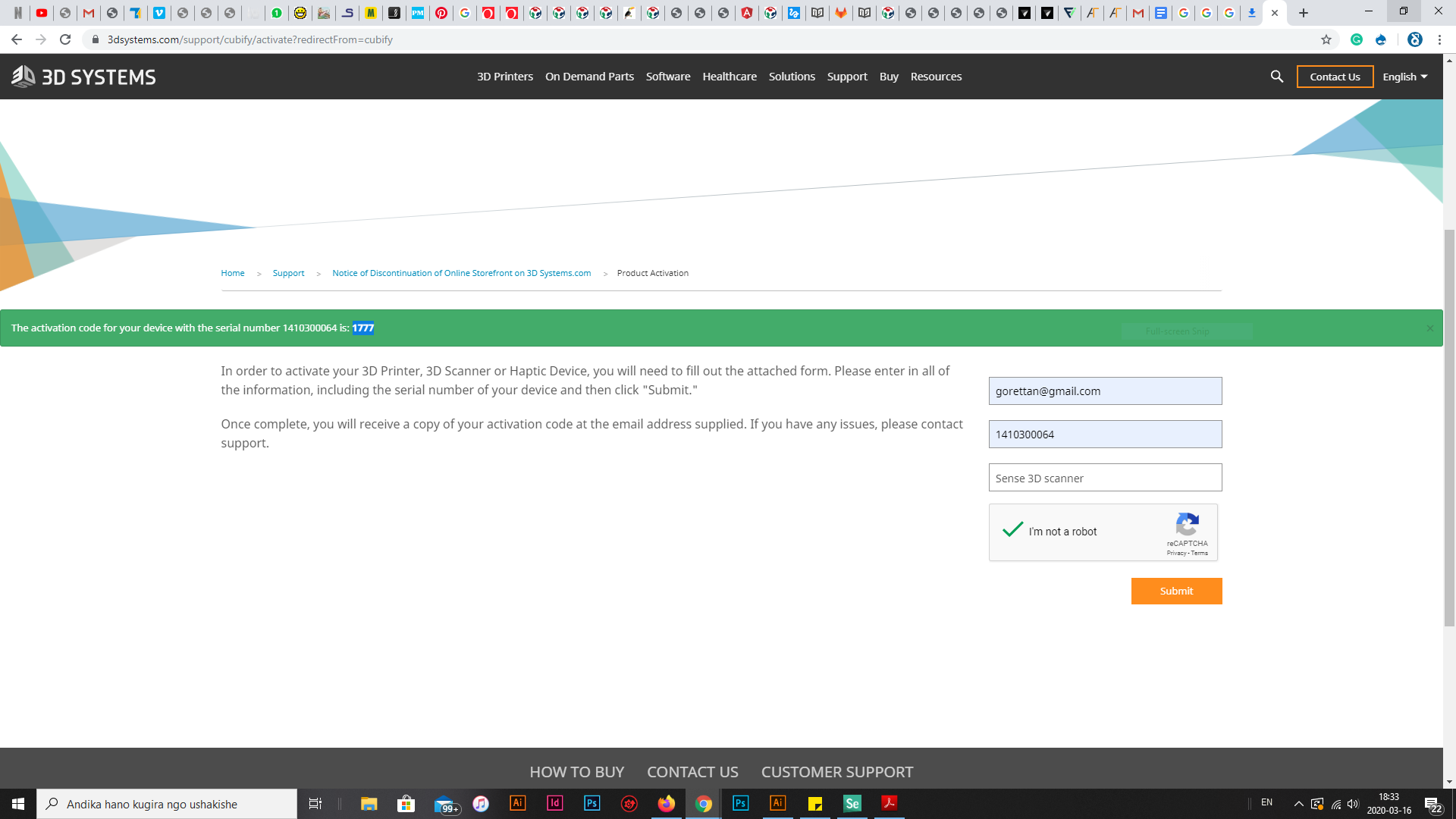

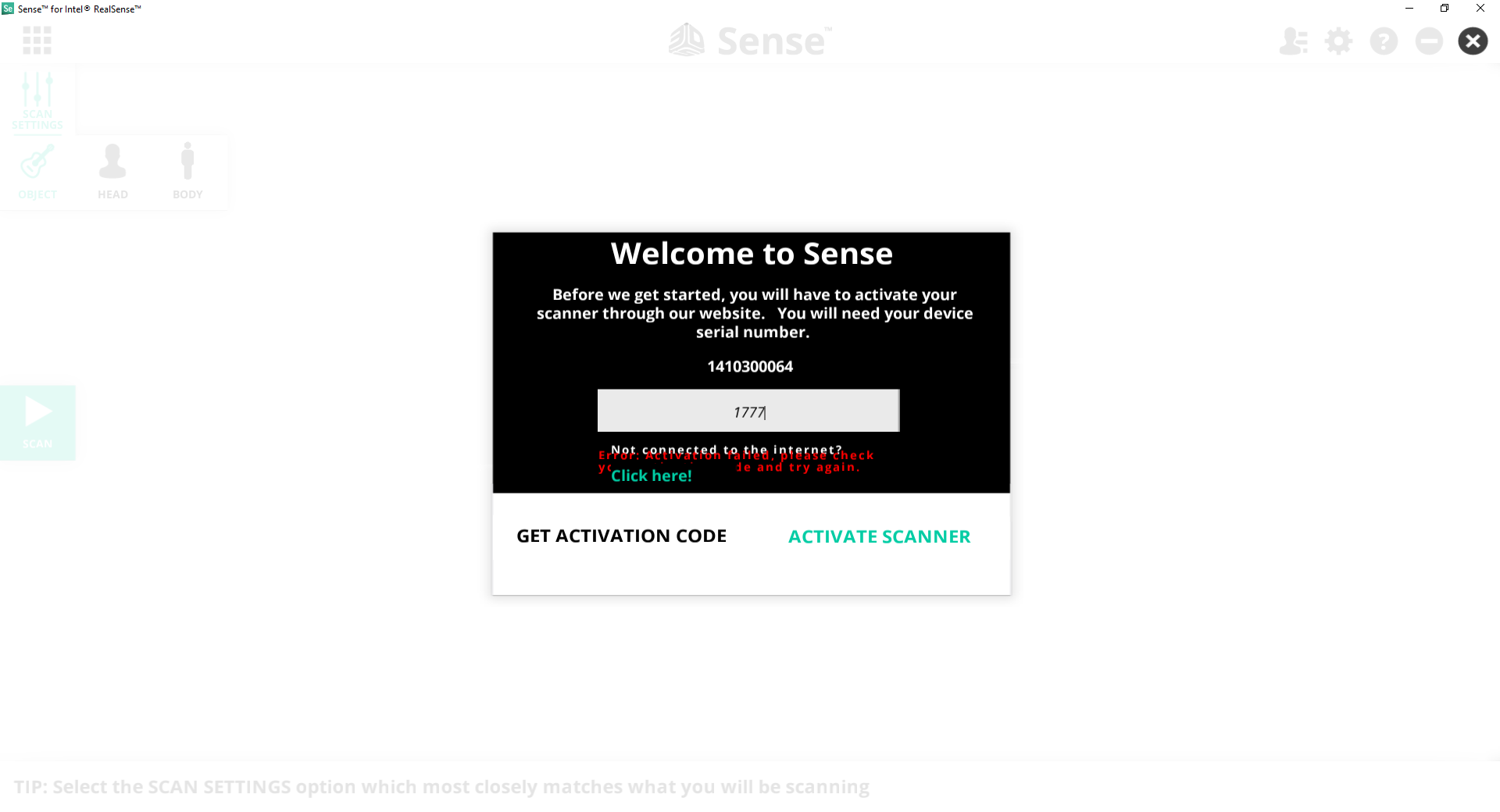

The above screenshot is about to show you where you can get the activation code for "Sense" program which connect the devices and program, you required to fill out the provided form and then copy and paste the “Activation code”

Here there are some important steps:1. Open the Sense application with the device connected If you do not have an activation code, select Get Activation Code

2. The 3D Systems Sense support site will display. Login to your 3D Systems account (if you do not have an account, create one).

3. The Activate Sense Scanner screen will display. Enter the serial number shown on the device in the Serial Number field.

4. Once acitvated online, you will be provided with a digit activation key (which is also e-mailed to you).

5. Once you have your activation code, you can enter it into the Sense activation dialog box. Click Activate Scanner to complete the activation.

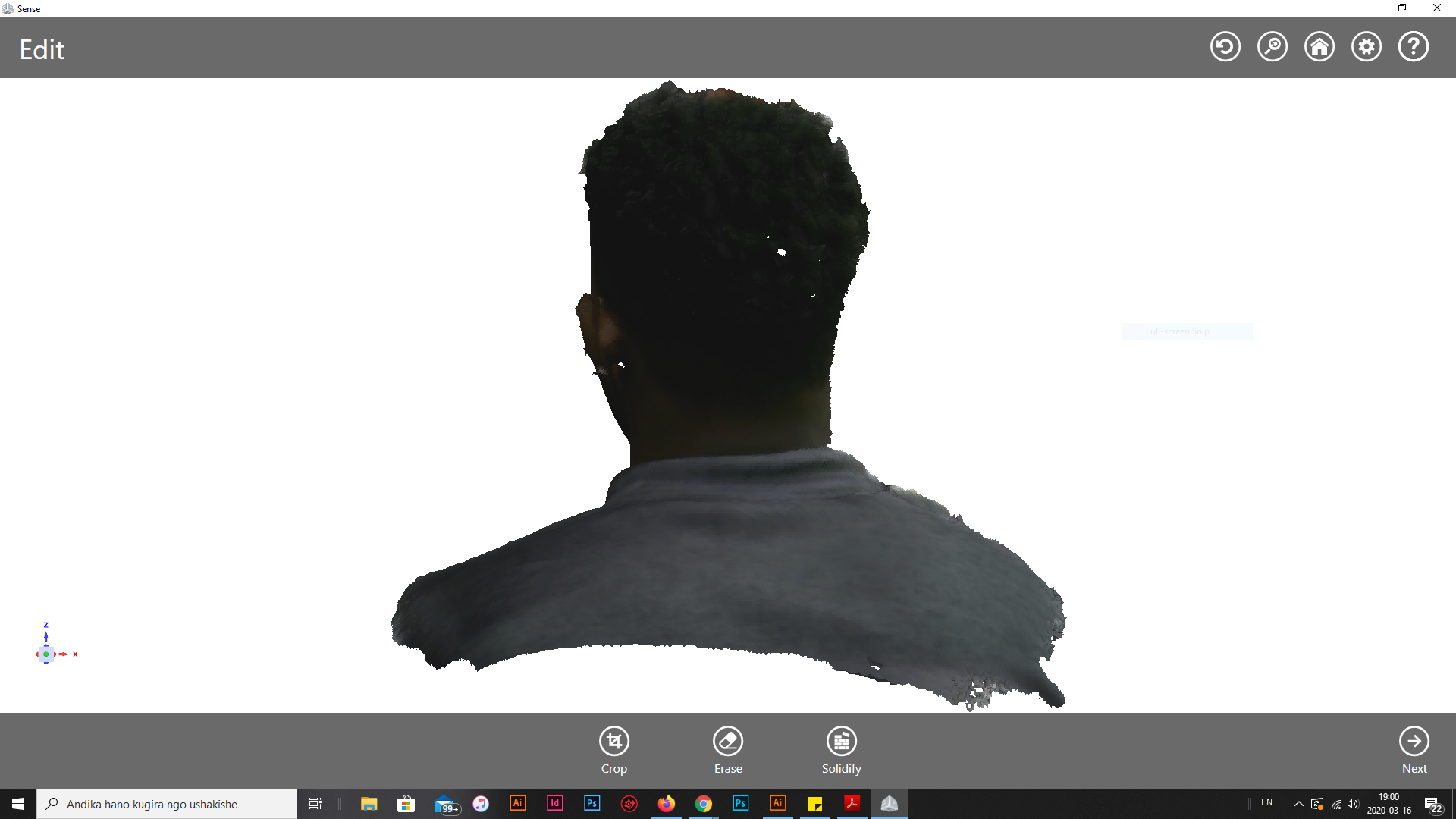

6. 3D Scanning process and final output (G Code File)

3D scanners are tri-dimensional measurement devices used to capture real-world objects or environments so that they can be remodeled or analyzed in the digital world. The latest generation of 3D scanners do not require contact with the physical object being captured.